A method for strengthening ultra-soft foundation with vacuum preloading and gas injection carbonization

A technology for conduit piles and foundations, applied in soil protection, infrastructure engineering, construction, etc., can solve problems such as high economic costs, poor environmental benefits, and low bearing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

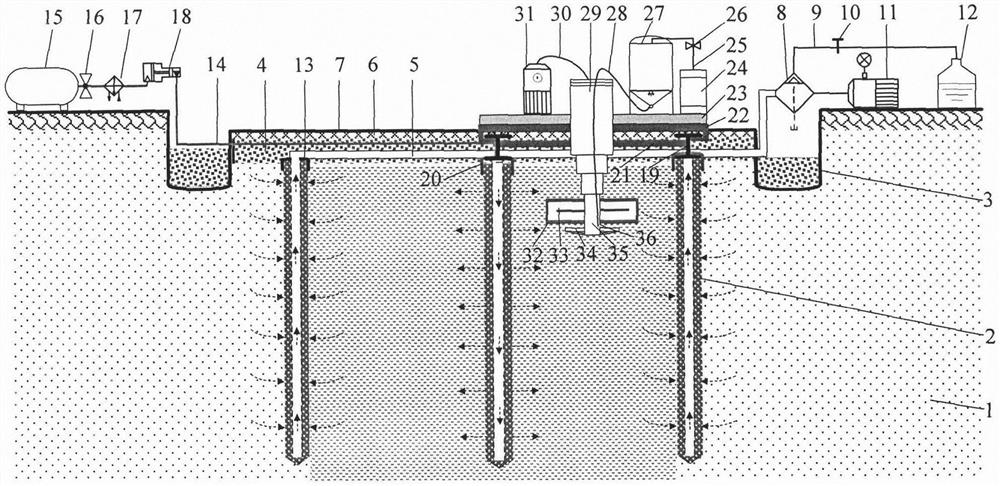

[0060] a. Site treatment and exploration: Clean up and level the ultra-soft foundation 1 and surrounding sites, excavate side ditches 3 with a depth and width of 1.0m along the periphery of the pre-treatment site, set up settlement observation piles outside the site, and measure the ultra-soft ground 1 The basic physical and chemical indicators, of which the site area is 2500m 2 , The mud depth is 4.5m, the water content is 130%, the specific gravity is 2.63, the liquid limit is 60%, the plastic limit is 30%, the organic matter content is 7.0%, and the pH value is 7.2;

[0061] b. The driving of the first pipe pile group: According to the basic physical and chemical indicators of the ultra-soft foundation 1, the pile length is determined to be 5.5m, the outer diameter of the cylindrical hollow pile is 0.4m, and the pile spacing is 2.0m. The driving width is the maximum working radius of the piling machine is 9m, five rows of pipe piles 2 are driven in the ultra-soft foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com