Medical infusion soft bag and method for producing the same, and shaping method

The invention relates to a soft infusion bag and a technology for a manufacturing method, which are applied in the manufacture and shaping of medical infusion soft bags, and the field of medical infusion soft bags. The effect of safety, small volume shrinkage and advanced processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

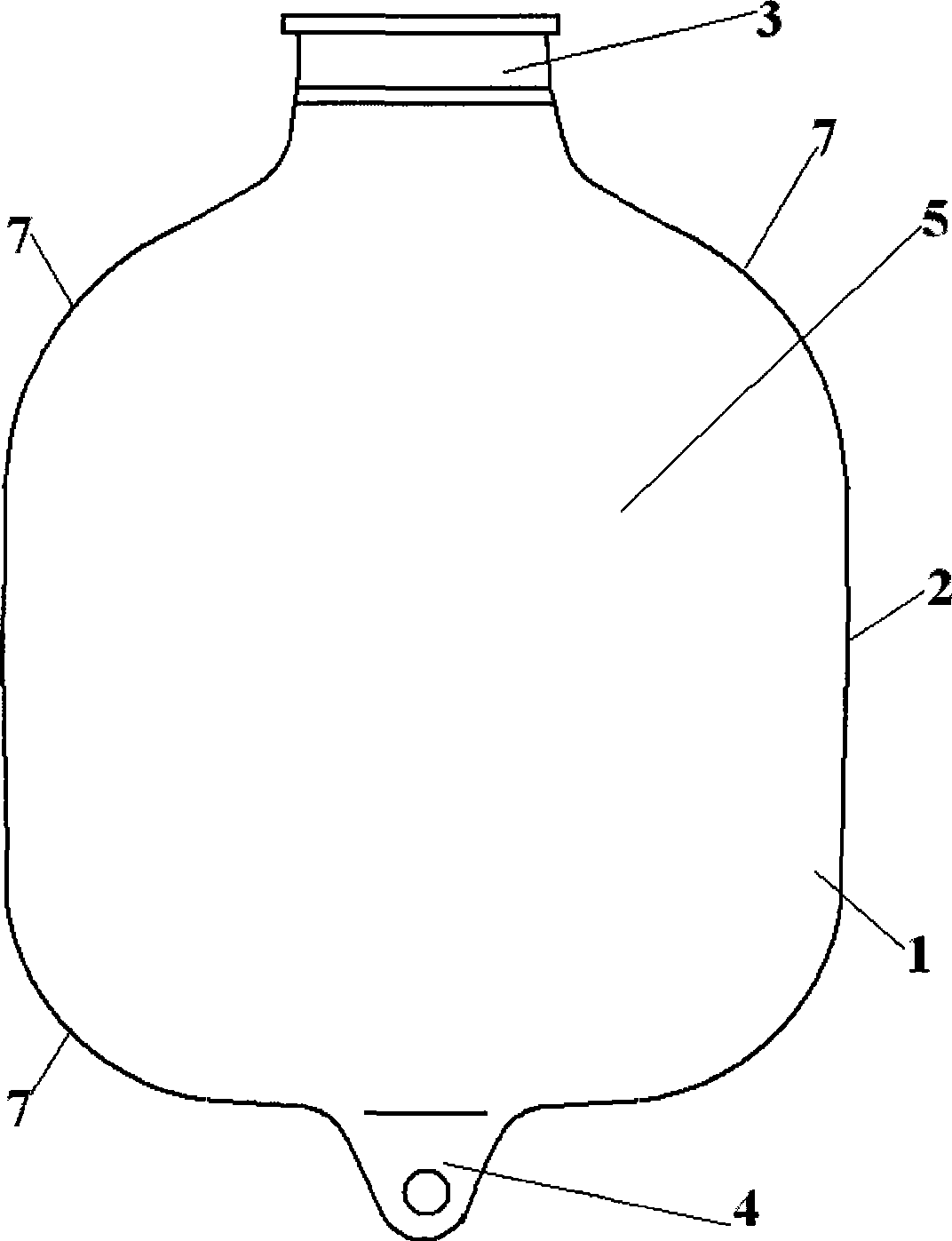

[0047] like figure 1 As shown, the projected contours of the turning points of the two main bag surfaces 5 are smooth curved transitions 7 . Because the bending part adopts a structure with angular edges, it is easy to crack and break due to stress concentration, and it is also difficult to manufacture.

