Device and method for pressure regulation of coke oven carbonization chamber

A technology of pressure regulation and carbonization chamber, which is applied in the field of coking, can solve the problems of no water seal valve, no water seal, damage to furnace wall bricks, etc., and achieve the effect of reducing environmental pollution, ideal effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

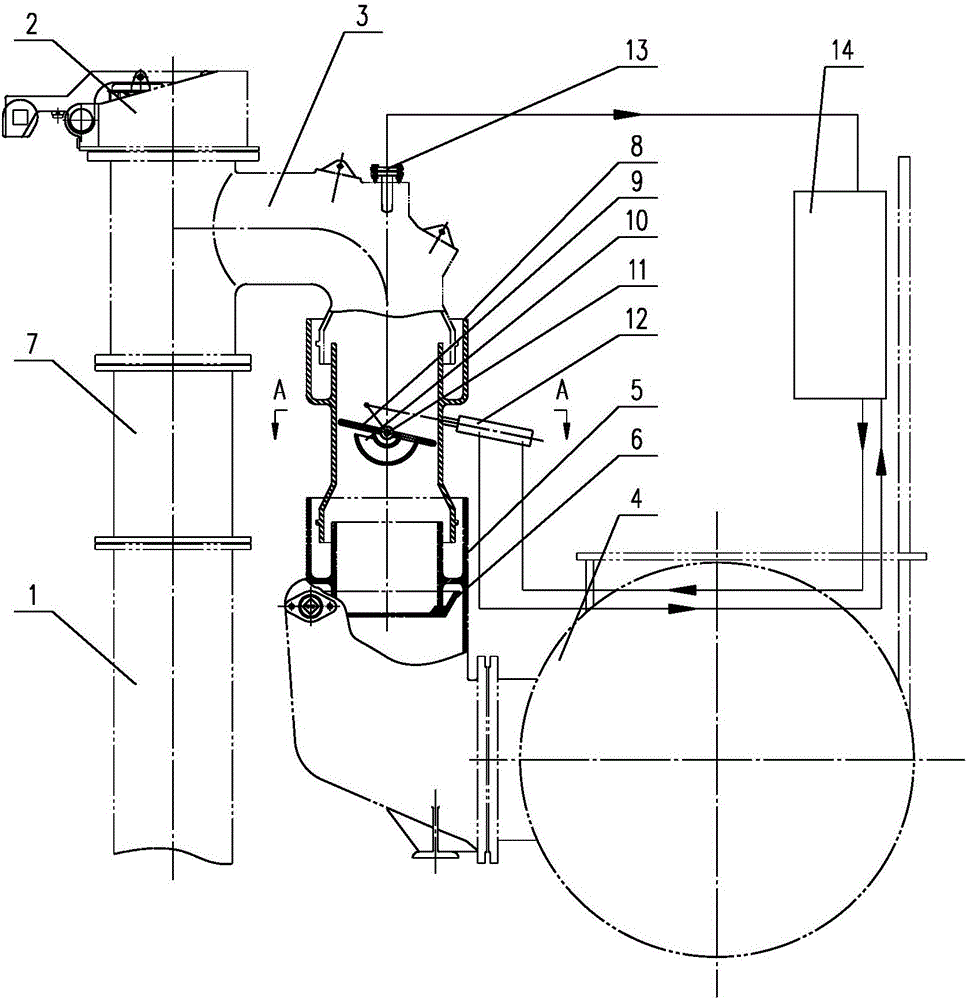

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

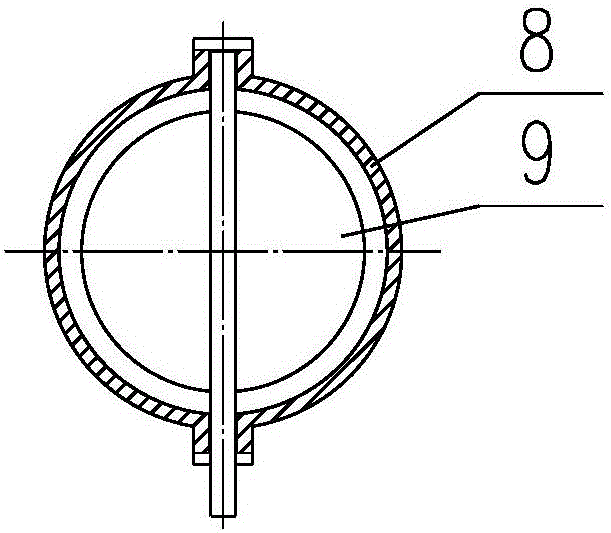

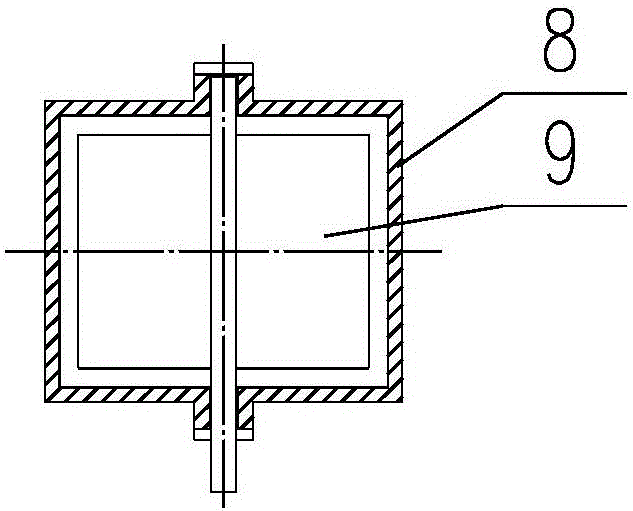

[0037] Such as figure 1 As shown, a coke oven coking chamber pressure regulating device according to the present invention includes a water seal valve arranged on the gas collecting pipe, and also includes a throttle; the throttle is composed of a casing 8, a flap 9, an overflow channel 10 and a rotating shaft 11, the housing 8 is fixed between the bridge pipe 3 and the water seal valve body 5, the flap 9 is installed in the housing 8 through the rotating shaft 11, and the rotating shaft 11 is driven by the actuator 12 and can drive the flap 9 to rotate; An overflow channel 10 is provided at the bottom of the flap 9 to form an ammonia water seal and overflow for ammonia water. The vertical section of the overflow channel 10 is arc-shaped. The space at the bottom of the plate 9; the bridge tube 3 is provided with a pressure measuring device 13, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com