A kind of matcha chocolate composition, coating and preparation method thereof

A composition and chocolate technology, applied in food ingredients as coating agent, food science, cocoa, etc., can solve the problems of weak tea aroma and affecting consumers' sensory experience, achieve pure flavor, improve taste and anti-oxidation effect, pure taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

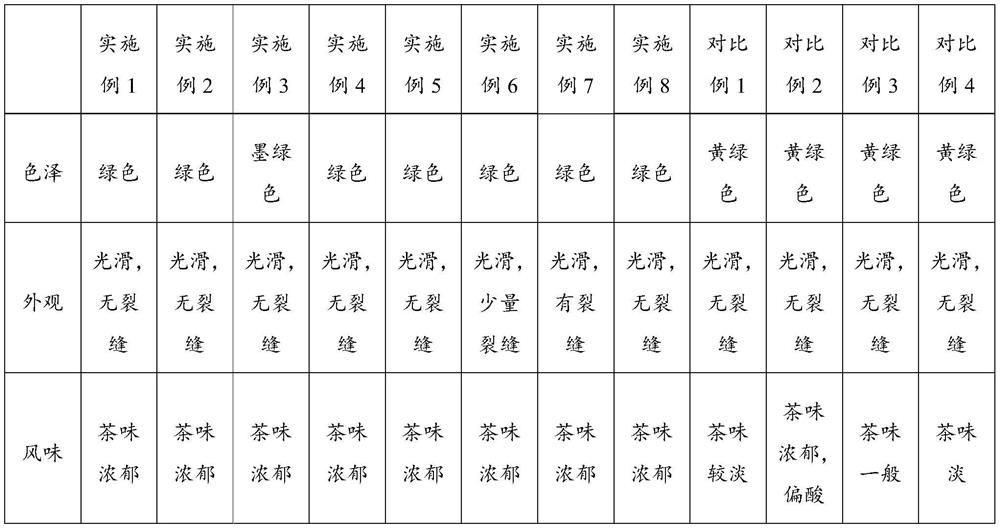

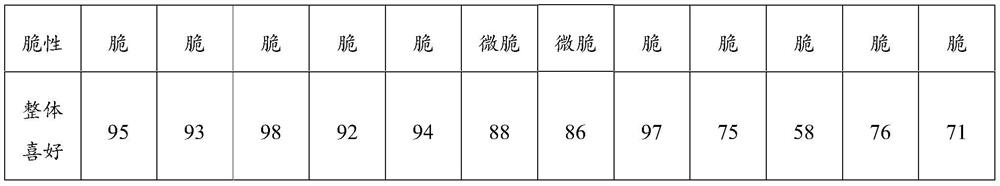

Examples

Embodiment 1

[0049] The present embodiment provides a matcha chocolate coating, which includes the following components:

[0050] Sugar 280kg, palm oil 240kg, coconut oil 220kg, skimmed milk powder 250kg, matcha powder 4.85kg, lecithin 3kg, polyglycerol ricinoleate 2kg, tea polyphenol 0.05kg, vitamin C 0.1kg.

[0051] Its preparation method is:

[0052] ①Crush the white granulated sugar with a pulverizer into powdered sugar with a fineness of 80 mesh, mix the powdered sugar, palm oil, coconut oil, and skimmed milk powder evenly, and add it to the ball mill;

[0053] ③ Put the above mixture in a ball mill, keep the temperature at 40°C, and grind for 2h;

[0054] ④ Pass cold water into the interlayer to cool down to 25℃ and keep it;

[0055] ⑤Add vitamin C, tea polyphenols, lecithin and polyglycerol ricinoleate in turn, and grind with nitrogen gas for 10min;

[0056] ⑥Add 800 mesh matcha powder, mix and grind for 20 minutes, then serve;

[0057] ⑦ Adjust the temperature of the chocolate ...

Embodiment 2

[0059] The present embodiment provides a matcha chocolate coating, which includes the following components:

[0060] Sugar 280kg, palm oil 240kg, coconut oil 220kg, skimmed milk powder 250kg, matcha powder 4.2kg, lecithin 3kg, polyglycerol ricinoleate 2kg, tea polyphenol 0.4kg, vitamin C 0.4kg.

[0061] Its preparation method is:

[0062] ①Crush the white granulated sugar with a pulverizer into powdered sugar with a fineness of 80 mesh, mix the powdered sugar, palm oil, coconut oil, and skimmed milk powder evenly, and add it to the ball mill;

[0063] ③ Put the above mixture in a ball mill at a temperature of 55°C for a grinding time of 6h;

[0064] ④ Pass cold water into the interlayer to cool down to 30℃ and keep it;

[0065] ⑤Add vitamin C, tea polyphenols, lecithin and polyglycerol ricinoleate in sequence, and grind with nitrogen gas for 20min at the same time;

[0066] ⑥Add 800 mesh matcha powder, mix and grind for 20 minutes, then serve;

[0067] ⑦ Adjust the temperatu...

Embodiment 3

[0069] The present embodiment provides a matcha chocolate coating, which includes the following components:

[0070] Sugar 280kg, palm oil 240kg, coconut oil 220kg, skimmed milk powder 250kg, matcha powder 4.55kg, lecithin 3kg, polyglycerol ricinoleate 2kg, tea polyphenol 0.15kg, vitamin C 0.3kg.

[0071] Its preparation method is:

[0072] ①Crush the white granulated sugar with a pulverizer into powdered sugar with a fineness of 80 mesh, mix the powdered sugar, palm oil, coconut oil, and skimmed milk powder evenly, and add it to the ball mill;

[0073] ③ Put the above mixture in a ball mill, keep the temperature at 50°C, and grind for 4h;

[0074] ④ Pass cold water into the interlayer to cool down to 28℃ and keep it;

[0075] ⑤Add vitamin C, tea polyphenols, lecithin and polyglycerol ricinoleate in sequence, and grind with nitrogen gas for 12 minutes at the same time;

[0076] ⑥Add 800 mesh matcha powder, mix and grind for 20 minutes, then serve;

[0077] ⑦ Adjust the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com