Maize flour low-temperature synchronous saccharification technique by double enzymatical process and its application

A technology of simultaneous saccharification and corn flour, applied in the fields of biofuel and fermentation, can solve the problems of high energy consumption and long reaction time, and achieve the effects of low energy consumption, low production cost and high glucose conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

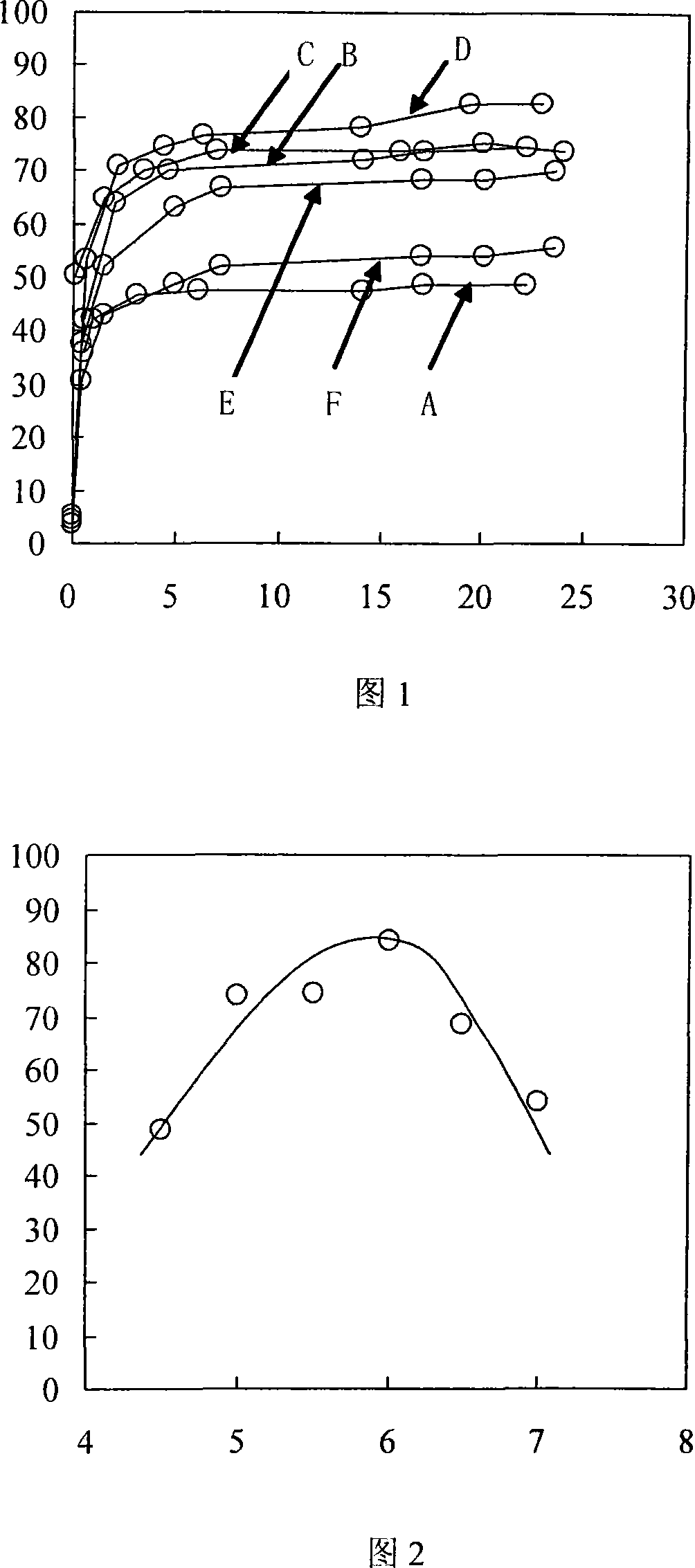

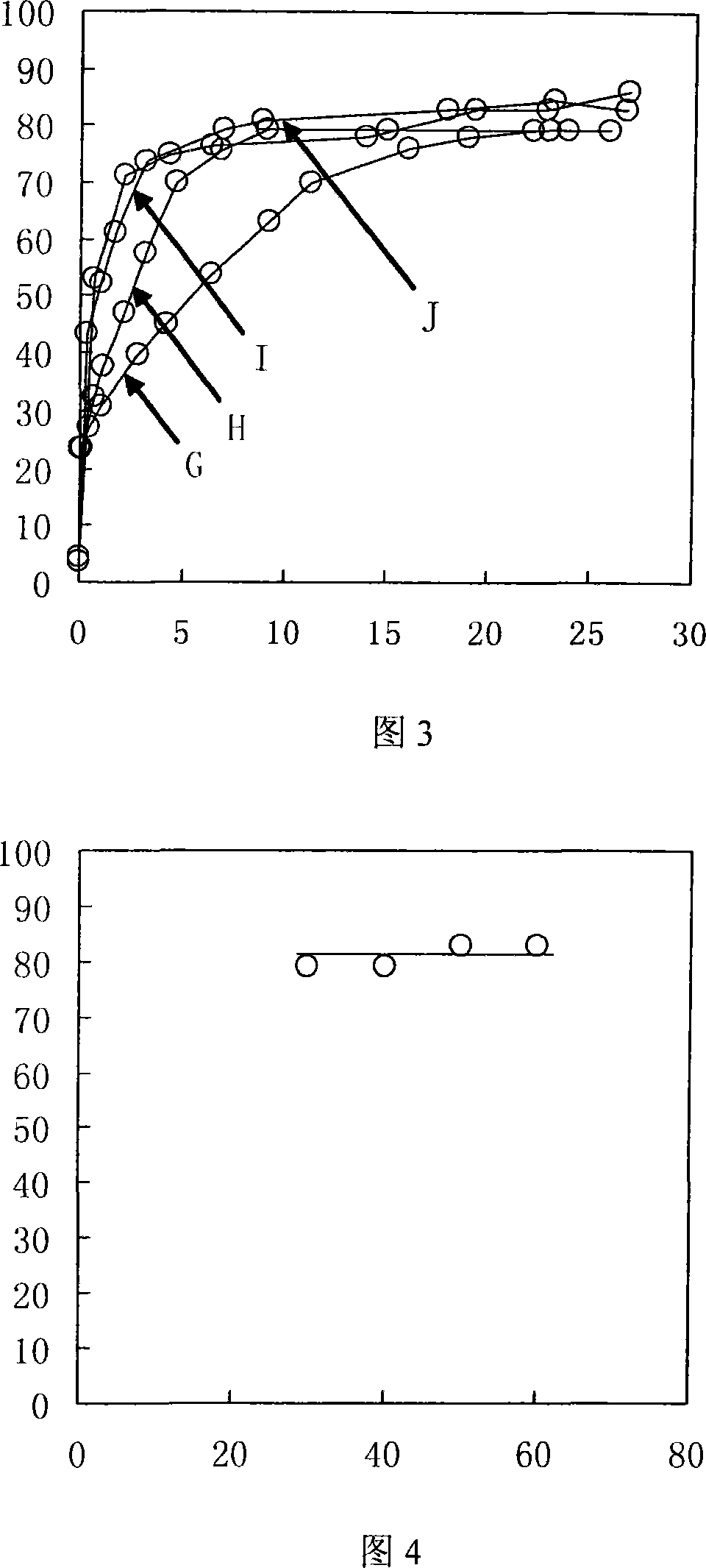

