Concrete curing compound and preparation method thereof

A concrete curing agent and solution technology, which is applied in the field of concrete admixtures, can solve the problems of unrepresented surface crack resistance, high cost, and less curing agent, so as to improve anti-aging ability, reduce crack resistance, and prevent water evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples.

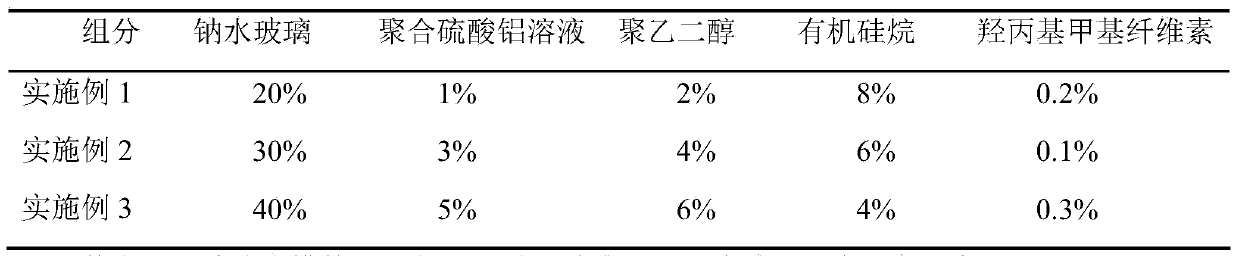

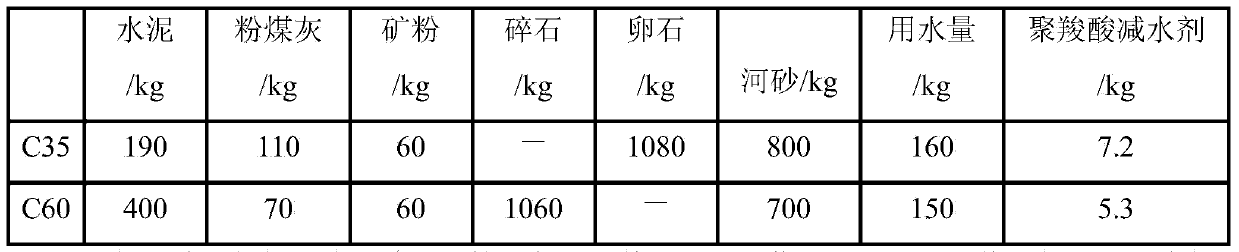

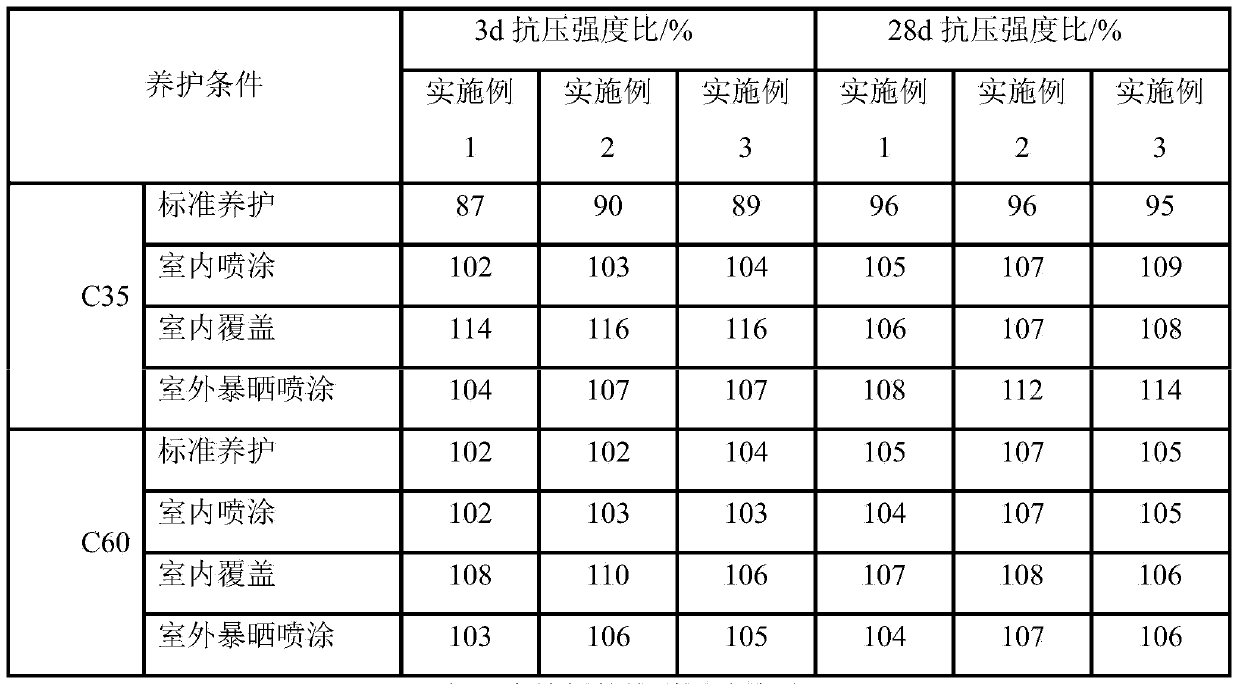

[0028] In the concrete curing agent in embodiments 1 to 3, the weight percentages of each component are as mixed in Table 1 (remainder is water, and the total weight percentage makes up 100%):

[0029]

[0030] Wherein, the water glass is industrial sodium water glass with a modulus of 2.0; the solid content of the polyaluminum sulfate solution is 37.1%; the number average molecular weight of polyethylene glycol is 200; the organosilane is vinyltrimethoxysilane; The viscosity of cellulose is 170000mPa·s.

[0031] The preparation method of concrete curing agent in each embodiment, comprises the following steps:

[0032] 1) Mix organosilane and polyethylene glycol with 20% of the total amount of water in the formula to prepare a solution;

[0033] 2) Swell the hydroxypropyl methylcellulose in the remaining water at 20-25°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com