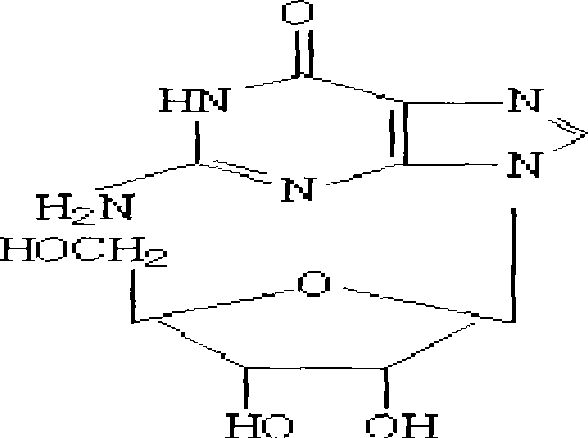

Production method of guanine nucleosides

A technology of guanosine and a production method, which is applied in the production field of guanosine, can solve the problems of low conversion rate and comprehensive extraction yield, less research on guanosine fermentation, low glucoside production level of strains, and the like. The effect of high simultaneous productivity, stable product quality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Concrete production method of the present invention is:

[0029] 1. Shake flask liquid culture:

[0030] ① Select Bacillus subtilis TA208-IMPD as the preserved strain;

[0031] 2. the primary strain culture medium prepared by glucose, inorganic salt, organic nitrogen, etc. is packed into an eggplant bottle, and the composition ratio of the primary strain culture medium is glucose: dipotassium hydrogen phosphate: magnesium sulfate: yeast powder: agar: water=1% :0.2%:0.1%:2%::2%:94.7%;

[0032] ③ Insert the preserved strains, the inoculum amount is 0.1%, and the primary strains are obtained after static culture at a temperature of 36°C for 24 hours;

[0033] ④Put the primary strains into a shaker flask with an inoculation amount of 0.1%, and cultivate them on a reciprocating shaker with a rotation speed of 160 rpm, a temperature of 36°C, and a time period of 10-12 hours. After the standard is reached, the shake bottle liquid bacteria can be obtained.

[0034] 2. Produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com