Patents

Literature

51results about How to "Solve the quality of production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spandex flannel fabric and manufacturing method thereof

InactiveCN103541145AEasy to feed yarn at constant speedGuaranteed stabilityWarp knittingYarnEngineering

The invention discloses a manufacturing method of a spandex flannel fabric. The manufacturing method is characterized by including the following steps of beaming, weaving, slitting, shaping, napping, lustering, cropping, shaping, dyeing and shaping, wherein the weaving is warp weaving in an electric active yarn feeding mode. The spandex flannel fabric is woven from surface yarn, middle yarn and bottom yarn, wherein the surface yarn is textured terylene yarn of 11.1 to 166.6 dtex; the middle yarn is semigloss terylene yarn of 55.5 to 83.3 dtex, and the bottom yarn is spandex of 33.3 to 44.4 dtex. The manufacturing method of the spandex flannel fabric guarantees the stability of warp woven fabric; the spandex flannel fabric is provided with high elasticity and high restoring force, and slit flannel is denser, softer and more elastic.

Owner:JIANGSU BOBOBEAR TEXTILE

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

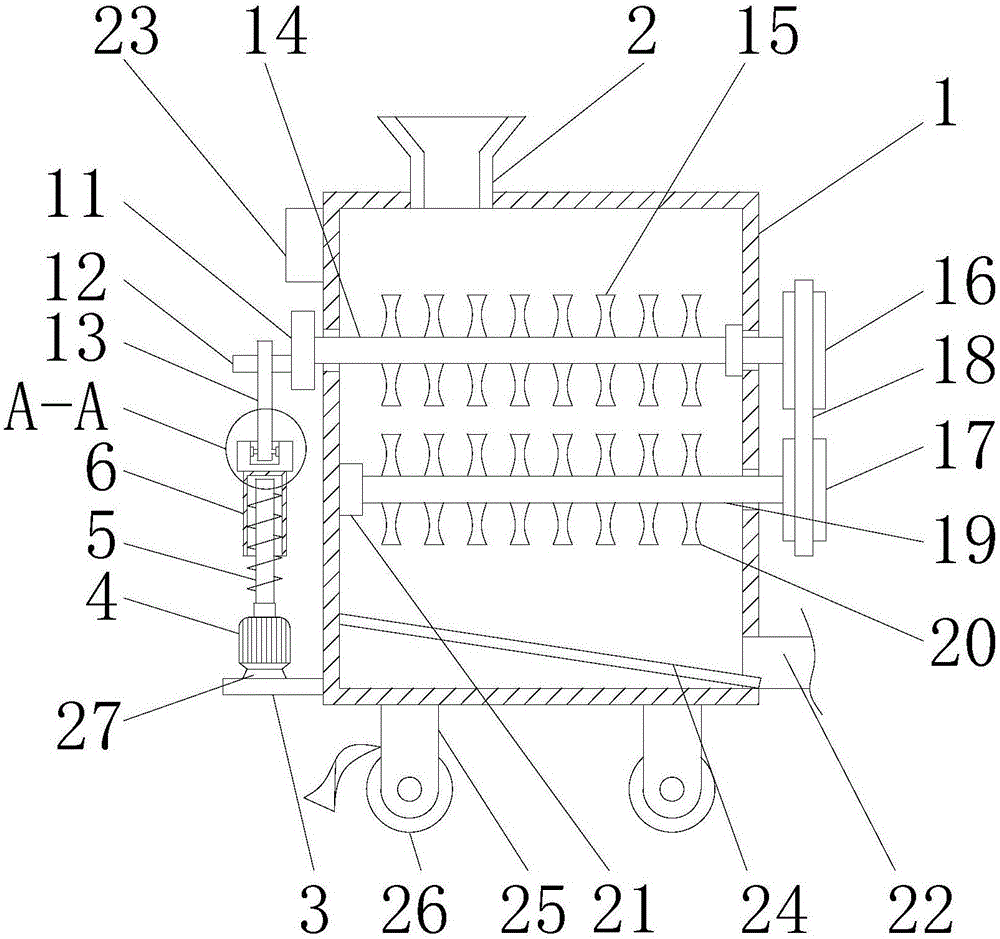

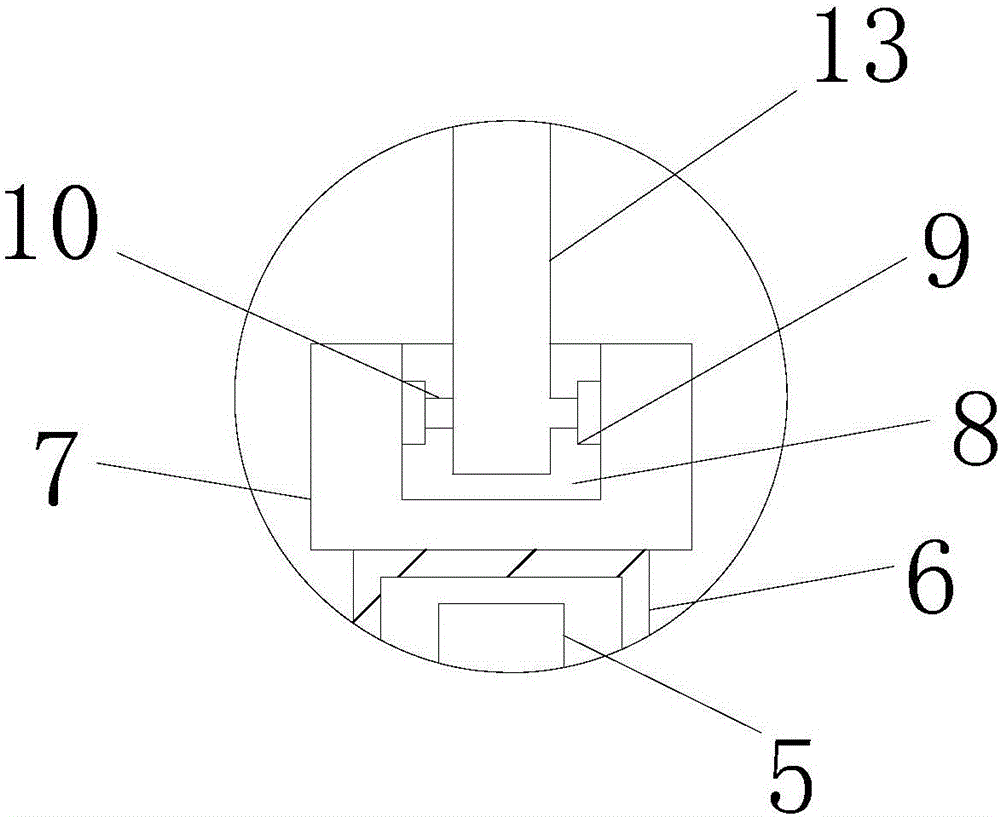

