Patents

Literature

71results about How to "Solve production efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

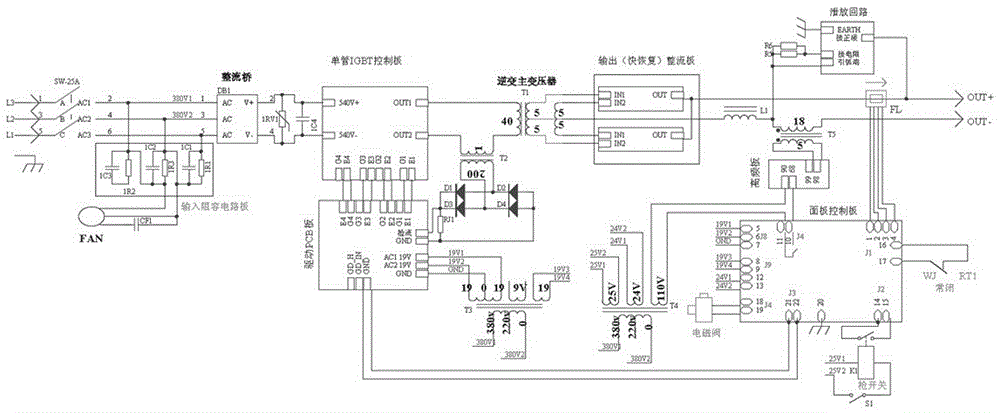

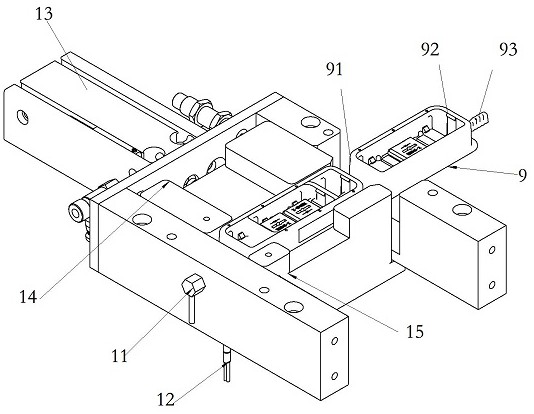

A method and device for producing high-power tube chip welding

InactiveCN102294526AReduce operating costsSolve production efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDie bonding

The invention discloses a welding method and device for producing high-power tube chips. The purpose of the present invention is to provide a high-power tube chip welding method and device thereof, which have automatic production, high production efficiency, saving enterprise operating costs and stable product quality. The steps of the invention include mold making, material suction, wire feeding, pressing, core welding, heat preservation, cooling, stacking and the like, and the invention is mainly used in chip factories to produce power tube chips.

Owner:JIEYANG HONGGAN ELECTRONICS

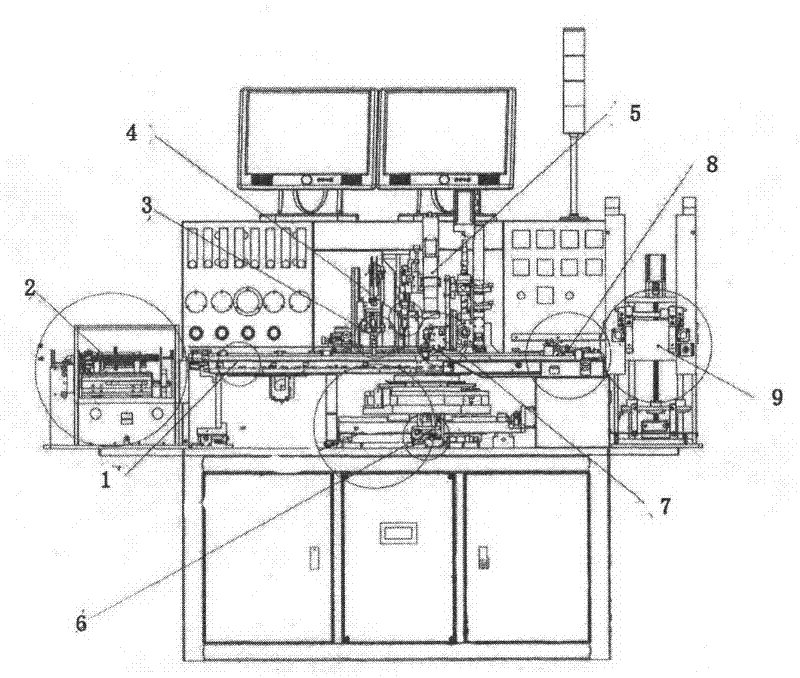

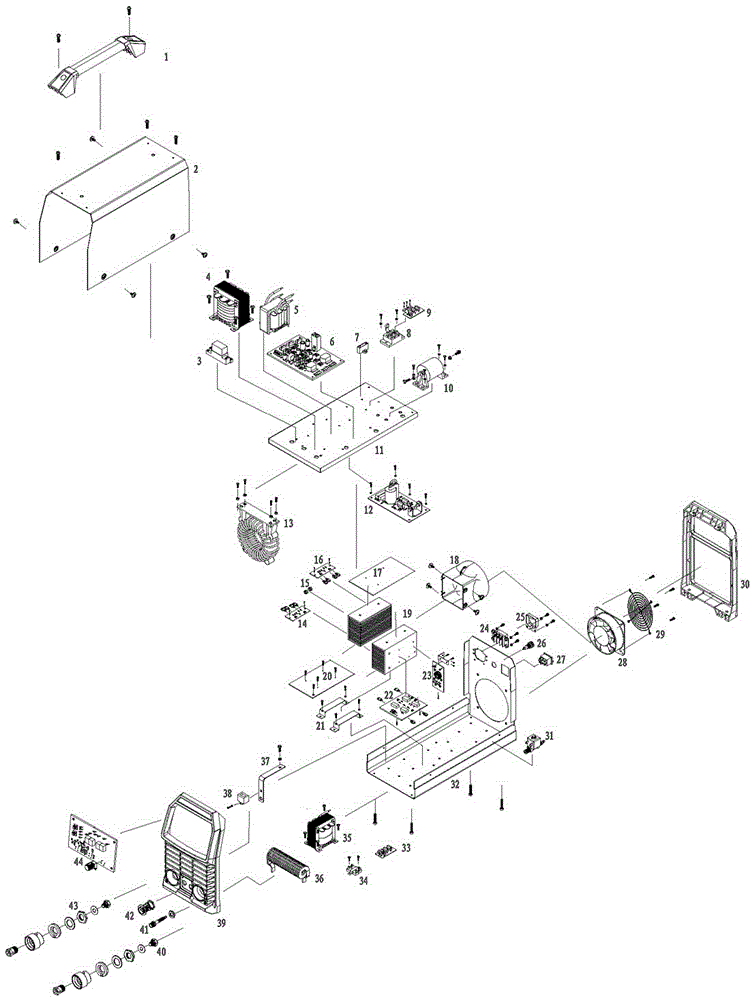

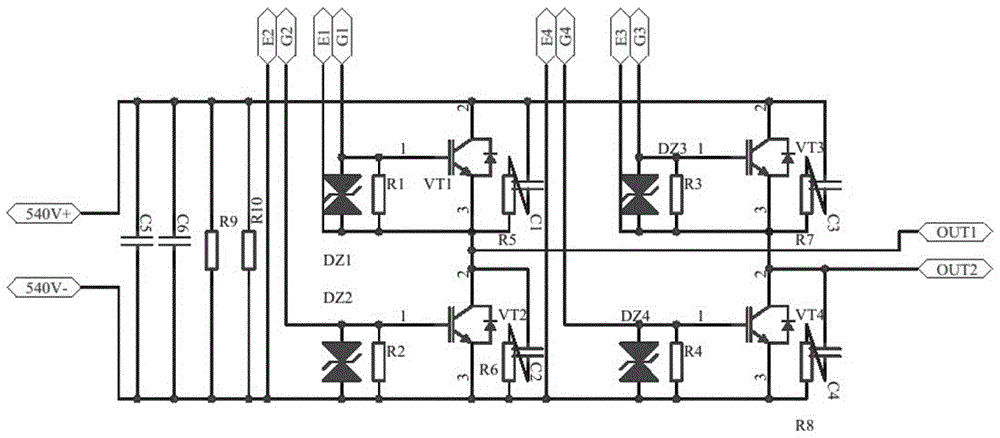

Microprocessor controlled contravariant multifunctional argon arc welding machine

ActiveCN106041267ASimple structural designFix performance issuesWelding accessoriesShielded metal arc weldingControl circuit

The invention relates to a microprocessor controlled contravariant multifunctional argon arc welding machine which comprises a shell part, a front panel part, a rear panel part and an internal control part; the internal control part comprises a contravariant main circuit, a monotube IGBT control circuit, a driving circuit, a rectification output circuit, a tapping loop circuit, a high-frequency circuit and a panel control circuit; the monotube IGBT control circuit and the rectification output circuit are connected in series onto the contravariant main circuit; the driving circuit is connected with the monotube IGBT control circuit and the panel control circuit; the driving circuit controls on-off of the monotube IGBT control circuit under the control of the panel control circuit; the high-frequency circuit is connected with the panel control circuit and the contravariant main circuit and realizes high-frequency or non-contact arc strike during argon arc welding under the control of the panel control circuit; and the tapping loop circuit is connected with the high-frequency circuit and the contravariant main circuit. The microprocessor controlled contravariant multifunctional argon arc welding machine has three functions of pulse argon arc welding, DC argon arc welding and manual arc welding and the characteristic of multiple purposes.

