Modified resin grinding wheel and manufacturing method thereof

A technology of modifying resin and grinding wheel, used in bonding grinding wheels, manufacturing tools, metal processing equipment, etc., can solve the problems of short polishing cycle, large wear and tear, high density, etc., to improve polishing and grinding performance and reduce surface energy. , the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

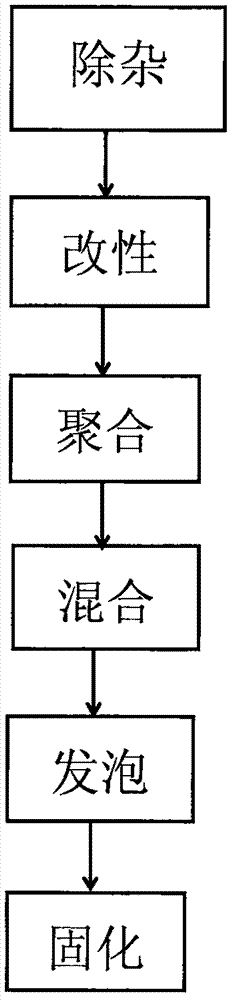

[0020] Example 1, see figure 1 Shown: a modified resin grinding wheel, including a grinding body and a reinforcing sheet placed inside the grinding body to enhance the rotational strength of the grinding body, characterized in that: the raw material of the grinding body and its The weight ratio is: 60 parts of abrasive, 11 parts of bisphenol A epoxy resin, 2 parts of coupling agent, 2 parts of toluene, 11 parts of toluene solution, 7 parts of foaming agent, and 7 parts of auxiliary agent. During preparation, weigh the abrasive, place the abrasive in hydrochloric acid solution and stir for 10 minutes, then repeatedly wash with deionized water until neutral, then take out the abrasive and dry it; then weigh the coupling agent and toluene; , toluene, and the abrasive after pickling are put into the container, and the temperature is 85 ℃ for the reaction in a water bath, and the solution after the reaction is suction filtered and dried; then the bisphenol A epoxy resin and formald...

Embodiment 2

[0021] Embodiment 2, the embodiment of embodiment 2 is roughly the same as embodiment 1, and its difference is: the raw material of described grinding body and weight ratio thereof are: abrasive material 52 parts, bisphenol A epoxy resin 9, even 1 part of joint agent, 1 part of toluene, 9 parts of toluene solution, 6 parts of foaming agent, 6 parts of auxiliary agent. It can also achieve the effect of Embodiment 1.

Embodiment 3

[0022] Embodiment 3, the embodiment of embodiment 3 is roughly the same as embodiment 1, and its difference is: the raw material of described grinding body and weight ratio thereof are: abrasive material 68 parts, bisphenol A epoxy resin 12, even 3 parts of joint agent, 3 parts of toluene, 12 parts of toluene solution, 9 parts of foaming agent, 8 parts of auxiliary agent. It can also achieve the effect of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com