High-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis

A carbon monoxide and isothermal transformation technology, applied in the field of temperature transformation process, can solve the problems of increasing process complexity and equipment investment, difficult to adjust the temperature of isothermal transformation furnace, unable to produce superheated steam, etc., to reduce investment and operation difficulty, improve grade, Effective adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] The difference between this embodiment and embodiment 1 is only: as Figure 4 As shown, the positions of the isothermal reaction zone B7 and the adiabatic reaction zone B6 are opposite. This structure is to adapt to different gasification technologies and shift processes, and finally achieve the purpose of controlling the outlet shift gas of the semi-isothermal reactor without overheating and superheating the self-produced saturated steam.

Embodiment 3

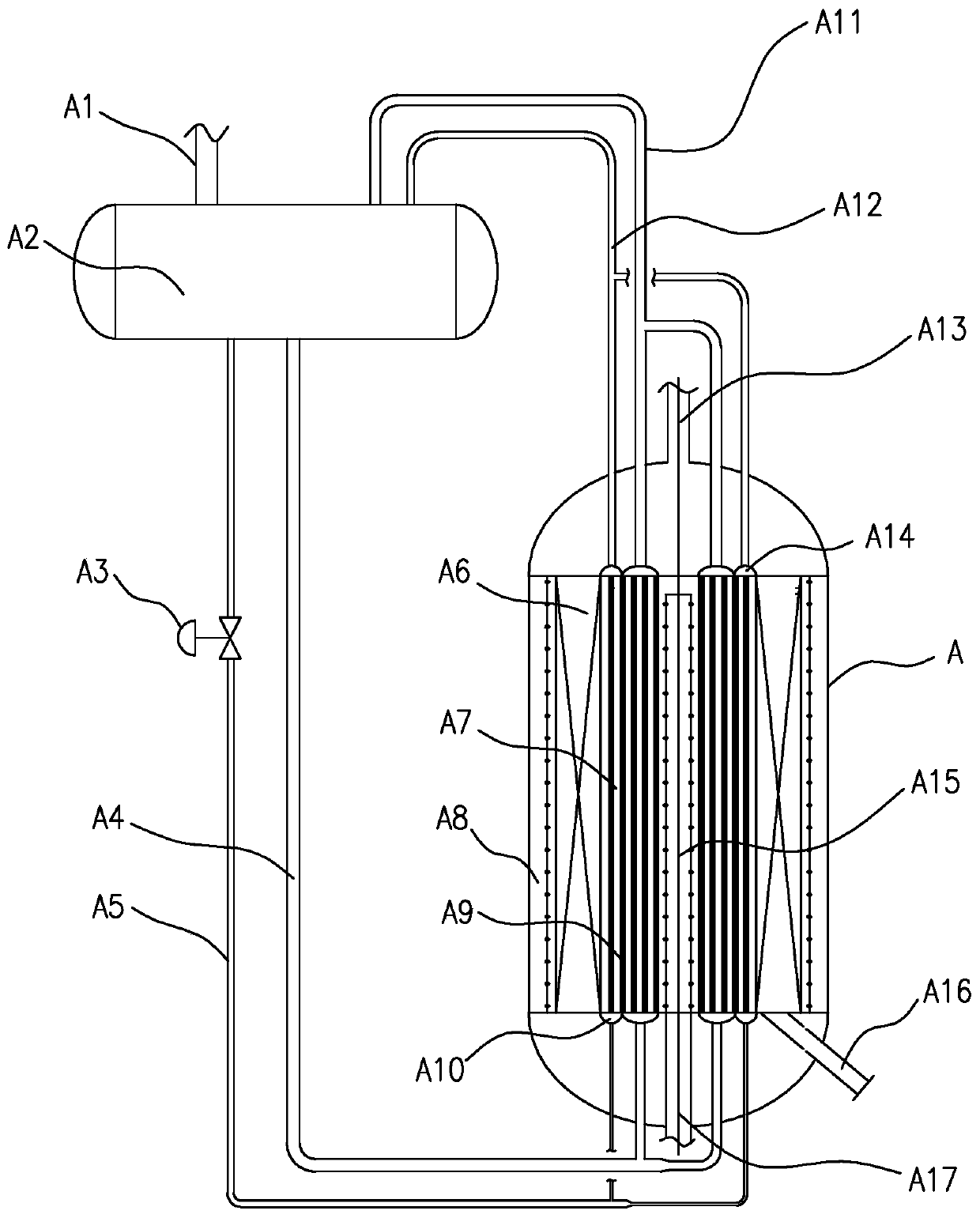

[0046] The difference between this embodiment and embodiment 1 is: as Figure 5 As shown, the controllable semi-isothermal reactor 6 of this embodiment includes a reactor shell C, which is shaped as a vertically extending cylinder, and the reactor shell C is provided along the central axis for Collect and guide the reacted shift gas out of the central tube C14 of the reactor. The outer periphery of the central tube C14 extends radially outwards and is provided with an adiabatic reaction zone C4, an isothermal reaction zone C3, and a feed gas inlet annulus C13 in sequence. The isothermal reaction zone C3 is provided with a plurality of vertically extending tubes C15 and a sleeve C5 set outside the tubes C15 for the isothermal reaction of the shifted gas, and the adiabatic reaction zone C4 is used for the adiabatic reaction of the shifted gas. The raw material gas inlet annulus C13 is used to evenly distribute the raw material gas entering the reactor. The top of the isothermal ...

Embodiment 4

[0049] The difference between this embodiment and embodiment 3 is only: as Image 6 As shown, the design structures of the steam plenum D12 and the boiler water header D2 are slightly different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com