Owner:ZHEJIANG KENDE MECHANICAL & ELECTRICAL

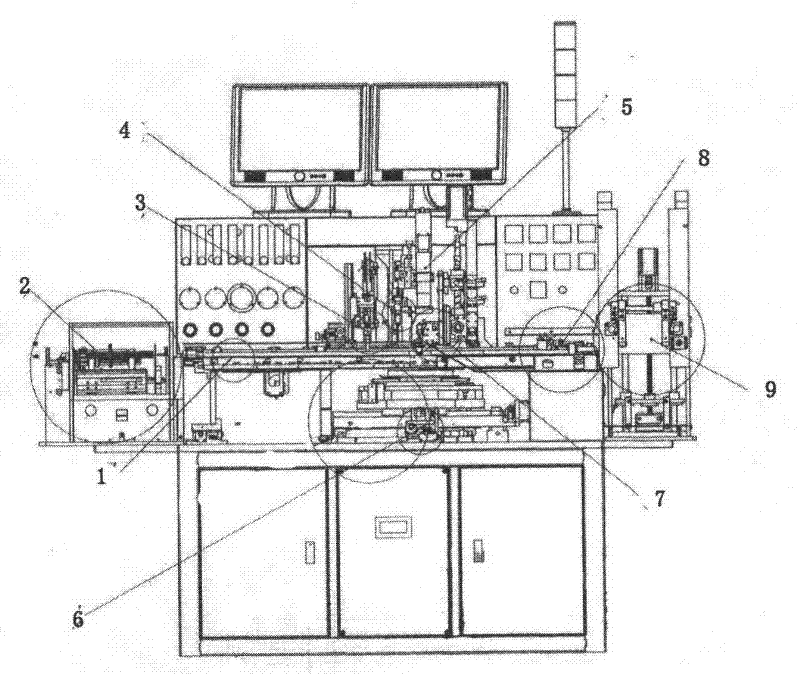

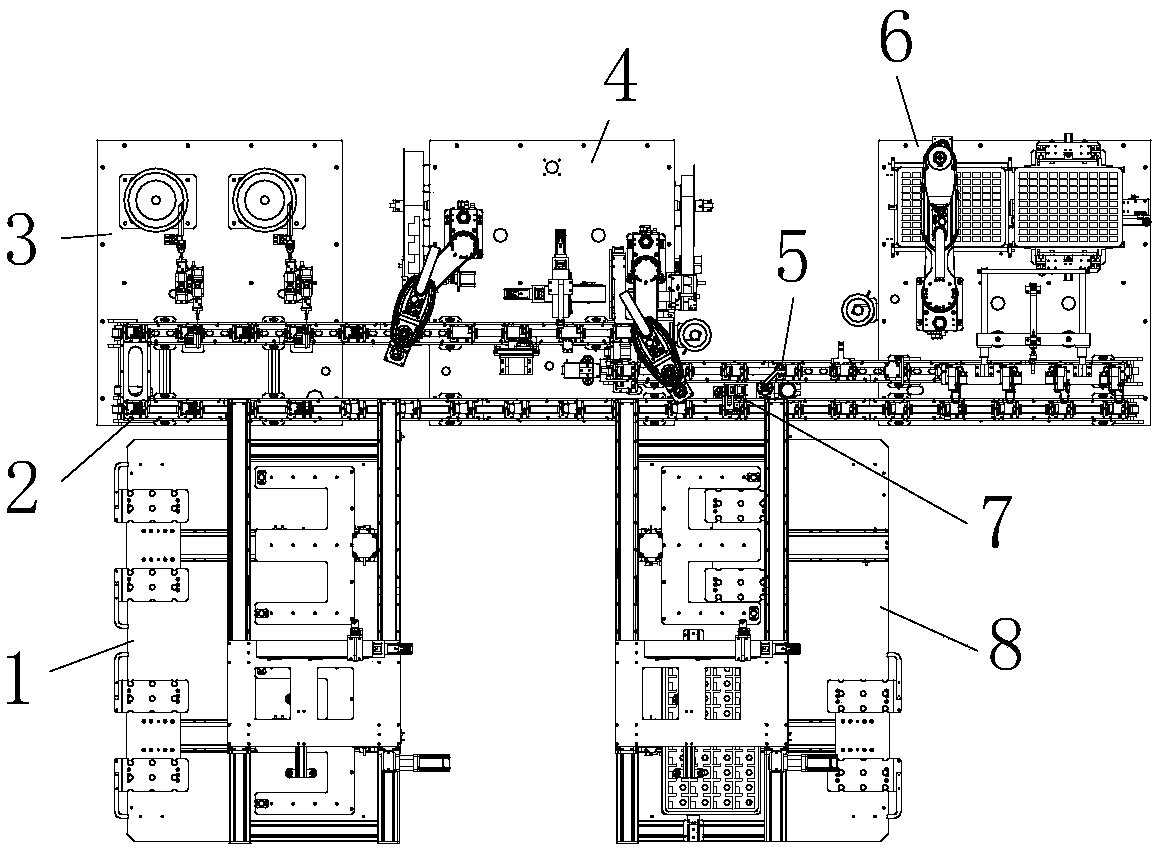

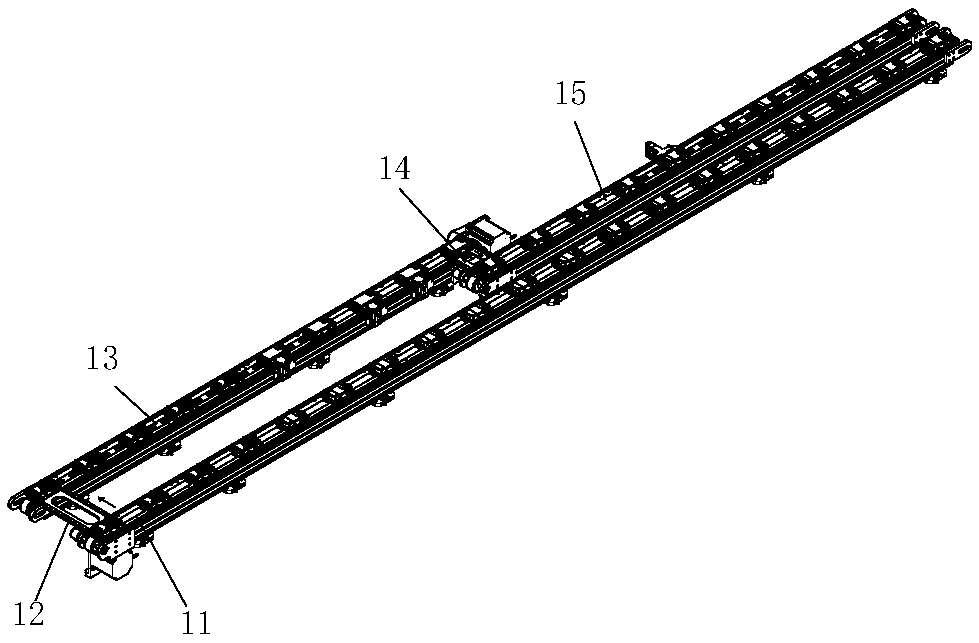

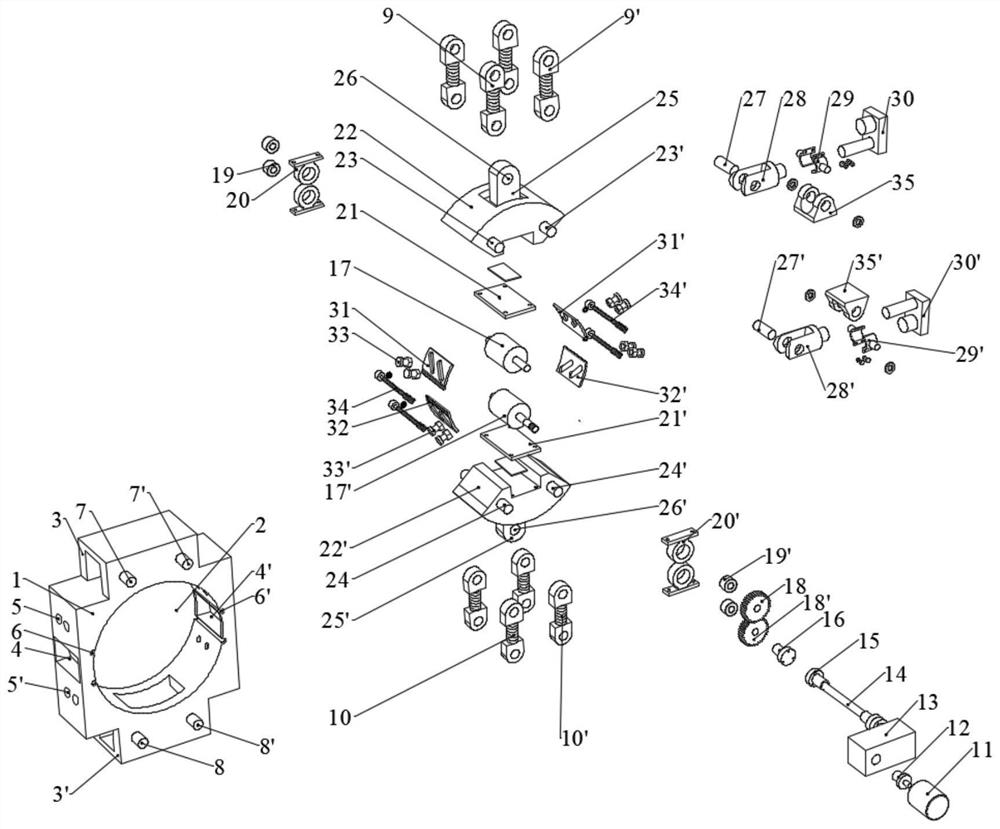

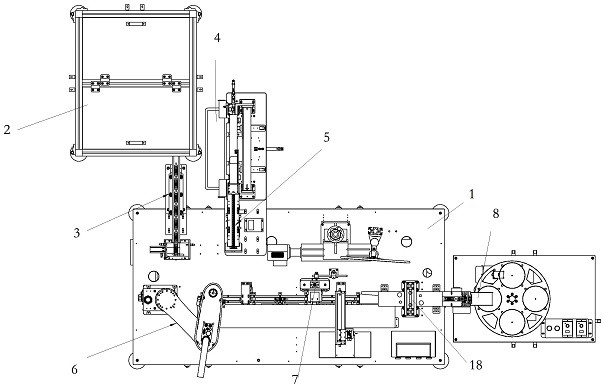

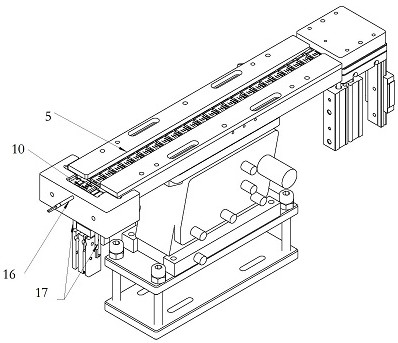

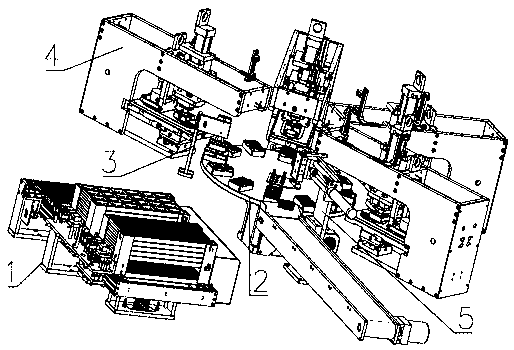

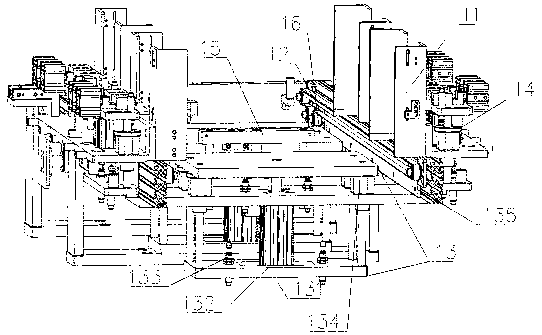

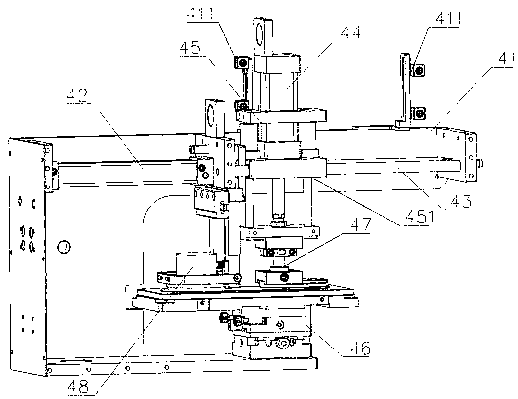

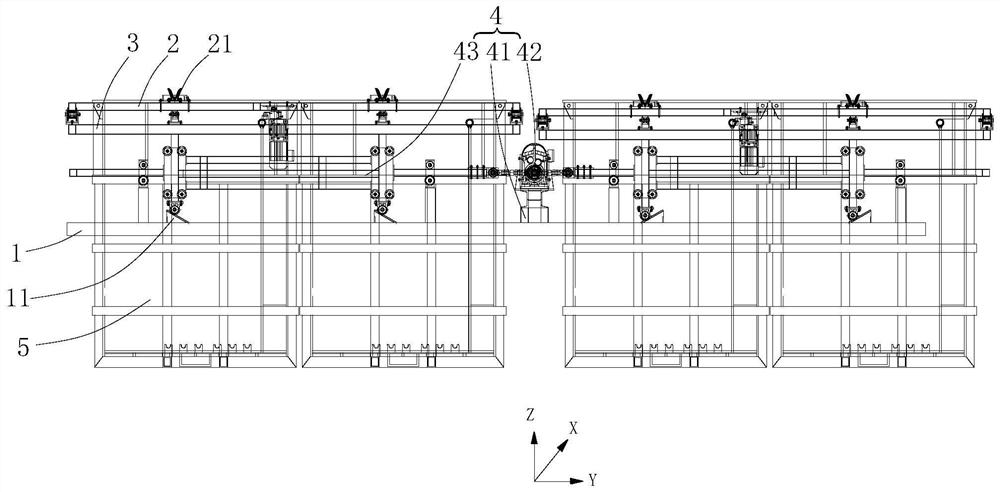

Microfluidic test card production line

ActiveCN107753032ASolve production efficiencySolve the production yieldLamination plant layoutLamination ancillary operationsProduction lineTest card

The invention relates to a microfluidic test card production line. The microfluidic test card production line comprises a conveying mechanism, a feeding mechanism, a steel needle assembling mechanism,a film sticking mechanism, a film tearing mechanism, a PCB assembling mechanism, a discharging turnover mechanism, a discharging mechanism and an isolation frame, wherein the conveying mechanism is arranged on the lower side of the feeding mechanism, the steel needle assembling mechanism is arranged on the upper side of the feeding mechanism, the film sticking mechanism is arranged on the right side of the steel needle assembling mechanism, the film tearing mechanism is arranged on the right side of the film sticking mechanism, the PCB assembling mechanism is arranged on the right side of thefilm tearing mechanism, the discharging turnover mechanism is arranged on the upper side of the discharging mechanism, and the discharging mechanism is arranged on the lower side of the PCB assembling mechanism. The production line has the functions of automatic feeding, adhesive dispense, solidification, film sticking, film wiping, film tearing, PCB assembly, gas tightness testing, discharging and the like, and by means of the design, the problems can be solved that currently, manual work is adopted, so that the production efficiency and the yield are low.

Owner:广东昭信智能装备有限公司

High-yield-ratio air-conditioner foil base material and preparation method thereof

The invention discloses a high-yield-ratio air-conditioner foil base material and a preparation method thereof in the technical field of calendaring manufacturing for aluminum foils, and aims at solving the technical problem that an aluminum foil for an air conditioner is incapable of being high in both extensibility and yield ratio, and not beneficial to reducing the production cost for fins forthe air conditioner, and increasing the production efficiency for the fins in the prior art. The base material comprises the following components in percentage by mass: Al, 0.57%-0.63% of Si, 0.77%-0.83% of Fe, not greater than 0.05% of Cu, not greater than 0.01% of Mn, not greater than 0.03% of Zn and not greater than 0.04% of Ti. The method comprises the following step: a cold-rolling phase of carrying out rough rolling on a finished cast-rolled coil to reach a preset thickness, and then carrying out intermediate homogenization annealing treatment.

Owner:JIANGSU DINGSHENG NEW MATERIAL JOINT STOCK CO LTD

Abrasive belt grinder for metal polishing

ActiveCN103182670AImprove resection rateIncrease grinding ratioBelt grinding machinesGrinding/polishing safety devicesEngineeringSurface grinding

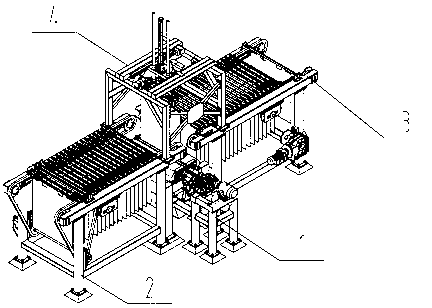

The invention discloses an abrasive belt grinder for metal polishing. A grinding device is arranged on the middle part of the abrasive belt grinder; a plate receiving chain conveying device is arranged at the front end of the abrasive belt grinder; a plate discharging chain conveying device is arranged at the rear end of the abrasive belt grinder; a two-dimensional shifting device is arranged on the upper part of the abrasive belt grinder; in the grinding device, a motor, a shaft coupler, a double-output shaft gearbox and a sliding polishing roller are arranged on the upper part of a rack; and a slide gear clamp is arranged on the lower part of the rack. According to the abrasive belt grinder for metal polishing, an abrasive belt is used as a grinding tool, so that the abrasive belt grinder for the metal polishing has a higher resection rate and a higher grinding ratio in comparison with the conventional steel wire brush polishing way, and therefore, a production efficiency problem and a surface burning problem of plate polishing are solved, and the service life of the plate is prolonged. Meanwhile, the distance between the grinding rollers in the grinding device is adjusted by the spring, so that the pressure, which is applied to the two sides of the starting sheet by the grinding roller, can be adjusted to be equal, and therefore, the uniformity quality of the plate surface grinding is improved.

Owner:JIANGXI NERIN EQUIP

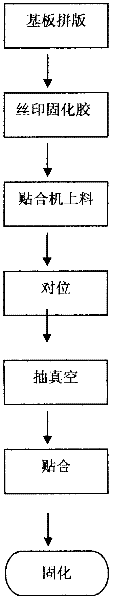

Water gel gluing process for capacitive touch screen

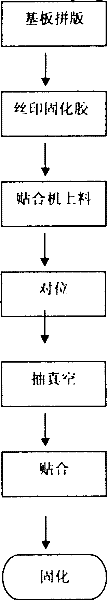

InactiveCN102649339ASolve production efficiency problemsDevelopment promotionLamination ancillary operationsLaminationAdhesiveEngineering

The invention discloses a water gel gluing process for a capacitive touch screen, which is characterized in that the water gel gluing process for the capacitive touch screen is as follows: base plate make-up, screen printing curing adhesive, loading of a laminating machine, counterpointing, vacuum-pumping, gluing, and solidifying. The invention discloses a brand-new gluing process for a capacitor screen, the problems in production efficiency of capacitor panel companies can be solved greatly, a great promoting effect is played to industrial development, and practical significance is achieved.

Owner:SHENZHEN YANGTZE LIVETECH

Flexible production line operation method and system

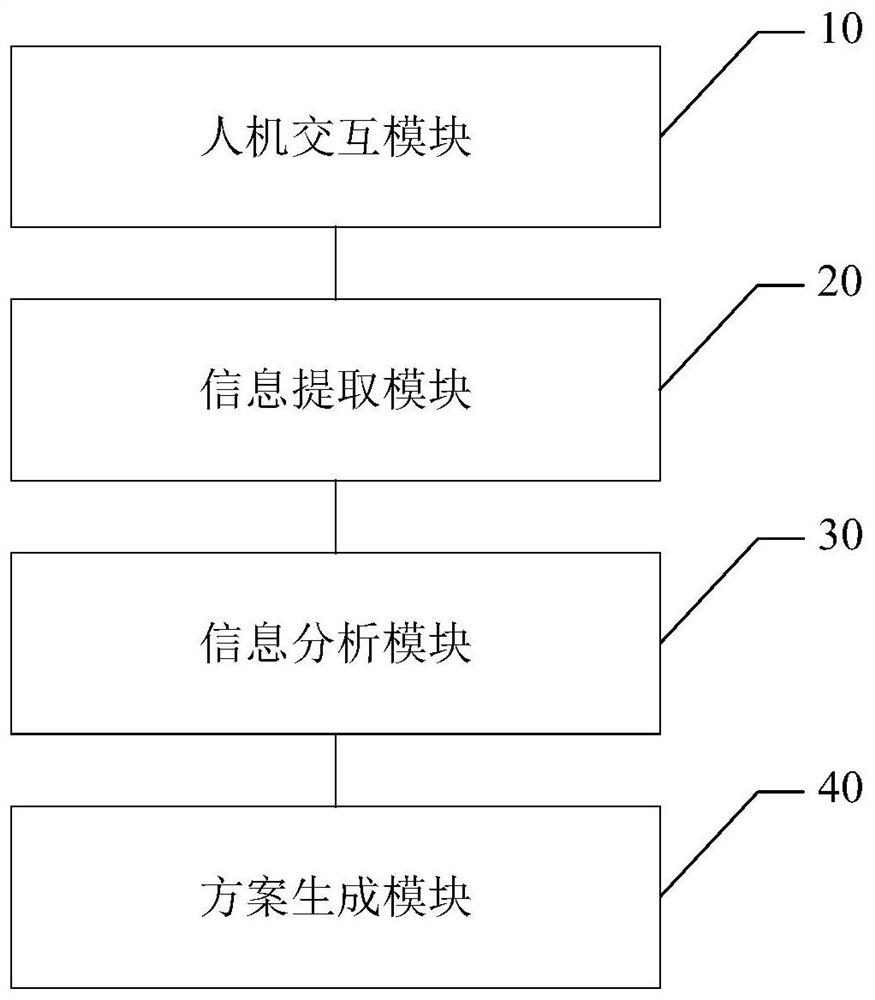

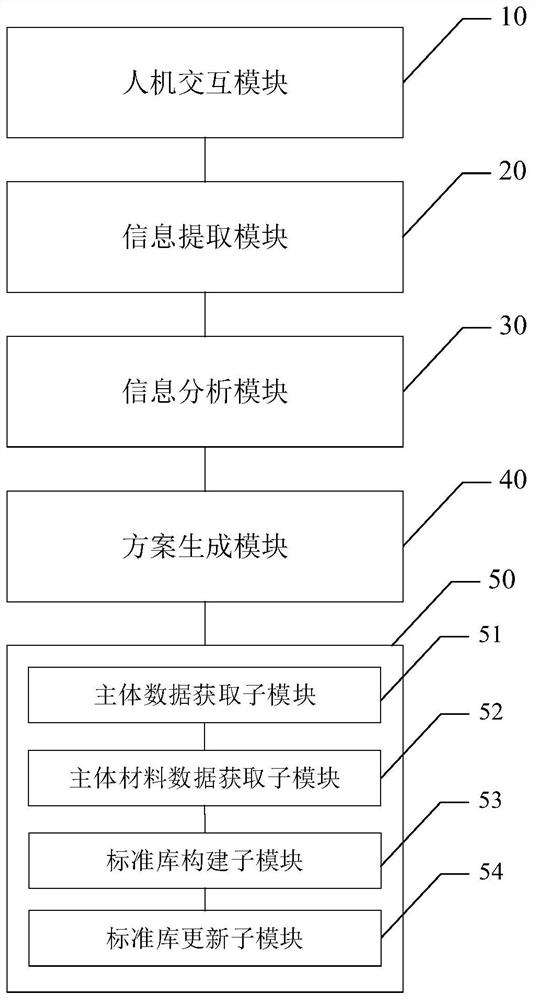

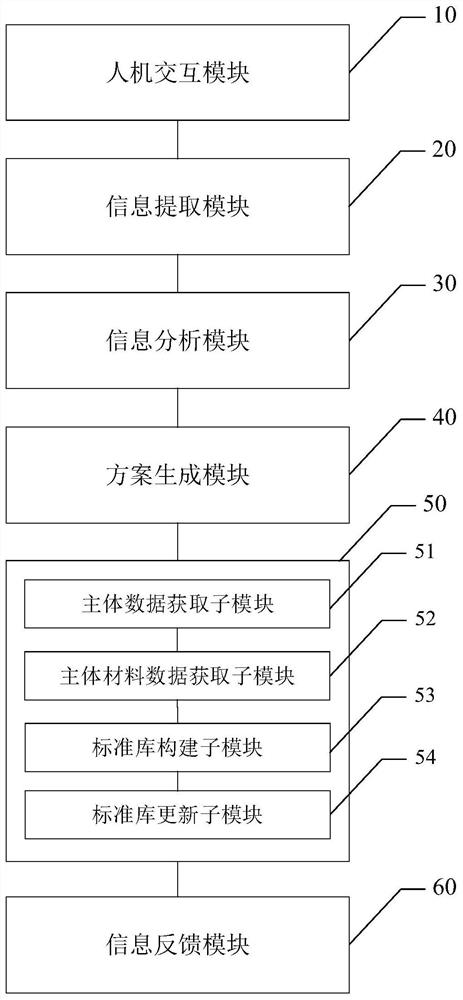

PendingCN111738676AImprove experienceRapid productionOffice automationManufacturing computing systemsUser needsInformation analysis

The invention discloses a flexible production line operation method and system, and the system comprises: a man-machine interaction module which is used for obtaining a production request of a user; an information extraction module which is used for acquiring image data of the target object according to the production request and extracting attribute information and material parameter informationof the target object from the production request; an information analysis module which is used for analyzing main body connection information of the target object according to the image data and the attribute information; and a scheme generation module which is used for obtaining a material and a connection scheme corresponding to the target object from a preset standard library according to the material parameter information and the main body connection information. Through implementation of the invention, the influence caused by manual operation can be avoided to the maximum extent, the production transformation scheme suitable for user requirements can be quickly, conveniently and efficiently generated for the user to select, the problems of low production efficiency and low quality caused by manual participation in an existing production process can be solved, and meanwhile better use experience can be brought to the user.

Owner:TIANJIN MASITE BODYWORK EQUIP TECH CO LTD

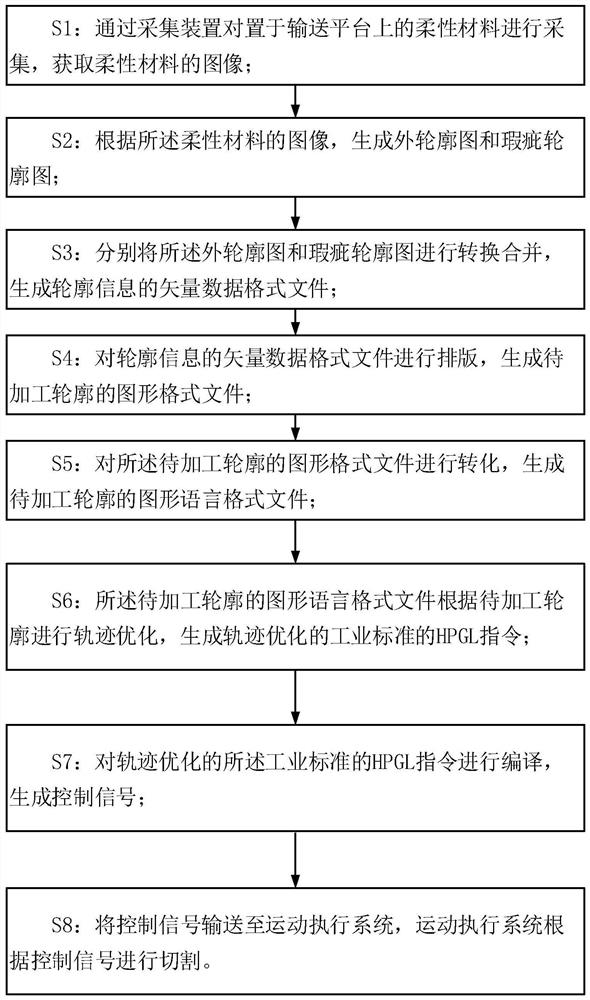

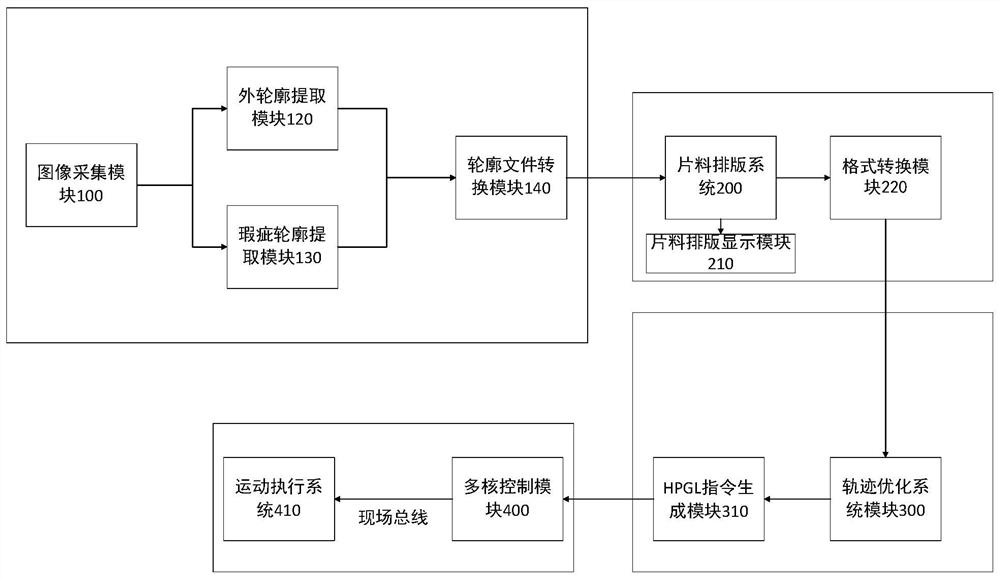

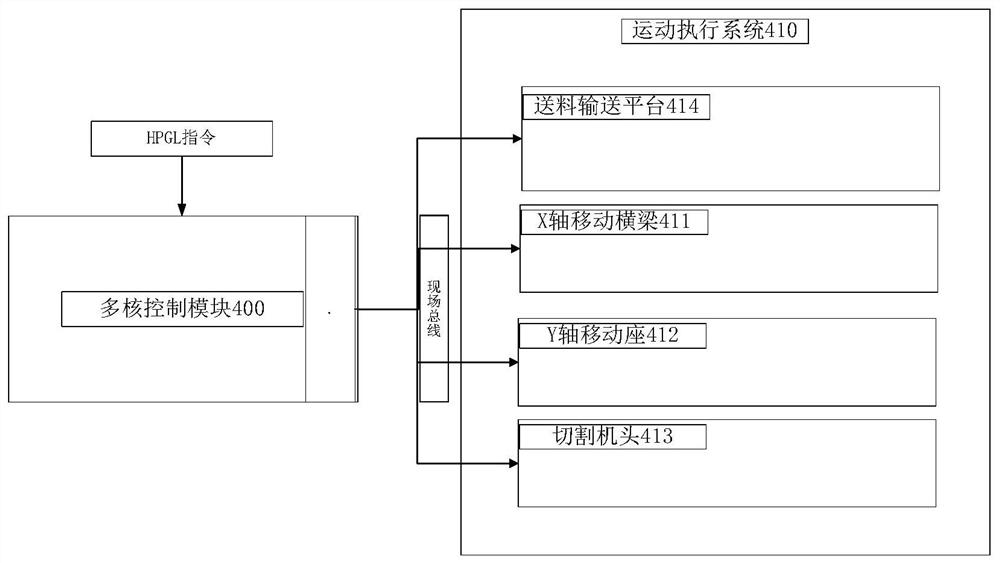

Intelligent continuous processing control method and equipment for flexible material

ActiveCN111950230ASolve production efficiencyProgramme controlImage enhancementControl signalEngineering

According to an intelligent continuous processing control method and equipment for a flexible material provided by the invention, the method comprises the steps of generating an outer contour map anda defect contour map through the collected images of the flexible material, and converting and combining the outer contour map and the defect contour map; generating a vector data format file of the contour information, carrying out typesetting according to the outer contour and the defect contour of the vector data format file of the contour information, generating a graphic format file of the to-be-processed contour, converting the graphic format file into a graphic language format file of the to-be-processed contour, and carrying out trajectory optimization to generate an industrial standard HPGL instruction; compiling the industrial standard HPGL instruction to generate a control signal, and sending the control signal to the motion execution system, wherein the motion execution systemperforms cutting according to the control signal. The technical problems that in the prior art, in the flexible material machining process, the file compatibility between equipment of all manufacturers is poor, the production process is discontinuous, and consequently the production efficiency and precision of the flexible material are reduced are solved.

