Arrangement for fixing wire harness onto covers of electric connection box and electric connection box thereof

A technology for electrical connection boxes and connection boxes, which is applied to structural parts of electrical equipment, electrical components, etc., can solve problems such as abnormal noise, wear and tear, and multi-assembly man-hours of vehicles, so as to prevent abnormal noise and wear of wiring harnesses, and improve distribution efficiency. Electrical reliability, the effect of preventing accidental falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

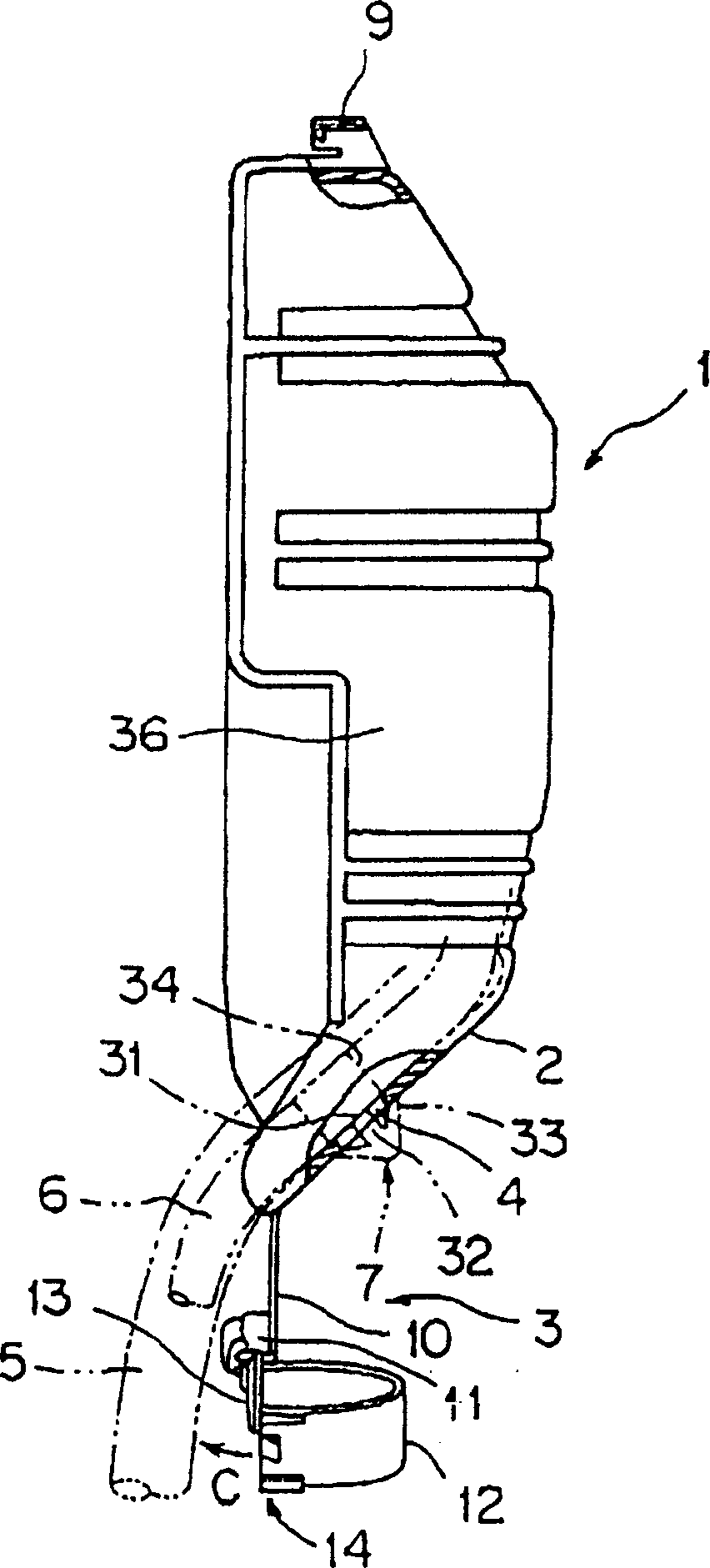

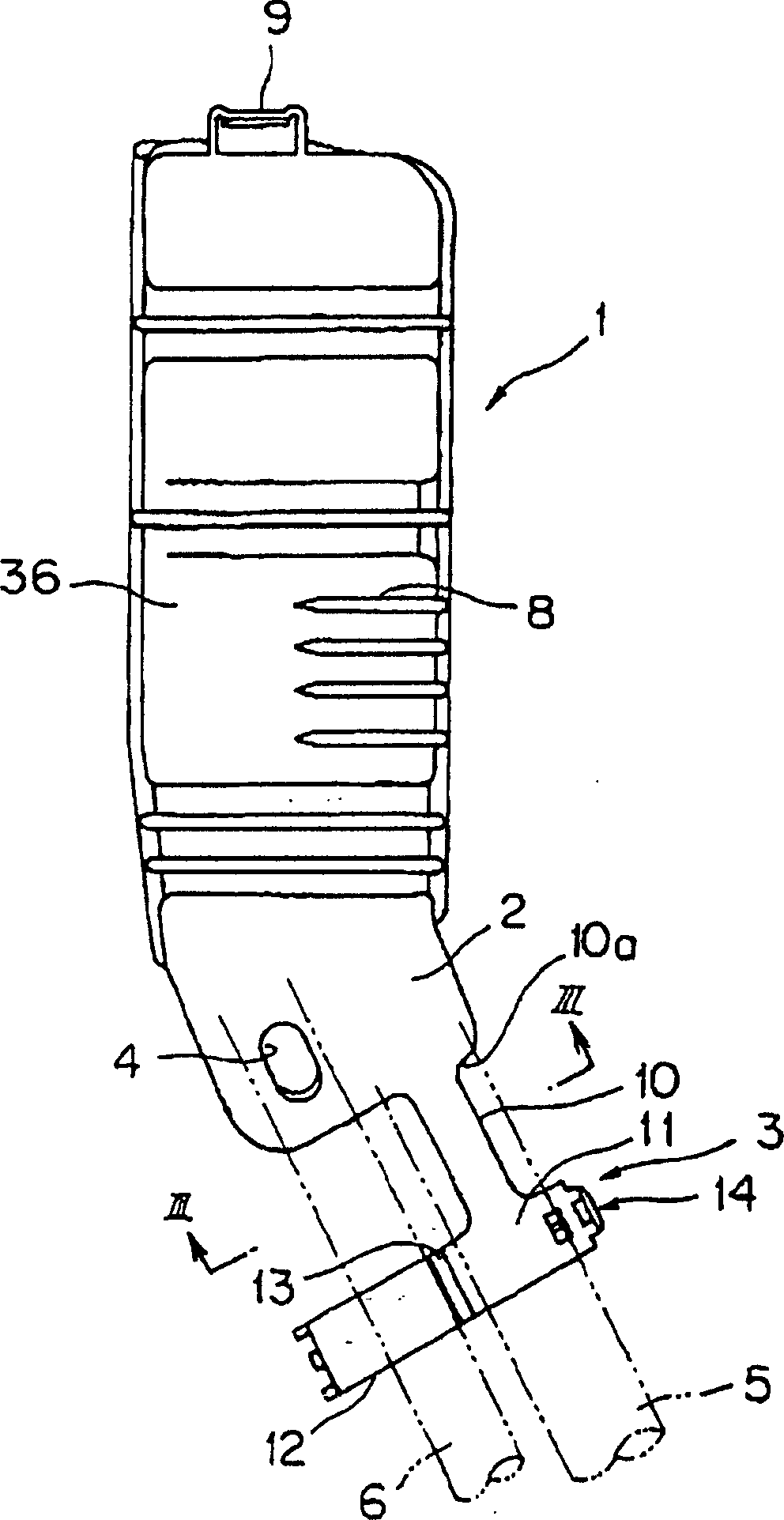

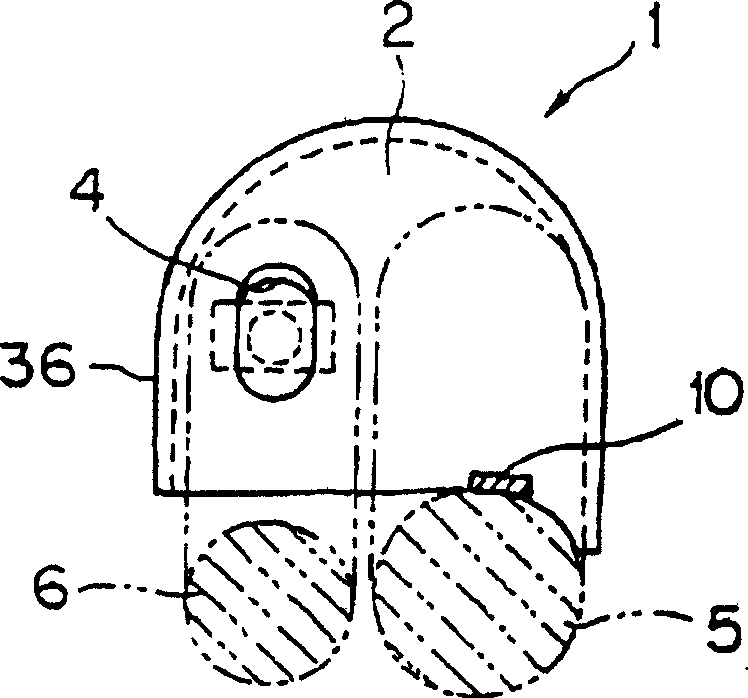

[0038] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0039] Each figure shows only the connector cover 1 made of synthetic resin, and omits the illustration of the main body of the electrical connection box on which electrical components such as relays and fuses, circuit boards, electronic components, and the like are mounted.

[0040] The connector cover 1 is approximately semicircular or approximately arc-shaped in section, and the middle part is formed in an approximately groove shape. Both ends in the longitudinal direction are inclined, and the height gradually decreases. Next to the inclined wall 2 on the side of one end, a wire harness is integrally provided. The holding part 3 is provided with a clip fitting hole 4 on the inclined wall 2 on one end side, and the thicker wire harness 5 is held by the wire harness holding part 3, and the holding clip 7 for fixing the thinner wire harness 6 fits into the clip fitti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com