Full-synthetic glass grinding fluid

A glass grinding fluid, fully synthetic technology, applied in the field of grinding fluid, can solve the problems of operator's skin and eye irritation, nitrite health problems, inaccurate processing accuracy, etc., to achieve excellent anti-wear lubrication and cooling performance, Highlight the effect of anti-corruption ability and ensure processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

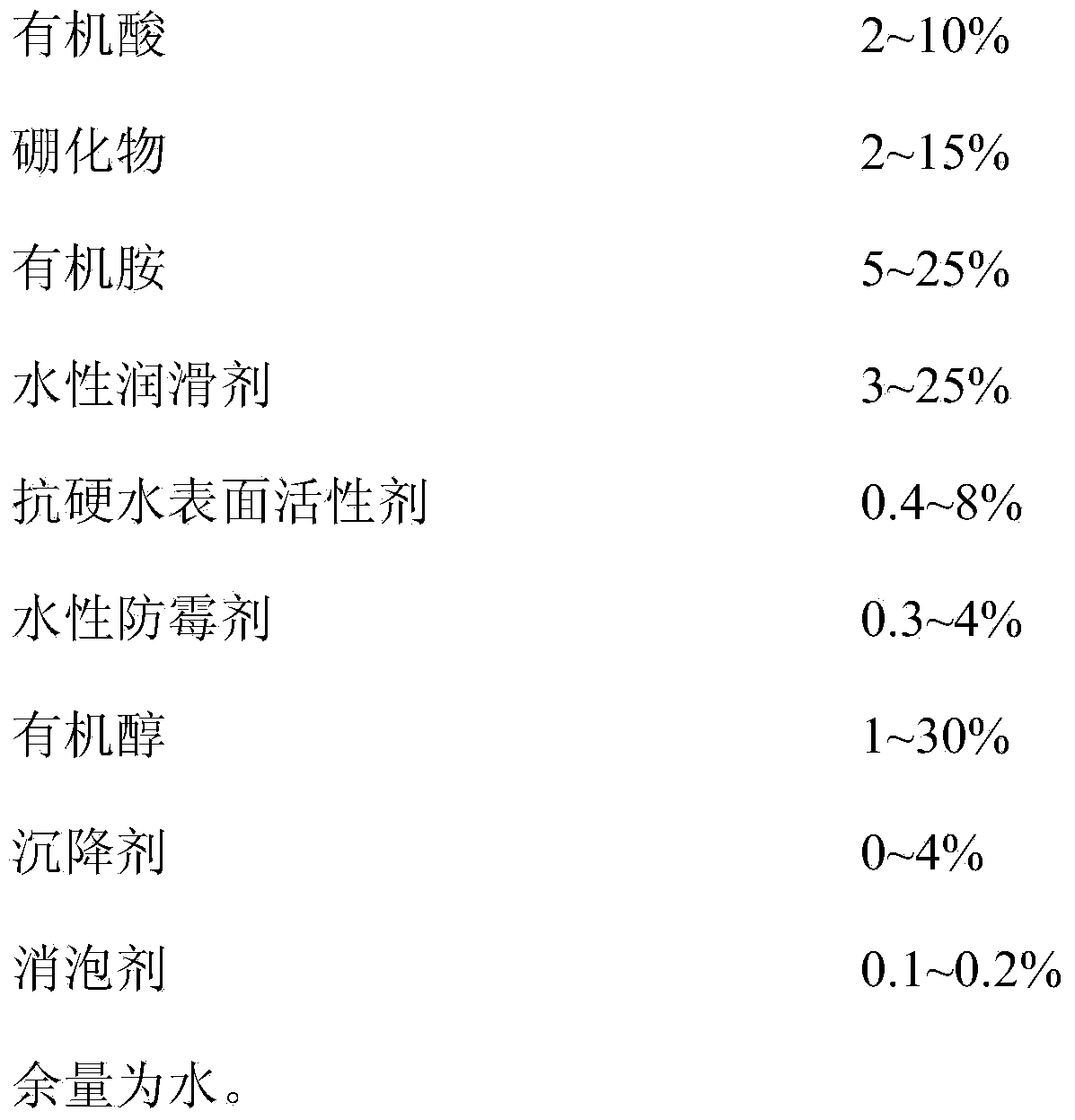

[0035] A fully synthetic glass grinding fluid, composed as follows by mass percentage:

[0036]