Owner:GUANGDONG UNIV OF TECH

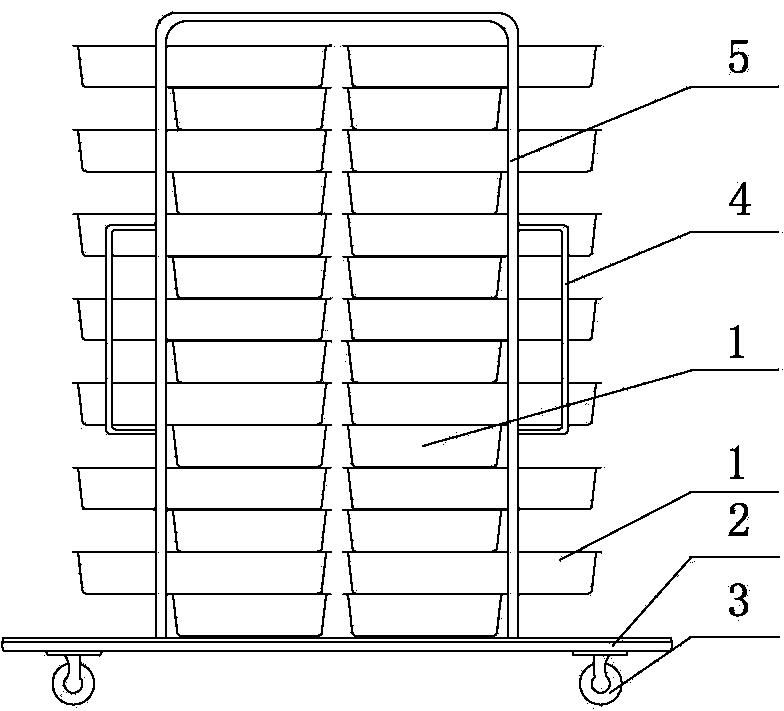

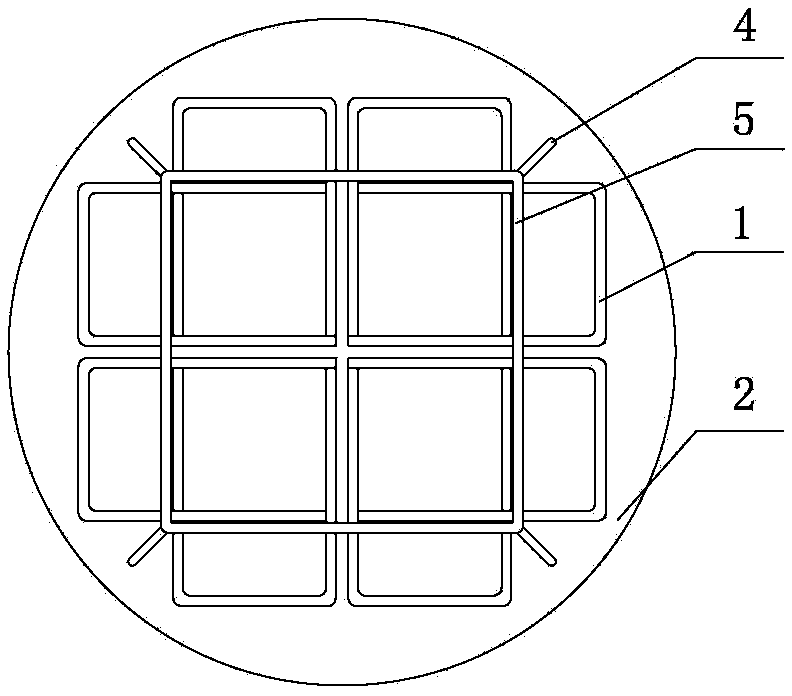

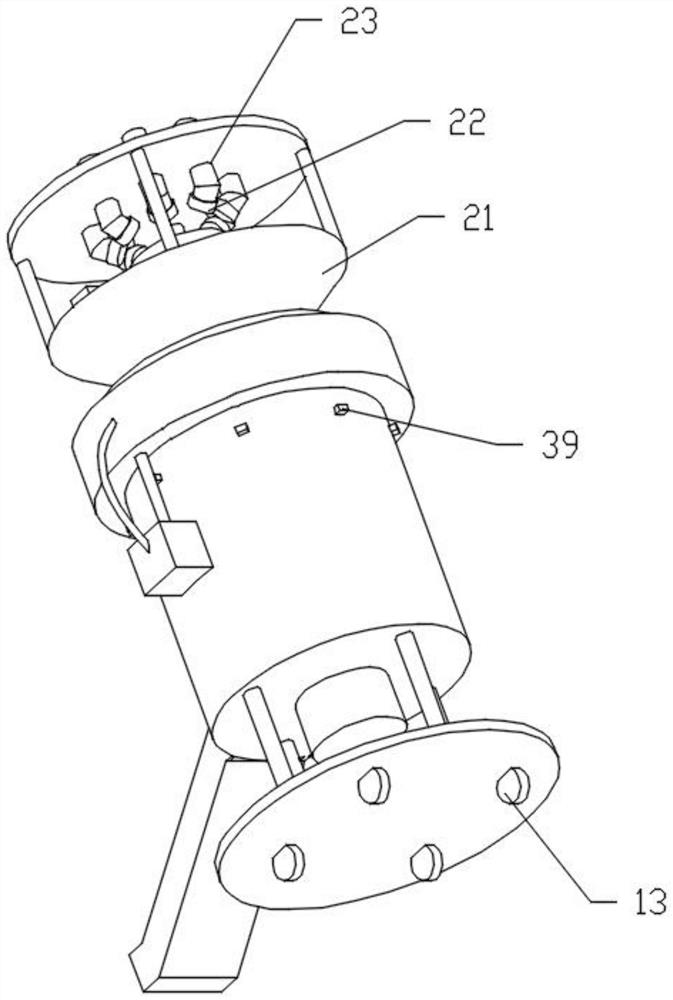

Maggot breeding car

InactiveCN103918616AUniform growthResolve technical issues that pile upAnimal husbandryMaggotInvertebrate

The invention belongs to invertebrate breeding devices, and relates to a maggot breeding car which is used for breeding and producing maggots. According to the technical scheme, at least two layers of breeding tools are installed on a frame body, openings are formed in the upper portions of the breeding tools, some breeding tools are arranged inside the frame body, the other breeding tools are arranged outside the frame body, the upper opening portions, located outside the frame body, of the two adjacent layers of breeding tools are perpendicular to each other, the bottom faces inside the breeding tools are inclined backwards and downwards by 10 degrees to 20 degrees, the breeding tools are internally provided with rotating shafts with screw blades, positioning inserts are arranged on the frame body so as to control the positions of the breeding tools, and the frame body is provided with wheels. Therefore, the technical problems that according to an existing fly maggot multilayer breeding device, adjacent upper and lower breeding boxes are stacked, observation of material charging and turning is troublesome, production management is inconvenient, the breeding boxes fixedly arranged inside a frame is hard to clean, the bred maggots need to be moved and poured repeatedly, the labor cost is high, and production efficiency is low are solved.

Owner:青岛中医秘方研究院

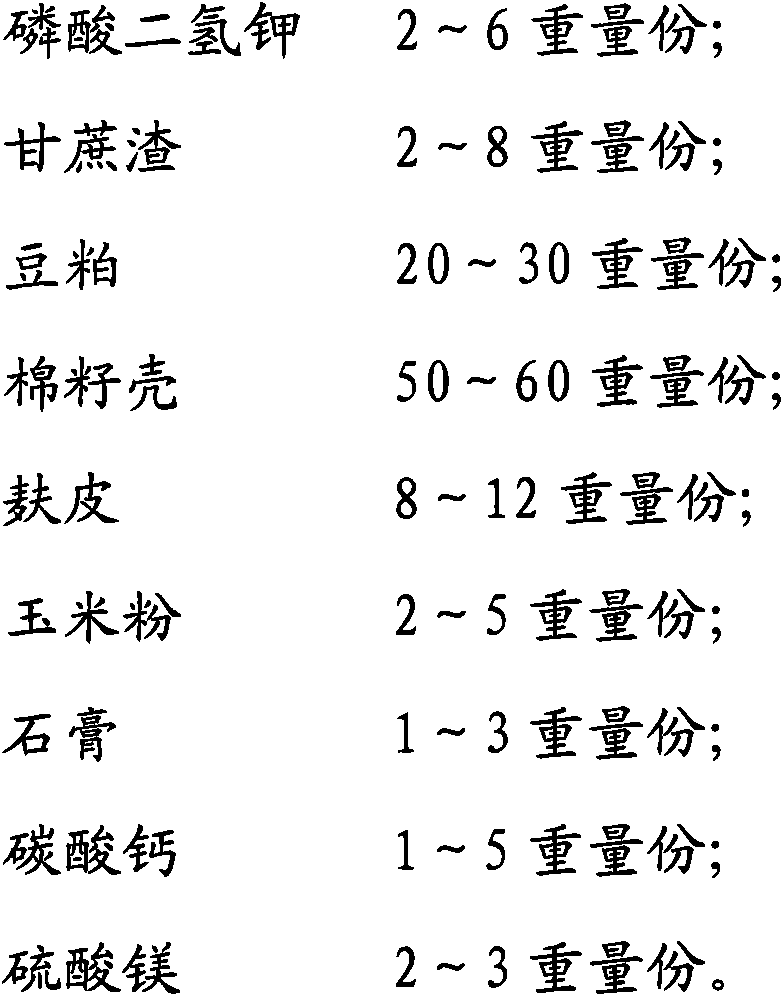

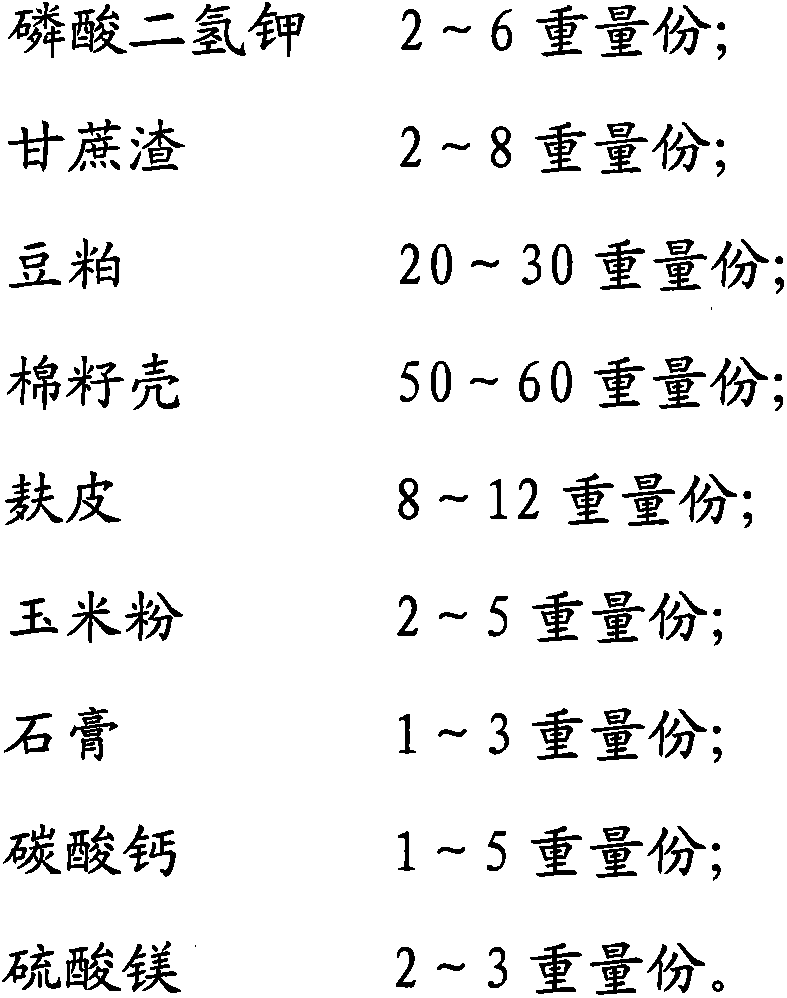

Coprinus comatus culture medium and preparation method thereof

The invention relates to a coprinus comatus culture medium and a preparation method thereof, belonging to the technical field of edible fungus production. The coprinus comatus culture medium aims to solve the following problems: the growth rate of the coprinus comatus in the existing culture medium for producing coprinus comatus is low, and the next collection can be performed only 45 days after the first collection, thereby influencing the production efficiency and income of the mushroom grower. The technical scheme is as follows: the coprinus comatus culture medium is composed of the following raw materials in parts by weight: 2-6 (preferably 3-5) parts of potassium dihydrogen phosphate, 2-8 (preferably 6) parts of bagasse, 20-30 (preferably 22-25) parts of bean pulp, 50-60 (more preferably 52-56) parts of cottonseed hull, 8-12 (more preferably 10) parts of bran coat, 2-5 parts of corn flour, 1-3 parts of gypsum, 1-5 parts of calcium carbonate and 2-3 parts of magnesium sulfate.