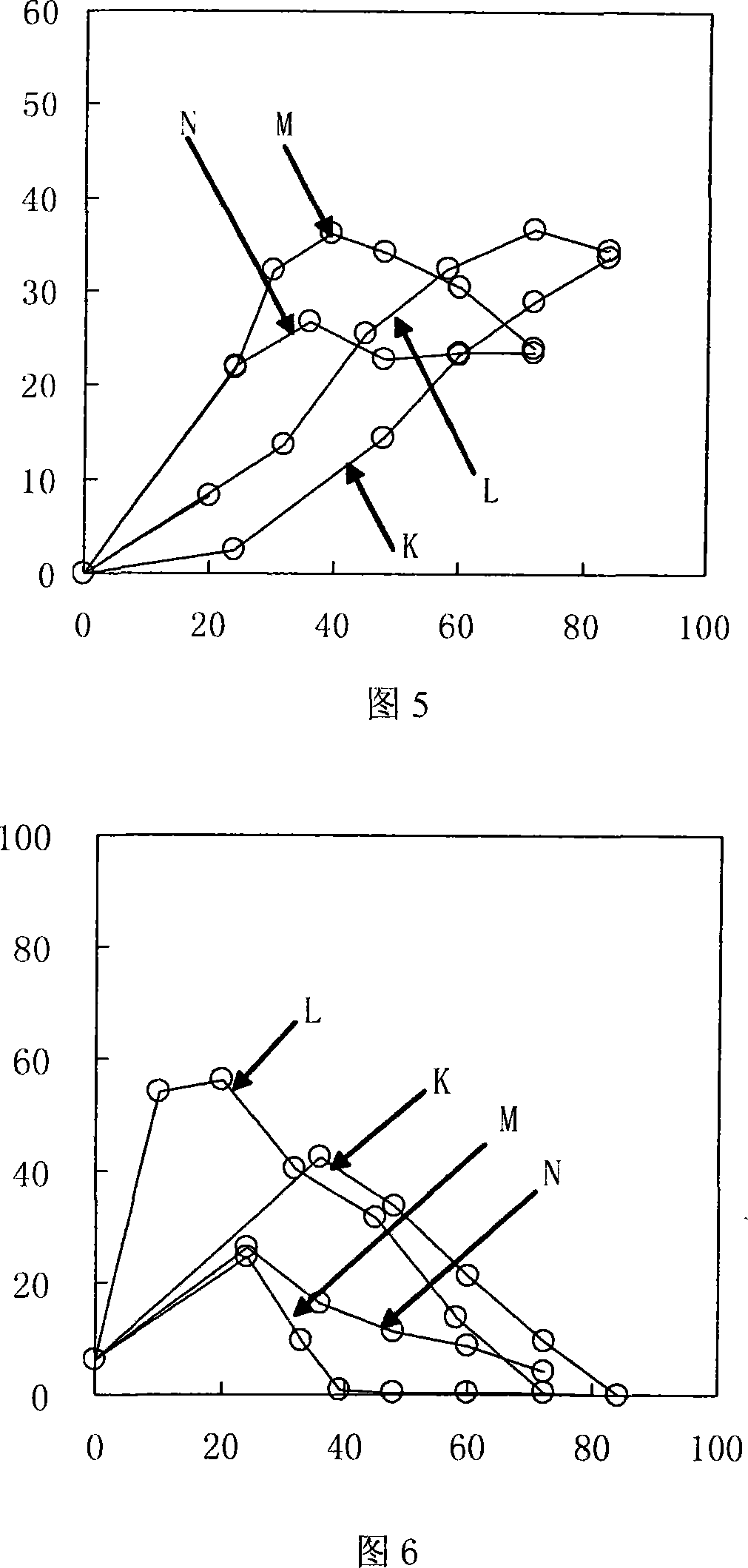

[0041] Embodiments 1-6 use a planetary ball mill (XQM-4L, Nanjing Institute of Experimental Instruments) to wet-grind peeled and degerminated corn flour for 3 hours to prepare a fine corn flour slurry. The mass ratio of corn flour to water is 1: 3; use a particle size distribution analyzer (2000, MALVERN, UK) to measure the particle size distribution of corn flour, and the median particle size is 14.6 μm: take the above-mentioned corn flour slurry equivalent to 60 g of dry matter in a container, and adjust the concentration 10% corn flour feed liquid; adjust the pH value of feed liquid to 4.5, 5.0, 5.5, 6.0, 6.5, 7.0 with acid solution and alkali solution; add α-amylase 10u / g to feed liquid, saccharification Enzyme 200u / g (based on dry matter of corn flour); put the container in a water bath at 60°C, and use an electric mixer to stir the feed liquid evenly, and the saccharification time is controlled at 24 hours; sample 3ml at intervals of 1 hour, and use a biosensing analyzer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com