Technique for cement pouring in well cementing engineering

A process method and cement injection technology, which are applied in chemical instruments and methods, earthwork drilling, drilling composition and other directions, can solve the problems of low casing centering, poor cement-bonded stratum quality, and inability to perform adequate replacement, etc. To achieve the effect of effective isolation, improve the quality of cementation, and improve the efficiency of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

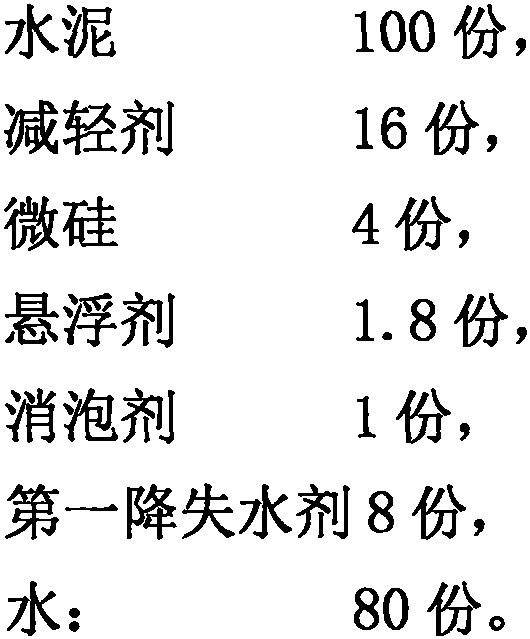

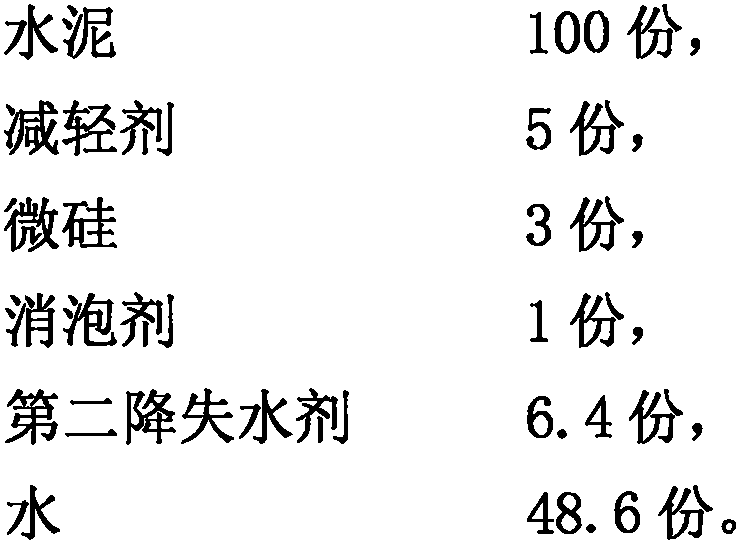

[0035] The preparation process of the 1.30sg spacer is as follows:

[0036] Add 100 parts of water in the first mixer;

[0037] Add 7.5 parts of Naki Sakato.

[0038] Fully hydrated, the time is 40-48h;

[0039] Add 1.5 parts of thickener, which is produced by Chengdu Dedao Industrial Co., Ltd., code-named D1001;

[0040] Add 38 parts of barite;

[0041] Fully stir, wherein, the stirring speed is 8000-10000r / min, and the stirring time is 60s.

[0042] Complete the preparation of 1.30sg spacer solution.

[0043] Adopt above-mentioned process method to make the experimental data of spacer liquid as follows:

[0044] experimental project Experimental results density 1.30 Density difference between upper and lower pulp <0.02

[0045] The six-speed numbers are as follows:

