Abrasive belt grinder for metal polishing

A grinding machine and abrasive belt technology, applied in abrasive belt grinders, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of high labor intensity in grinding and burn the substrate of the seed plate, and improve the surface quality and service life. , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

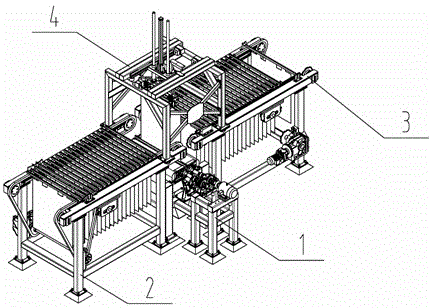

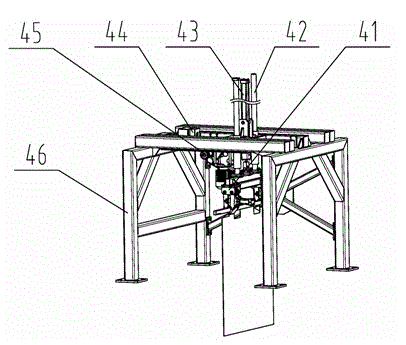

[0010] The grinding device is installed in the middle of the equipment, and the front end is equipped with a plate receiving chain device, the rear end is equipped with a plate chain device, and the upper part is equipped with a two-dimensional transfer device, and each station is equipped with a proximity switch or a photoelectric switch. .

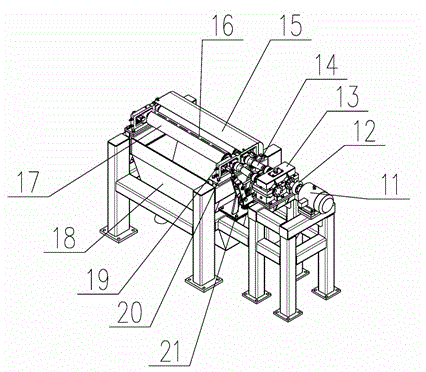

[0011] In the grinding device of the present invention, the motor, shaft coupling, double output shaft gearbox and sliding grinding roller are installed on the upper part of the frame, and the sliding gear clamp is installed on the lower part of the frame, wherein the output shaft of the double output shaft gearbox The clamps of the sliding grinding roller and the sliding gear fixture are installed in pairs, and the torque is transmitted through the universal coupling between the double output shaft gearbox and the sliding grinding roller. The steel pipe in the sliding grinding roller is wrapped with a diamond-shaped groove. The rubber c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com