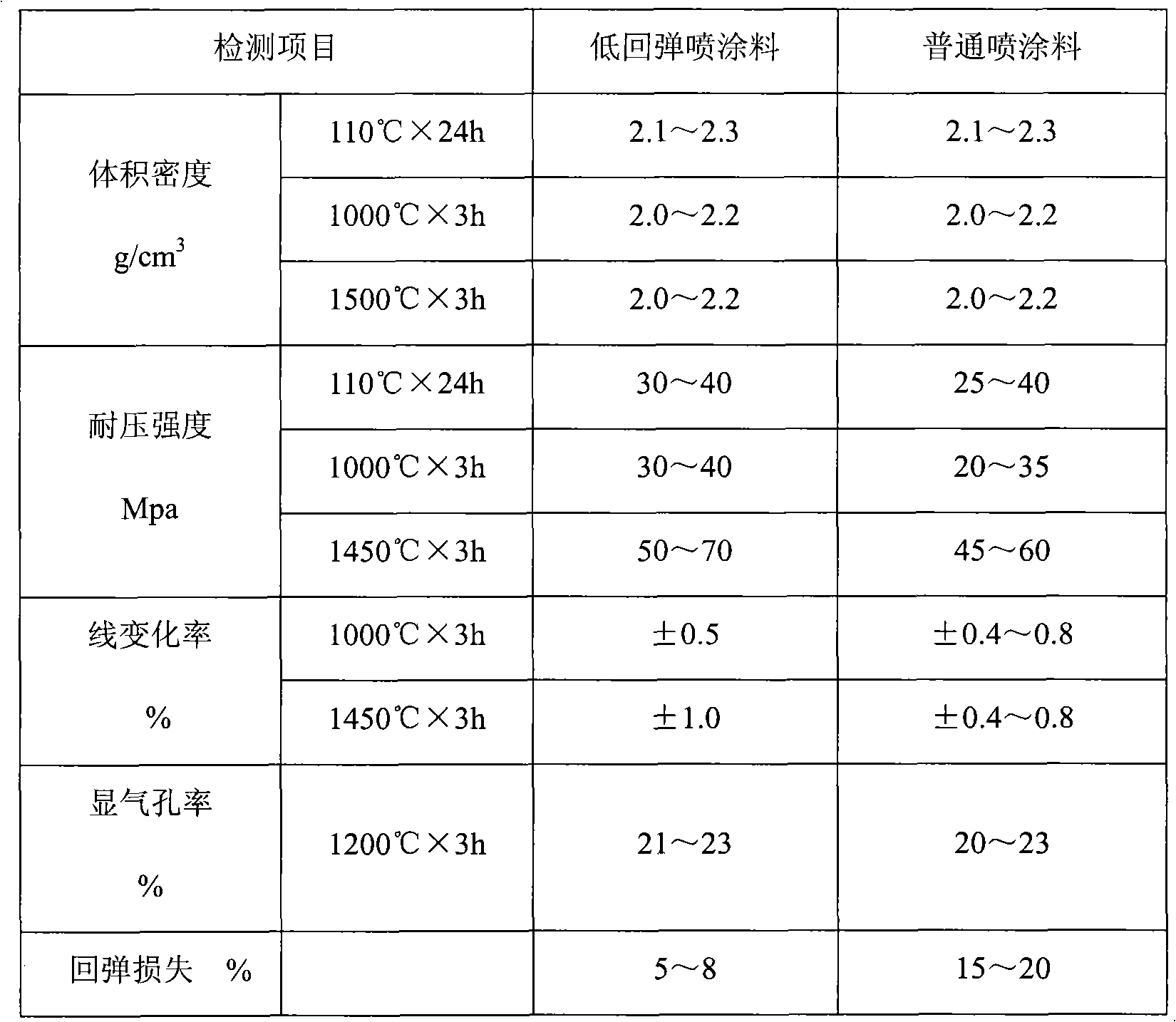

Low springback rate spraying and coating material for thermal-state blast furnace maintenance and preparation method thereof

A low-rebound and paint-spraying technology, applied in the field of unshaped refractory materials, can solve the problems affecting the performance of gunning materials, and achieve the effects of suitable performance indicators, low rebound loss and low rebound loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

