Multi-layer discharge and mining device for multiple seam developed area

A technology with developed areas and multiple coal seams, applied in the fields of fluid extraction, earth-moving drilling, wellbore/well components, etc., can solve the problems of coal seam pressure excitation, coal layer pressure excitation, affecting gas production effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

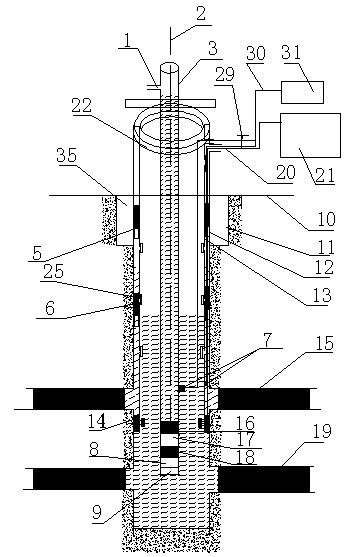

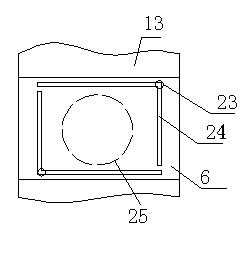

[0019] Depend on figure 1 and figure 2 Shown is a multi-coal seam development area combined seam drainage equipment, including an additional casing 13 with a drainage device inside, the outer ring of the additional casing 13 is fixedly sleeved with a production casing 12, and the outer ring of the upper part of the production casing 12 is sleeved There are surface casing 11, additional casing 13, production casing 12 and surface casing 11 are all arranged vertically, and the upper outer ring of additional casing 13 is provided with a plugging member 22, which is blocked in the additional casing. Between the top of the pipe 13 and the top of the production casing 12, the wall of the additional casing 13 on the lower side of the plugging member 22 is provided with a flow hole 25, and the additional casing 13 is provided with an elastic pad covering the flow hole 25. The elastic pad is a rubber pad 6, and the circumference of the water hole 25 is provided with a bar-shaped angl...

Embodiment 2

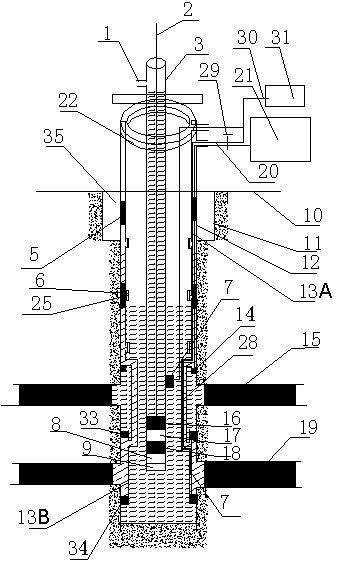

[0037] Depend on image 3 The difference between the multi-coal seam development area combined-bed drainage equipment shown in Example 1 is that the additional casing 13 is divided into upper and lower sections, and the plugging member 22, the first packing body 14 It is arranged up and down on the upper section 13A of the additional casing and is respectively located at the top and bottom of the upper section 13A of the additional casing. There is a centralizer 5 , the blocking member 22 is located between the additional casing 13 and the production casing 12 , and the first packing body 14 is blocked between the additional casing 13 and the bottom end of the production casing 12 . The second packer 33 and the third packer 34 are arranged above and below the outer ring of the lower section 13B of the additional casing, and a connecting pipe 28 is fixedly connected between the upper and lower sections 13A and 13B of the additional casing. There is a connecting hole on the upp...

Embodiment 3

[0041] Depend on Figure 4 Shown is a multi-coal seam development area combined seam drainage equipment, including an additional casing 13 with a drainage device inside, and a surface layer casing 11 is set on the outer ring of the upper part of the additional casing 13, the additional casing 13 and the surface layer casing 11 They are all vertically arranged, and the upper outer ring of the additional casing 13 is provided with a plugging member 22, which is blocked between the top of the additional casing 13 and the top of the wellbore 35, and the additional casing on the lower side of the plugging member 22 The pipe wall of the pipe 13 is provided with a flow hole 25, and the additional casing 13 is provided with an elastic pad covering the flow hole 25. The elastic pad is a rubber pad 6, and the circumference of the flow hole 25 is provided with a strip for pressing the rubber pad 6. Shaped angle iron 24, angle iron 24, rubber pad 6 and additional sleeve 13 are nailed toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com