Embodiment 2

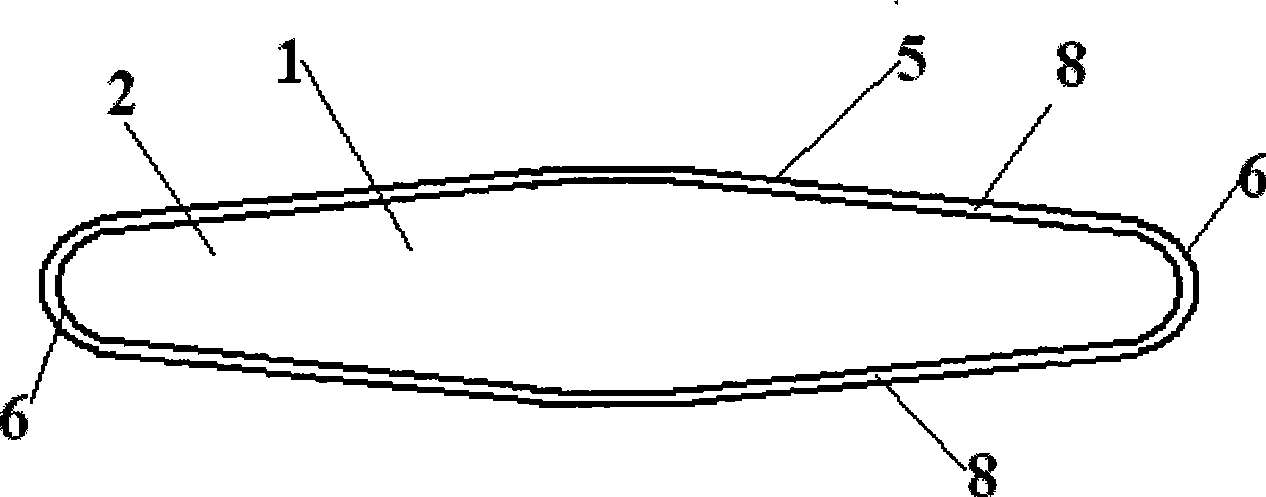

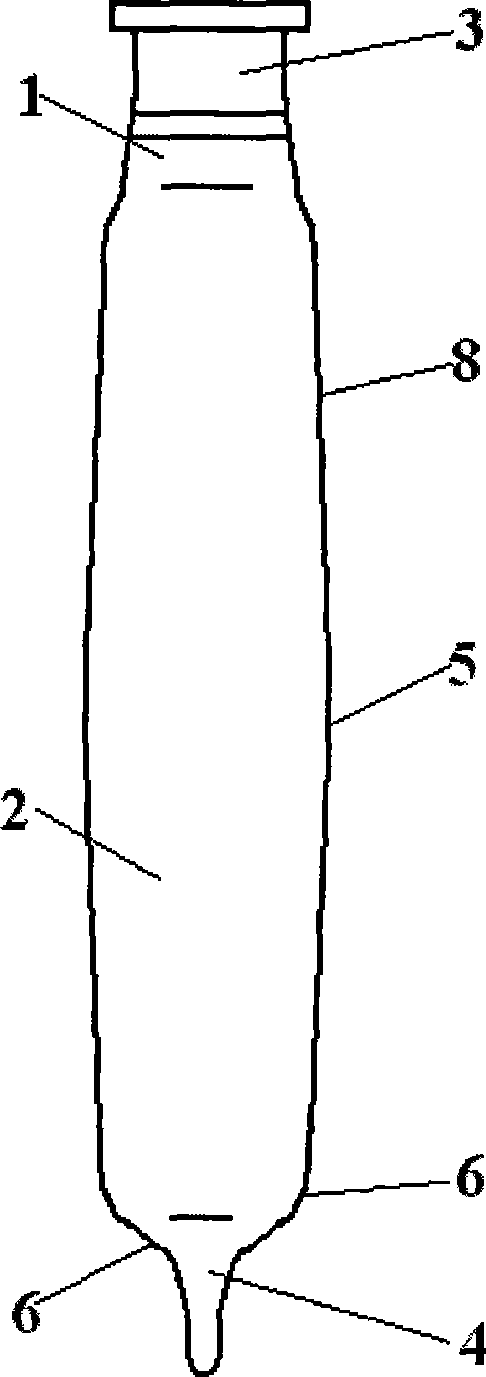

[0049] like figure 2 and image 3 As shown, on the basis of Embodiment 1, the distance between the two main bag body surfaces 5 is further greater than the distance between the edges near the edge, that is, the slope 8 is from the middle of the main bag body surface 5 to its edge . Like this, promptly can make infusion soft bag 1 have certain capacity, guarantee again at the same time after infusion soft bag 1 infusion, can be fully flattened, promptly two main bag face 5 can fit fully, can not stay in the bag too much. Too much medicine. If the side of the infusion soft bag 1 is a very large plane, and the main bag body surface 5 is also completely plane, then when the infusion ends, it will not be able to fully shrink at the edge, which will cause a contrast between the pressure of the human body and the infusion bag, that is, the pressure of the human body's veins. The pressure is greater than the pressure of the liquid medicine in the infusion bag, causing venous blood...

Embodiment 3

[0052] like figure 1 and image 3 As shown, on the basis of the above embodiments, the connection between the infusion bag opening 3 and the infusion bag body 2 is made into a smooth curved surface transition 6 . This solution ensures that there is no obvious connection surface and connection structure between the tube body of the infusion bag mouth 3 and the infusion bag body 2, so no leakage will occur. At the same time, the smooth curved surface transition 6 is not easy to cause cracks. One-time molding during manufacture, the structure and process are simplified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com