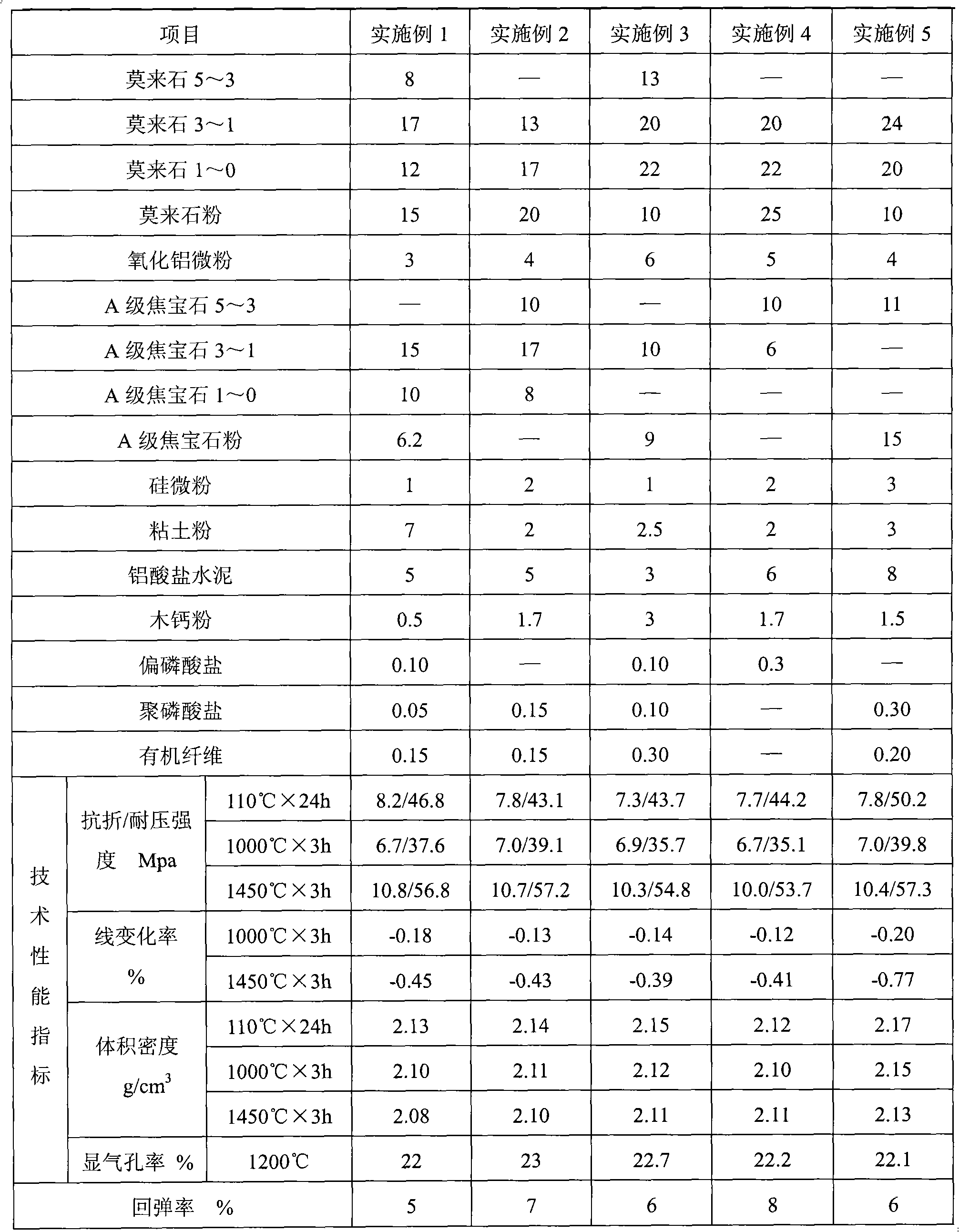

[0030] The present invention will be further described below in conjunction with specific examples, and the following examples are only used to illustrate the present invention rather than limit the present invention.

[0031] Table 2 lists the raw materials and their contents measured by mass percentage and main technical performance indexes of the spray coating materials for hot state maintenance of blast furnaces of the present invention.

[0032] Table 2 each embodiment and performance

[0033]

[0034] The manufacture method of each embodiment is identical, and its method is as follows:

[0035] First, weigh various raw materials according to the proportioning composition of various raw materials in Table 2; then, in the first step, microsilica powder, alumina micropowder, clay powder, aluminate cement, polyphosphate, metaphosphate, Wood calcium powder plus a part of mullite powder is pre-mixed. In the second step, the organic fiber and refractory aggregate are mixed....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com