Monolithic column, preparation method and application thereof

A technology of monolithic columns and ligands, applied in the field of preparation of monolithic separation media, can solve the problems of easy chain transfer, difficult to precisely control the pore size, poor mechanical properties, etc., to improve the non-uniformity of the column structure and the reproducibility of the preparation method. Good, improve the effect of volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

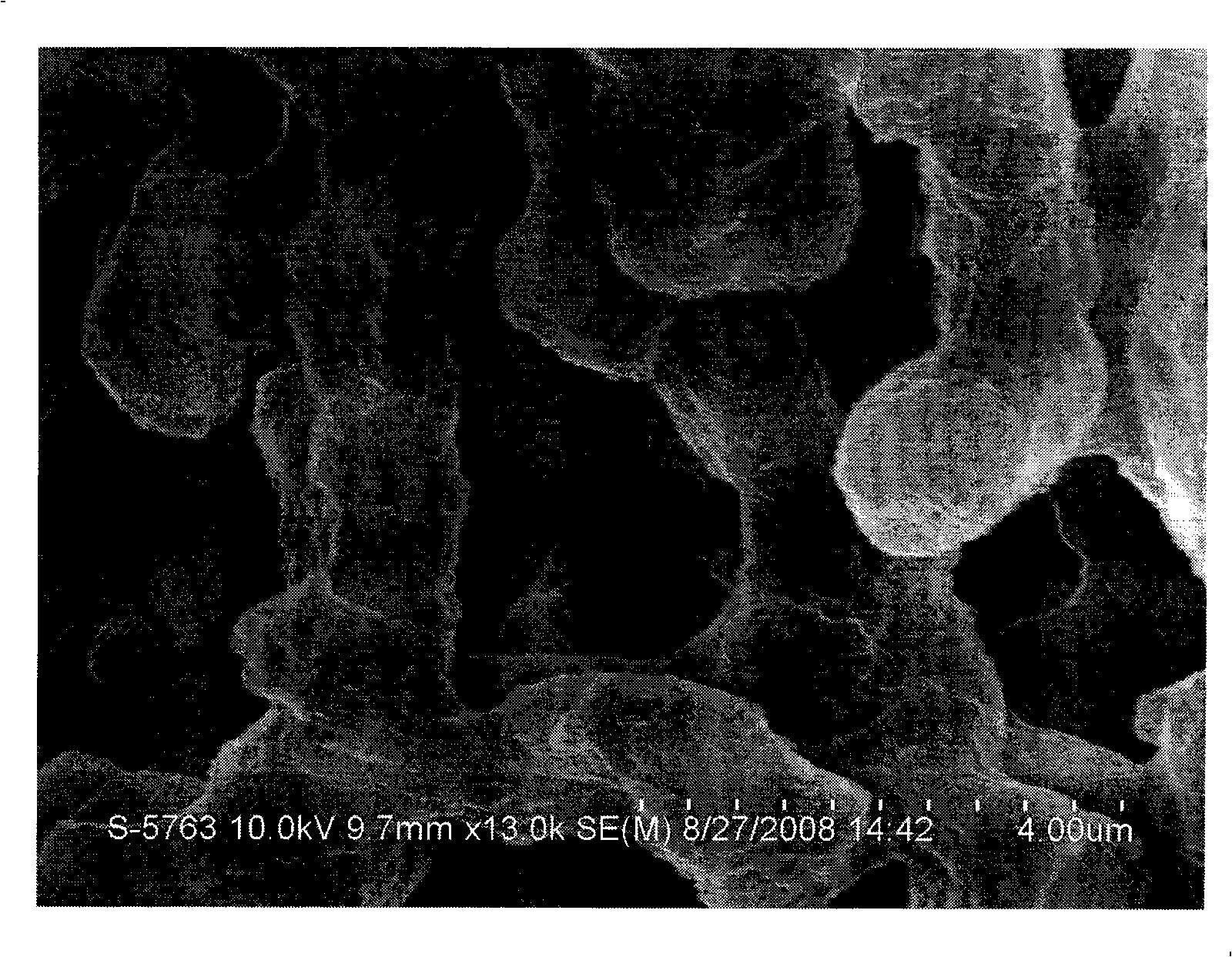

[0021] In the method for preparing a monolithic column provided by the present invention, the polymer monolithic separation medium used is formed by the polymerization of divinyl polymerized monomers ethylene glycol methacrylate and divinylbenzene, and the polymerization system also includes methanol and n-hexane A composite porogen composed of two organic substances, a composite porogen composed of toluene and dodecanol, an initiator, a catalyst and a catalyst ligand.

