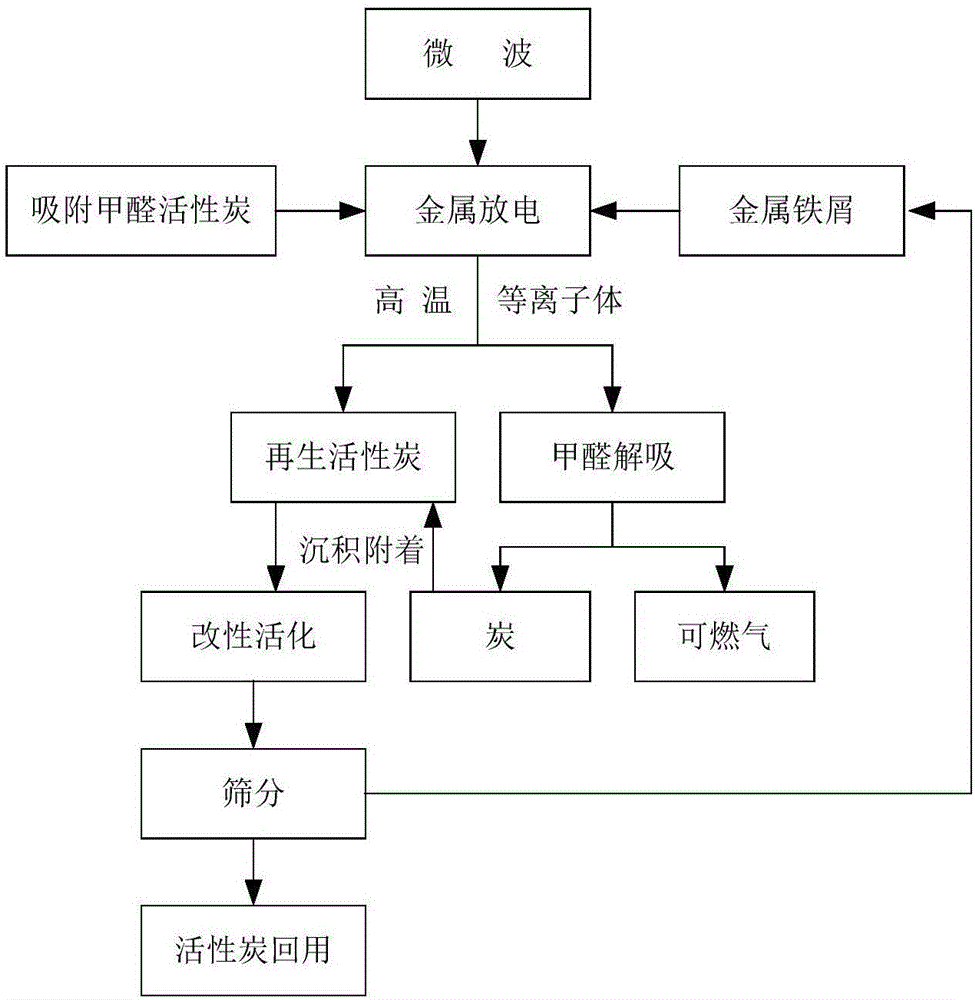

Method and device of simultaneously carrying out formaldehyde loaded activated carbon regeneration and desorbed gas quenching

A regeneration device and activated carbon technology, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problems of complicated regeneration devices, increase regeneration costs, etc. Effects of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] 1. Prepare saturated formaldehyde-loaded activated carbon in advance, and calculate and record the adsorption capacity of activated carbon.

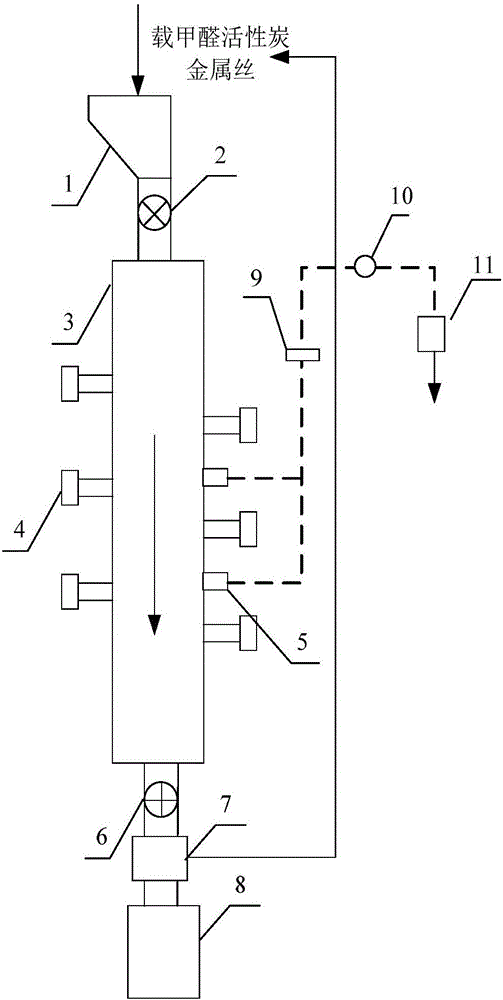

[0014] 2. Carry out a blank test without metal wire (metal powder), that is, simple microwave radiation regeneration as a control. Weigh 5g of formaldehyde-loaded activated carbon and put it into the regeneration device 3 and seal it. Then put the regeneration device 3 in the microwave oven and connect the pipeline. Keep purging until the end of the experiment. After the experiment, the desorbed gas was purified. The adsorption characteristics of activated carbon after microwave regeneration, the pore structure of activated carbon and the basic physical and chemical characteristics of activated carbon under different conditions such as microwave power, regeneration time, and activated carbon particle size were investigated.

[0015] 3. Take by weighing 5g of formaldehyde-loaded activated carbon and an appropriate amount of metal...

specific Embodiment approach 2

[0019] 1. Prepare saturated formaldehyde-loaded activated carbon in advance, and calculate and record the adsorption capacity of activated carbon.

[0020] 2. Weigh 50 kg of formaldehyde-laden activated carbon and metal wire (mass ratio 49:1) and put them into the storage hopper 1 on the regeneration device. The maximum continuous processing capacity of the microwave regeneration device 3 is 100 kg / h. By controlling the feed 2 and the output The rotating speed of the feeding device 6 is regulated; the output power of the microwave magnetron 4 is continuously adjustable from 0 to 10 kW. Before the start of the microwave, 3 L / min of nitrogen was introduced to purge the regeneration device 3, and the purge was kept until the end of the experiment. The adsorption characteristics of activated carbon after microwave regeneration, the pore structure of activated carbon, and the loss on ignition of activated carbon under different microwave power and regeneration time conditions were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com