Method and equipment for carrying multi-layer stacked material boxes in storage rack

A handling equipment and multi-layer stacking technology, which is applied in the field of logistics handling and storage systems, can solve the problems of increasing storage capacity, large space in storage cabinets, wasting space, etc., and achieve the effect of avoiding space waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

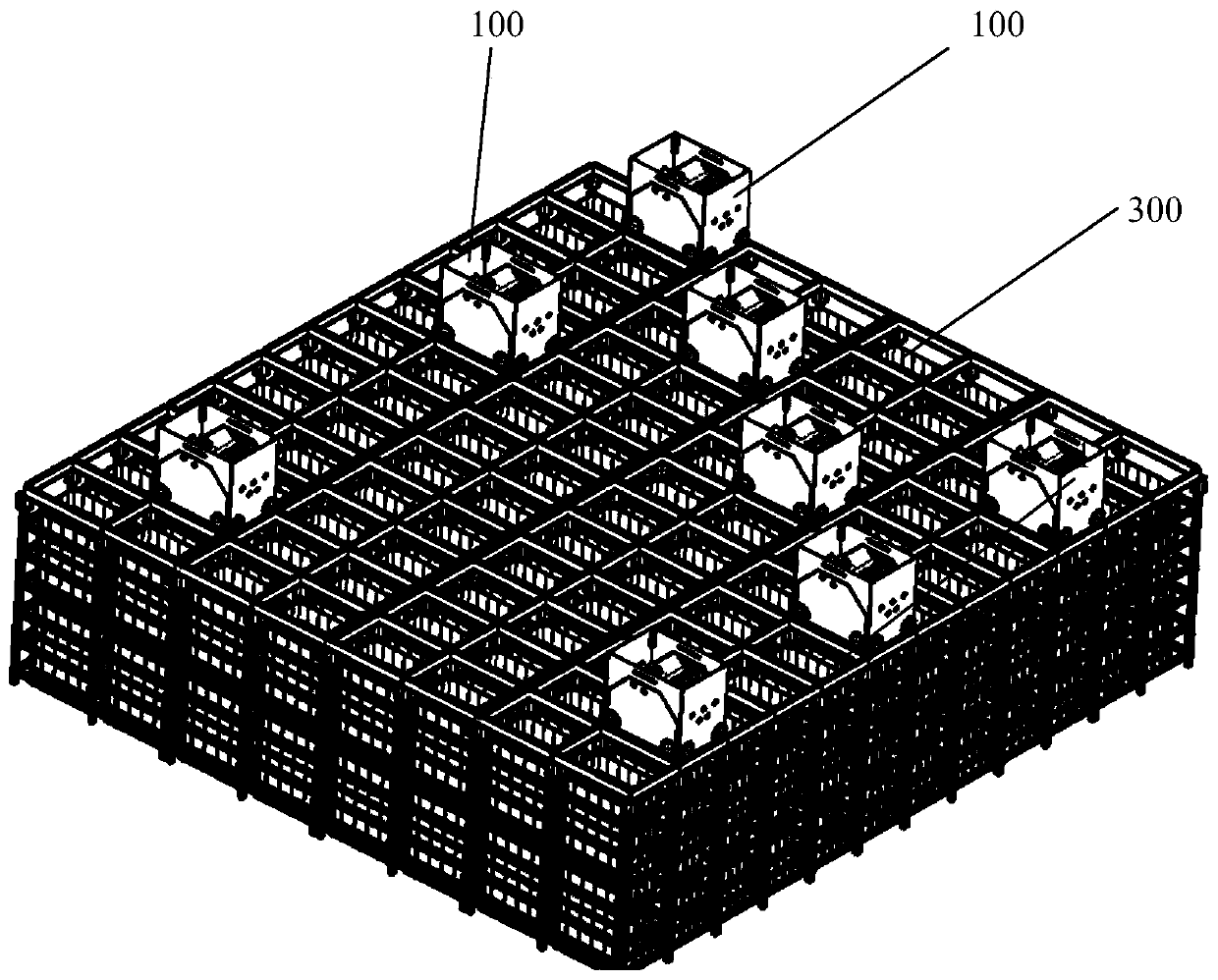