[0022] The concrete steps of this method are as follows:

[0023] 1) Synthesis of monolithic column:

[0024] Inject the reaction solution after mixing the above substances into the mold, such as 50×4.6mm i.d., 100×4.6mm i.d. stainless steel chromatographic column tube, react at room temperature for a sufficient time, and then connect it to the high-pressure infusion pump and rinse with organic solvent Porogens and other soluble substances in the column;

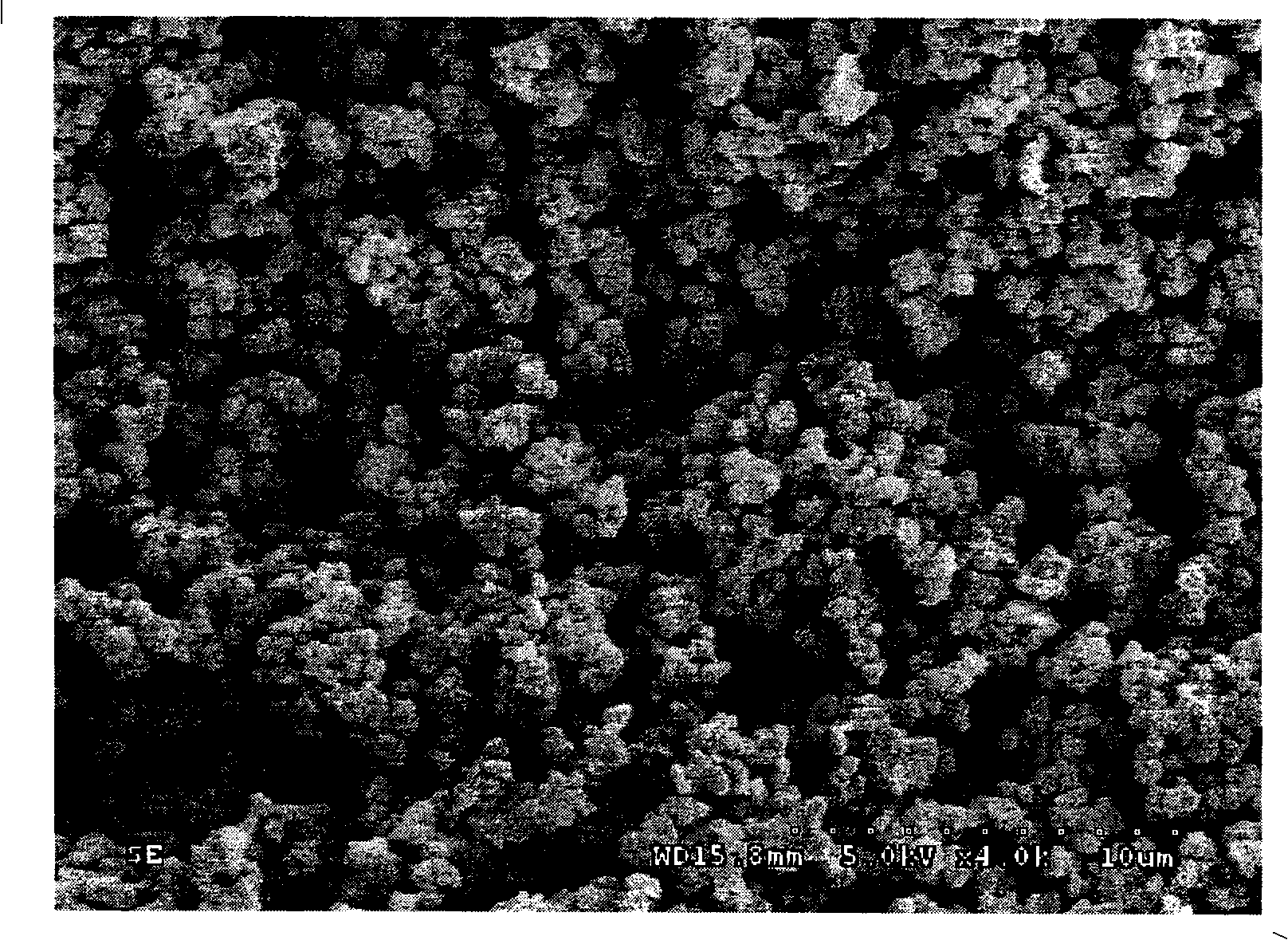

[0025] 2) Modification of the integral column:

[0...

Embodiment 1

[0030] Reagents and solvents:

[0031] The polymerization monomer is ethylene glycol methacrylate (EDMA); the porogen is methanol and n-hexane; the initiator is bromopropionate (BPE); the catalyst is CuBr and CuBr 2 ; The polyamine is pentamethyldiethylenetriamine (PDMETA), the bipyridine is 2,2-bipyridine (BPY), the antioxidant is ascorbic acid (vitamin C, Vc), and the modified functional monomer is methacrylic acid n-butyl ester.

[0032] Column preparation process:

[0033] The first step, column synthesis

[0034] EDMA 0.50mL (2.64mM), 0.50mL methanol, 0.50mL n-hexane, 0.050mL (0.39mM) BPE, 0.056g (0.39mM) CuBr, 0.080mL (0.39mM) PDMETA mixed together, ultrasonically mixed and injected into stainless steel In the chromatographic column tube, after reacting at room temperature for 24 hours, install the chromatographic column head at both ends of the column tube, and then connect it to a high-pressure infusion pump. 1, v / v) Washing with mixed solvent, and then carry out A...