[0046] Temp / ℃ / speed 600 300 200 100 6 3 56 92 60 45 32 7 5

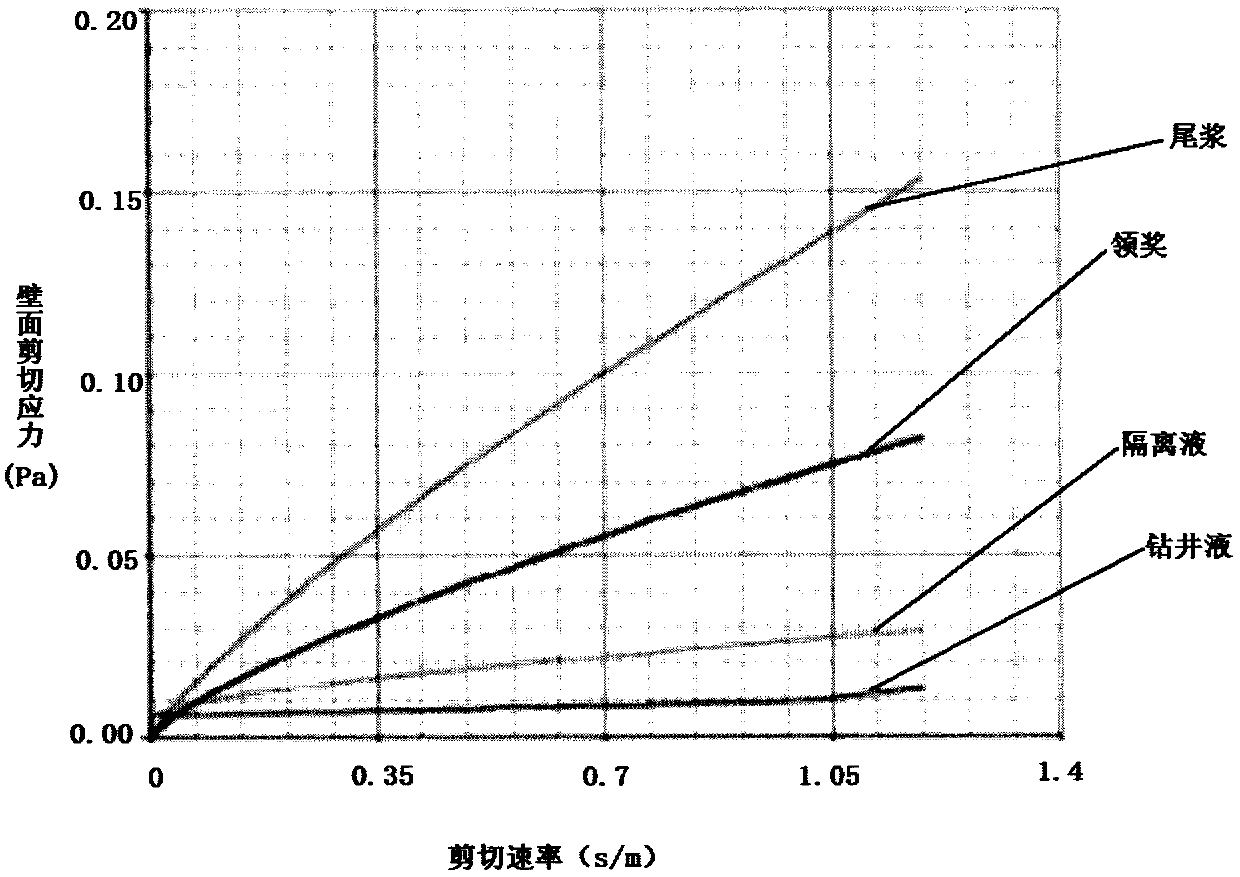

[0047] Based on the six-speed value of the 1.30sg spacer fluid circulating in the we...

Embodiment 1

[0086] Present embodiment 1 is the highly deviated well (oil well) that well depth is 2366m, and maximum well deviation is 79 °, and described well internal circulation temperature is 56 °, and used drilling fluid is the drilling fluid that density is less than 1.18sg, and average well diameter is 13in (inch), the casing diameter is 9.625in (inch), and the average annular cross section is 0.03867m 2 .

[0087] Step 1, run the casing in the wellbore;

[0088] Step 2. After the casing is run in, the drilling fluid is injected into the drilling fluid in a jacking cycle (generally 2 weeks), the displacement is slow and the pump pressure is stable from 0.38m 3 / min commission to 2.73m 3 / min, adjust the performance of the drilling fluid so that the viscosity of the funnel is less than 45Pa s, and the dynamic shear force is less than 5Pa;

[0089] Step 3. Inject spacer fluid: use a cement truck to inject 16m of spacer fluid 3 , its displacement is 0.7955m 3 / min;

[0090] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com