A countercurrent internal pressure reducing pipeline water exchanger

A technology for exchanging water heaters and pipes, which is applied in the field of hot water supply devices, which can solve the problems of user inconvenience, frequent water leakage at weld points, etc., and achieve the effects of preventing erosion, improving heat exchange efficiency, and increasing anti-aging strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

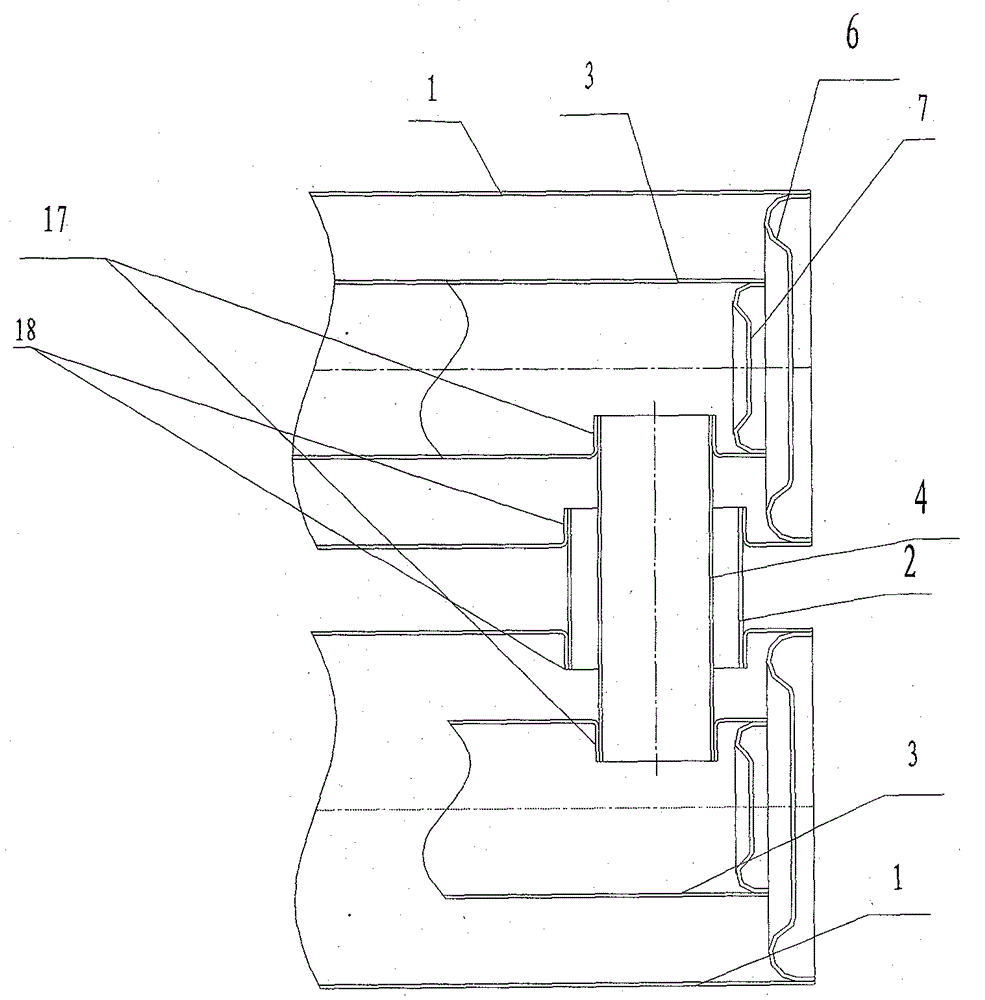

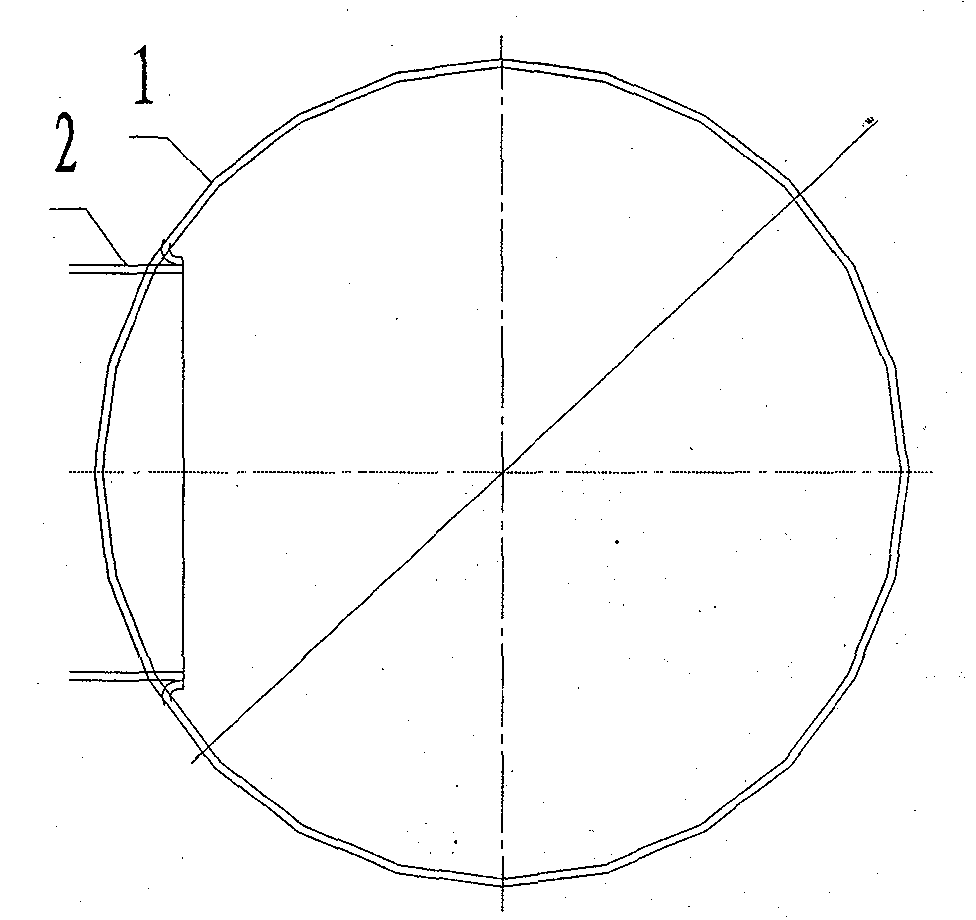

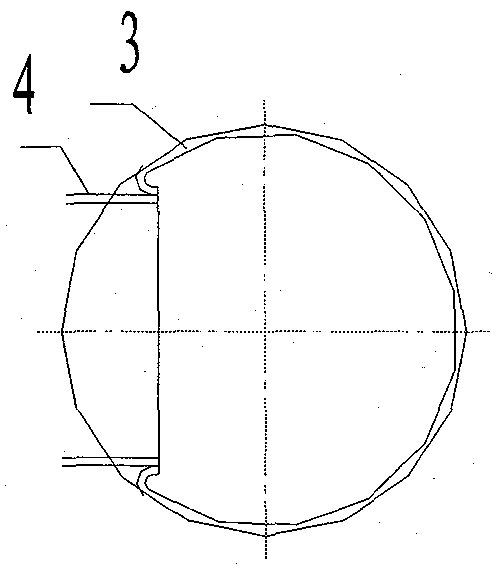

[0012] The invention as Figure 1 to Figure 4 As shown, the structure is a kind of countercurrent internal pressure reduction pipeline water exchange heater, including several tap water heat pipes connected in series 1, tap water heat pipe connecting parts 2, heating pipes 3, inner pipe connecting parts 4, connecting parts 5, inner Circular chamfered head 6, small inner circular chamfered head 7, air release valve 8, heating inlet inner wire connector 9, heating outlet inner wire connector 10, tap water inlet inner wire connector 11, tap water outlet inner wire connector Composed of 12, it is characterized in that the two ends of the several tap water heat pipes 1 are connected with the tap water heat pipe connecting piece 2, the inner pipe connecting piece 4, the connecting piece 5, and welded in series to form a rectangle, which can be placed horizontally or vertically , the tap water heat pipe 1, the heating pipe 3, the connecting piece 2, and the inner pipe connecting piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com