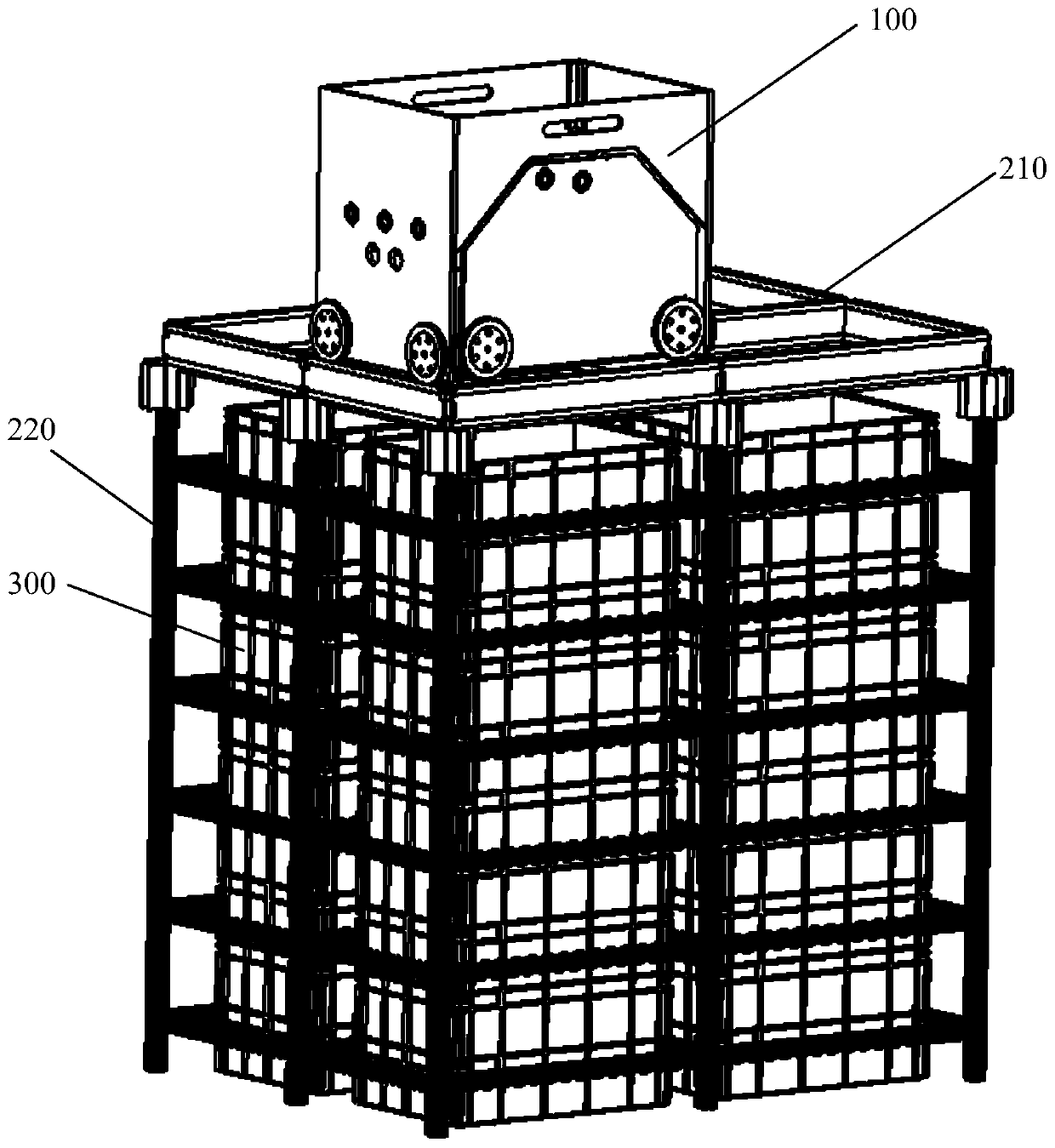

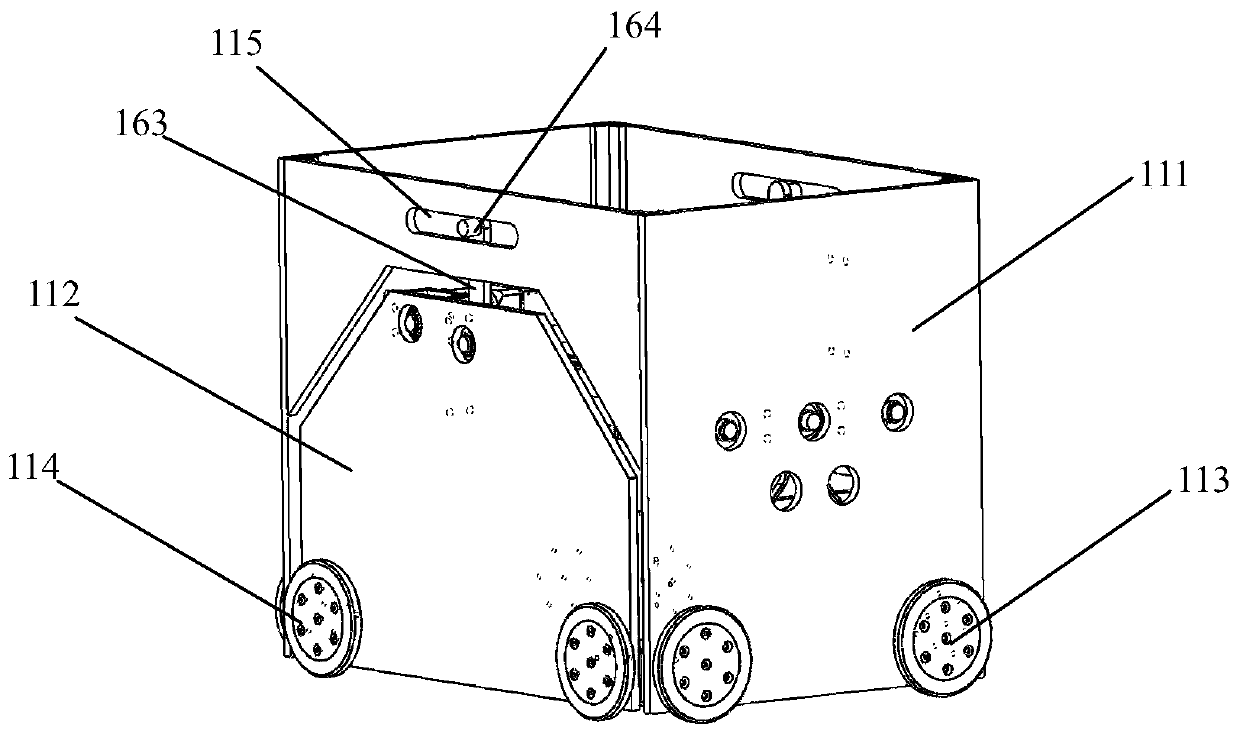

[0032] The invention provides a method for transporting multi-layer stacked material boxes in a storage shelf, which is used for transporting several material boxes stacked up and down. The equipment is used to pull up the material box in the shelf and place the material box down in the shelf to realize the pick-and-place of the stacked material box.

[0033] The specific operation of this handling method includes:

[0034] When the handling equipment takes the uppermost material box from the shelf, the handling equipment moves to the top of the material box, and takes out the material box by cooperating with the material box;

[0035] When the handling equipment takes the designated material box that is not at the top from the shelf, that is, when there are other material boxes on the designated material box that needs to be taken o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com