A method for microbial solidification and stabilization of domestic waste incineration fly ash

A waste incineration fly ash and domestic waste incineration technology, which is applied in the field of hazardous solid waste disposal, can solve the problems of high post-disposal costs, harmful heavy components, and unstable effects, achieving low processing costs, stable fly ash, and avoiding secondary waste. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In this example, a method for microbial solidification and stabilization of domestic waste incineration fly ash, the steps of the method are as follows:

[0037] a. Mix the waste incineration fly ash and the bacterial liquid evenly according to the weight ratio of 1:0.7, and let it stand for 1 hour, so that the microorganisms in the bacterial liquid are adsorbed on the surface of the waste incineration fly ash particles;

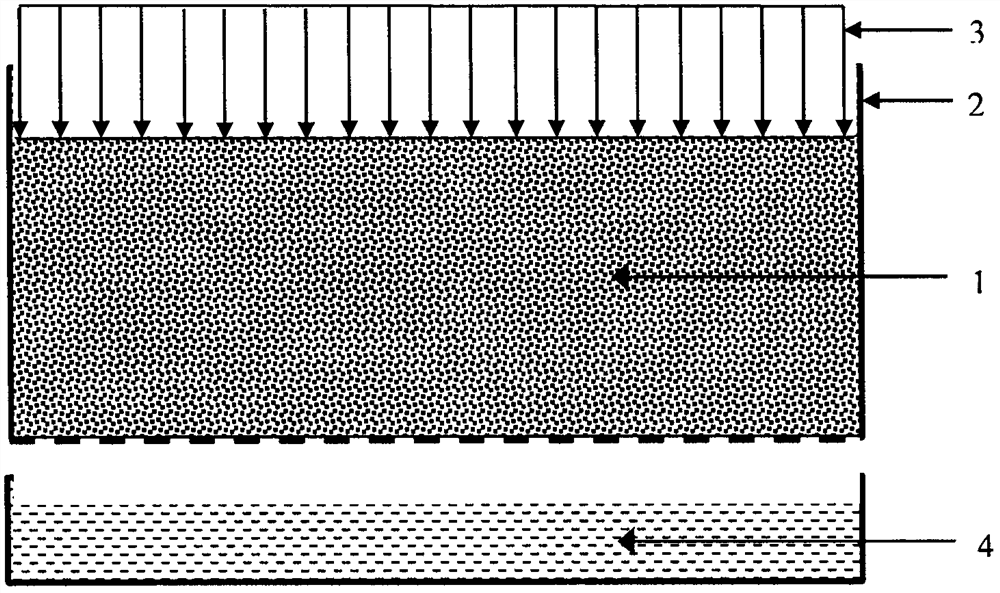

[0038] b. Mix the waste incineration fly ash mixed with the bacteria liquid and the reaction solution according to the weight ratio of 1:0.5 to evenly make the fly ash mixture 1, and put it into the bottom permeable mold 2;

[0039] c. Apply 10kPa air pressure 3 to the top of the fly ash mixture 1, remove the air pressure 3 after 4 hours, and let it stand for 24 hours to induce the microorganisms to produce carbonate minerals, fix harmful substances in the waste incineration fly ash and form strength;

[0040] d. Collect and filter the exudate 4 flowi...

Embodiment 2

[0045] In this example, a method for microbial solidification and stabilization of domestic waste incineration fly ash, the steps of the method are as follows:

[0046] a. Mix the waste incineration fly ash and the bacterial liquid evenly according to the weight ratio of 1:0.6, and let it stand for 1 hour, so that the microorganisms in the bacterial liquid are adsorbed on the surface of the waste incineration fly ash particles;

[0047] b. Mix the waste incineration fly ash mixed with the bacteria liquid and the reaction solution according to the weight ratio of 1:0.4 to evenly make the fly ash mixture 1, and put it into the bottom permeable mold 2;

[0048] c. Apply 55kPa air pressure 3 to the top of the fly ash mixture 1, remove the air pressure 3 after 3 hours, and let it stand for 18 hours to induce the microorganisms to produce carbonate minerals, fix harmful substances in the waste incineration fly ash and form strength;

[0049] d. Collect and filter the exudate 4 flowi...

Embodiment 3

[0054] In this example, a method for microbial solidification and stabilization of domestic waste incineration fly ash, the steps of the method are as follows:

[0055] a. mix the waste incineration fly ash and the bacterial liquid according to the weight ratio of 1:0.5, and let it stand for 1 hour, so that the microorganisms in the bacterial liquid are adsorbed on the surface of the waste incineration fly ash particles;

[0056] b. Mix the waste incineration fly ash mixed with the bacteria solution and the reaction solution according to the weight ratio of 1:0.3 and mix evenly to make the fly ash mixture 1, and put it into the bottom permeable mold 2;

[0057] c. Apply 100kPa air pressure 3 to the top of the fly ash mixture 1, remove the air pressure 3 after 2 hours, and let it stand for 12 hours to induce microorganisms to produce carbonate minerals, fix harmful substances in the waste incineration fly ash and form strength;

[0058] d. Collect and filter the exudate 4 flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com