Stepping type cup packer capable of achieving dragging under pressure and using method

A leather cup packer and dragging technology under pressure, applied in the directions of sealing/packaging, earthwork drilling, wellbore/well components, etc. The effect of reducing the probability of wear and meeting the requirements of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

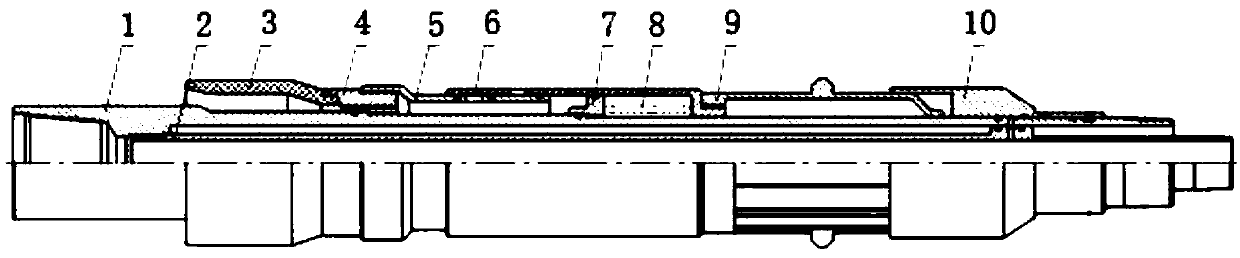

[0029] Reference figure 1 , The stepped cup packer capable of dragging under pressure of the present invention includes a hollow main shaft 1 and a mandrel 2 installed inside the main shaft 1 for pressure transmission. The outer diameter of the main shaft 1 is threadedly connected The cup seat 4 and the cup 3 directly vulcanized to the cup seat 4, the back of the cup seat 4 is connected with a pressure relief sub-section 5, and the back of the pressure relief sub-section 5 is installed with a sealing seat 7 And the return spring 8, the outer side of the sealing seat 7 and the return spring 8 is installed with a sliding sleeve 6 that is in sealing cooperation with the pressure relief sub-section 5, and the sliding sleeve 6 is connected with an elastic claw 9, the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com