Owner:吴迪

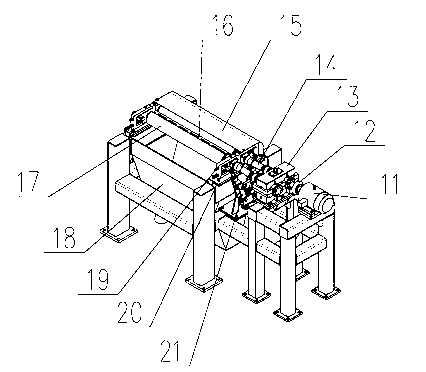

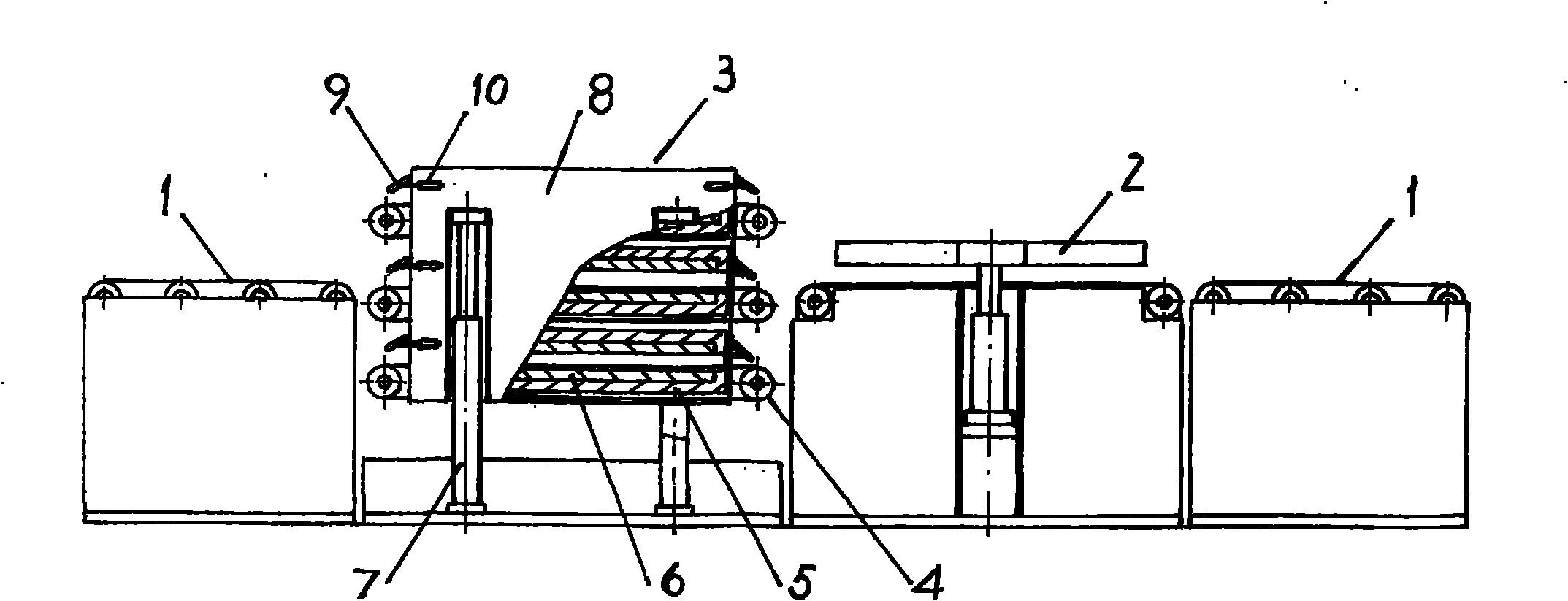

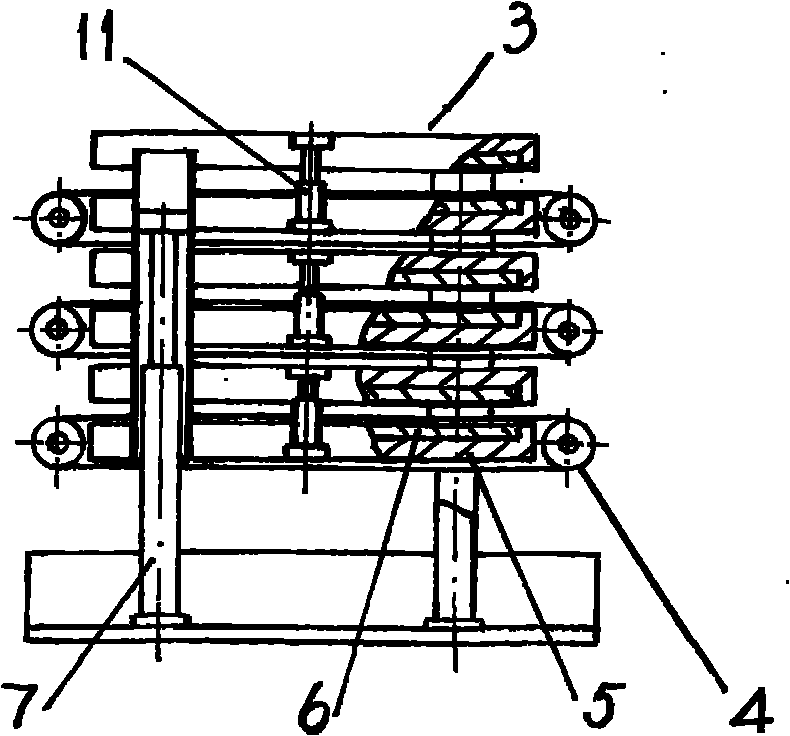

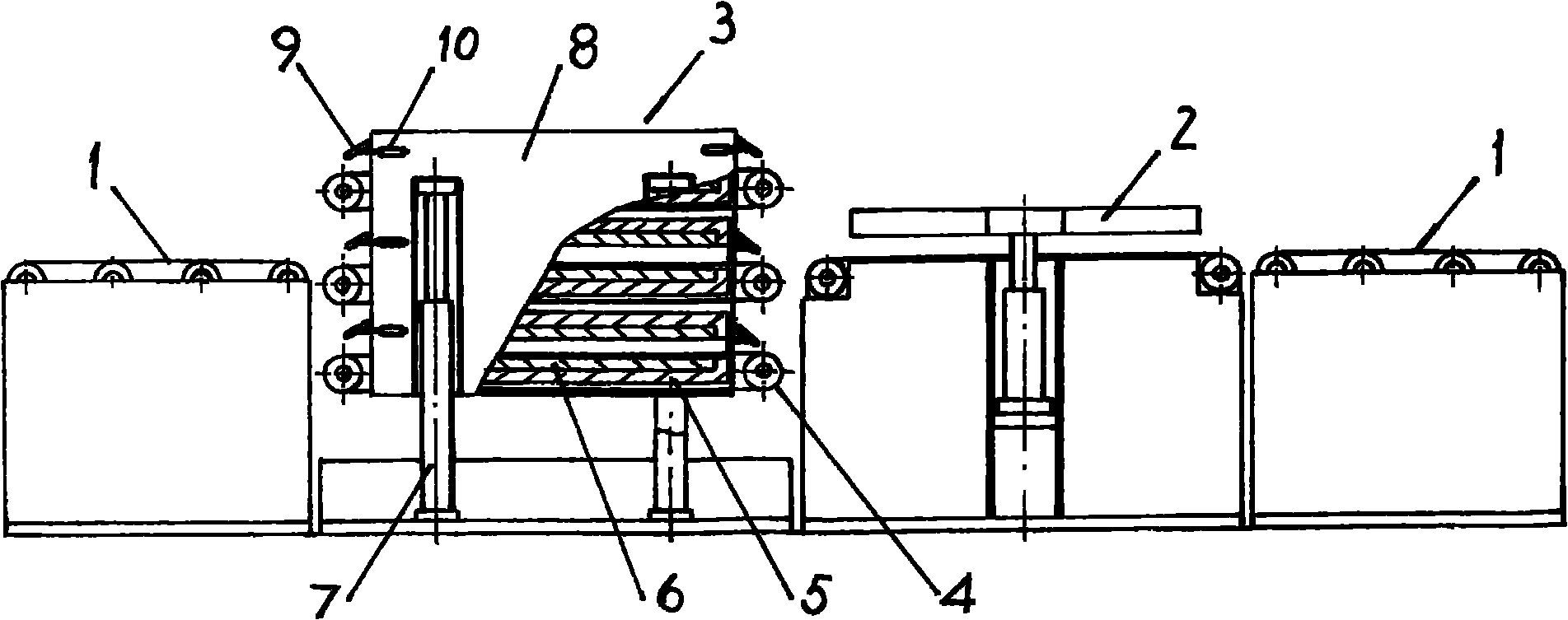

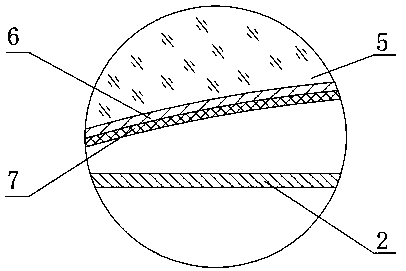

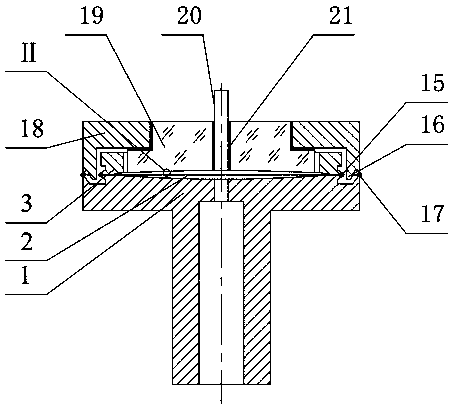

Laminated curing equipment of solar-cell panel

InactiveCN102059843AHeating evenlyGuarantee product qualityLamination ancillary operationsLaminationProduction lineEngineering

The invention discloses laminated curing equipment of a solar-cell panel, comprising conveying worktables which are respectively arranged at the front part and the rear part of the laminated curing equipment and a laminating machine jointed with the front conveying worktable, wherein a laminated curing furnace is joined behind the laminating machine; two groups of heating and curing units comprising a conveying mechanism, an upper heat-insulating casing, a lower heat-insulating casing and a heating plate arranged on the inner side of the heat-insulating casing are at least laminated on the laminated curing furnace; and curing furnace lifting oil cylinders are symmetrically arranged on two sides of the laminated curing furnace. According to the invention, by matching the laminated curing furnace with the laminating machine, the laminating step and the curing step are sequentially joined on the same production line and are mutually matched, the problem that the improvement on the production efficiency of the production line of the solar-cell panel is limited because the curing time is longer than the laminating time is solved, and the production efficiency of the production equipment of the solar-cell panel can be improved. Meanwhile, by adopting a curing furnace structure in which the solar-cell panel is heated by the heating plate, the solar-cell panel is uniformly heated and thereby the quality of the solar-cell panel products can be ensured.

Owner:张云峰

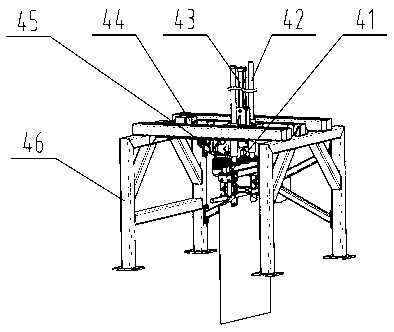

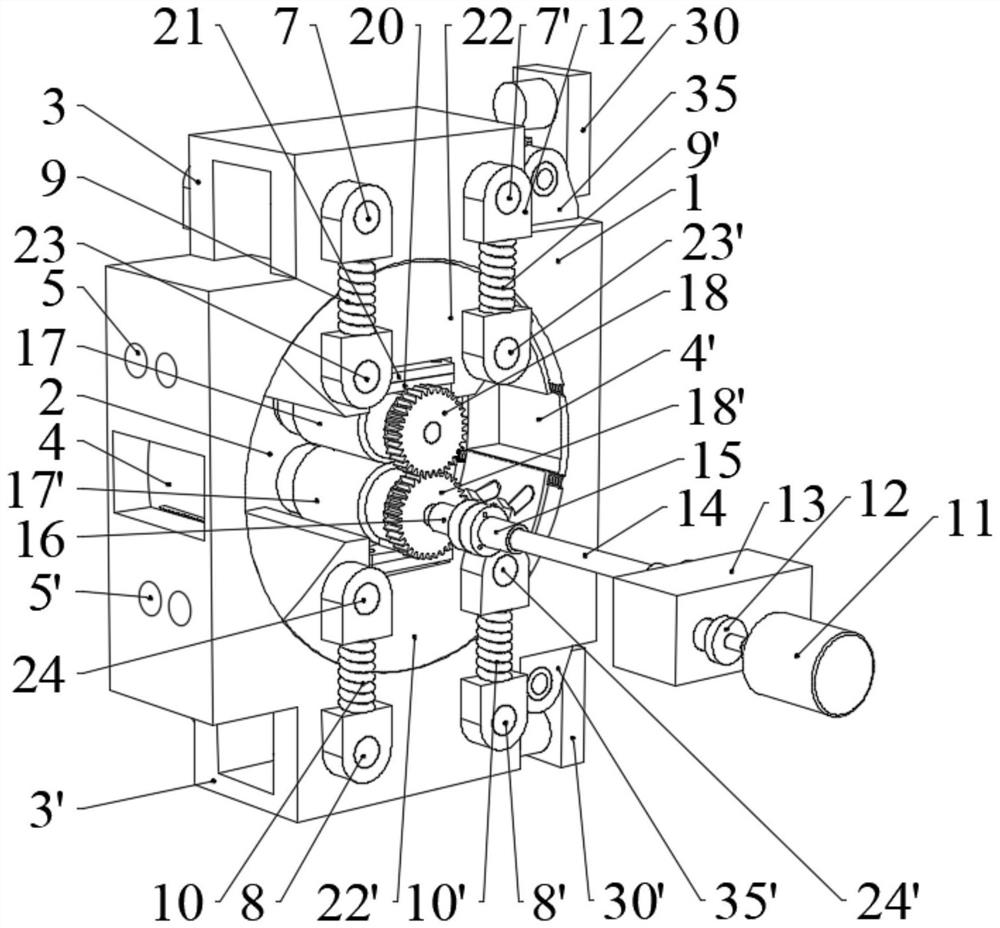

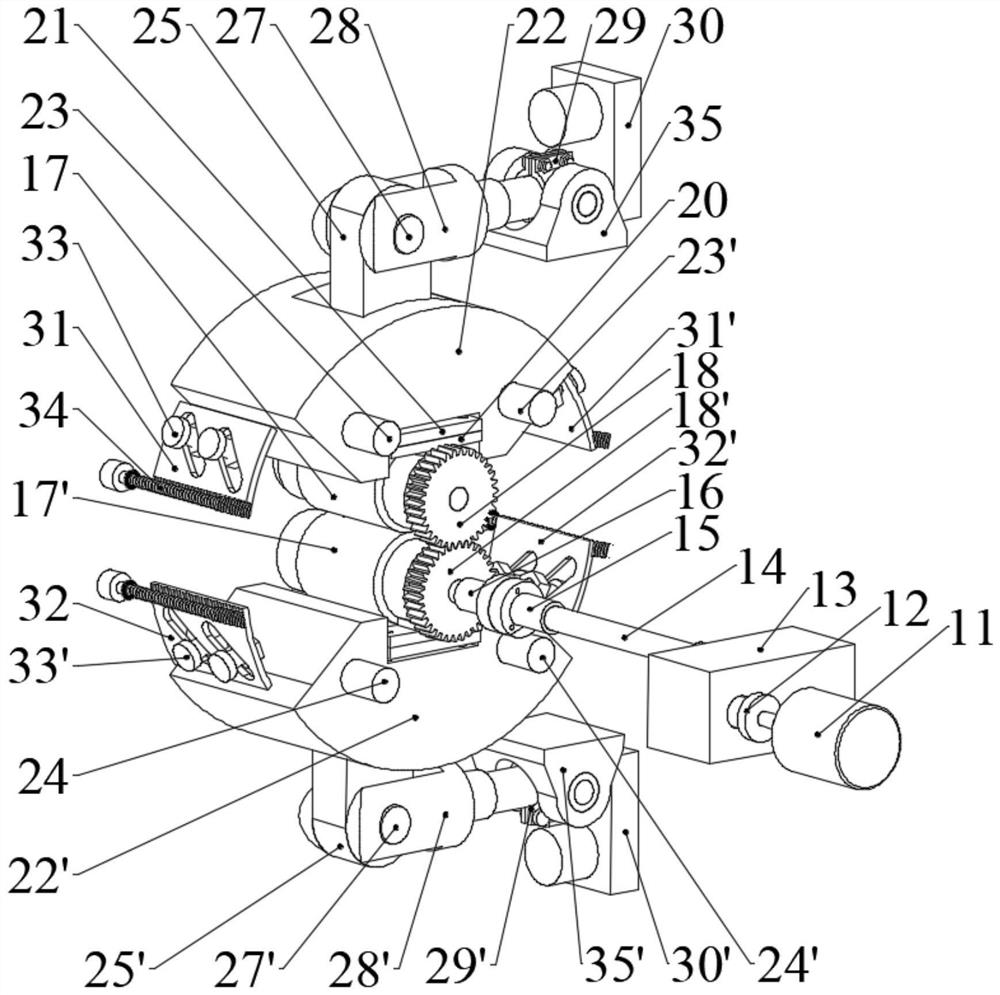

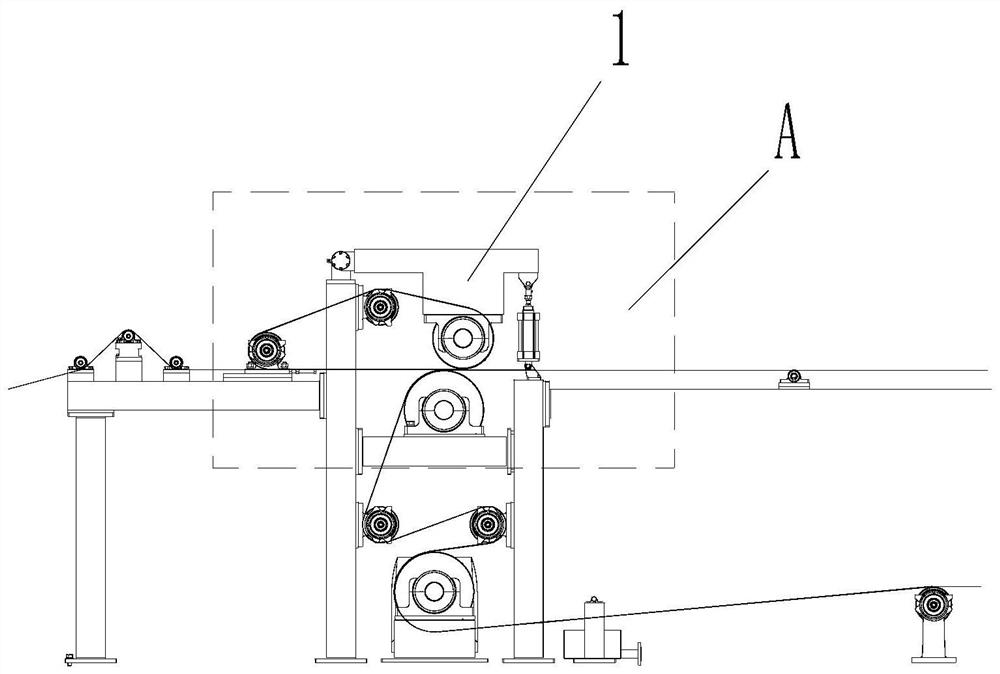

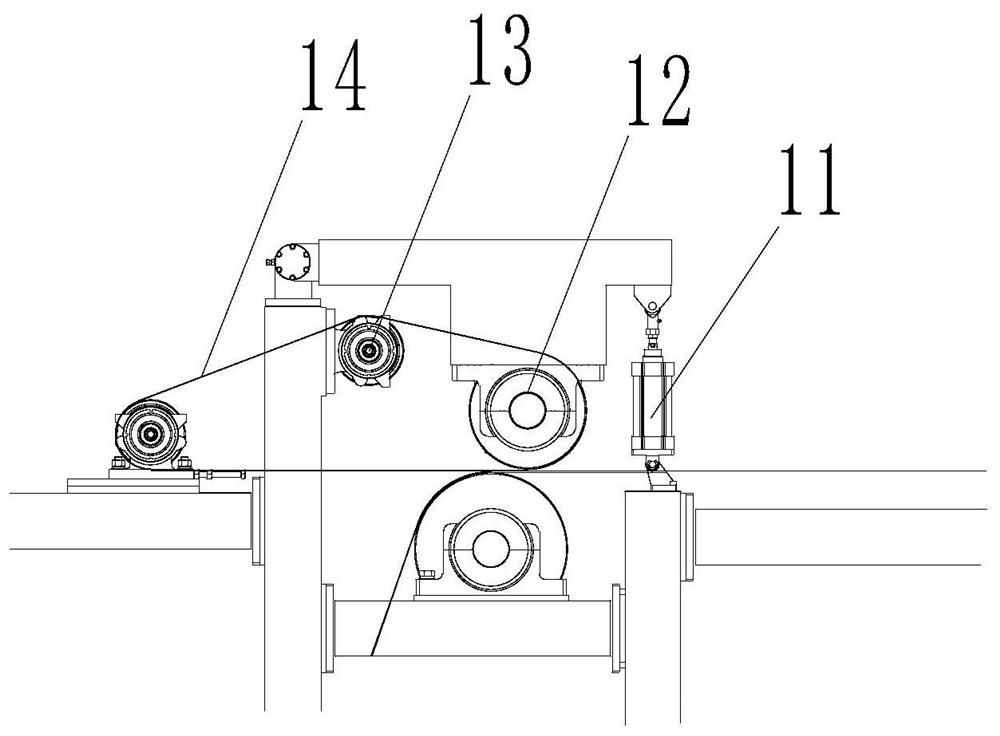

Special metal pole plate rolling machine

ActiveCN112547799ASolve production efficiencyLow costMetal rolling stand detailsRolling equipment maintainenceCouplingEngineering

The invention discloses a special metal pole plate rolling machine, and belongs to the technical field of metal pole plate manufacturing. A machine body is a square body with a circular through hole in the middle, and an upper press roll and a lower press roll are mounted in the circular through hole, are mounted in grooves of an upper fan-shaped rotating body and a lower fan-shaped rotating bodythrough bearing seats, are respectively connected with an upper rotating block and a lower rotating block which are symmetrically arranged, and are respectively connected with an upper servo electriccylinder and a lower servo electric cylinder through connecting rod mechanisms. The upper press roll and the lower press roll are finely adjusted. Four identical arc-shaped plates are mounted on the inner surface of the circular through hole and used for positioning the upper rotating block and the lower rotating block. A main transmission drives the lower press roll to rotate by a servo motor through a safety coupling, a reduction gearbox and a cross coupling. The machine has the advantages that the defects in the prior art are overcome, continuous processing and production can be achieved, the cost is lower, and the product quality is good.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

