Polypyrrole-titanium dioxide or titanium nitride-polyaniline coaxial three-layer nanotube array composite material, and preparation method and application thereof

A technology of polypyrrole nanotubes and nanotube arrays, which is applied in the fields of nanotechnology, nanotechnology, hybrid/electric double layer capacitor manufacturing, etc. Small area and other problems, to achieve the effect of high specific capacitance value, good cycle stability, and enhanced cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

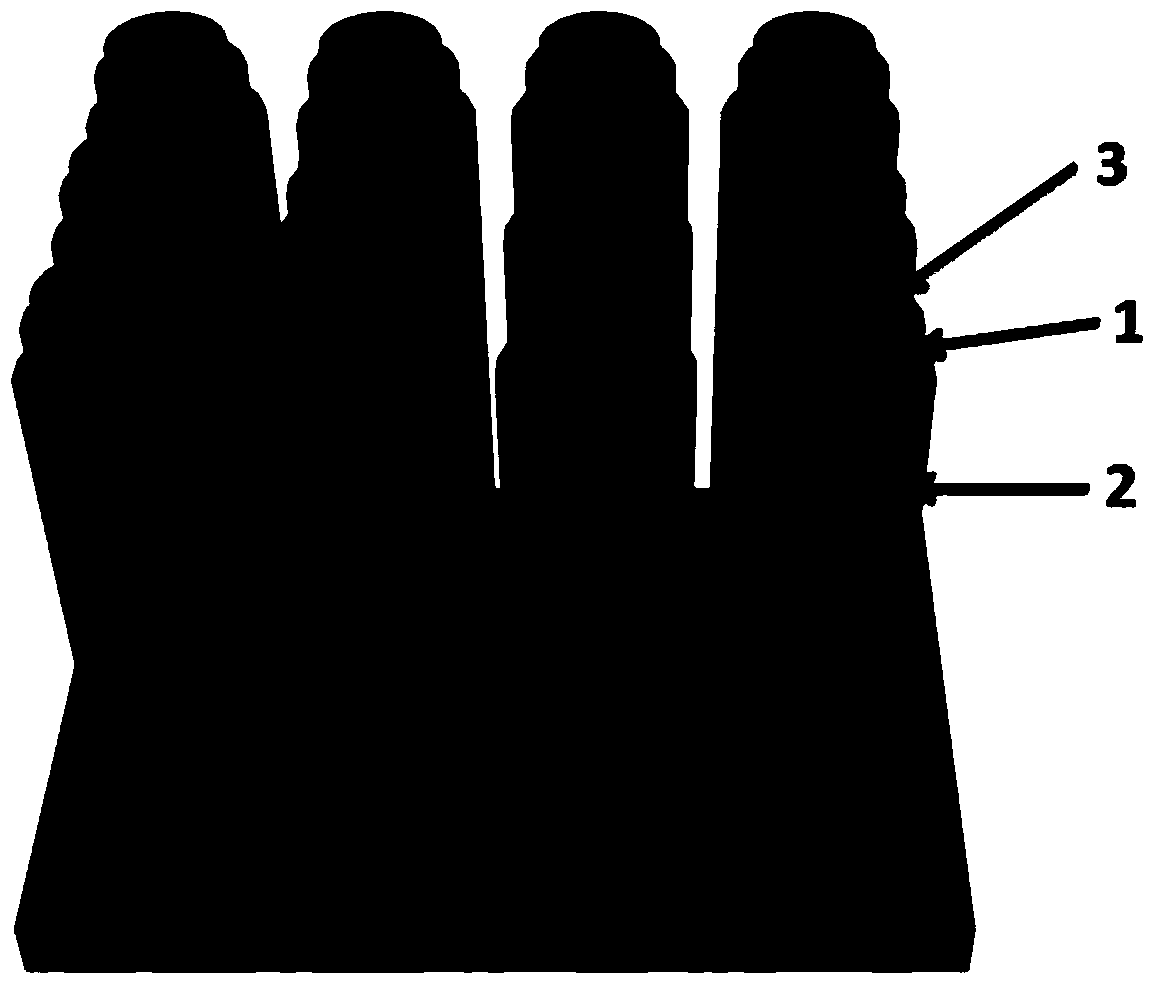

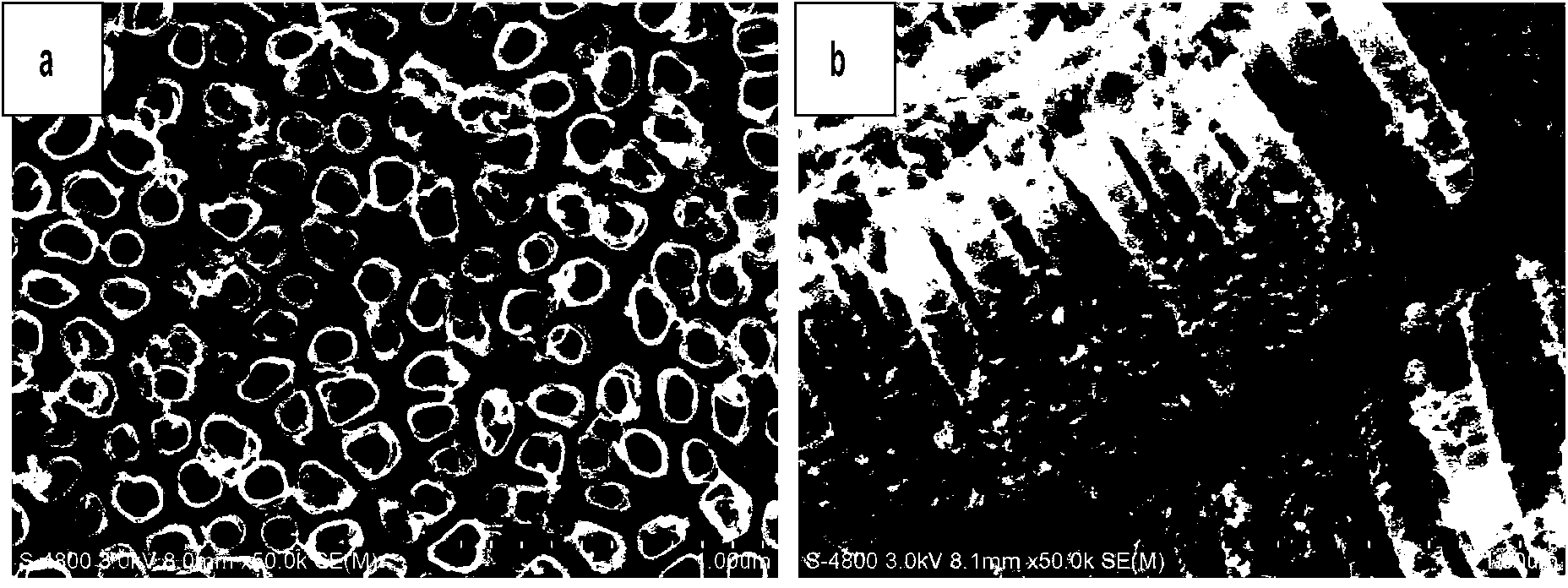

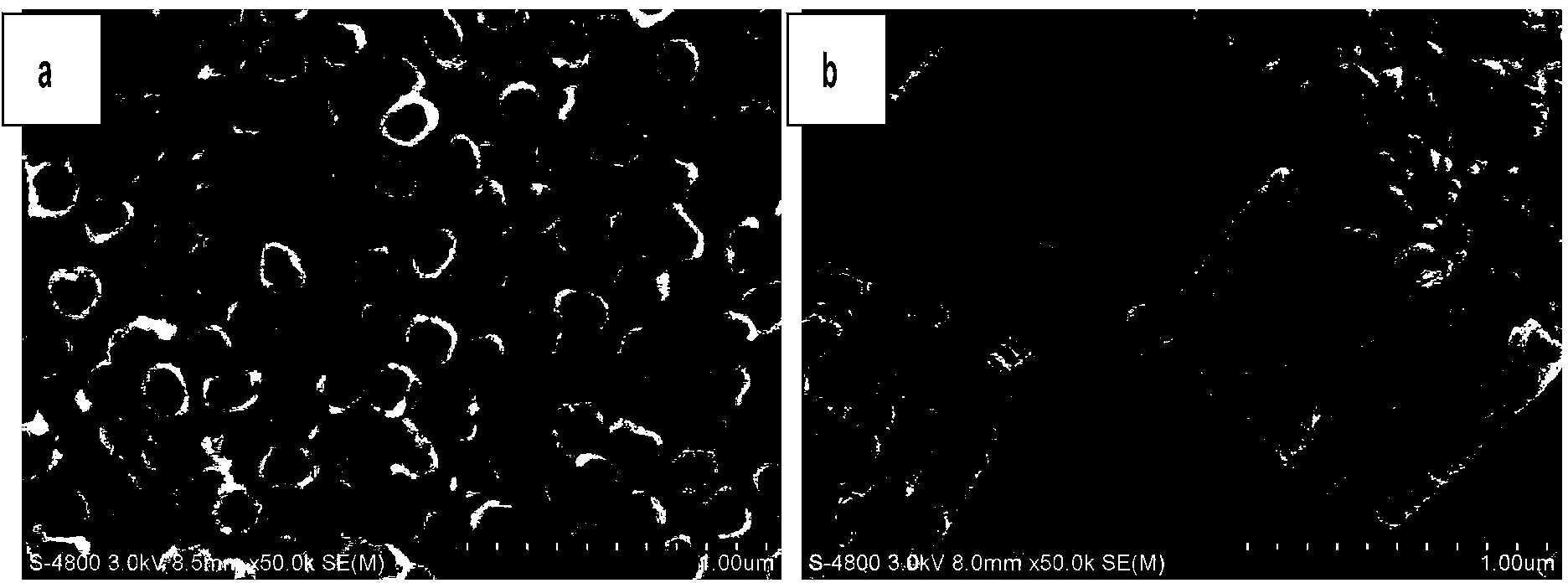

[0042] (1) Preparation of titanium dioxide and titanium nitride nanotube array skeleton materials: the titanium sheet was ultrasonically cleaned in ethanol, acetone, and deionized water for 30 minutes, and then polished in hydrogen fluoride / nitric acid / water solution with a volume ratio of 1:4:5 Treatment; in the two-electrode electrochemical reaction system, the titanium sheet is used as the anode, the platinum sheet is used as the cathode, and the ammonium fluoride of 0.2mol / L, the phosphoric acid of 0.5mol / L, the volume fraction 5% methanol and the volume fraction 40% ethylene