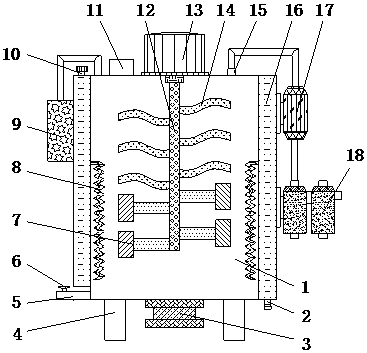

Stirring device for production of plastic valves

ActiveCN106626128ATo achieve the effect of rotationTo achieve the mobile effectArchitectural engineeringThreaded rod

The invention discloses a stirring device for production of plastic valves. The stirring device comprises a stirring box, wherein the top of the stirring box is communicated with a feeding hopper; a fixing plate is fixedly connected to the bottom of the left side of the stirring box; a motor is arranged at the top of the fixing plate; a threaded rod is fixedly connected with an output shaft of the motor; a thread bushing is movably connected with the top of the threaded rod; a fixing block is fixedly connected to the top of the thread bushing. Due to the arrangement of the motor, the threaded rod can be driven to rotate; with the arrangement of the threaded rod, the thread bushing can be driven to move; with the arrangement of a rotary rod, a movable rod can be drive to rotate; with the arrangement of a first stirring rod, a first gear can be driven to rotate; with the arrangement of a conveying belt, a second gear and a second stirring rod can be driven to rotate, and the problem that the production quality of the plastic valves is reduced due to insufficient stirring is solved.