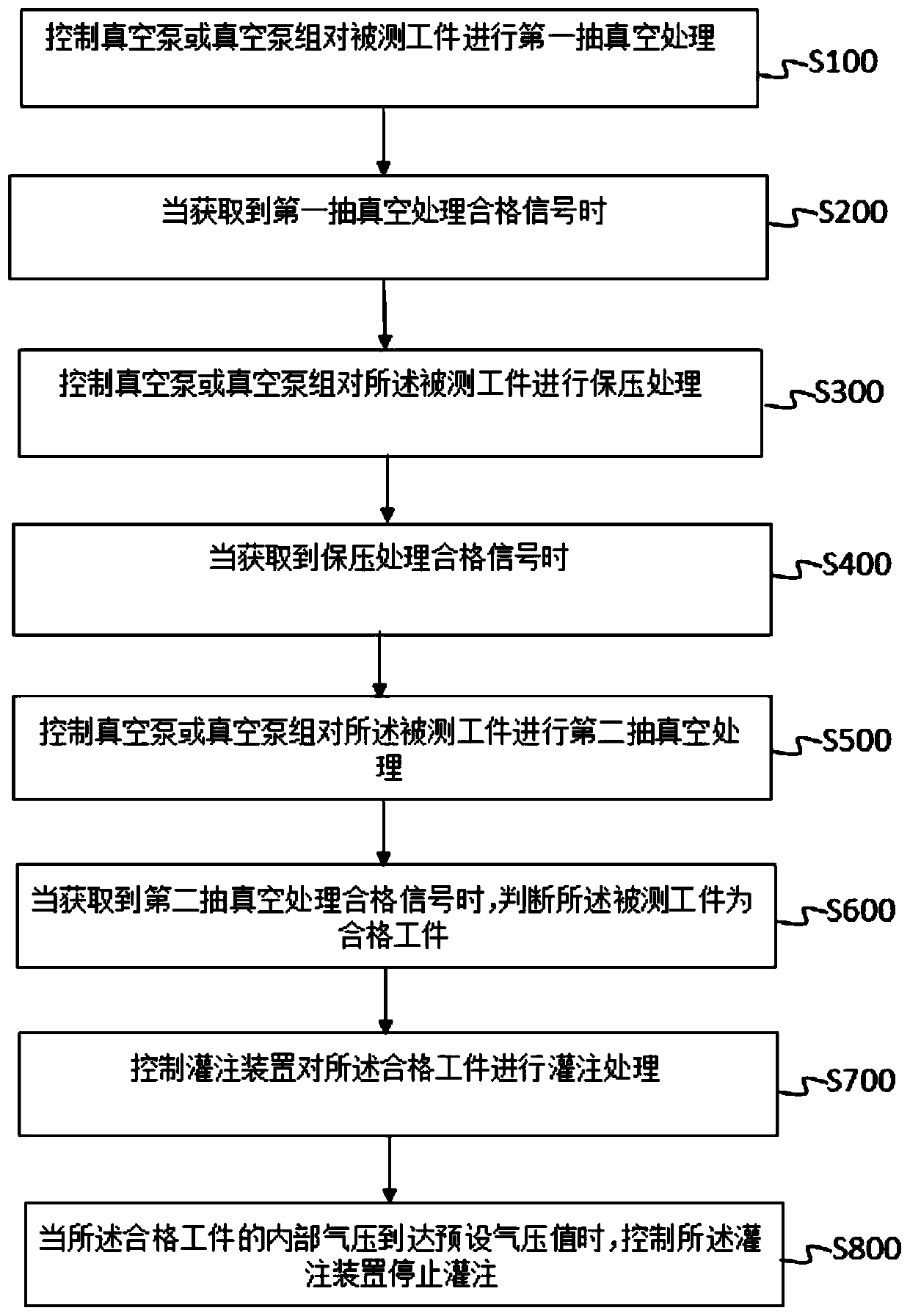

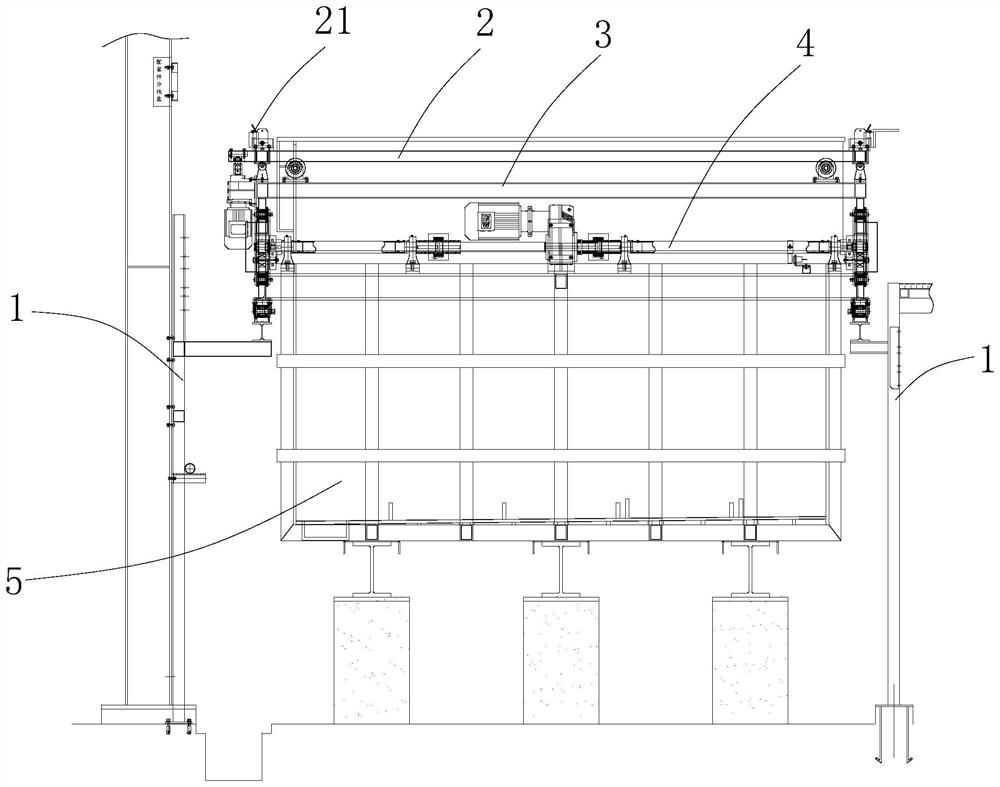

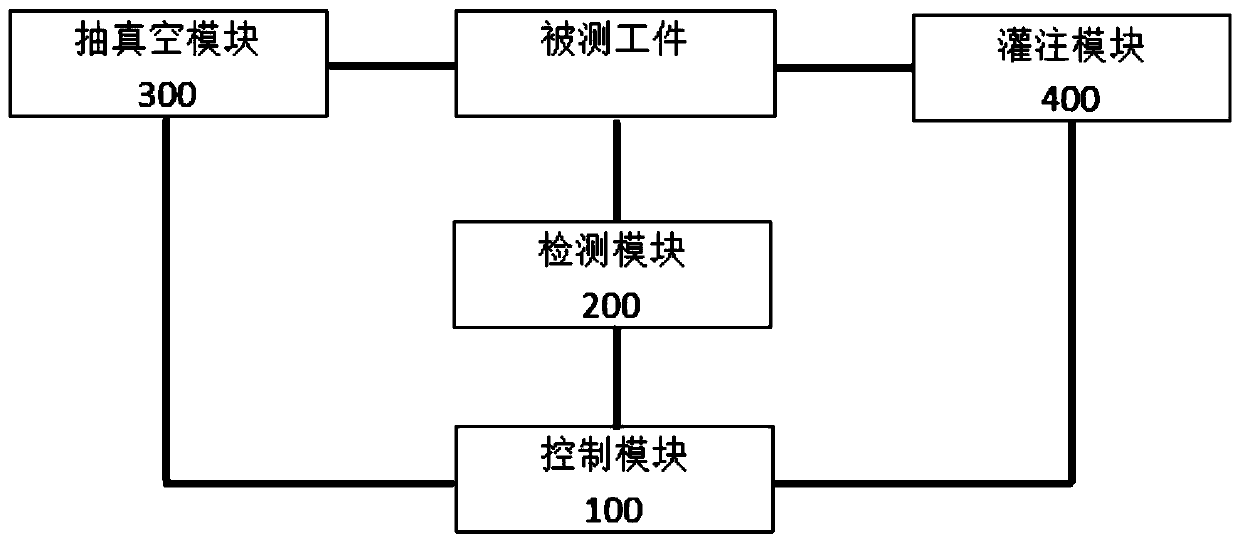

Integrated control method for vacuum detection and filling of workpiece

ActiveCN109733667AImprove accuracyEfficient and accurate process switchingVacuum gaugesPackaging automatic controlAutomatic controlIndustrial engineering

Owner:广州市真量纯科技有限公司

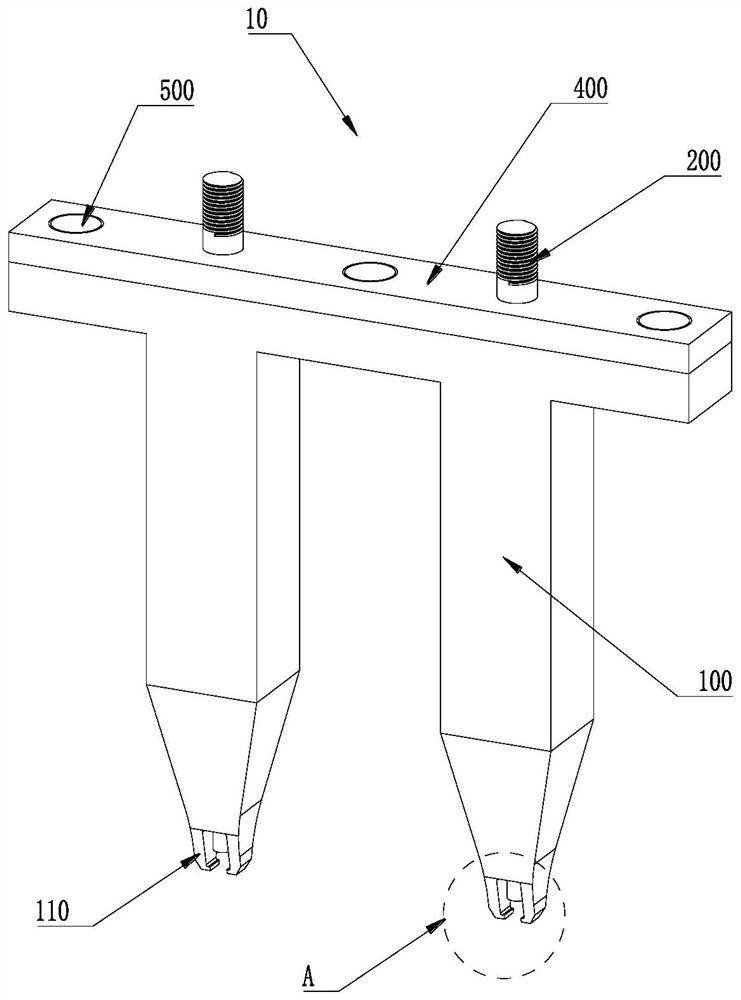

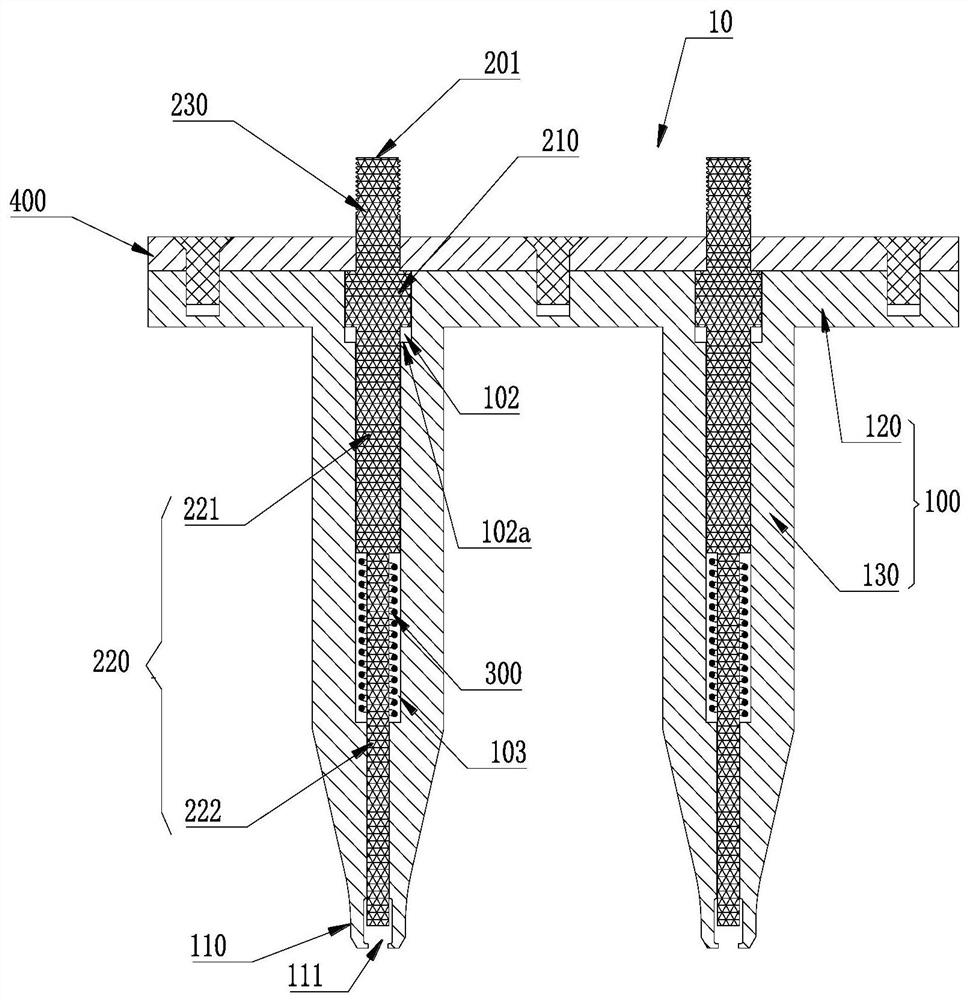

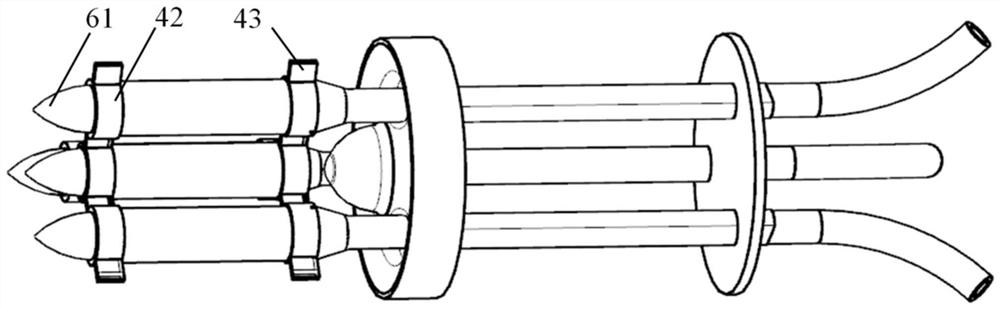

Assembling equipment

InactiveCN113399983ASolve production efficiencyAddress reliabilityMetal working apparatusEngineeringMechanical engineering

The embodiment of the invention provides assembling equipment. The assembling equipment comprises a main body mechanism and a pushing piece. A penetrating hole is formed in the main body mechanism, the main body mechanism is provided with a clamping end, the clamping end is provided with a clamping space used for clamping a target element, and the clamping space communicates with the penetrating hole; and one end of the pushing piece is a connecting end used for being connected with a driving mechanism, the other end of the pushing piece is a pushing end, and the pushing piece penetrates through the penetrating hole in a sliding manner, wherein the connecting end is exposed out of one end of the penetrating hole, the pushing end penetrates out of the other end of the penetrating hole and is located in the clamping space, and the pushing end is used for abutting against the target element. According to the assembling equipment, the clamping space of the clamping end is matched with the pushing end of the pushing piece to press a coaxial connector male head, so that the coaxial connector male head is stably clamped, the coaxial connector male head cannot deviate, accurate connection of the coaxial connector male head and a coaxial connector female head is ensured, the assembly production of a coaxial connector is automatic, and the production efficiency and the assembly reliability are improved.

Owner:合肥移瑞通信技术有限公司

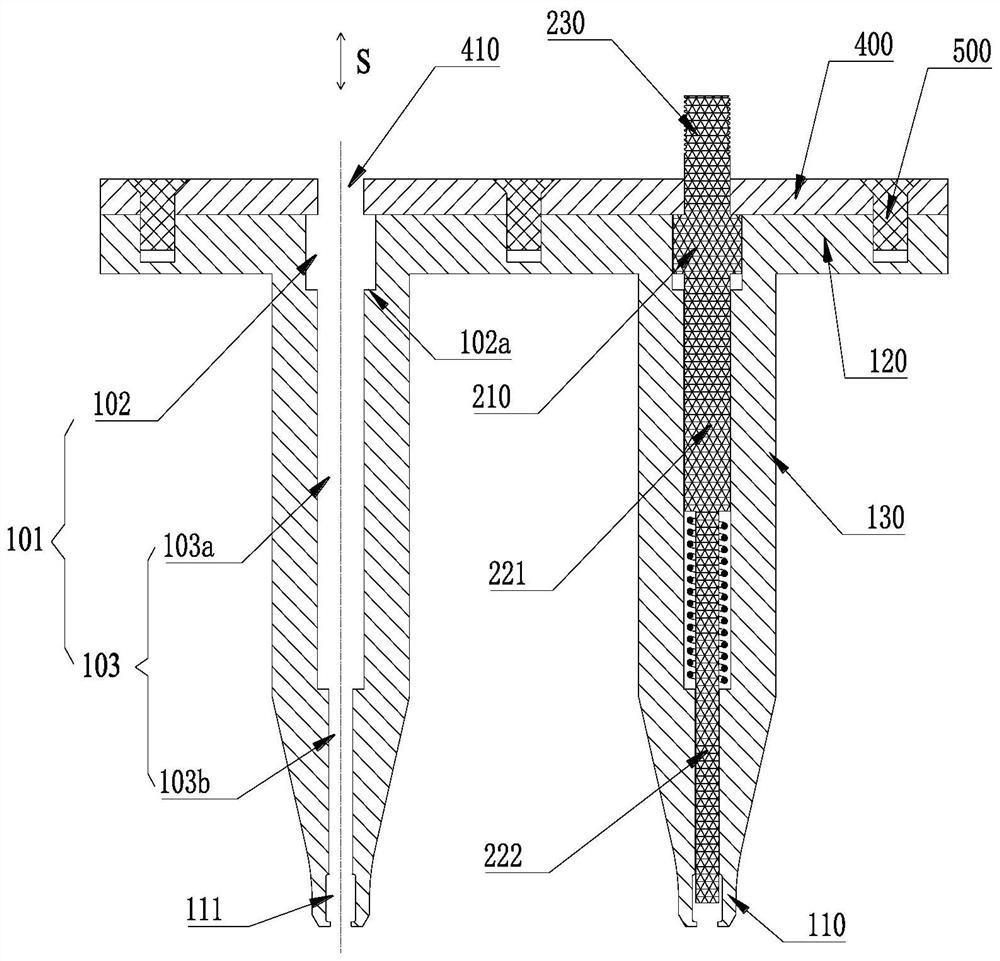

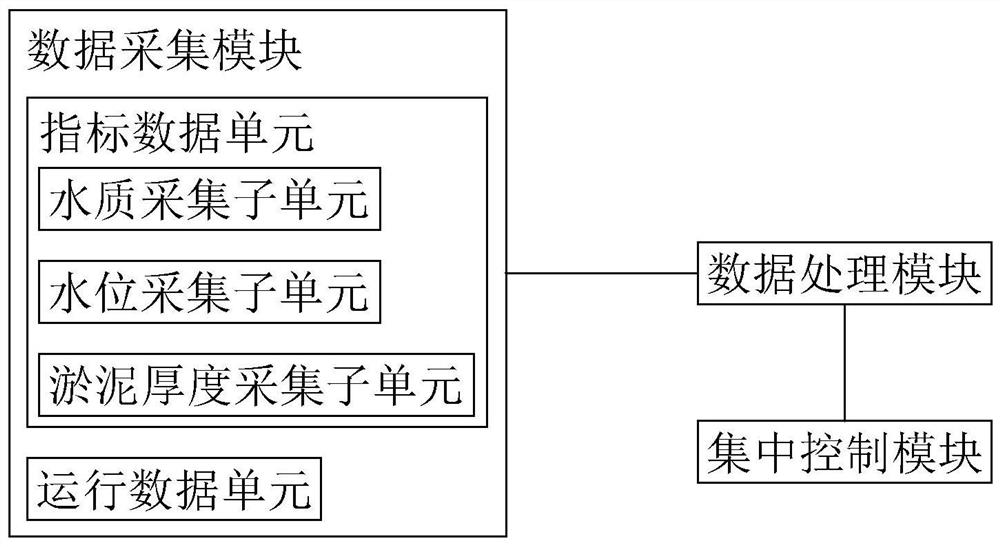

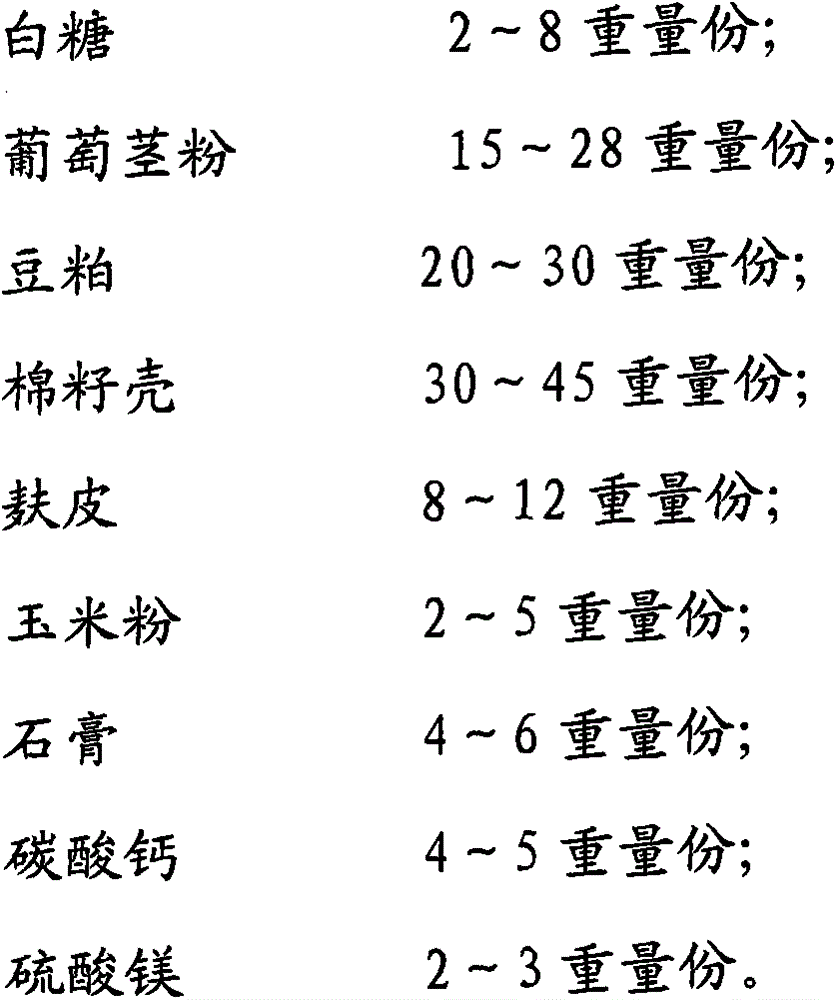

Sewage treatment remote monitoring system and method thereof

InactiveCN112631221AGuaranteed uptimeCurb excess emissionsTesting waterTotal factory controlControl signalData acquisition

The invention relates to a sewage treatment remote monitoring system and a sewage treatment remote monitoring method. The monitoring system comprises a data acquisition module, a data processing module and a centralized control module, wherein the data acquisition module is used for acquiring index parameters of each production index in sewage treatment; the data processing module is connected with the data acquisition module and is used for receiving the index parameters, comparing each index parameter with a corresponding preset index value, and if one index parameter is abnormal, outputting a control signal corresponding to the abnormal index parameter according to a preset abnormal relationship library; and the centralized control module is connected with the data processing module and is used for receiving the control signal and controlling an execution unit of the corresponding equipment to act according to the control signal. When the index parameters are abnormal, the corresponding control signal is output according to the abnormal relation library, so the corresponding equipment is controlled to operate according to the control signal, the abnormality is handled in time, the normal operation of the sewage treatment plant is ensured, and the excessive sewage discharge is effectively restrained through remote monitoring.

