A method for regenerating water glass sand by using calcium carbide slag

A technology of water glass sand and carbide slag, which is applied in the cleaning/processing machinery of casting materials, casting molding equipment, metal processing equipment, etc., to achieve the effects of high economic benefits, fast regeneration, and saving fresh water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

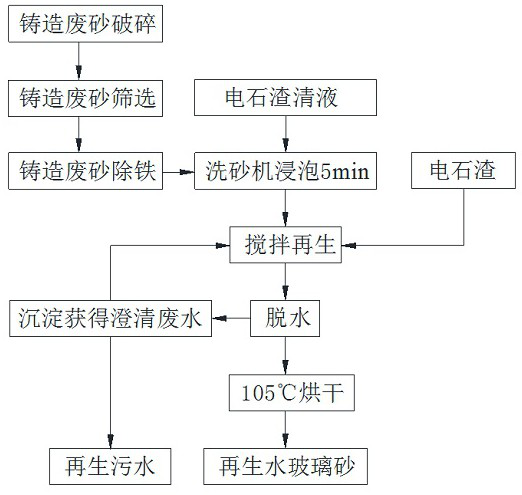

Method used

Image

Examples

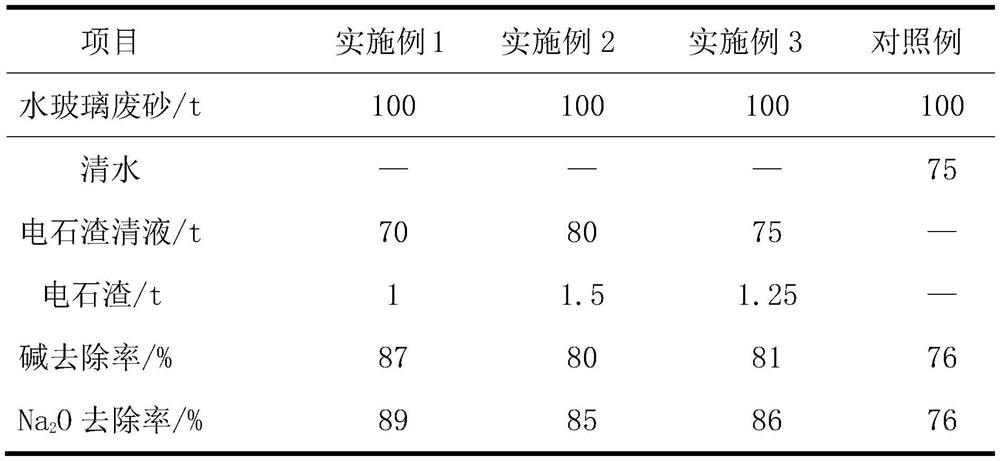

Embodiment 1

[0053] The invention relates to a method for regenerating sodium silicate sand by using calcium carbide slag. The mass parts of raw materials used in the method are: 100 parts of sodium silicate casting waste sand, 70 parts of calcium carbide slag clear liquid and 1 part of calcium carbide slag; The regeneration method includes the following steps:

[0054] Step 1. Preparation of carbide slag powder: precipitate and separate the waste carbide slag and carbide slag clear liquid discharged from the preparation of acetylene, collect the carbide slag clear liquid and carbide slag mud, dry and grind the carbide slag mud for 200 mesh to prepare carbide slag powder;

[0055] Step 2. Screen breaking: use mechanical vibration to break and screen the water glass casting waste sand to remove the large stones and wood blocks in the water glass casting waste sand;

[0056] Step 3: magnetic separation: roll magnetic separation is carried out for the broken sodium silicate casting waste sand wit...

Embodiment 2

[0063] The invention relates to a method for regenerating sodium silicate sand by using calcium carbide slag. The mass parts of raw materials used in the method are: 100 parts of sodium silicate casting waste sand, 80 parts of calcium carbide slag clear liquid and 1.5 parts of calcium carbide slag; The method comprises the following steps:

[0064] Step 1. Preparation of carbide slag powder: precipitate and separate the waste carbide slag and carbide slag clear liquid discharged from the preparation of acetylene, collect the carbide slag clear liquid and carbide slag mud, dry and grind the carbide slag mud for 250 mesh to prepare carbide slag powder;

[0065] Step 2. Screen breaking: use mechanical vibration to break and screen the water glass casting waste sand to remove the large stones and wood blocks in the water glass casting waste sand;

[0066] Step 3: magnetic separation: roll magnetic separation is carried out for the broken sodium silicate casting waste sand with electro...

Embodiment 3

[0073] The invention relates to a method for regenerating sodium silicate sand by using calcium carbide slag. The mass parts of raw materials used in the method are: 100 parts of sodium silicate casting waste sand, 75 parts of calcium carbide slag clear liquid and 1.25 parts of calcium carbide slag; The method comprises the following steps:

[0074] Step 1. Preparation of carbide slag powder: precipitate and separate the waste carbide slag and carbide slag clear liquid discharged from the preparation of acetylene, collect the carbide slag clear liquid and carbide slag mud, dry and grind the carbide slag mud for 300 mesh to prepare carbide slag powder;

[0075] Step 2. Screen breaking: use mechanical vibration to break and screen the water glass casting waste sand to remove the large stones and wood blocks in the water glass casting waste sand;

[0076] Step 3: magnetic separation: roll magnetic separation is carried out for the broken sodium silicate casting waste sand with electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com