Preparation method for spherical cellulose aerogel

A technology of cellulose airgel and cellulose hydrogel, which is applied in the field of airgel preparation, can solve the problems of structural collapse, low specific surface area of airgel, volume shrinkage, etc., achieve low cost, overcome structural collapse, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

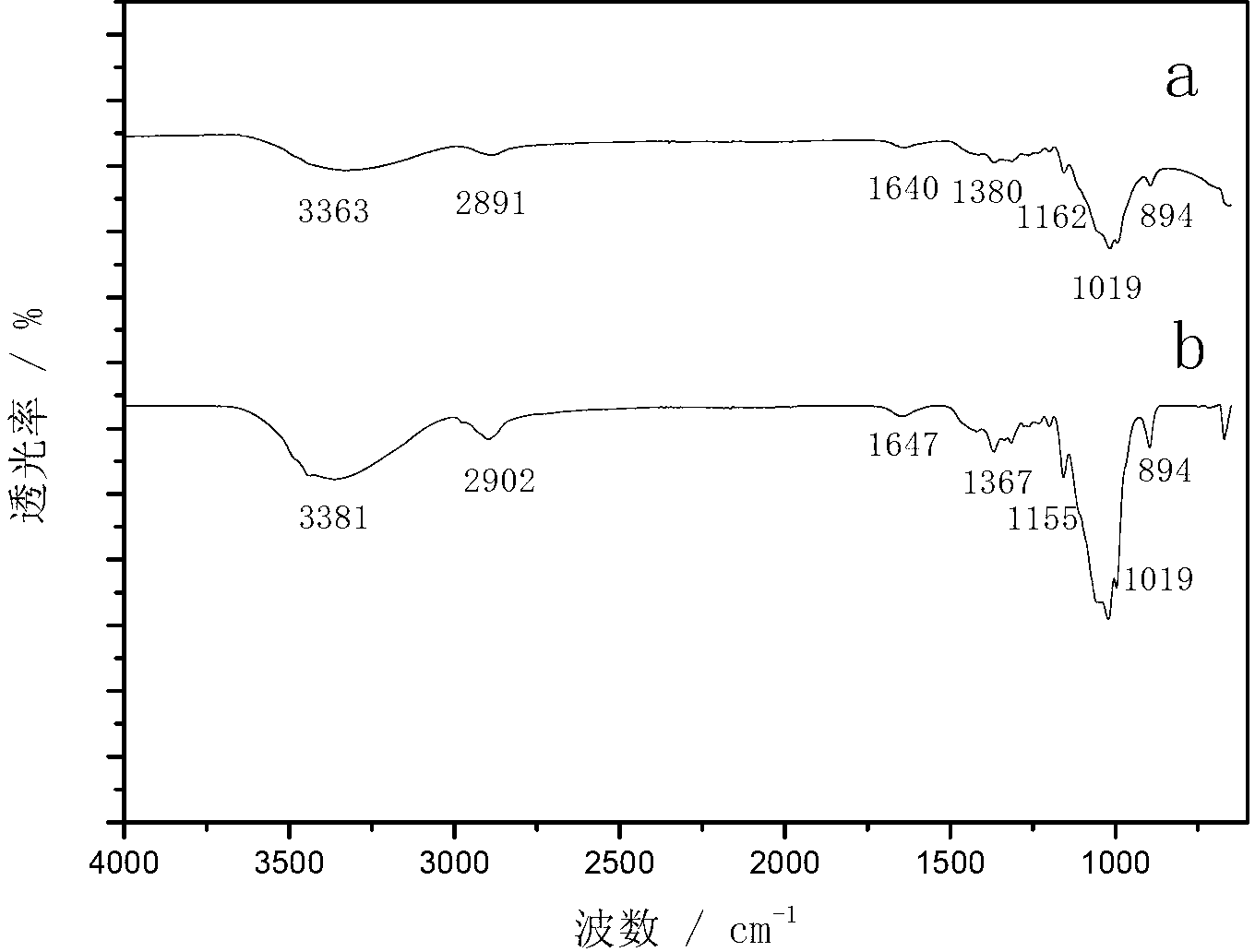

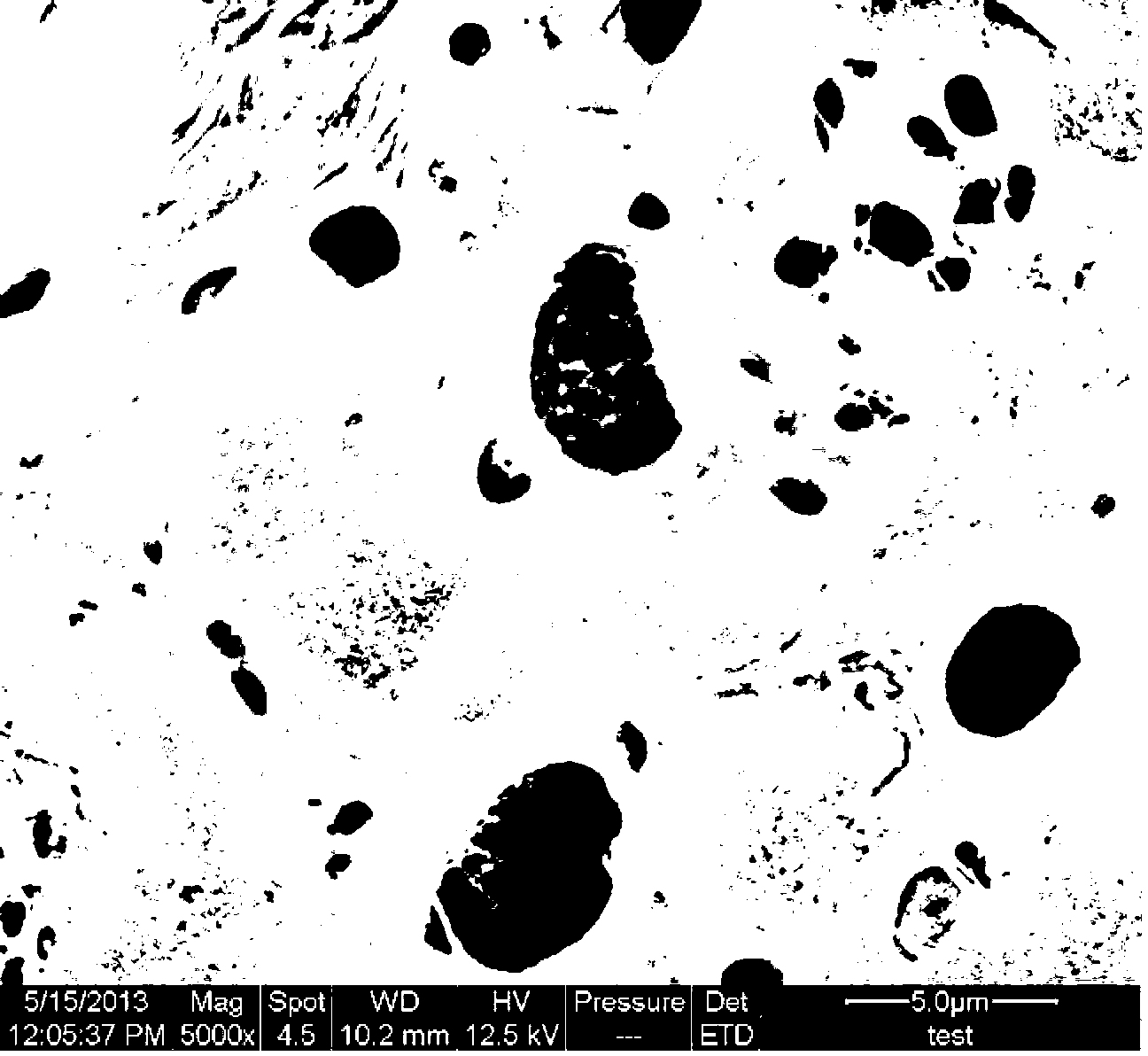

[0017] Specific embodiment one: the preparation method of spherical cellulose airgel in this embodiment is realized according to the following steps:

[0018] 1. Weigh 1.00~3.00g of plant fiber and put it into the mixed solution of urea and NaOH to obtain a mixed system. Put the mixed system at -18~-20℃ and freeze it for 2~4 hours, take it out, and thaw it at room temperature , and then stirred into a solution to obtain a plant fiber / alkali urea solution;

[0019] 2. Mix 100-200mL of chloroform and 100-200mL of ethyl acetate evenly, and then add 20-40mL of glacial acetic acid to obtain an organic solution of glacial acetic acid;

[0020] 3. Titrate the plant fiber / alkali urea solution obtained in step 1 into the organic solution of glacial acetic acid in step 2 with a titration device to form beads, then place the beads in the organic solution of glacial acetic acid in step 2 for aging for 5~ After 15min, a white spherical gel was obtained;

[0021] 4. Put the white spherica...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment is different from Embodiment 1 in that the plant fiber is bamboo fiber, wood fiber or straw fiber. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass ratio of NaOH, urea and water in the mixed solution of urea and NaOH in step 1 is 7:12:81. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com