Owner:SICHUAN LYUSHUI ENVIRONMENTAL PROTECTION ENG

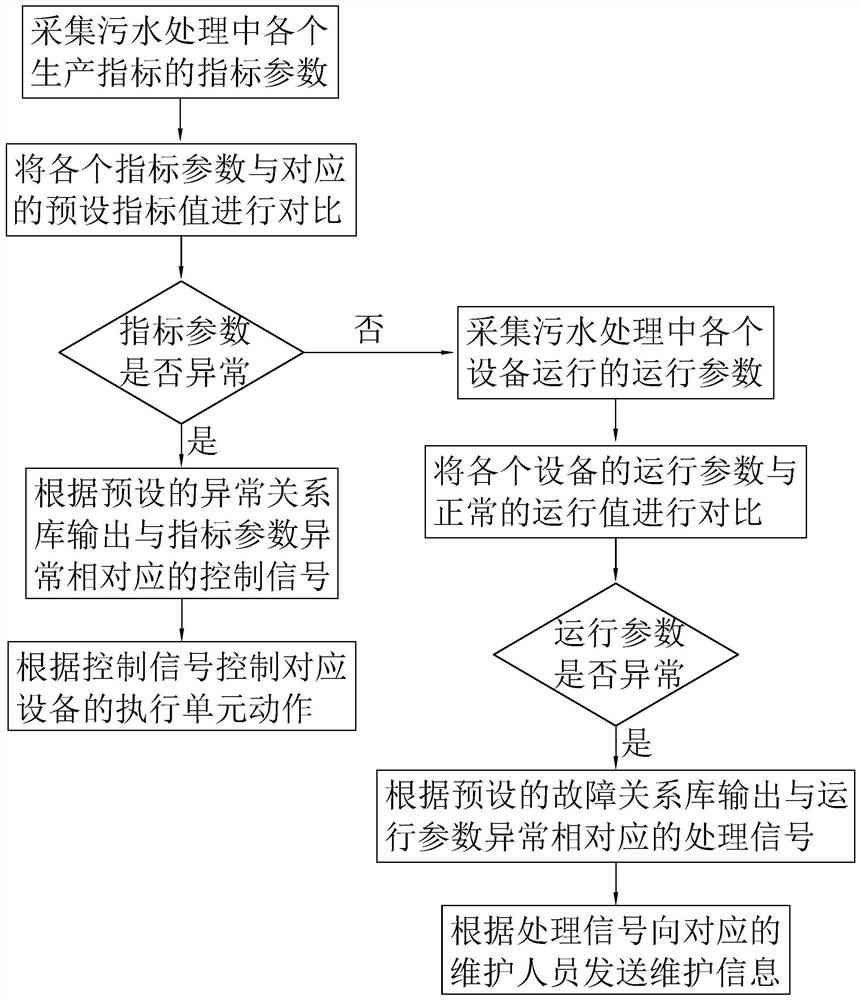

Agrocybe aegerita culture base material and preparation method thereof

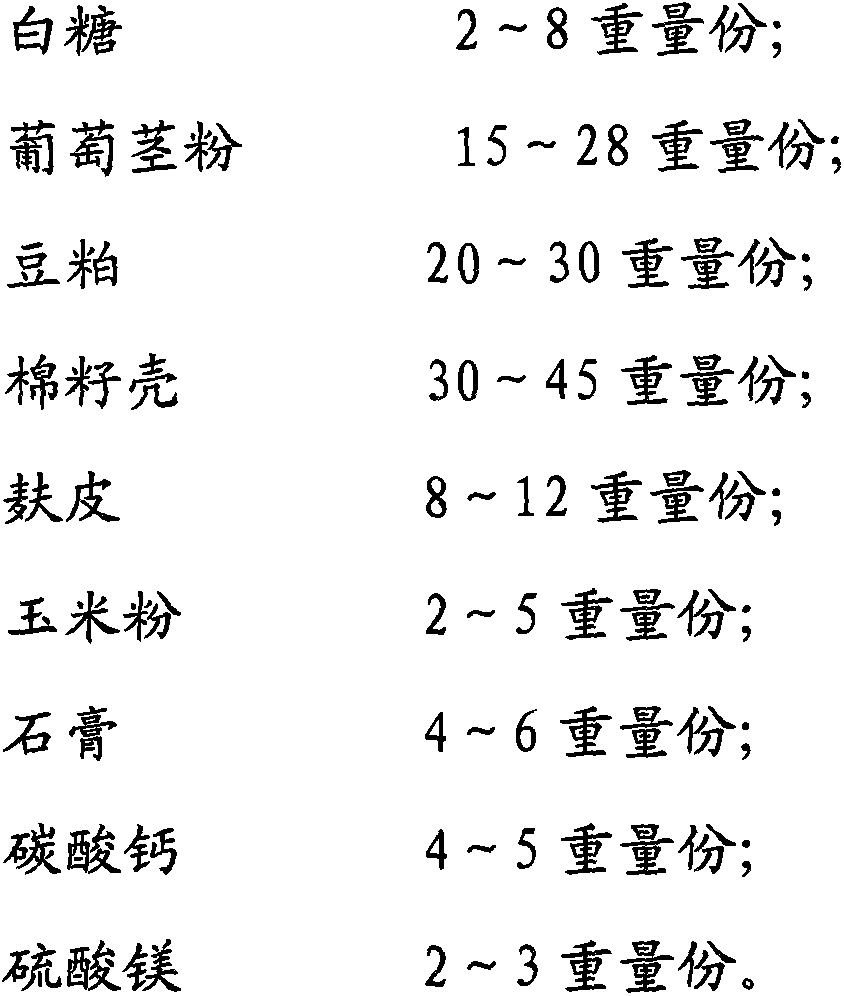

The invention relates to an agrocybe aegerita culture base material and a preparation method thereof, which relate to the technical field of edible fungus production, and solve the problems of the existing culture medium that agrocybe aegerita grows slowly, the yield is low, and the production efficiency and income of fungus farmers can be influenced. According to the technical scheme, the agrocybe aegerita culture base material consists of the following raw material components: 2 to 8 parts by weight of white sugar, 15 to 28 parts by weight of creeping stem powder, 20 to 30 parts by weight of soybean meal, 30 to 45 parts by weight of cottonseed hull, 8 to 12 parts by weight of wheat bran, 2 to 5 parts by weight of corn powder, 4 to 6 parts by weight of gypsum, 4 to 5 parts by weight of calcium carbonate and 2 to 3 parts by weight of magnesium sulfate. In a preferable solution, the agrocybe aegerita culture base material comprises 3 to 5 parts by weight of white sugar and 22 to 25 parts by weight of soybean meal. In a more preferable solution, the agrocybe aegerita culture base material comprises 32 to 40 parts by weight of cottonseed hull and 10 parts by weight of wheat bran.

Owner:吴迪

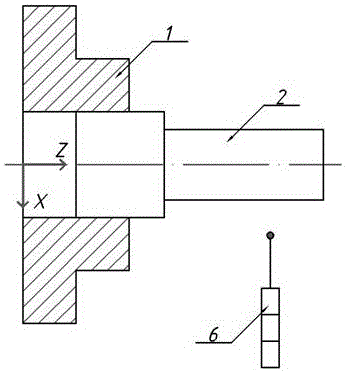

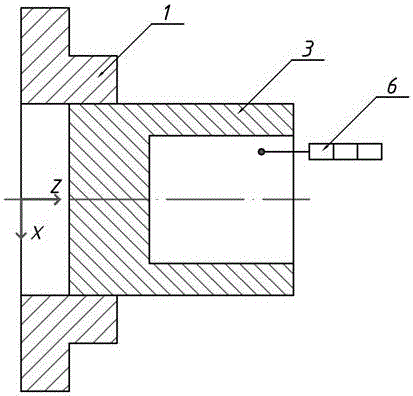

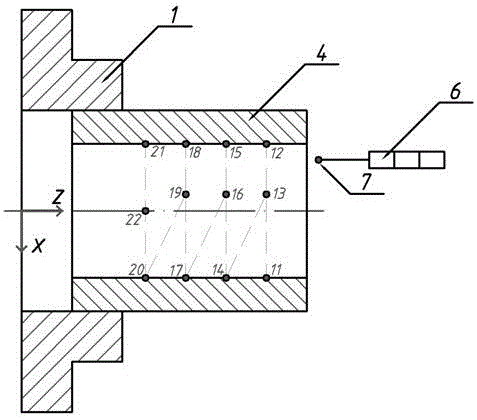

On-line detection system and detection method for machining accuracy of parts for CNC lathes

ActiveCN102785128BImprove the efficiency of machining accuracy detectionSimple and fast operationProgramme controlComputer controlCommunication interfaceMachine parts

The invention relates to an on-line detection system and detection method of machining accuracy of parts for a numerically controlled lathe. The detection system comprises a chuck, a workpiece and a lathe probe, wherein the workpiece is arranged on the chuck, and the lathe probe is arranged at the side of the workpiece; and a signal output terminal of the lathe probe is connected with a controller of the detection system. The detection method comprises the following steps that 1) the lathe probe is arranged at the side of the workpiece; 2) the lathe probe is calibrated; 3) the measuring path and code generation of geometrical parts and curved-surface parts are planned; and 4) the heat distortion temperature error compensation and machining error analysis of parts are carried out by the controller of the detection system. The parts do not need to leave the lathe after being machined, a touch probe is used for replacing a turning tool, and the detection path of the probe is automatically planned and the detection code is generated according to the geometric outline and detection items of the machined workpiece; and through a communication interface of the numerically controlled lathe, the detection code is driven, so that the automatic measurement of the size and precision of size and form of the machined part is realized, and the detection accuracy and efficiency of the workpiece are improved.

Owner:GUANGDONG UNIV OF TECH

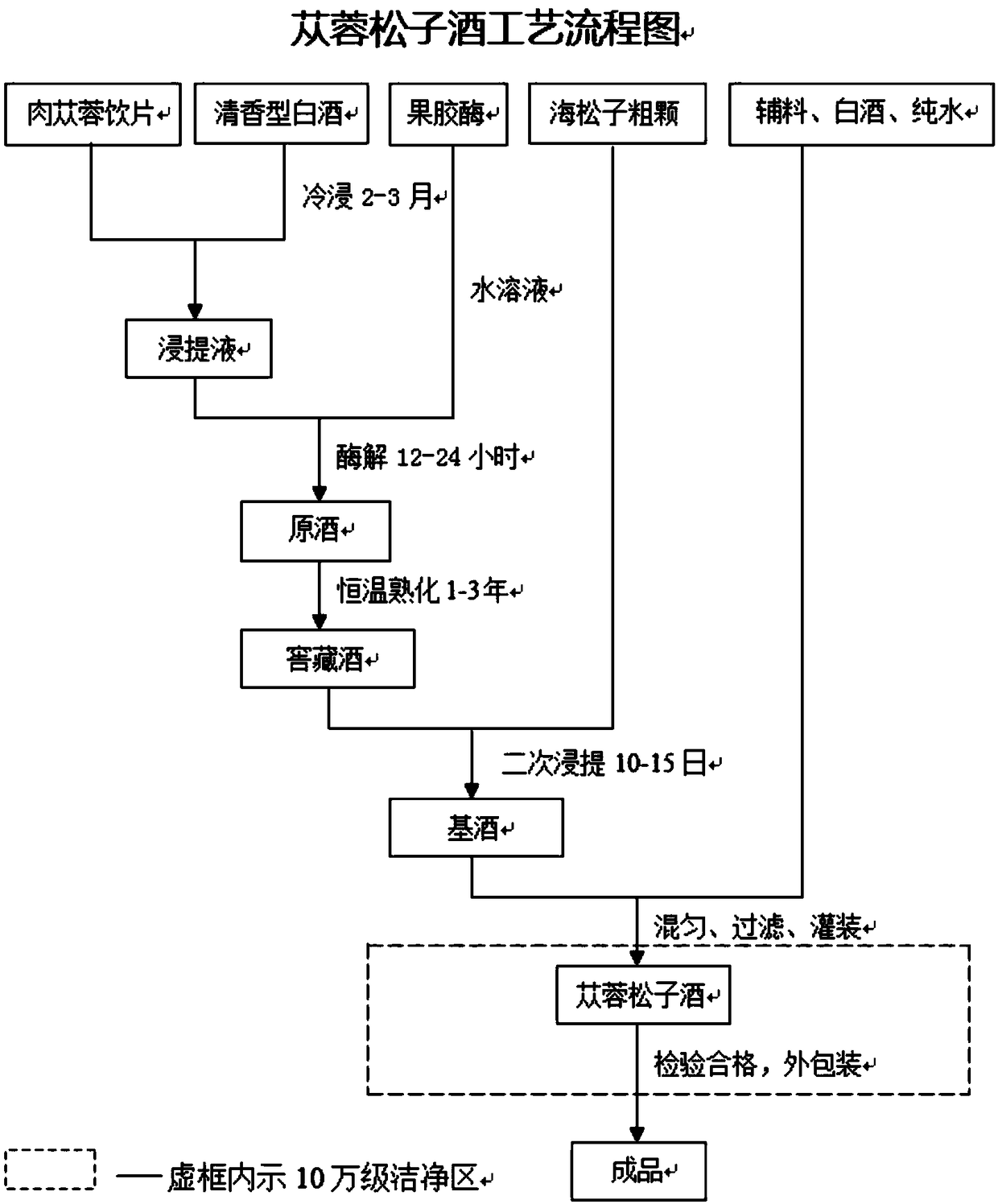

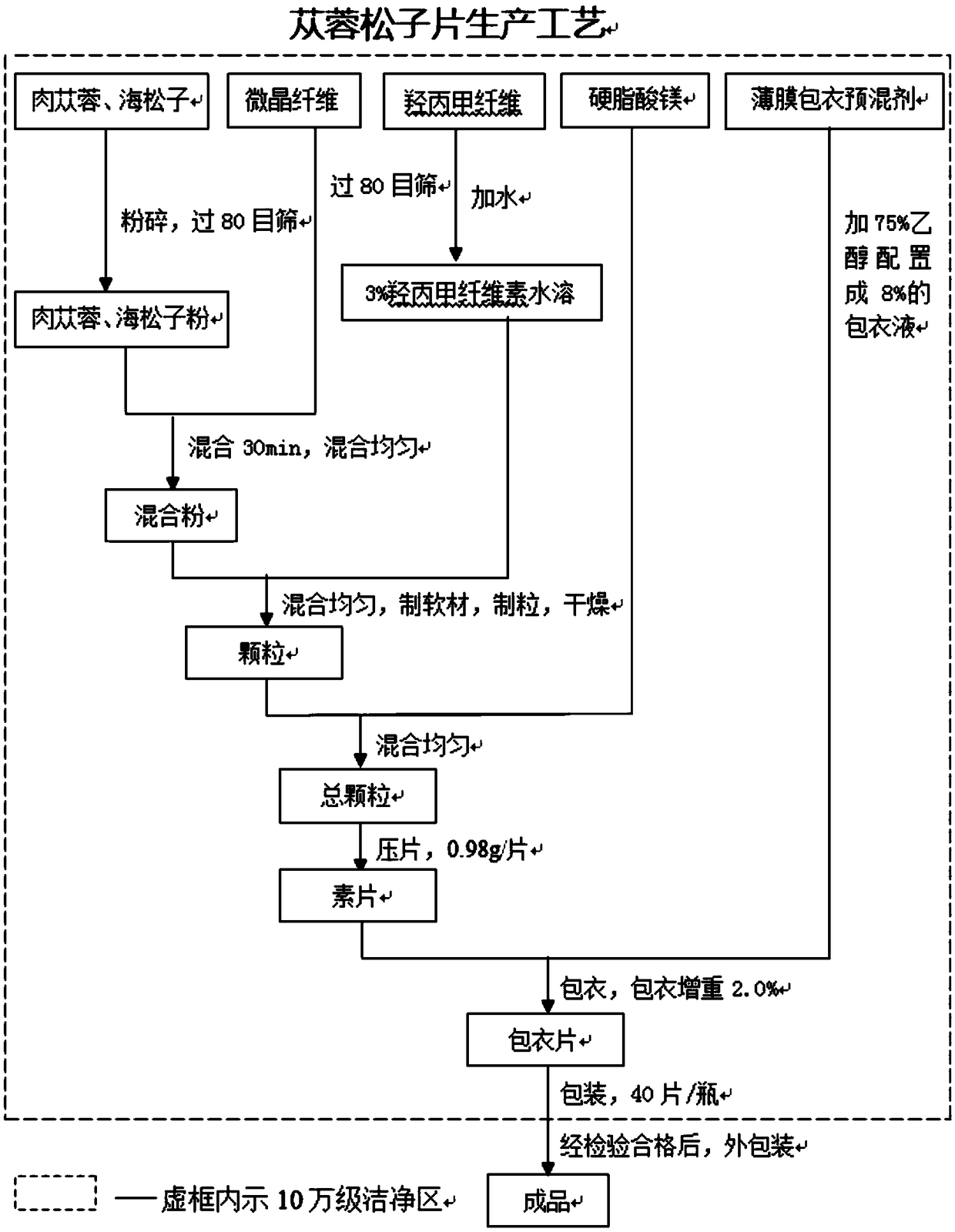

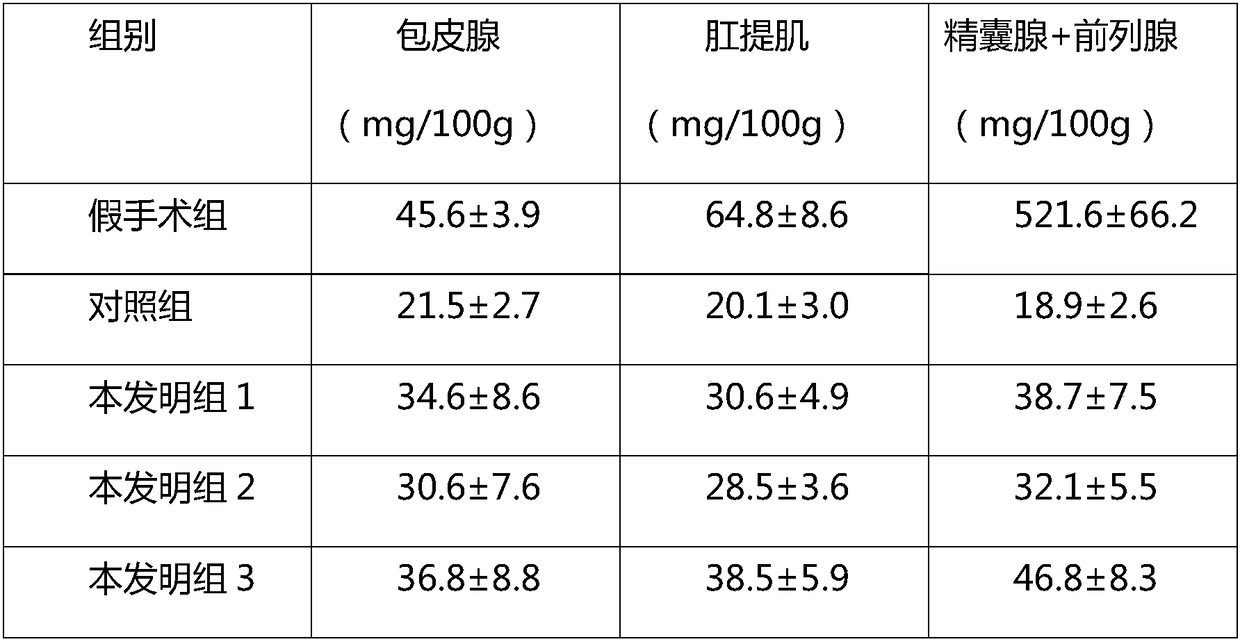

Health-care wine prepared from desert cistanche and Korean pine seeds and preparation method thereof

InactiveCN109486633ACompliance with securityCompliance with validityAlcoholic beverage preparationRed yeast riceBiotechnology

The invention discloses wine with desert cistanche and Korean pine seeds. The wine is prepared from herba cistanche and Korean pine seeds, adopting proper crystal sugar, red yeast rice and honey and adopting fragrant type white wine with the alcohol concentration being (55-65)+ / -(v / v). Simultaneously, side products in the preparation process also can be used for preparing tablets with the desert cistanche and the pine seeds. By the product, the symptoms and vital signs of kidney-deficiency type patients can be effectively relieved.

