Isolation sealing device of viscous fluid conveyor

A technology of fluid conveying and sealing device, applied in the direction of engine sealing, machine/engine, rotary piston type/swing piston type pump parts, etc. problems such as lowering, to achieve the effect of enhancing the isolation and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

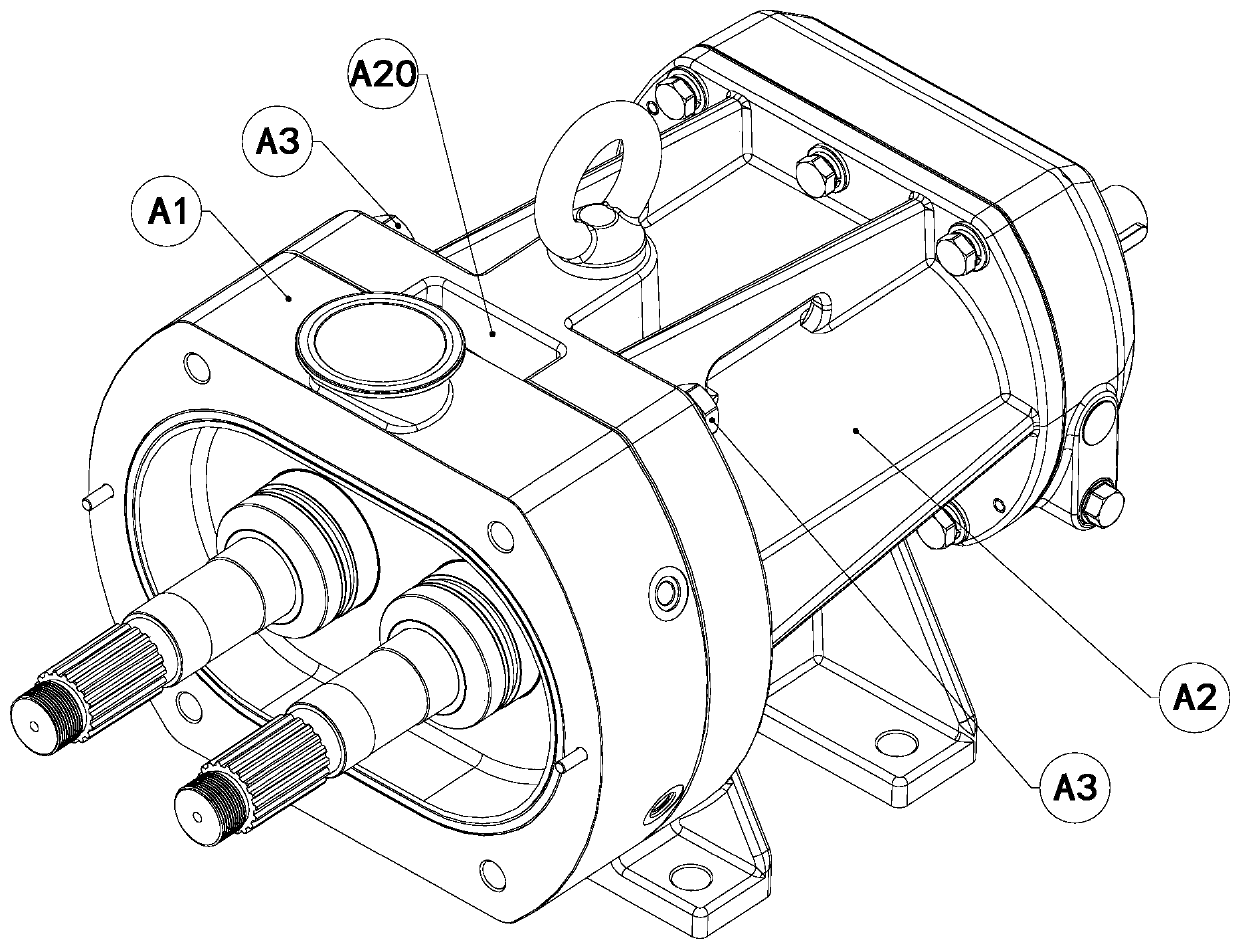

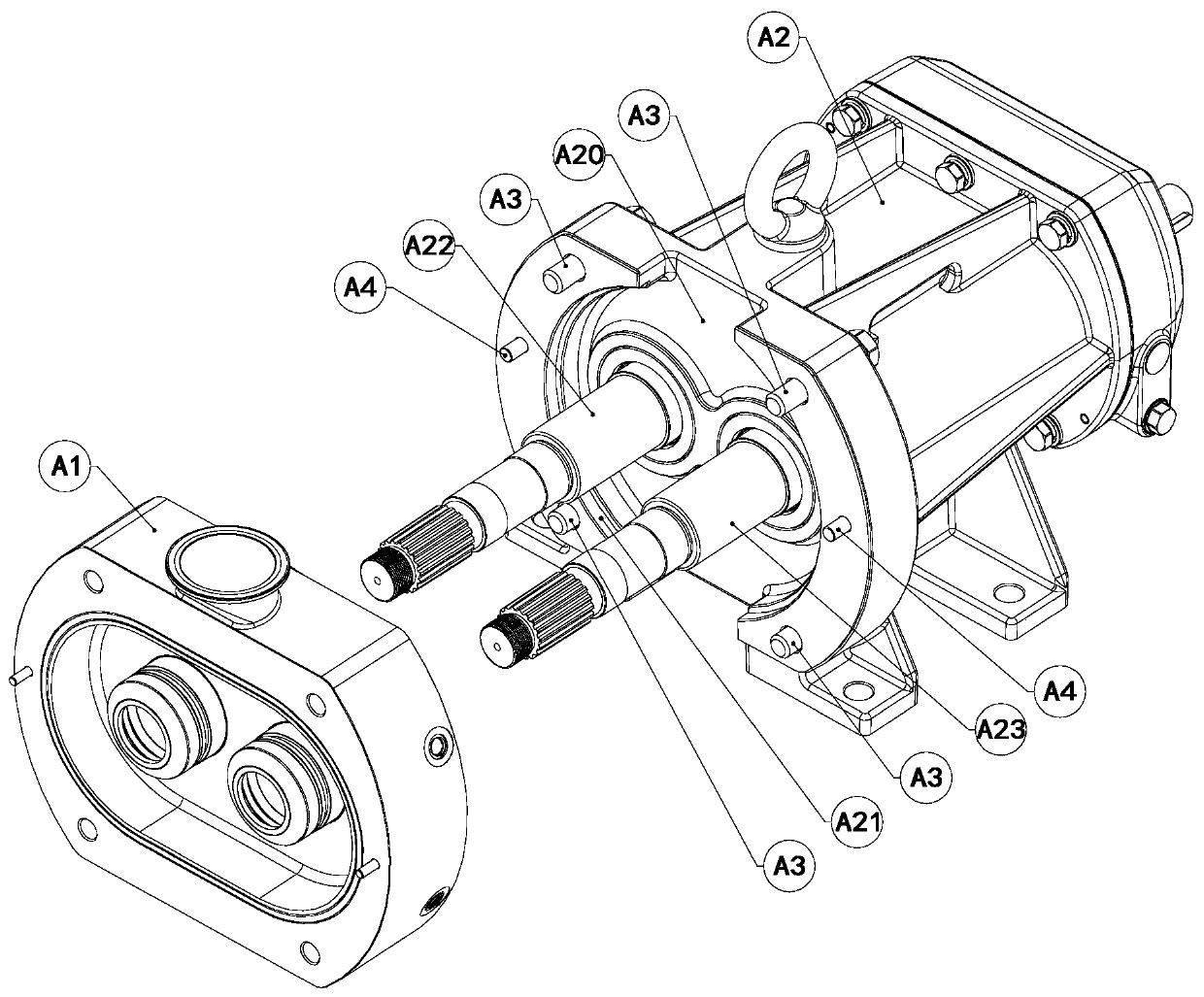

[0032] Embodiment 1: A kind of isolation and sealing device of viscous fluid conveyer, such as figure 1 , figure 2 As shown, it includes sealing assembly (A1), bearing housing (A2), sealing assembly fastening screw (A3), sealing assembly positioning pin (A4), bearing housing (A2) is provided with isolation chamber (A20) and sealing The assembly positioning step surface (A21), the bearing box (A2) has a left journal (A22) and a right journal (A23), and the left journal (A22) and the right journal (A23) are symmetrically arranged on the bearing box (A2) The side near the seal assembly (A1).