di The aqueous solution of alcohol is the reaction electrolyte solution, using the anodic oxidation method, under the condition of constant voltage 30V, 25 ℃ constant temperature reaction for 2h, then fully rinsed with deionized water and then dried naturally to obtain a titanium dioxide nanometer with independent tube walls and open tube openings. tube array. High-temperature calcination treatment of...

Embodiment 2

[0062] The preparation method of the polypyrrole-titanium dioxide-polyaniline composite material is prepared by a step-by-step selective synthesis reaction method of chemical polymerization reaction, electrochemical polymerization reaction and photo-assisted electrochemical polymerization reaction, including the following steps:

[0063] (1) Preparation of titanium dioxide nanotube arrays: The titanium sheet was ultrasonically cleaned in ethanol, acetone, and deionized water for 30 minutes, and then polished in hydrogen fluoride / nitric acid / water solution with a volume ratio of 1:4:5; using constant potential Anodic oxidation synthesis method, in the two-electrode chemical reaction system, the titanium sheet is used as the anode and as the working electrode, the platinum sheet is used as the cathode and as the auxiliary counter electrode, with 0.25mol / L ammonium fluoride, 0.4mol / L phosphoric acid, volume An aqueous solution with a fraction of 5% methanol and a volume fraction o...

Embodiment 3

[0069] The preparation method of the polypyrrole-titanium dioxide-polyaniline composite material is prepared by a step-by-step selective synthesis reaction method of chemical polymerization reaction, electrochemical polymerization reaction and photo-assisted electrochemical polymerization reaction, including the following steps:

[0070] (1) Preparation of titanium dioxide nanotube arrays: The titanium sheet was ultrasonically cleaned in ethanol, acetone, and deionized water for 30 minutes, and then polished in hydrogen fluoride / nitric acid / water solution with a volume ratio of 1:4:5; using constant potential Anodic oxidation synthesis method, in the two-electrode chemical reaction system, the titanium sheet is used as the anode and the working electrode, the platinum sheet is used as the cathode and as the auxiliary counter electrode, with 0.15mol / L ammonium fluoride, 0.5mol / L phosphoric acid, volume An aqueous solution with a fraction of 6% methanol and a volume fraction of 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com