Preparation method of injectable in-situ self-assembled sodium hyaluronate hydrogel

A technology of sodium hyaluronate and hyaluronic acid, which is applied in skin care preparations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve complex purification processes, inability to remove, toxic and side effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

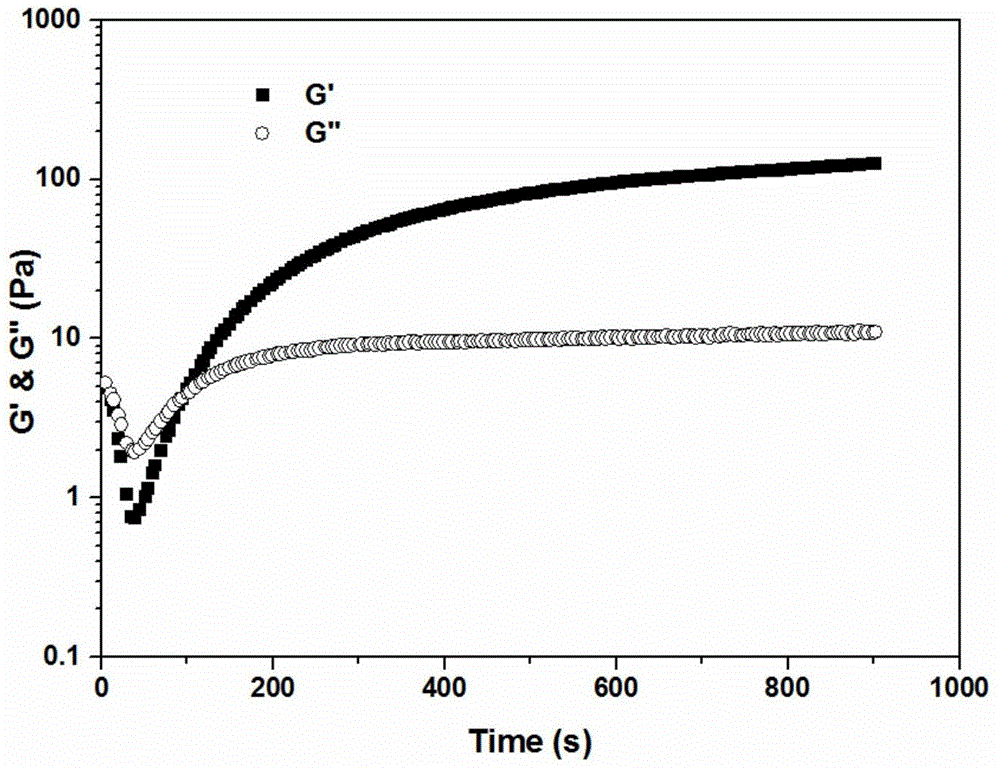

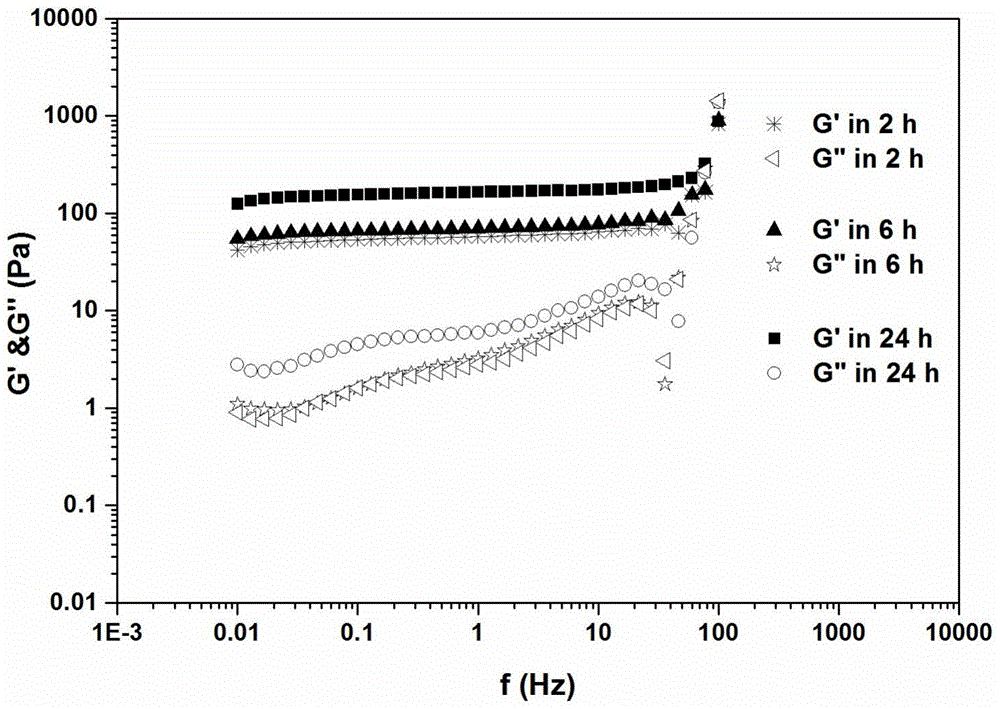

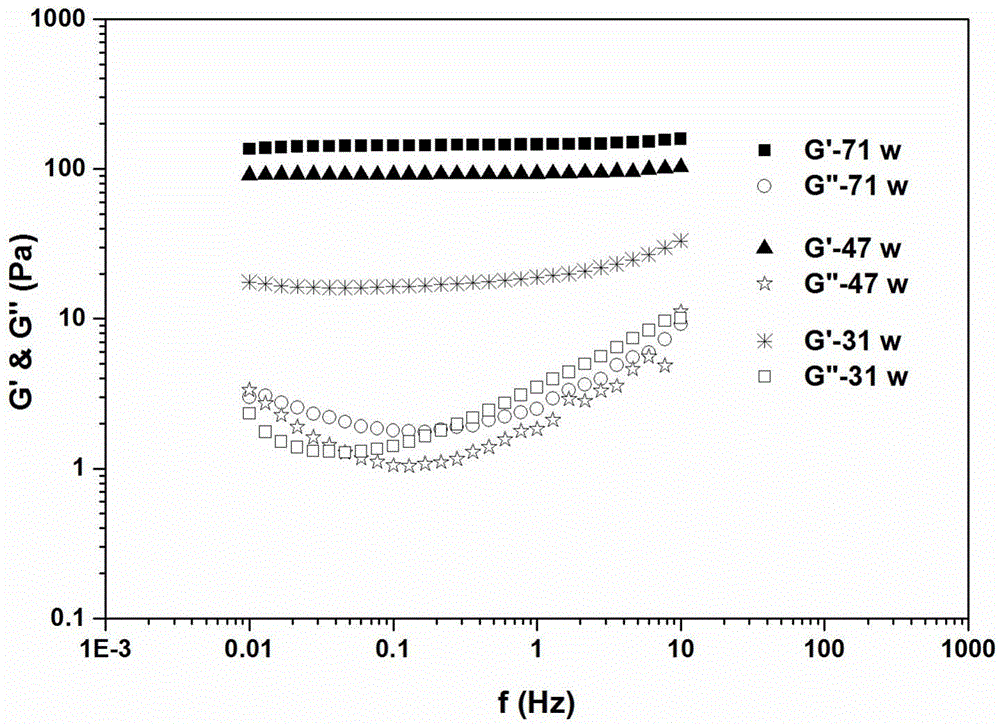

Embodiment 1

[0020] Dissolve 0.5 g of cystamine dihydrochloride in 15 mL of water, adjust the pH to 4, weigh 1 g of sodium hyaluronate dry powder (molecular weight 1,300,000 DA), stir well, weigh 1 g of DMTMM, dissolve it completely in 5 mL of water and Adjust the pH value to 4, then add it into the mixture, and react at 4°C for 2 days after complete stirring. After the reacted gel was cut into pieces, it was dialyzed with PBS buffer, and the dialysate was changed every 1 h and weighed until the gel mass no longer increased, and the dialysis was terminated. After the gel was pulverized and granulated, the pH value of the gel was adjusted to 8 with 1 M NaOH aqueous solution, after mixing evenly, 2 g of dithiothreitol was added, and the reaction was carried out overnight at room temperature, and the pH of the obtained reaction solution was adjusted with hydrochloric acid solution After reaching about 3, transfer the solution to a dialysis bag (molecular weight cut-off 10,000), dialyze with 1...

Embodiment 2

[0024] Dissolve 0.25 g of cystamine dihydrochloride in 15 mL of water, adjust the pH to 6, weigh 1 g of sodium hyaluronate dry powder (molecular weight 310,000 DA), stir well, weigh 0.5 g of DMTMM, dissolve it completely in 5 mL of water, and adjust the pH The value