Owner:内蒙古坤华生物科技有限公司

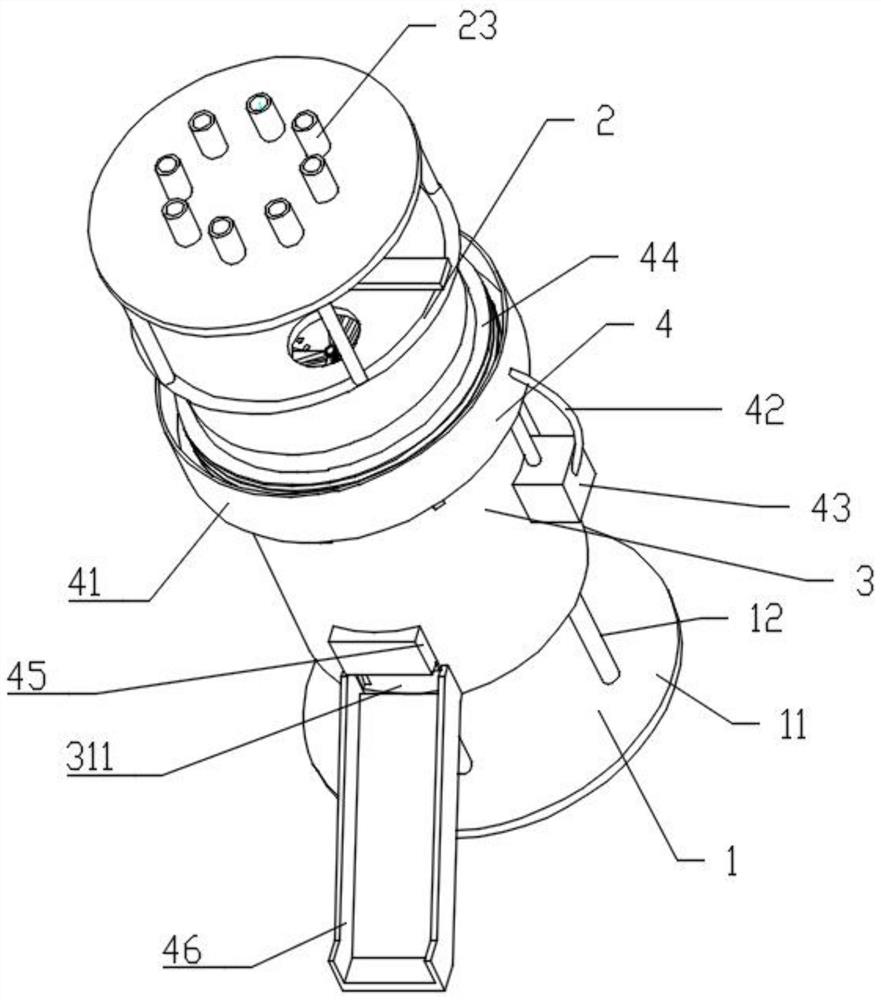

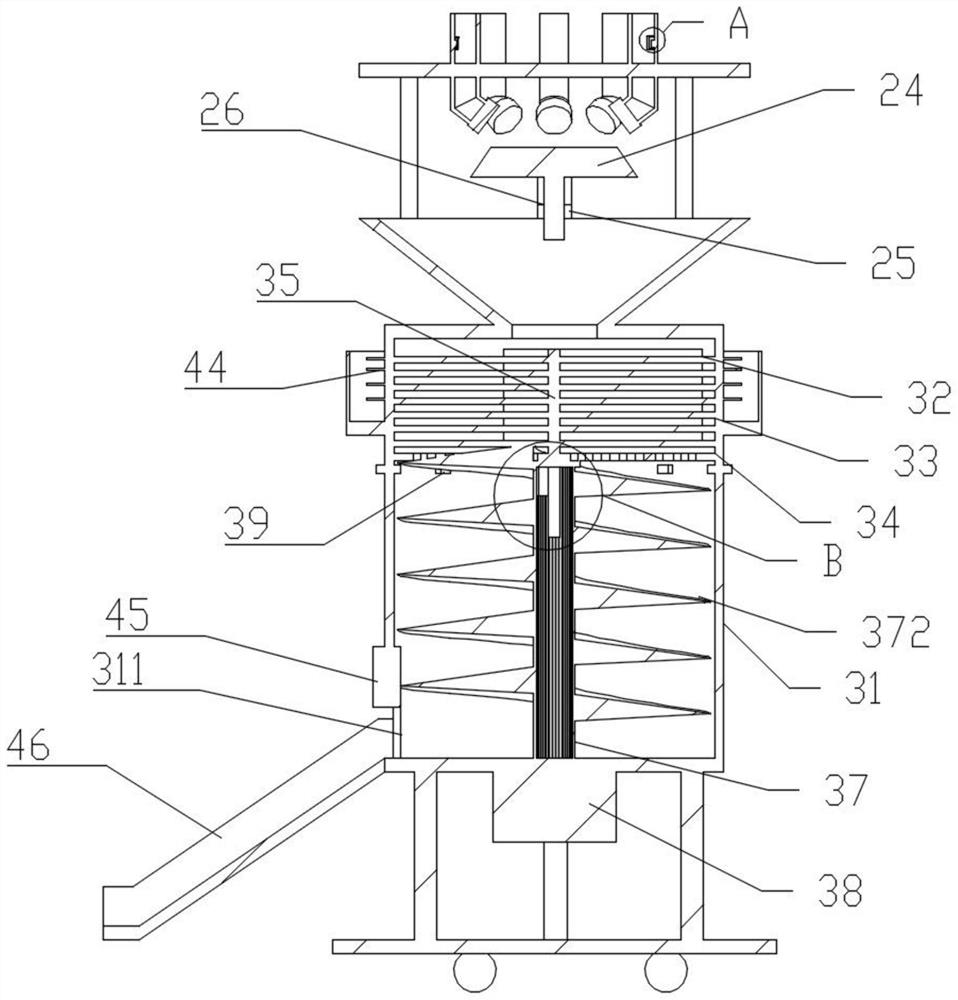

Preparation method and device of functional feed capable of improving resistance of livestock and poultry

ActiveCN112892772ASolve production efficiencyQuick breakFeeding-stuffGrain treatmentsBiotechnologyAgricultural science

The invention discloses a preparation method and device of a functional feed capable of improving the resistance of livestock and poultry. A base of a supporting assembly is connected with a support, a feeding shell of a feeding assembly is connected with the support, a plurality of feeding valves and a plurality of raw material pipes are arranged at one side of the feeding shell, and a sealing head and a sealing frame are arranged between the feeding shell and the raw material pipes; and a mixing shell of a mixing assembly is communicated with the feeding shell, crushing blades are driven by driving a transmission gear and a rotating rod to rotate through a sleeve rod on a driving motor, supporting blades are arranged at one sides of the crushing blades, and a sieve plate is arranged at one sides of the crushing blades. The crushed feed with the diameter smaller than the preset diameter enters a spiral column on the sleeve rod through the sieve plate to be fully stirred and then can be discharged, so that raw materials can be quickly crushed and stirred, the working efficiency is improved, and the problem that the feed production efficiency is affected due to the fact that crushing operation and mixing operation are separately carried out in existing equipment is solved.

Owner:YANCHENG TIANBANG FEED SCI & TECH CO LTD

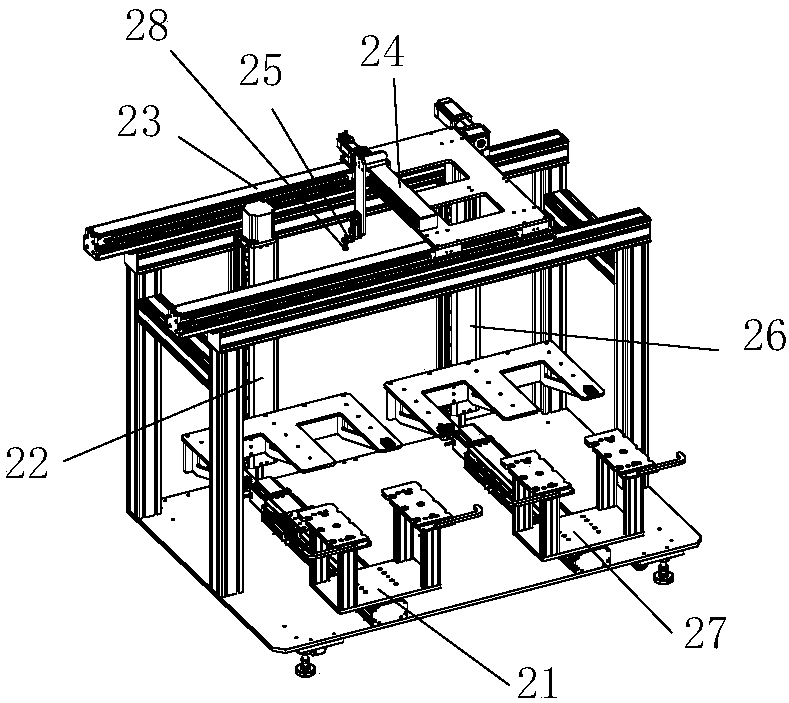

Automatic assembling device for photovoltaic module

PendingCN114758970APrevent scrapping and abnormality of equipmentSolve production efficiency problemsSemiconductor/solid-state device manufacturingConveyor partsManipulatorDiode

An automatic photovoltaic module assembling device comprises a rack, an injection molding part bin arranged on the rack, an injection molding part direct vibration track connected to the injection molding part bin, a module diode bin arranged on the rack, a module diode material direct vibration track connected to the module diode bin, a manipulator unit, a press fitting station and a material receiving station, a first detection unit used for detecting the orientation of injection molding parts is arranged at the tail end of the injection molding part direct vibration rail, and a second detection unit used for detecting the orientation of module diodes is arranged at the tail end of the module diode material direct vibration rail. And the manipulator unit positions the injection molding part and the module diode on the press fitting station according to the preset direction and position according to the detection results of the first detection unit and the second detection unit, and the injection molding part and the module diode are collected by the material collecting station after press fitting is completed on the press fitting station. Due to the adoption of the technical scheme, the direction of the component can be automatically judged and adjusted, scrapping and equipment abnormity are prevented, and the problem of production efficiency is solved.

Owner:SUZHOU XTONG PHOTOVOLTAIC TECH CO LTD

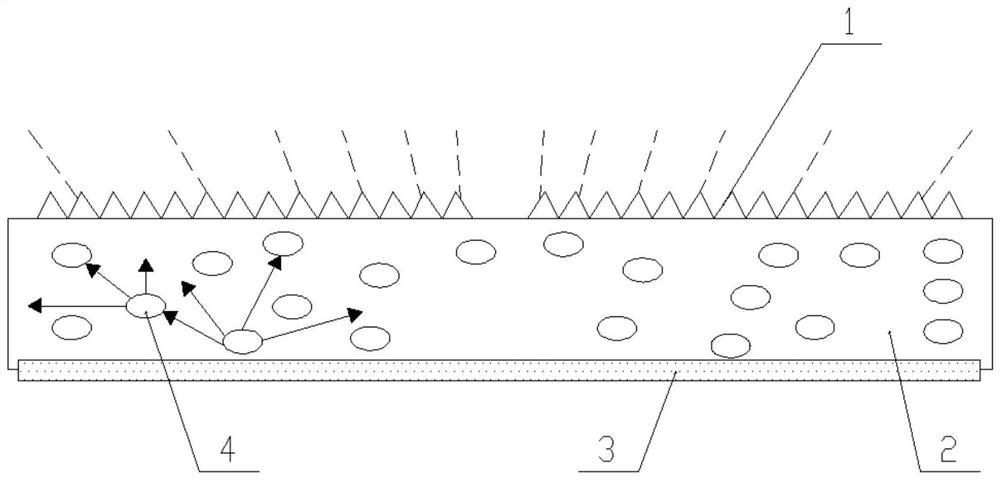

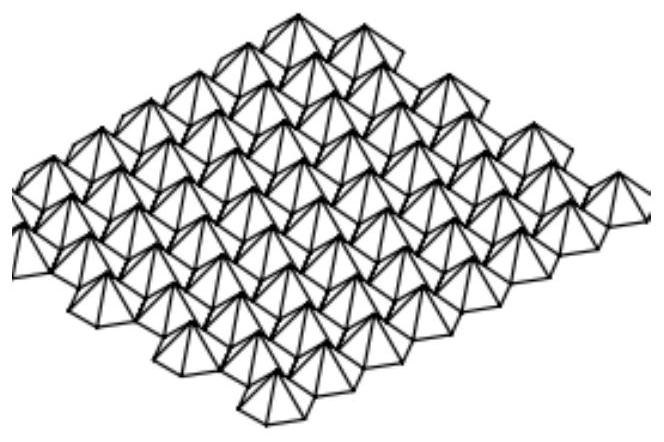

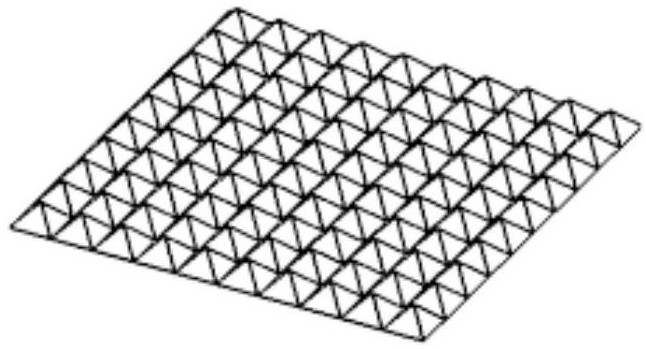

Diffusion and brightening composite optical film and preparation method thereof

ActiveCN113504591AReduce use costIncrease productivityPrismsDiffusing elementsThin membraneChemistry

The invention provides a diffusion and brightening composite optical film and a preparation method thereof, the diffusion and brightening composite optical film is prepared by co-extruding and compounding a diffusion layer with a diffusion microstructure function and a brightening layer with a brightening functional structure, and the problems that in the coating process of an existing optical diffusion film product, the production efficiency and the quality yield of the prepared product are reduced, The result shows that the PET extrusion film cannot meet the optical requirements of high fog and high transmittance; meanwhile, a coating process is adopted, so that pollution to the environment is caused, and in the subsequent processing process, the defect that the product quality is affected by dust generated by coating falling does not occur. The use convenience and the thin film use turning-out are improved, the use cost is reduced, and the production efficiency is improved.

