Production method of resin for artware

A production method and handicraft technology, applied in the field of resin production for handicrafts, can solve the problems of high production cost, high material price, and poor physical properties, and achieve the effects of improving strength and toughness, enhancing surface energy, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

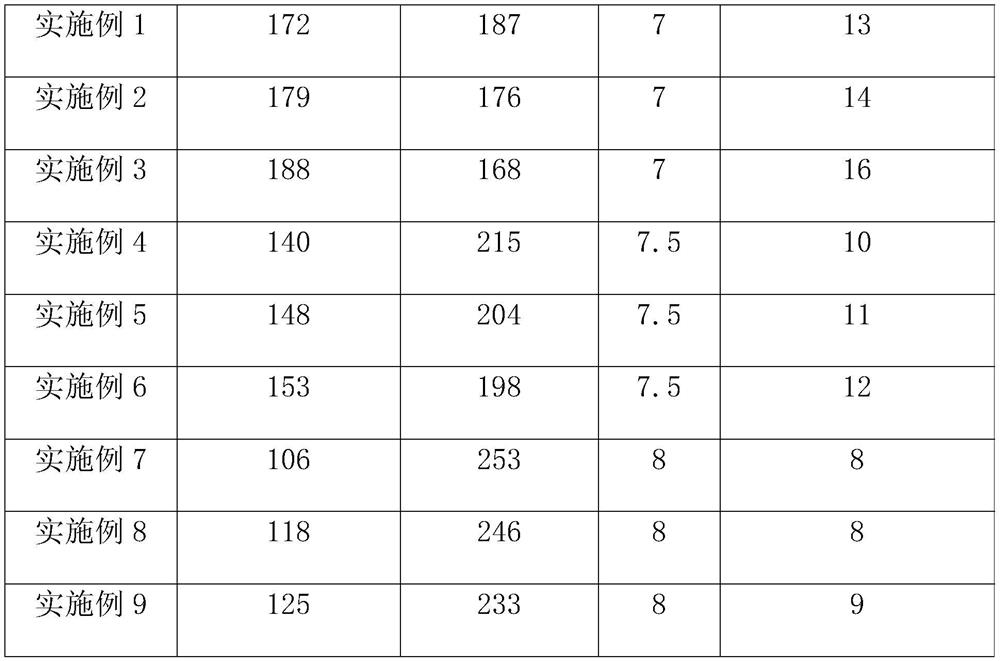

Examples

Embodiment Construction

[0027] A method for producing resin for handicrafts provided by the present embodiment comprises the following raw materials by weight:

[0028] 10~50 parts of unsaturated resin

[0029] Filling material 30~90 parts

[0030] Hardener 1 to 3 parts

[0031] Wherein, the filler is ceramic powder or gypsum powder.

[0032] The production method of this resin comprises the steps:

[0033] S1: Take the target number of unsaturated resin and filler, add the unsaturated resin into the mixer, add the filler while stirring, and stir evenly to form a slurry;

[0034] S2: Take the target shape mold, make a comprehensive inspection of the mold, and prepare for grouting;

[0035] S3: The product is a hollow structure, first check and fix the mold, add the curing agent of the target component into the resin slurry, stir evenly for 3 minutes, then pour the slurry, pour the resin slurry into the mold, and use a vacuum machine to pump the inside of the mold Vacuum, the vacuum time is 1 ~ 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com