Improved smokeless environment-friendly stemming and manufacturing method thereof

An improved and environmentally friendly technology, applied in the field of high-temperature refractory materials, can solve the problems of adverse environmental effects, difficulty in adapting to furnace requirements, etc., and achieve the effects of suitable porosity, short heat hardening time, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

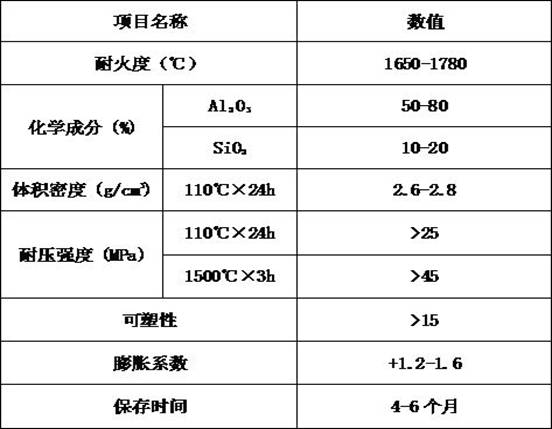

Image

Examples

Embodiment 1

[0029] Embodiment 1: A kind of improved smokeless environmental protection gun clay, comprises the following components of weight percent:

[0030] Burnt Gem Aggregate 40%

[0031] Suzhou No.1 Clay 11%

[0032] Elemental silicon fine powder 1%

[0033] Andalusite 7%

[0034] Cerium oxide fine powder 1.5%

[0035] Zirconium silica powder 4%

[0036] Corundum fine powder 12%

[0037] Zircon powder 8%

[0038] Silica powder 4%

[0039] Binder 11%

[0040] Humectant 0.35%

[0041] Plasticizer 0.15%.

[0042] A kind of manufacturing method of improved smokeless environmental protection gun clay, it comprises the following steps:

[0043] (1) Ingredients: Measure each component according to the formula, mix coke gemstone aggregate, Suzhou No. 1 mud, elemental silicon fine powder, andalusite, cerium oxide fine powder, zirconium silicon fine powder, corundum fine powder, zircon powder, silica Powder, binder were stirred and bundled for 23 hours to obtain base material, and ...

Embodiment 2

[0046] Embodiment 2: An improved smokeless environmental protection gun clay, including the following components in weight percentage:

[0047] Burnt Gem Aggregate 45%

[0048] Suzhou No.1 Clay 8%

[0049] Elemental silicon fine powder 1.2%

[0050] Andalusite 8%

[0051] Cerium oxide fine powder 1.3%

[0052] Zirconium silica powder 3%

[0053] Corundum fine powder 10%

[0054] Zircon powder 9%

[0055] Silica powder 3%

[0056] Binder 13%

[0057] Humectant 0.32%

[0058] Plasticizer 0.18%.

[0059] A kind of manufacturing method of improved smokeless environmental protection gun clay, it comprises the following steps:

[0060] (1) Ingredients: Measure each component according to the formula, mix coke gemstone aggregate, Suzhou No. 1 clay, elemental silicon fine powder, andalusite, cerium oxide fine powder, zirconium silicon fine powder, corundum fine powder, zircon stone powder, silica Powder, binder were stirred and bundled for 25 hours to obtain base material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com