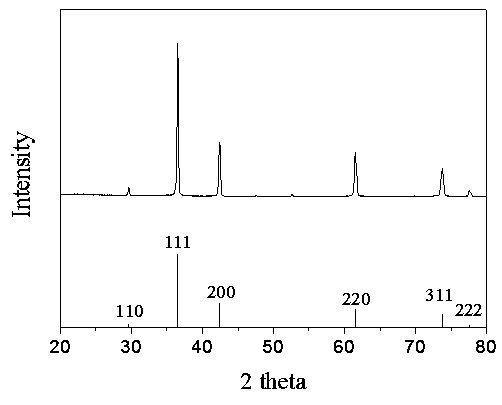

Preparation method of micro-nano cuprous oxide particles with controllable morphology and size

A technology of cuprous oxide and micro-nano structure, which is applied in the direction of copper oxide/copper hydroxide, nanotechnology for materials and surface science, nanotechnology, etc. It can solve the problems of low product purity, difficult exploration conditions, and high environmental governance costs. problem, to achieve the effect of uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Add 0.5 ml of copper sulfate solution to 8.5 ml of deionized water, then add 0.75 g of PVP, mix with the copper solution, stir for 10 min, and then ultrasonically shake for 5 min to mix the solution evenly to obtain brilliant blue colored solution;

[0029] (2) Then add 0.5 ml of sodium citrate solution and 0.5 ml of sodium carbonate solution in sequence to adjust the pH value of the solution to be greater than 7, and the color of the solution becomes light blue at this time;

[0030] (3) After standing the light blue solution in (2) for 10 min, add 0.5 ml of glucose solution, mix and oscillate with ultrasonic waves for 5 min to make the solution evenly mixed.

[0031] (4) Place the solution in (3) in a constant temperature water bath and heat at 80 °C for 1 h to obtain a cuprous oxide suspension.

[0032] (5) After washing the suspension obtained in (4) with distilled water, centrifuge it with a centrifuge, and finally put the particles in 40 °C N 2 Dry in the at...

Embodiment 2

[0035] (1) Add 0.5 ml of copper sulfate solution to 8.5 ml of deionized water, then add 3.00 g of PVP, mix with the copper solution, stir for 10 min, then ultrasonically oscillate for 5 min, and mix the solution evenly to obtain a bright blue solution;

[0036] (2) Then add 0.5 ml sodium citrate solution and 0.5 ml sodium carbonate solution in sequence to adjust the pH value of the solution to be greater than 7, and the color of the solution turns light blue at this time;

[0037] (3) After standing the light blue solution in (2) for 10 min, add 0.5 ml of glucose solution, mix and oscillate with ultrasonic waves for 5 min to make the solution evenly mixed.

[0038] (4) Place the solution in (3) in a constant temperature water bath, heat at 70 °C for 2 h, and finally obtain a suspension of cuprous oxide.

[0039] (5) After washing the suspension obtained in (4) with distilled water, centrifuge it with a centrifuge, and finally put the particles in 60 °C N 2 Drying in the atmos...

Embodiment 3

[0041] (1) Add 0.5 ml of copper sulfate solution to 8.5 ml of deionized water, then add 0.75 g of PVP, mix with the copper solution, stir for 10 min, then ultrasonically oscillate for 5 min, and mix the solution evenly to obtain a bright blue solution;

[0042] (2) Then add 0.5 ml sodium citrate solution and 0.5 ml sodium carbonate solution in sequence to adjust the pH value of the solution to be greater than 7, and the color of the solution turns light blue at this time;

[0043] (3) After standing the light blue solution in (2) for 10 min, add 0.5 ml of glucose solution, mix and oscillate with ultrasonic waves for 5 min to make the solution evenly mixed.

[0044] (4) Place the solution in (3) in a constant temperature water bath and heat it at 60 °C for 1 h to obtain a suspension of cuprous oxide.

[0045] (5) After washing the suspension obtained in (4) with distilled water, centrifuge it with a centrifuge, and finally put the particles in 40 °C N 2 Dry in the atmosphere t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com