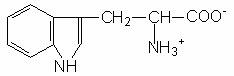

Method for producing L-tryptophan

A production method, tryptophan technology, applied in the field of microbial fermentation, can solve the problems of breeding technology, backward production technology, less research on L-tryptophan fermentation, low conversion rate and extraction comprehensive yield, and achieve production cost Low content, small content fluctuation, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1. Shake flask liquid culture:

[0047] ①Put the primary strain culture medium into eggplant bottles, then inoculate the Corynebacterium glutamicum strain at an inoculum amount of 0.1%, and obtain the primary strain after static cultivation at 32°C for 24 hours;

[0048] ②Put the shake flask culture medium into the shake flask, insert the primary strain culture medium solution obtained in the previous step, and cultivate it on a reciprocating shaker with an inoculum size of 0.1%, a rotation speed of 120 rpm, a temperature of 32°C, and a time period of 18 hours. , to obtain shake flask liquid strains, the obtained strains were uniform, strong and non-polluting under the microscope, measured with a 752 spectrophotometer (range: 10mm, wavelength: 600nm) and the OD was 0.68.

[0049] 2. Production of glucose solution:

[0050] ① Soak the corn in the soaking tank for 4 hours and maintain the temperature at 50°C;

[0051] ② Grind the corn into corn milk slurry with a sand m...

Embodiment 2

[0066] 1. Shake flask liquid culture:

[0067] ①Put the primary strain culture medium into the eggplant bottle, then inoculate the Corynebacterium glutamicum strain according to the inoculum amount of 0.2%, and obtain the primary strain after static cultivation at 30-33°C for 20-24 hours;

[0068] ②Put the shake flask culture medium into the shake flask, insert the primary strain culture medium obtained in the previous step, and cultivate it on a reciprocating shaker with an inoculum size of 0.15%, a rotation speed of 140 rpm, a temperature of 30-33°C, and a time of After a period of 16 hours, the liquid strains in shake flasks were obtained. Microscopically, the obtained strains were uniform, strong, and pollution-free. Measured with a 752 spectrophotometer (range: 10mm, wavelength: 600nm), the OD was 0.6.

[0069] 2. Production of glucose solution:

[0070] ① Soak the corn in the soaking tank for 3-5 hours, and the soaking temperature is 55°C;

[0071] ②Use a sand mill to ...

Embodiment 3

[0086] 1. Shake flask liquid culture:

[0087] ①Put the primary strain culture medium into eggplant bottles, and then inoculate the Corynebacterium glutamicum strain according to the inoculum amount of 0.15%, and obtain the primary strain after static cultivation at 30-33°C for 20-24 hours;

[0088] ②Put the shake flask culture medium into the shake flask, insert the primary strain culture medium solution obtained in the previous step, and cultivate it on a reciprocating shaker with an inoculum size of 0.2%, a rotation speed of 130 rpm, a temperature of 30-33°C, and a time of After a period of 16 hours, the liquid strains in shake flasks were obtained. Microscopically, the obtained strains were uniform, strong, and pollution-free. Measured with a 752 spectrophotometer (range: 10mm, wavelength: 600nm), the OD was 0.8.

[0089] 2. Production of glucose solution:

[0090] ① Soak the corn in the soaking tank for 3-5 hours, and the soaking temperature is 53°C;

[0091] ②Use a san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com