was adjusted to 6, and then added to the mixture, and after being completely stirred evenly, it was reacted at room temperature for 1 day. After the reacted gel was cut into pieces, it was dialyzed with PBS buffer, and the dialysate was changed every 1 h and weighed until the gel mass no longer increased, and the dialysis was terminated. After the gel was pulverized and granulated, the pH value of the gel was adjusted to 8 with 1M NaOH aqueous solution, and after mixing evenly, 1.5 g of dithiothreitol was added and reacted overnight at room temperature, and the resulting reaction solution was adjusted to a pH of After 3 or so, transfer the solution to a dialysis bag (molecular weight cut-off 10,000), dialyze with 1...

Embodiment 3

[0028] Dissolve 1 g of cystamine dihydrochloride in 15 mL of water, adjust the pH to 7, weigh 1.2 g of sodium hyaluronate dry powder (molecular weight 710,000 DA), stir well, weigh 1 g of DMTMM, dissolve it completely in 5 mL of water and Adjust the pH value to 7, then add it into the mixture, and react at 4°C for 3 days after complete stirring. After the reacted gel was cut into pieces, it was dialyzed with PBS buffer, and the dialysate was changed every 1 hour and weighed until the gel mass no longer increased, and the dialysis was terminated. After the gel was pulverized and granulated, the pH value of the gel was adjusted to 8 with 1 M NaOH aqueous solution, after mixing evenly, 2.5 g of dithiothreitol was added, and the reaction was carried out overnight at room temperature, and the pH of the obtained reaction solution was adjusted with hydrochloric acid solution After about 3, the solution was transferred to a dialysis bag (molecular weight cut-off 10000), dialyzed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com