Coke dry quenching method and system

A technology of dry quenching and coke quenching tower, which is used in furnace safety devices, coke ovens, coke cooling, etc., and can solve the problems of coke floating and scattering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

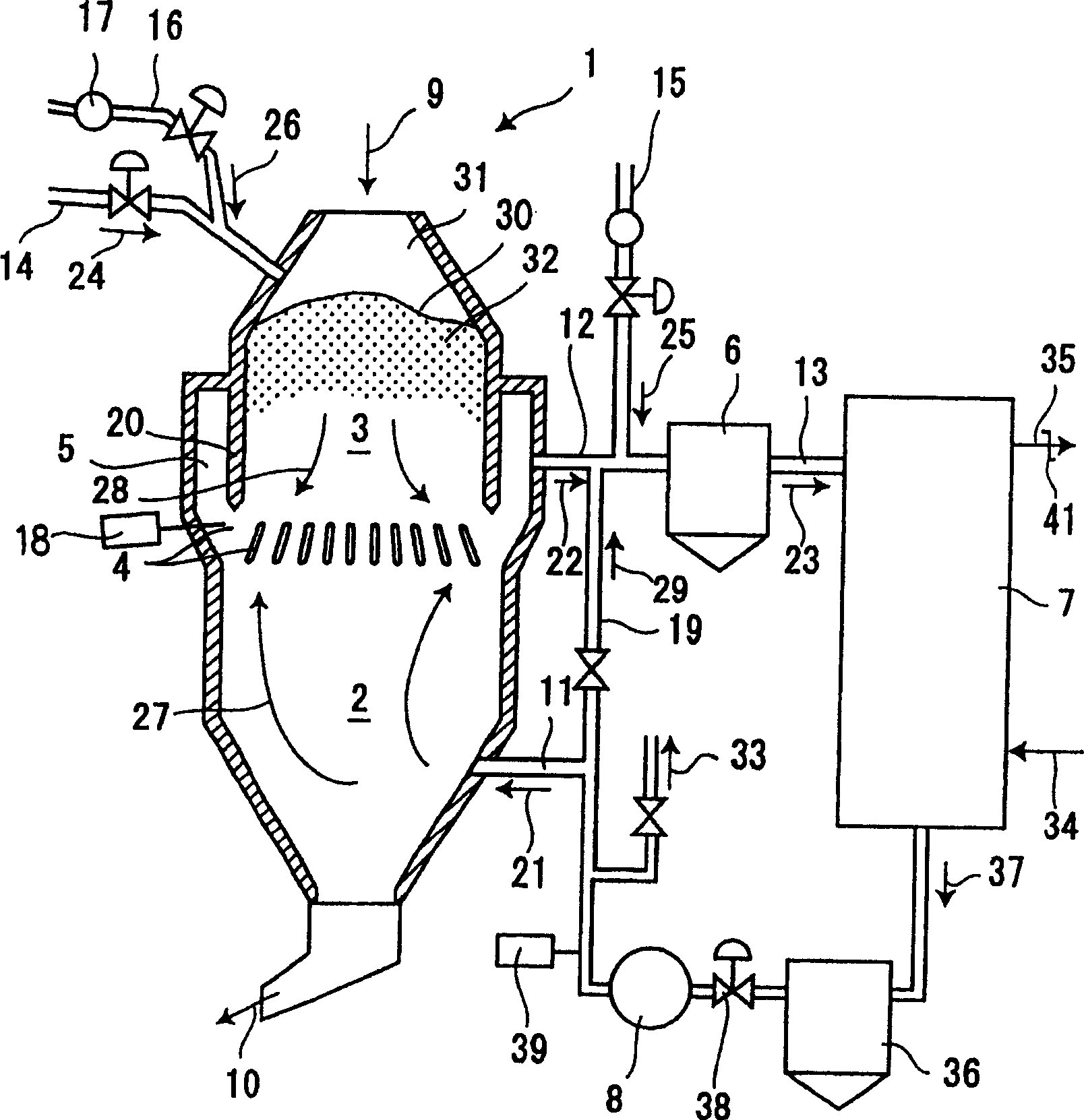

[0184] exist figure 1 The present invention is applicable to the CDQ device shown. The inner volume of cooling chamber 2 of CDQ device is 600m 3 , the inner volume of the prechamber 3 is 300m 3 . The red-hot coke 9 with an average temperature of 980° C. was cooled under the condition of an average discharge rate of 170 tons / hour.

[0185] PC air is blown from the upper part of the pre-chamber into the space 31 formed by the upper surface 30 of red-hot coke and the pre-chamber. In addition, PC water / steam 26 for adjusting the temperature of the pre-chamber is mixed with PC air 24 in the piping of the air blowing device 14, and the mixed gas is blown into the pre-chamber.

[0186] In order to combust combustible components in exhaust gas 22 from coke quenching tower 1 and control components in circulating gas 37 while raising the temperature of exhaust gas, a device for blowing SF air 25 is provided in gas discharge pipe 12 .

[0187] Furthermore, a part of the inert gas su...

Embodiment 2

[0246] exist figure 1 The coke dry quenching device shown is applicable to the present invention. The inner volume of cooling chamber 2 of CDQ device is 600m 3 , the inner volume of the prechamber 3 is 300m 3 . The red-hot coke 9 with an average temperature of 980° C. was cooled under the condition of an average discharge rate of 170 tons / hour.

[0247] As the blowing device 46 for blowing air and water into the prechamber at the same time, it refers to the use of Image 6 In the form shown, two devices are arranged in the pre-chamber. Two blowing devices are arranged at θ=180° along the circumferential direction. As a temperature measurement method in the pre-chamber, radiation thermometers are installed at two places in the inclined flue section, and the temperature of the red-hot coke observed through the annular duct is measured in a non-contact manner, and the temperature measurement results at these two places are used. The average temperature was used as the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com