[0037] Organic acid selected from C8 ~C 24 of unit fatty acids, C 8 ~C 24 Any one or a mixture of at least two of the polybasic fatty acids or dimer acids. Borides are boric acid or / and boric acid amides. The organic amine is selected from monoethanolamine, diethanolamine, triethanolamine, monoisopropanolamine, diisopropanolamine, triisopropanolamine, alkanolamine or 2-amino-2-methyl-1-propanolamine Any one or a mixture of at least two alcohols. The water-based lubricant is selected from any one or at least two of low-molecular trans polyethers, water-soluble self-emulsifying esters, higher alcohols with a number average molecular weight of 400-2000, cis-polyethers, fatty acid esters or fatty acid amides. mixture of species. The low-molecular trans polyether is a block copolymer of EO (ethylene oxide) and PO (propylene oxide) with a number average molecular weight of 1000...

Embodiment 2

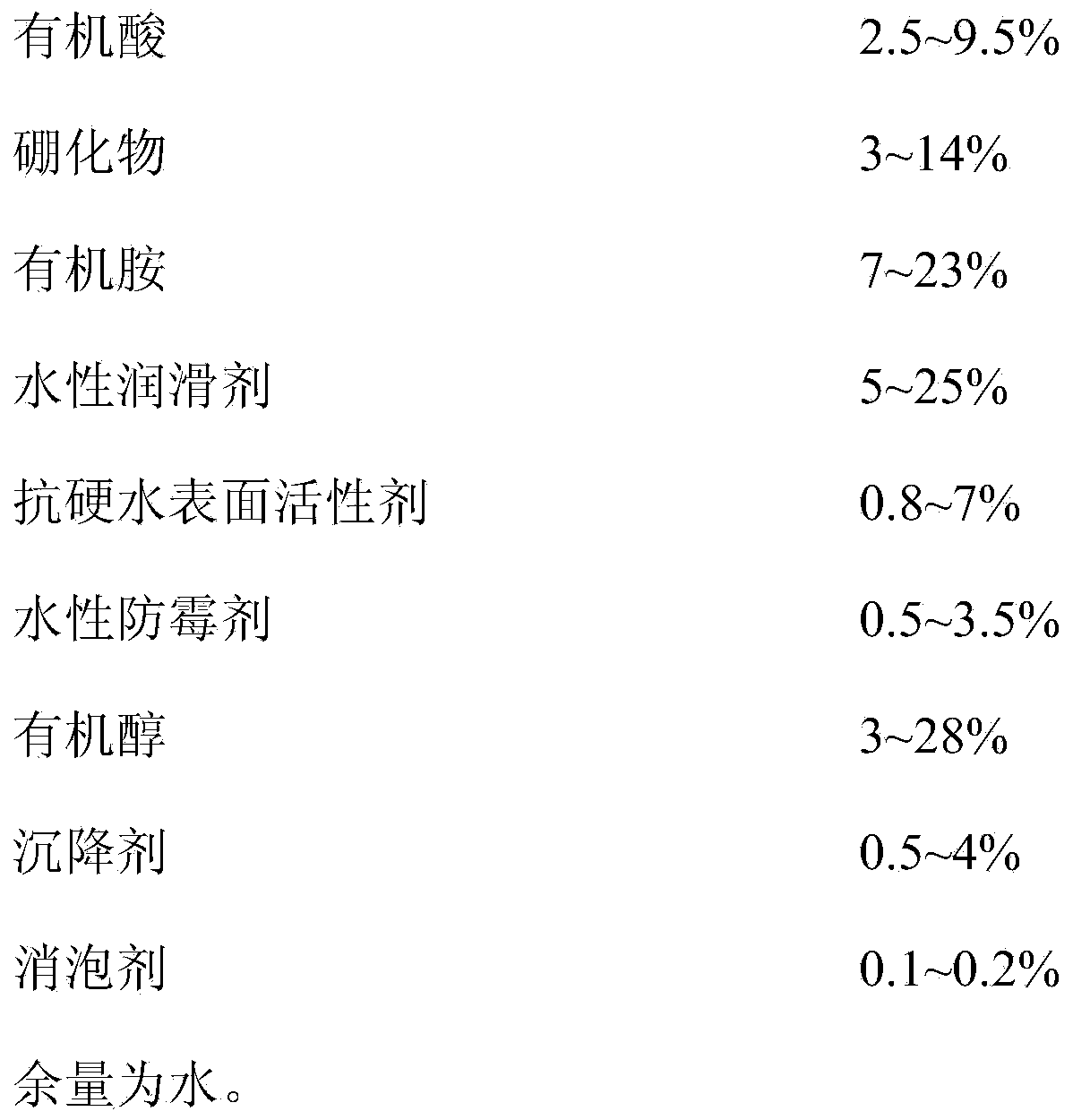

[0039] A fully synthetic glass grinding fluid, composed as follows by mass percentage:

[0040]

[0041] All the other are with embodiment 1, except not containing sedimentation agent.