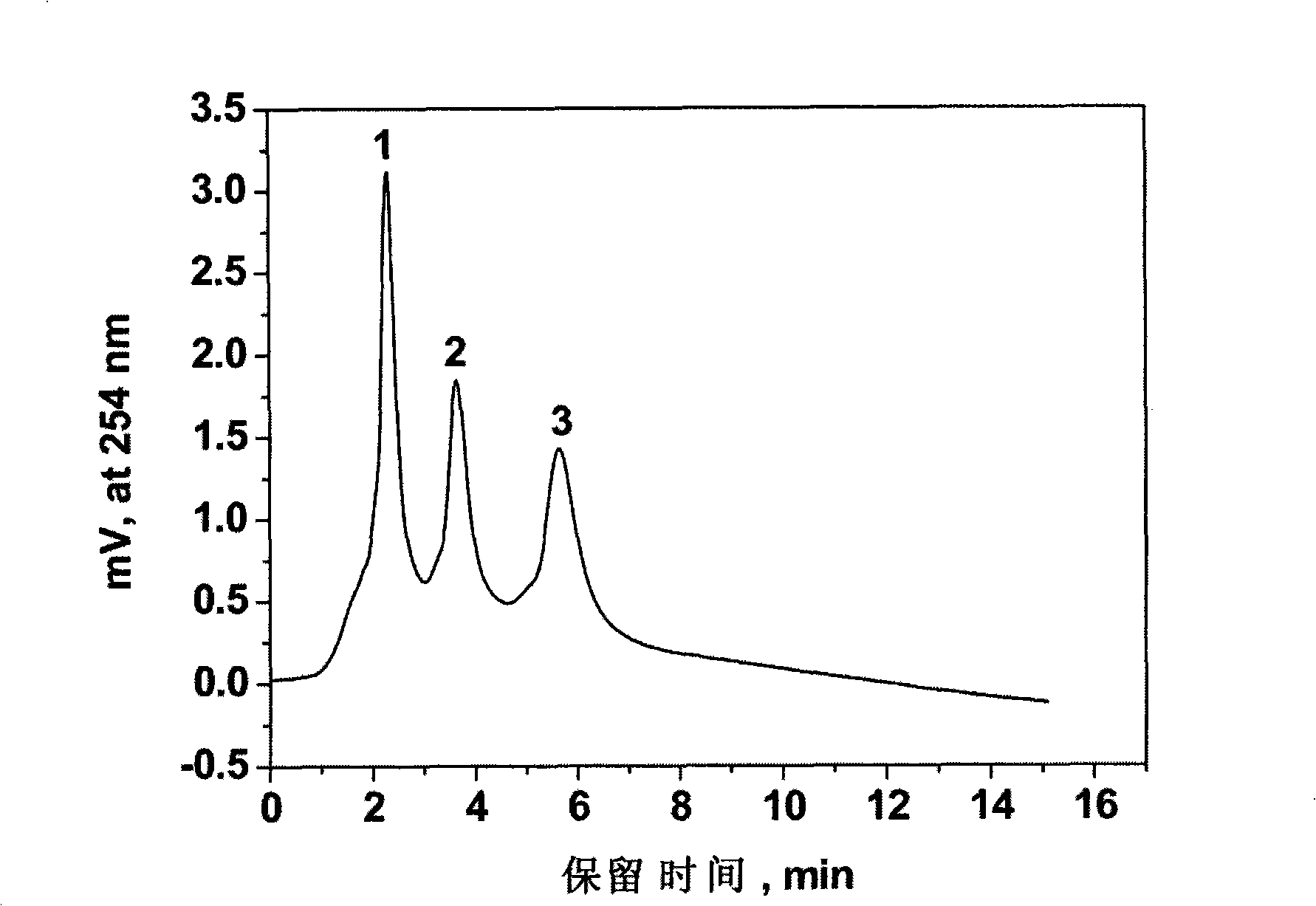

Embodiment 2

[0042] Reagents and solvents:

[0043] The polymerization monomer is ethylene glycol methacrylate (EDMA); the porogen is methanol and n-hexane; the initiator is bromopropionate (BPE); the catalyst is CuBr and CuBr 2 The polyamine is pentamethyldiethylenetriamine (PDMETA), the bipyridine is 2,2-bipyridine (BPY), the antioxidant is ascorbic acid (vitamin C, Vc), and the modified functional monomer is ethyl methacrylate ester.

[0044] Column preparation process:

[0045] The first step, column synthesis

[0046] This step is exactly the same as the first step in Example 1.

[0047] The second step, cylinder modification

[0048] The proportion of grafting reaction solution is 68mg (0.39mM) CuBr 2 , 87mg (0.39mM) PMDETA, methanol and n-hexane (1:1, v / v) 50.0mL, ethyl methacrylate 3.12g (27.3mM), Vc 0.27g (1.56mM), after ultrasonic mixing, use The syringe pump was injected into the chromatographic column at a flow rate of 3.0 mL / h and reacted at room temperature for 14 h. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com