Method for preparing high fructose corn syrup

A technology of high fructose syrup and fructose, applied in the field of food additives, can solve the problems of high ash content of sugar liquid, poor quality of fructose, poor stability, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

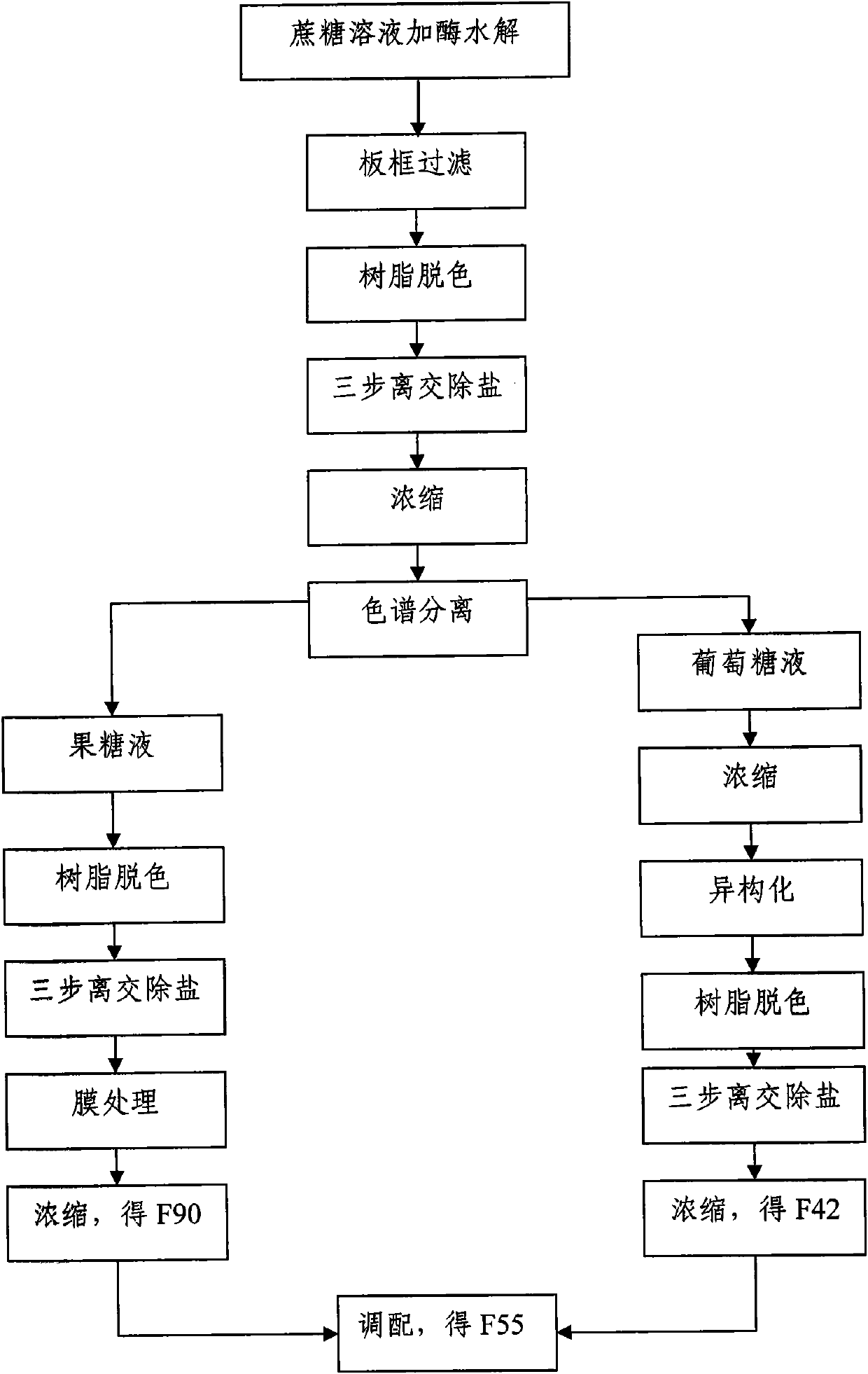

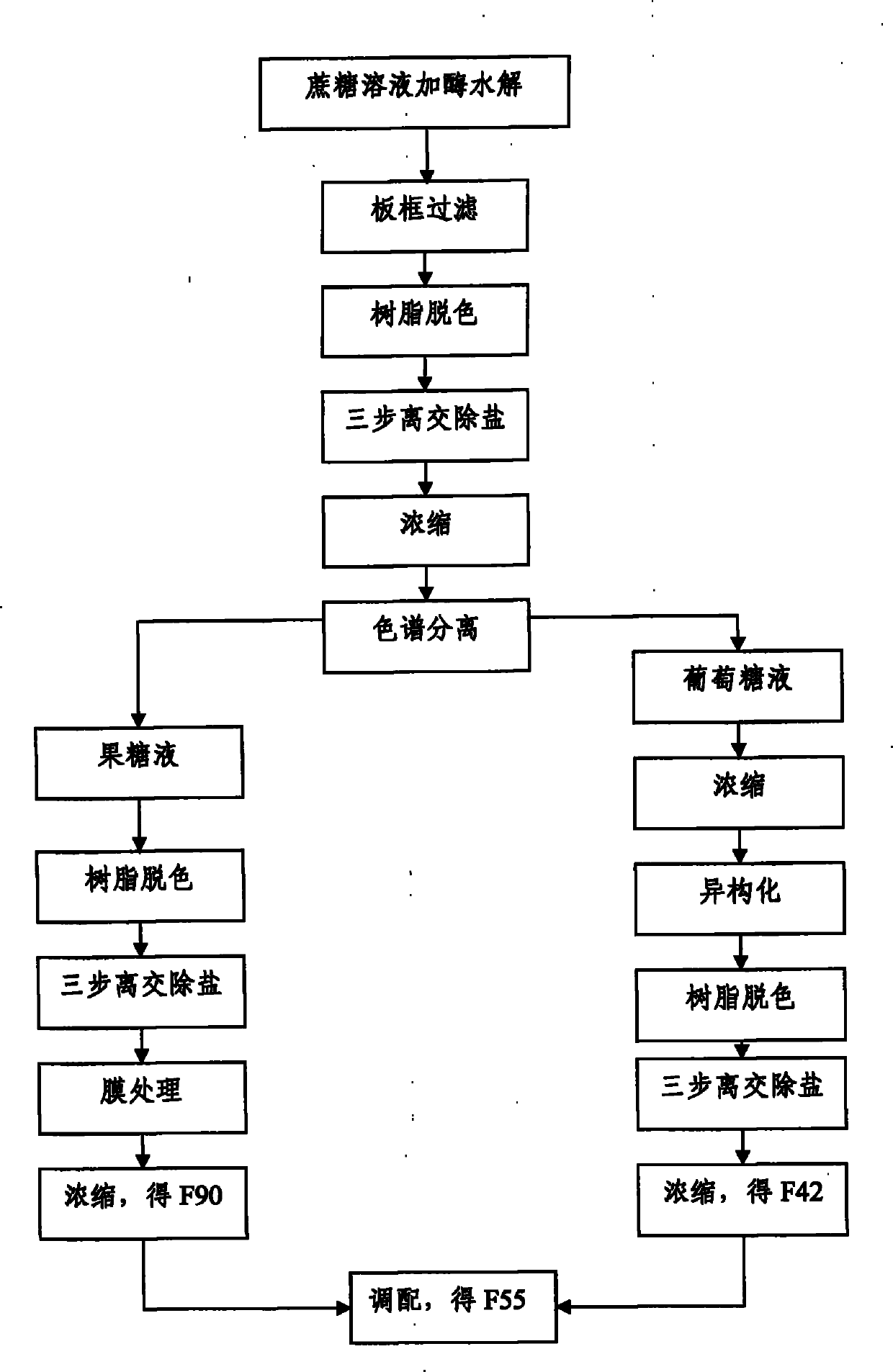

Method used

Image

Examples

Embodiment 1

[0018] 1 ton of sucrose solution with a solid content of 35%, adjust the pH value to 4.5, and the temperature is 40-50°C, add 11g of yeast sucrose hydrolase (commercially available, or self-extracted), react for 20 hours, and measure the hydrolysis rate of sucrose 97.7%. The temperature of the enzymolysis solution is raised to 80-90°C, and the protein and other impurities are removed by plate-and-frame filtration (the filter cloth has a pore size of 100,000 molecular weight (MD)). The filtrate has used Rohm and Haas AmberliteXAD16 type resin to decolorize the filtrate, and the light transmittance (measured at 420nm) is above 95%. Finally, the electrical conductivity is controlled below 20us / cm, and finally the sugar solution is concentrated using a plate evaporator. The temperature must not exceed 80°C, and the sugar solution is concentrated to a solid content of 40%. The concentrated liquid enters the chromatography (resin model is Rohm and Haas 1320), the feed temperature i...

Embodiment 2

[0020] 1 ton of sucrose solution with a solid content of 40%, adjust the pH value to 5, the temperature is 40-50°C, add 20g of yeast sucrose hydrolase, react for 18 hours, and the hydrolysis rate of sucrose is 99.2%. The temperature of the enzymolysis solution is raised to 80-90°C, and the protein and other