Embodiment 3

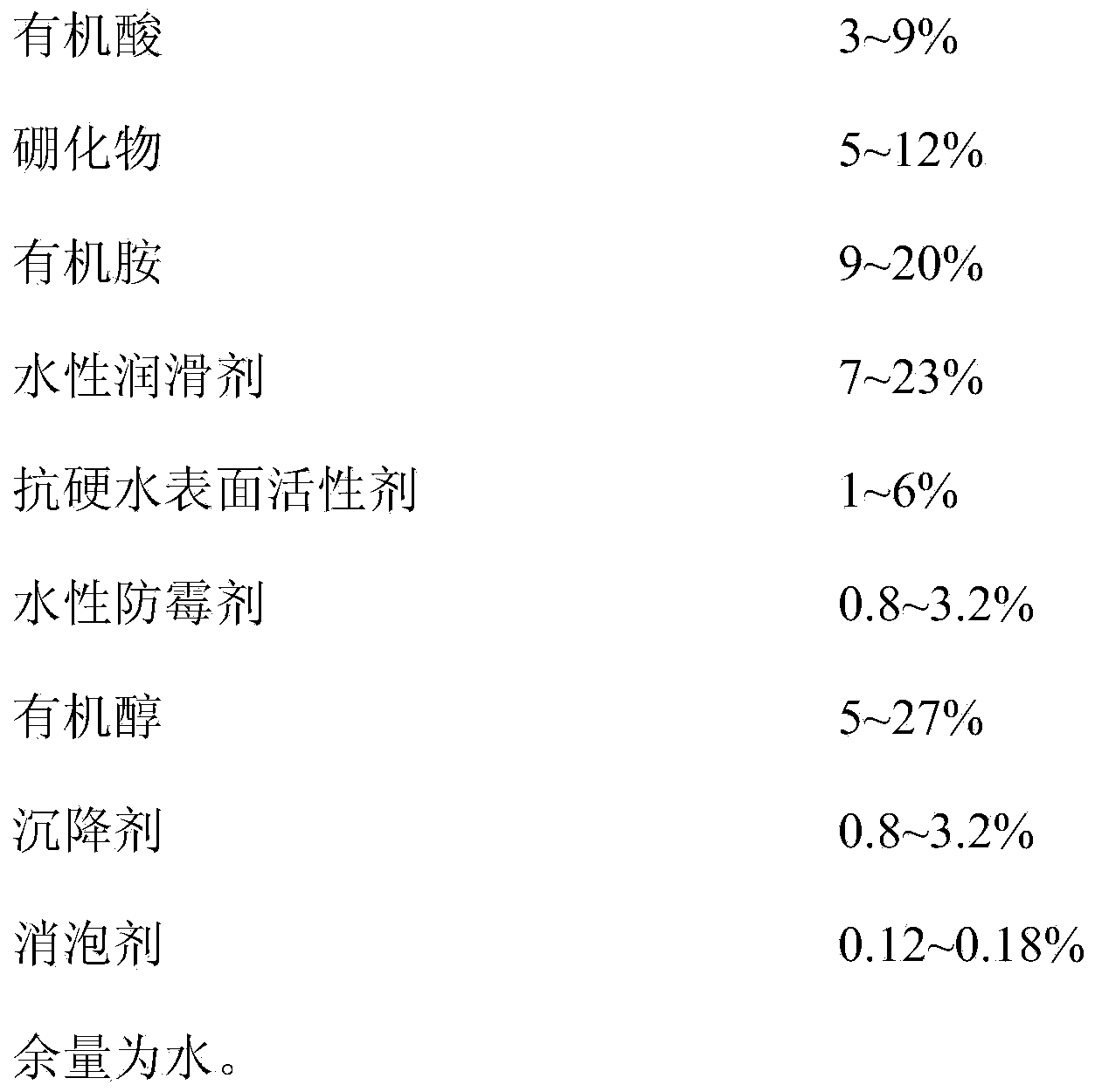

[0043] A fully synthetic glass grinding fluid, composed as follows by mass percentage:

[0044]

[0045] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com