Method for manufacturing tea leaf wine

A production method and technology of tea wine, applied in the preparation of alcoholic beverages, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of impure tea taste and insufficient fermentation, and achieve slow fermentation, full fermentation, strong tea effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

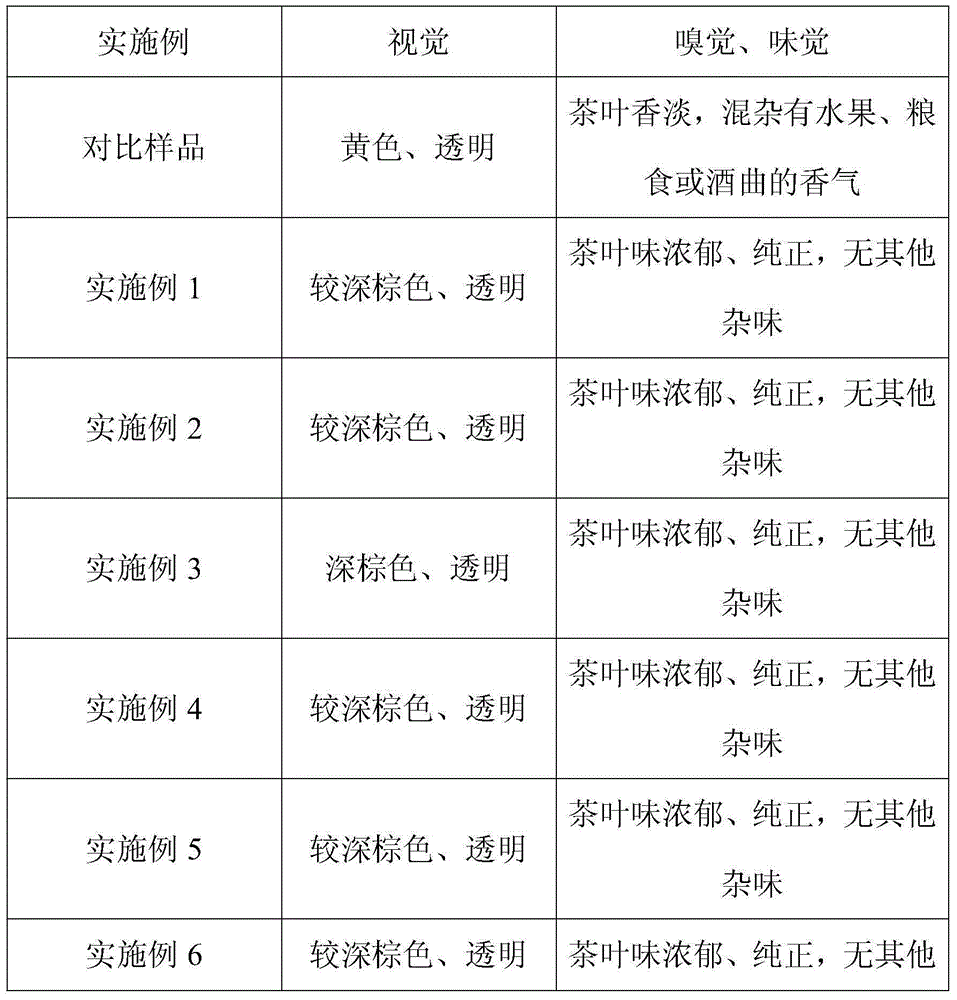

Examples

Embodiment 1

[0027] A method for preparing tea wine, comprising the steps of:

[0028] ①Preparation of fermented raw materials: weigh the tea leaves, pour 20°C water into the tea leaves and soak the tea leaves for 2 hours; take out the soaked tea leaves, filter and dry them, and steam them at 110°C for 25 minutes, then cool them down to 30°C, Obtain fermentation raw materials;

[0029] ②Preparation of seed liquid: insert Saccharomyces cerevisiae into 1.5% sterilized glucose solution by mass percentage, the mass ratio of glucose solution to Saccharomyces cerevisiae is 15:1, and then cultivate at room temperature at a shaking rate of 150r / min in summer Shaking culture for 32 days to obtain activated seed solution;

[0030] ③Stacking heat preservation: add the seed liquid obtained in step ② to the fermented raw material prepared in step ①, the amount of the seed liquid is 5% of the mass ratio of the fermented raw material, then add white sugar and mix well, the amount of the white sugar is t...

Embodiment 2

[0034] A method for preparing tea wine, comprising the steps of:

[0035] ①Preparation of raw materials for fermentation: Weigh the tea leaves, pour 25°C water into the tea leaves and soak the tea leaves for 0.5h; take out the soaked tea leaves, filter and dry them, and steam them at 130°C for 35 minutes, then cool them down to 24°C , to obtain the fermentation raw material;

[0036] ②Preparation of seed liquid: Insert Saccharomyces cerevisiae into sterilized glucose solution with a mass percentage of 3.0%, the mass ratio of glucose solution to Saccharomyces cerevisiae is 10:1, and then cultivate at room temperature at a shaking rate of 200r / min in summer Shaking culture for 38 days to obtain activated seed solution;

[0037] ③Stacking heat preservation: add the seed liquid obtained in step ② to the fermentation raw material prepared in step ①, the amount of the seed liquid is 8% of the mass ratio of the fermentation raw material, then add white sugar and mix well, the amount...

Embodiment 3

[0041] A method for preparing tea wine, comprising the steps of:

[0042] ①Preparation of fermented raw materials: weigh the tea leaves, pour 22°C water into the tea leaves and soak the tea leaves for 1 hour; take out the soaked tea leaves, filter and dry them, and steam them at 120°C for 30 minutes, then cool them down to 28°C, Obtain fermentation raw materials;

[0043] ②Preparation of seed liquid: Insert Saccharomyces cerevisiae into 2.5% sterilized glucose solution by mass percentage, the mass ratio of glucose solution to Saccharomyces cerevisiae is 12:1, and then culture at room temperature at a shaking rate of 180r / min in summer Shaking culture for 35 days to obtain activated seed solution;

[0044]③Stacking heat preservation: add the seed liquid obtained in step ② to the fermented raw material prepared in step ①, the amount of the seed liquid is 6% of the mass ratio of the fermented raw material, then add white sugar and mix well, the amount of the white sugar is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com