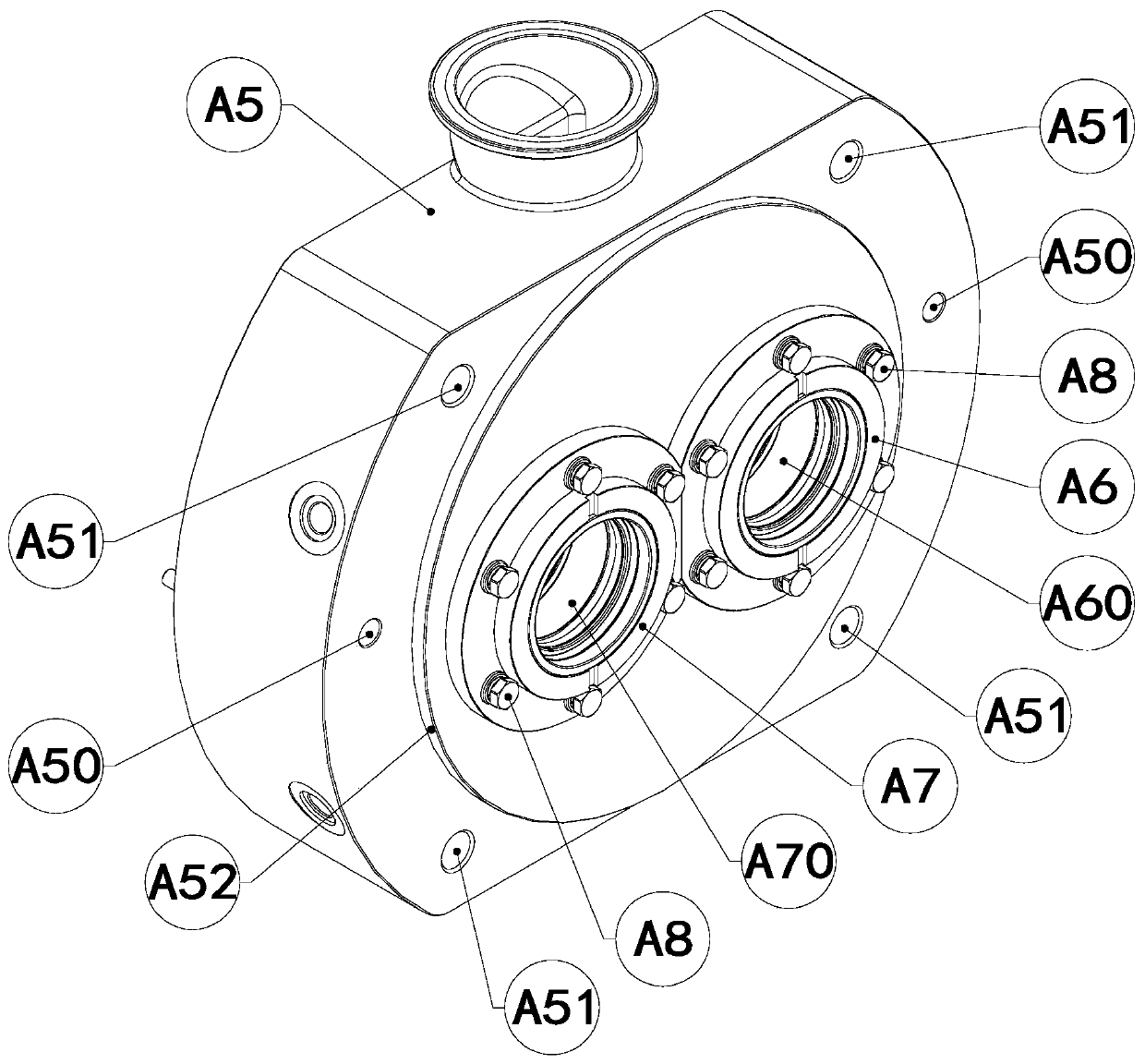

[0033] Such as image 3 , Figure 4 As shown, the sealing assembly (A1) includes the sealing seat (A5), the left sealing assembly (A6), the right sealing assembly (A7), the sealing assembly fastening screw (A8), and the positioning pin hole is arranged on the sealing seat (A5) (A50), assembly fixing threaded hole (A51), cylindrical stepped surface (A52), sealing assembly fixing threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com