Preparation device and method of microfluidic tube for intelligent robot motor

A technology of intelligent robots and preparation devices, applied in workpiece heating devices, manufacturing tools, metal rolling, etc., can solve the problems of many production processes and long threads of amorphous microfluidic tubes, and achieve high degree of automation, high production efficiency, The effect of high degree of amorphization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

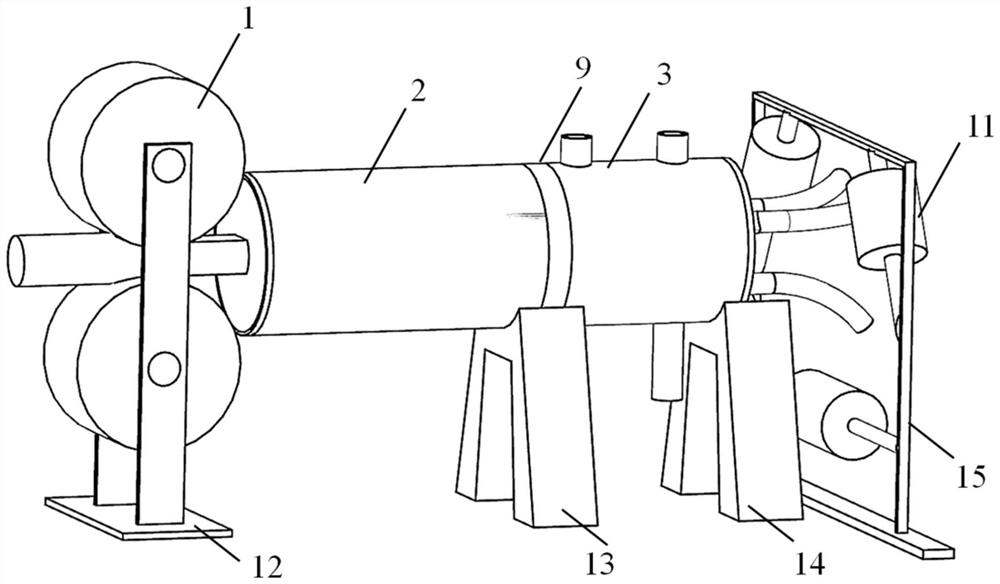

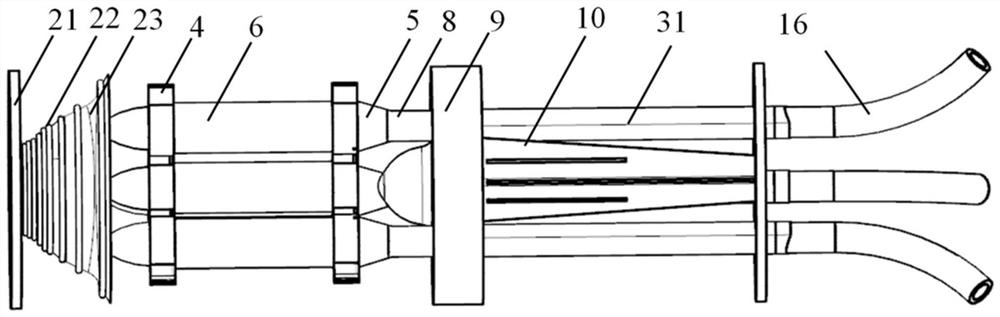

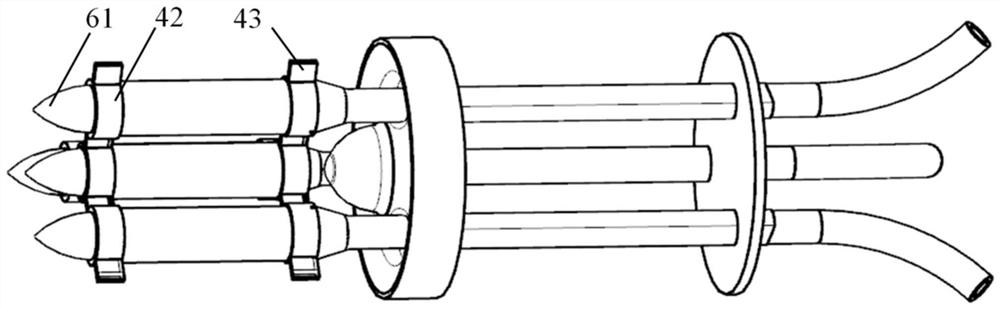

[0035] Such as figure 1 Shown, the present invention a kind of preparation device of microfluidic pipe for intelligent robot motor, it comprises roll 1, heating tube 2, cooling tube 3, porous connection block 9, three crimping machines 11, roll support frame 12, heating tube support Frame 13, cooling cylinder support frame 14 and crimping machine integrated frame 15. The heating cylinder 2 and the cooling cylinder 3 are connected by a porous connection block 9; the cooling cylinder 3 is cooled by liquid nitrogen, and the cooling cylinder 3 has three liquid nitrogen inlets and outlets, with two liquid nitrogen inlets on the top and one liquid nitrogen outlet on the bottom; The support frame 12 , the heating cylinder support frame 13 , and the cooling cylinder support frame 14 respectively support the roll 1 , the heating cylinder 2 and the cooling cylinder 3 ; The wire is bitten into the heating cylinder 2 by the roller 1 . The reduction of roll 1 is 1 / 4 of the wire diameter....

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com