impurities are removed by plate-and-frame filtration (the pore size of the filter cloth is 50,000 MD). The filtrate has used Rohm and Haas AmberliteXAD16 type resin to decolorize the filtrate, and the light transmittance (measured at 420nm) is above 95%. Finally, the electrical conductivity is controlled below 20us / cm, and finally the sugar solution is concentrated using a plate evaporator. The temperature must not exceed 80°C, and the sugar solution is concentrated to a solid content of 45%. The concentrated liquid enters the chromatography, the feed temperature is 60-65°C, the pH value is adjusted to 6, the washing water temperature is 60-65°C, the conductivity shall not ...

Embodiment 3

[0022]1 ton of 35% sucrose solution, adjust the pH value to 4.5, the temperature is 40-50 ° C, add 17.5 g of yeast sucrose hydrolase, react for 18 hours, and the hydrolysis rate of sucrose is 98.5%. The temperature of the enzymolysis solution is raised to 80-90°C, and the protein and other impurities are removed by plate-and-frame filtration (filter cloth pore size: 100,000 MD). The filtrate has used Rohm and Haas AmberliteXAD16 type resin to decolorize the filtrate, and the light transmittance (measured at 420nm) is above 95%. Finally, the electrical conductivity is controlled below 20us / cm, and finally the sugar solution is concentrated using a plate evaporator. The temperature must not exceed 80°C, and the sugar solution is concentrated to a solid content of 50%. The concentrated liquid enters the chromatography, the feed temperature is 60-65°C, the pH value is adjusted to 6, the washing water temperature is 60-65°C, the conductivity shall not exceed 5us / cm, the purity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com