Owner:JIANGXI SHENGHUI OPTICAL TECH

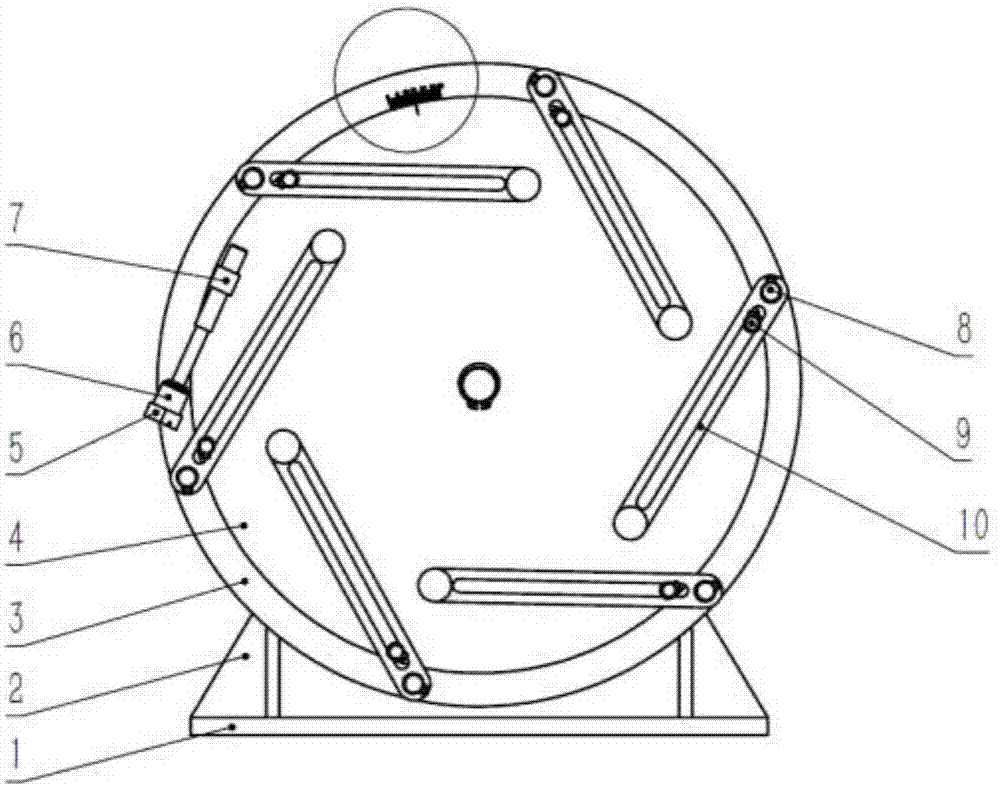

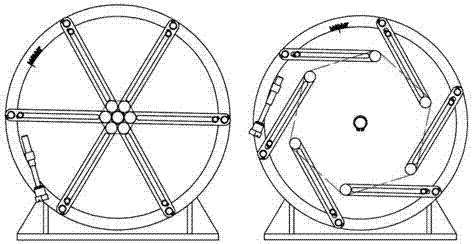

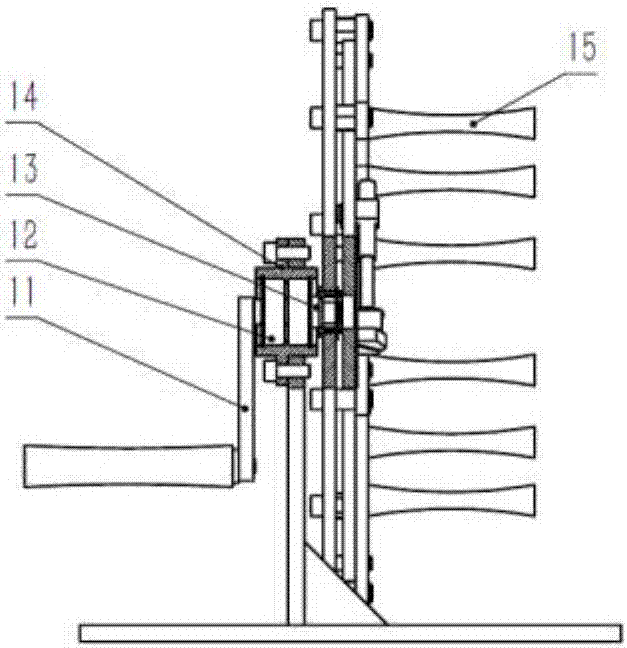

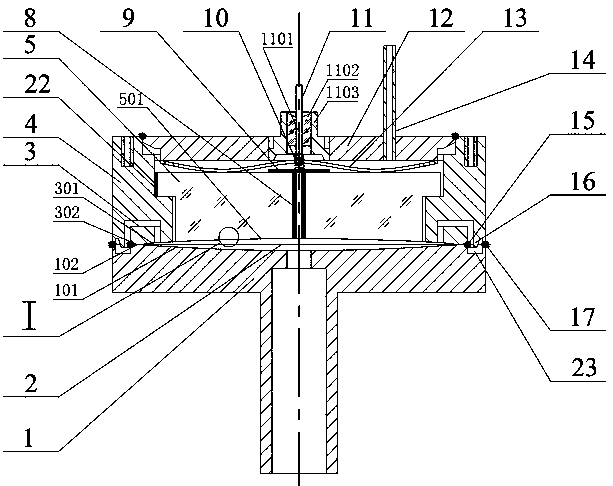

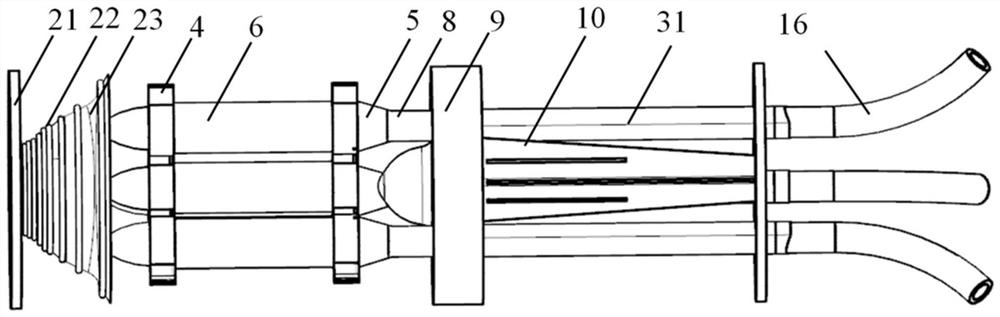

Adjustable fiber coiling device capable of automatically adjusting diameter

ActiveCN106873107AReduced variety and manufacturing costsShorten the development cycleFibre mechanical structuresEngineeringFiber

The invention discloses an adjustable fiber coiling device capable of automatically adjusting diameter. The fiber coiling device comprises a fixed part and a rotating part. The fixed part comprises a base, a support and a bearing bracket. The rotating part is fixed on the support through the bearing bracket. The rotating part comprises a fiber winding driving device, a bearing, a rotating shaft and a fiber winding device. The fiber coiling device is characterized in that the fiber winding device is mainly composed of a rotating disc, an adjusting disc and a diameter adjusting device. The rotating shaft is installed at the central position of the rotating disc and fixed. The adjusting disc is installed at the external side of the rotating disc and the diameter is less than that of the rotating disc. The installing structure is a structure freely rotating around the rotating shaft. According to the fiber coiling mould capable of automatically adjusting the diameter, the fiber coiling mould is enabled to have the universality, the type and the manufacturing cost of the fiber coiling mould can be reduced and the research period of the amplifier product can be reduced so that the fiber is enabled to be easily taken down from the fiber coiling mould without damaging the fiber, and the problems of influencing the production efficiency and the operation quality caused by frequent replacing of the fiber coiling mould can be solved.

Owner:上海传输线研究所

Electrode suspension type capacitive pressure sensor adopting assembled fixed electrode

PendingCN109115392ALittle influence of temperatureSolving Measurement ErrorsFluid pressure measurement using capacitance variationCapacitive pressure sensorThermal expansion

The invention relates to an electrode suspension type capacitive pressure sensor adopting an assembled fixed electrode. The electrode suspension type capacitive pressure sensor adopting the assembledfixed electrode comprises a fixed electrode single-end suspension structure and a movable electrode single-end suspension structure which are oppositely welded by using a thin-wall cutting edge, wherein the fixed electrode single-end suspension structure adopts an assembled fixed electrode structure and comprises a fixed electrode assembled suspension shell, a fixed electrode insulator supported in the fixed electrode assembled suspension shell, an elastic locator, and end cover welded on the top of the fixed electrode assembled suspension shell, a three-wave compression spring arranged between the end cover and the fixed electrode insulator and a glass insulator welded on the end cover, the fixed electrode assembled suspension shell, the end cover and the three-wave compression spring aremade of a constant elasticity alloy with the thermal expansion coefficient being the same as or matched with that of the fixed electrode insulator, and the surfaces of the fixed electrode assembled suspension shell, the end cover and the three-wave compression spring are gold-plated. The electrode suspension type capacitive pressure sensor adopting the assembled fixed electrode fundamentally solve the problems of low production efficiency and high production cost of the existing electrode single-end suspension type capacitive pressure sensors, the measurement result is hardly influenced by the temperature, the measurement accuracy of the sensor is ensured, and the stability is good.

Owner:SHENYANG SENSOR TECH INST

Process for coating formaldehyde-free ecological board with high-tensile-strength PP film veneer

ActiveCN112706237AHigh viscosityIncreased chain extension reactionWood veneer joiningAdhesivesSolid woodEngineering

The invention discloses a process for coating a formaldehyde-free ecological board with a high-tensile-strength PP film veneer. The process comprises the following steps that (1) a prepared multi-layer solid wood board base material is enabled to pass through a double-shaft laminator in cooperation with formaldehyde-free glue, and the formaldehyde-free glue is uniformly smeared on the front and back surfaces of the base material; (2) a base material plate at the front end of the laminator is pushed for lamination, then a laminated plate is connected at the rear end of the laminator and a PP film is laid, a backer of a long side and a short plate is arranged on a lifting platform for connecting the plates and stacking, then a bottom PP film is laid, the laminated plate is flatly placed on a stacking lifting platform, then a front PP film is laid, and the steps are repeated; (3) the laid PP film formaldehyde-free plate is placed in a cold press to be pre-pressed; (4) after prepressing is finished, the plate is moved to a hot press to be subjected to hot pressing; and (5) after the hot pressing is finished, the board is subjected to edge sawing treatment, and a high-tensile-strength PP film veneer decorative formaldehyde-free ecological board is prepared. The formaldehyde-free ecological board prepared by the invention is excellent in performance and high in production efficiency, and can meet production and application requirements.

Owner:广西贵港市泰翔木业有限公司

Tobacco sheet coating device and method

PendingCN113576018ASolve the quality and efficiencySolve production efficiencyTobacco treatmentHot blastMechanical engineering

The invention discloses a tobacco sheet coating device. The tobacco sheet coating device comprises hot air drying equipment, net pressing equipment, a tension roller frame and a winding device which are arranged in sequence, the hot air drying equipment comprises a conveying unit and a drying unit, and the drying unit is arranged below the conveying unit and used for drying the tobacco sheets borne on the conveying unit; the net pressing equipment is connected with the conveying unit and used for pressing the dried tobacco sheets; the tension roller frame is connected with the net pressing equipment; and the winding device is connected with the tension roller frame and used for winding the tobacco sheets. According to the tobacco sheet coating device and method provided by the invention, the situation that the material is cracked or fractured due to tension during rolling can be effectively reduced.

Owner:湖南三匠人科技有限公司

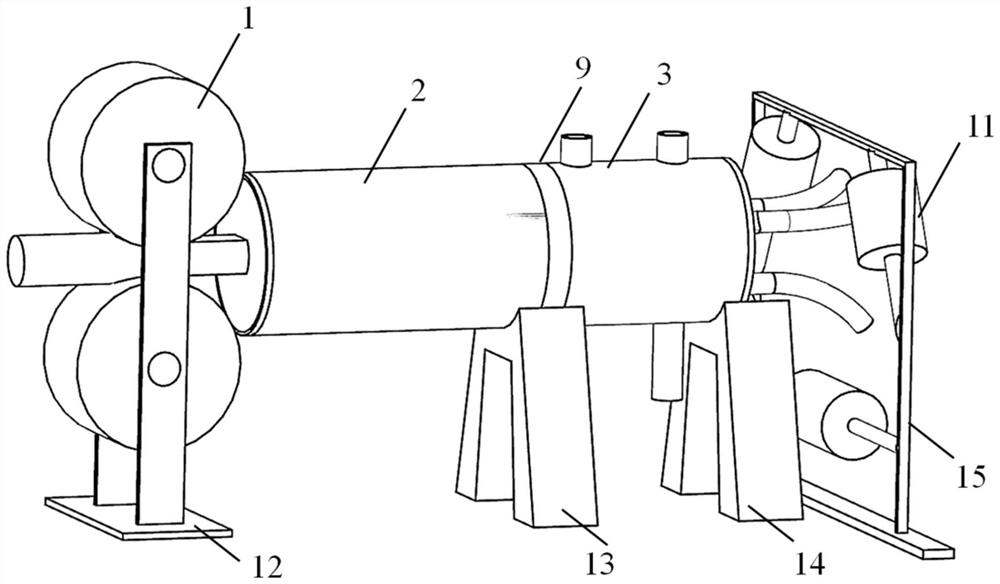

Preparation device and method of microfluidic tube for intelligent robot motor

ActiveCN112588827ASolve production efficiencyHigh degree of automationWork heating devicesMetal rolling arrangementsLiquid nitrogen coolingEngineering

The invention discloses a preparation device and method of a microfluidic tube for an intelligent robot motor. The device mainly comprises a roller, a heating cylinder, a cooling cylinder, a porous connecting block and a crimping machine, wherein the roller feeds a metal wire into the heating cylinder, the heating cylinder rapidly heats metal into liquid, the liquid flows into the cooling cylinderby means of the porous connecting block and is rapidly cooled to form an amorphous tube, and the tube is wound on a coiling machine to form a coiled material. The device is high in automation degree,can achieve full-thread and multi-procedure highly-integrated automatic production from wire feeding to final product, three microfluidic tube forming openings are formed, the production efficiency is high, through segmented heating and liquid nitrogen cooling, a non-crystallization degree is high, a length and a diameter of the produced microfluidic tube are not limited, a thickness of the produced microfluidic tube is 10 micrometers and 500 micrometers, for the tube with a thickness of 500 micrometers, the maximum error of the produced microfluidic tube is 10 micrometers, an amorphous rateof the produced microfluidic tube is not lower than 95%, and the problems of low production efficiency and low precision in the current amorphous tube forming process are solved.

Owner:ZHEJIANG LAB

Fully automatic spraying machine with variable color registration

ActiveCN108466482BIncrease productivitySolve production efficiencyPrintingConveyor partsClip deviceEngineering

The invention discloses an automatic spraying machine with a variable color register. The top of a box bracket is divided into a loading area and a printing area; an automatic tray feeding and changing mechanism and a feeding mechanism are placed in the loading area, and a product printing mechanism and a product discharging mechanism are placed in the printing area; the automatic tray feeding andchanging mechanism is provided with a full tray clip device, an empty tray clip device, a tray conveying mechanism, a full tray pushing mechanism, an empty tray pushing mechanism, a full tray removalmechanism, and an empty tray removal mechanism; the full tray clip device and the empty tray clip device are mounted on the top of the tray conveying mechanism; the bottom of the tray conveying mechanism is fixedly connected to the top of the box bracket; the full tray pushing mechanism and the empty tray pushing mechanism are arranged at the bottom of the tray conveying mechanism and are symmetric to the full tray clip device and the empty tray clip device in order; and the full tray removal mechanism and the empty tray removal mechanism are arranged at the side of the tray conveying mechanism.

Owner:羊宋英

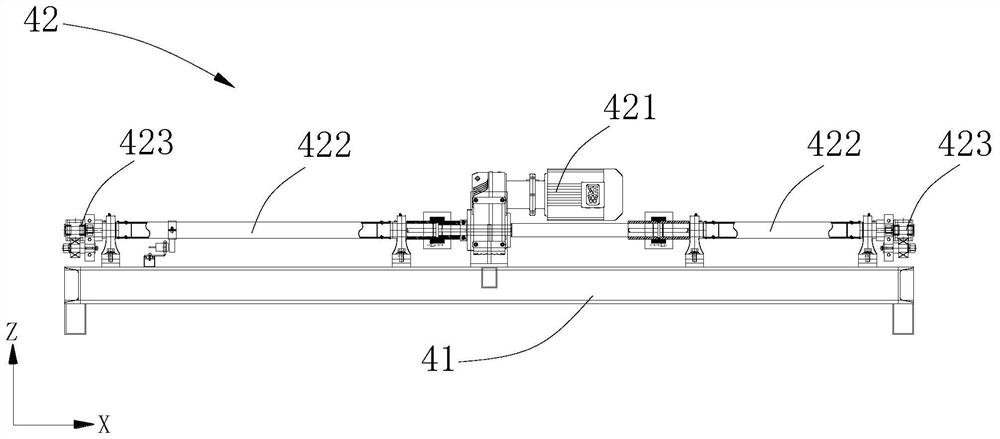

Moving device and electroplating bath

ActiveCN114364828ASolve production efficiencySolve the quality of productionCellsTanksMobile deviceElectrical and Electronics engineering

The invention relates to the technical field of mobile equipment, and discloses a mobile device and an electroplating bath. The moving device comprises a supporting frame, a top seat, a base and a linkage module, a pole seat is arranged on the top seat, and the pole seat is used for placing a part to be moved; a top seat is arranged on the bases, and the number of the bases is at least two; wherein the linkage module comprises a linkage support, a first driving mechanism and a transmission mechanism, the linkage support is arranged on the supporting frame, the first driving mechanism is arranged on the linkage support, the transmission mechanism is connected to the driving end of the first driving mechanism, and the base is arranged at the driving end of the transmission mechanism.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Workpiece vacuum detection and filling integrated control system

ActiveCN109733692AImprove accuracyEfficient and accurate process switchingVacuum gaugesPackaging automatic controlAutomatic train controlAutomatic control

The invention provides a workpiece vacuum detection and filling integrated control system. The workpiece vacuum detection and filling integrated control system can automatically detect the vacuum performance of a workpiece and conduct filling. The system automatically control the implementation process of a preset decision value and is changed from traditional manual control to automatic control.Under the condition of ensuring that finished workpiece products reach the standard, the system optimizes the evacuation time according to the vacuum value and automatically starts and stops an evacuation valve and a filling valve. Moreover, the valve status and the operation status form the feedback mechanism. High-efficiency accurate working procedure switching is realized. The overall production efficiency is improved. The system does not need manual intervention. The labor cost is reduced. Extra errors caused by artificial judgment is avoided. The accuracy degree of detection results is effectively improved.

Owner:广州市真量纯科技有限公司

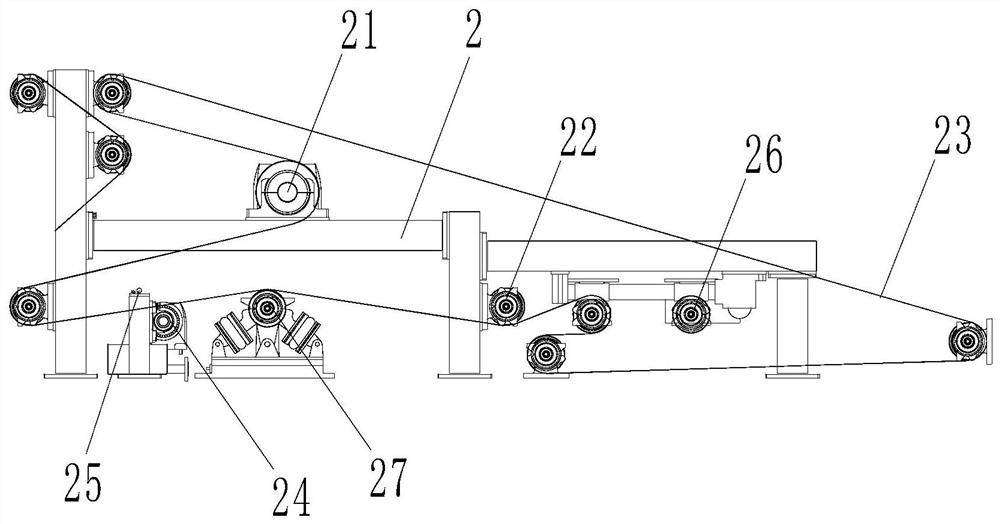

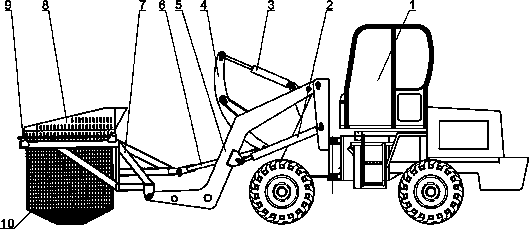

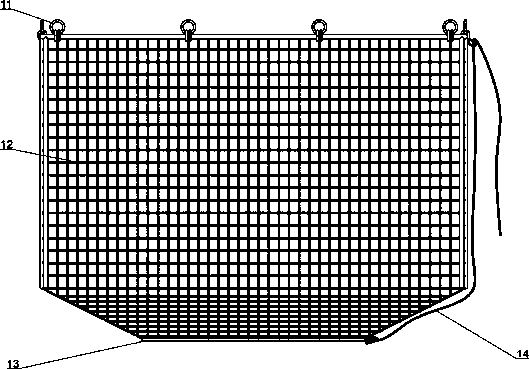

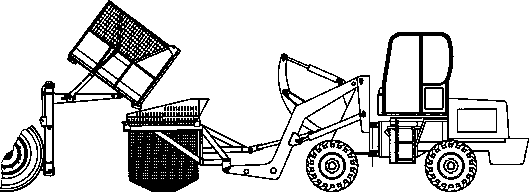

Tuck net conveyor in sugarcane field and operation method

PendingCN108819815ALower acquisition costsSolve production efficiencyItem transportation vehiclesVehicle with parallel load movementEngineeringRocker arm

The invention discloses a tuck net conveyor in a sugarcane field and an operation method, which comprises a field transferring vehicle, a lifting oil cylinder, a lifting arm, a tuck net supporting frame, a charging hopper, a quick charging and discharging device, a sugarcane charging tuck net and a translation mechanism consisting of an adjusting oil cylinder, a rocker arm and a pull rod; the lifting arm is hinged between the front part of the field transferring vehicle, the lifting oil cylinder is hinged between the lifting arm and the field transferring vehicle, the middle part of the rockerarm is hinged on the lifting arm, one end of the adjusting oil cylinder is hinged at the front part of the field transferring vehicle, and the other end of the adjusting oil cylinder is hinged on theupper part of the rocker arm, the two ends of the pull rod are respectively hinged with the lower end of the rocker arm and the tuck net supporting frame; another articulated shaft of the tuck net supporting frame is hinged at the front part of the lifting arm, the charging hopper and the quick charging and discharging device are arranged on the tuck net supporting frame, the sugarcane charging tuck net is arranged at the lower part of the charging hopper and quick charging and discharging device, the sugarcane charging tuck net can be quickly hung with and disassembled from the quick charging and discharging device of a tuck net, the problem of sugarcane transferring can be solved if sufficient sugarcane charging tuck nets are provided, and the operation efficiency of a sugarcane harvester is effectively increased.

Owner:LUOYANG CHENHAN AGRI EQUIP TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com