Owner:吴江市强塑阀门管件厂

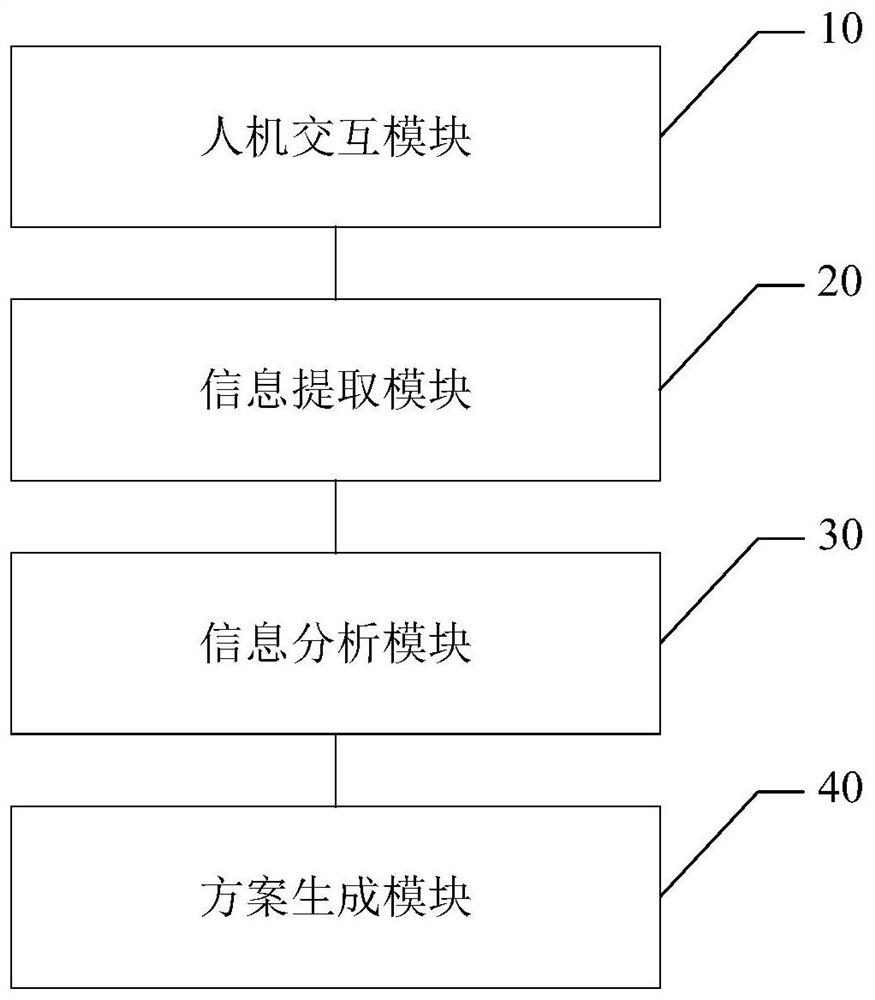

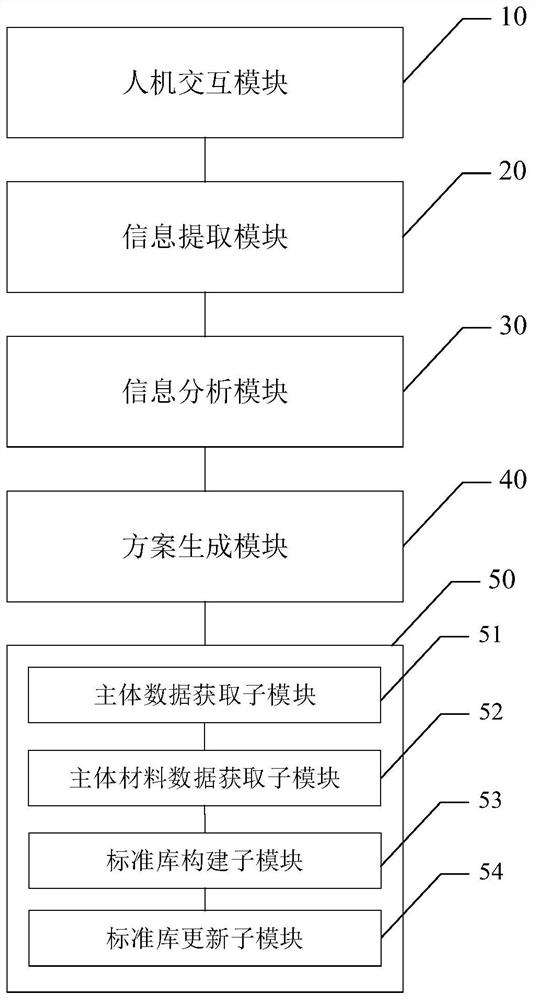

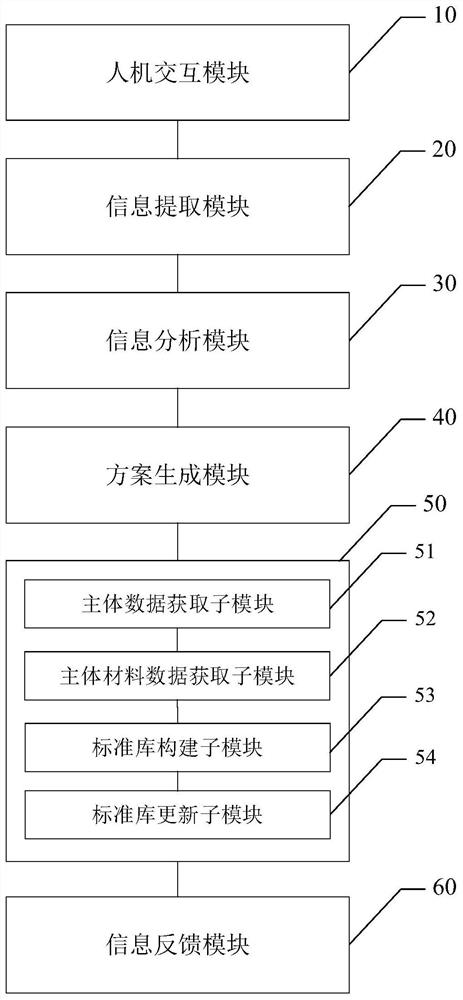

Flexible production line operation method and system

PendingCN111738676AImprove experienceRapid productionOffice automationManufacturing computing systemsUser needsInformation analysis

The invention discloses a flexible production line operation method and system, and the system comprises: a man-machine interaction module which is used for obtaining a production request of a user; an information extraction module which is used for acquiring image data of the target object according to the production request and extracting attribute information and material parameter informationof the target object from the production request; an information analysis module which is used for analyzing main body connection information of the target object according to the image data and the attribute information; and a scheme generation module which is used for obtaining a material and a connection scheme corresponding to the target object from a preset standard library according to the material parameter information and the main body connection information. Through implementation of the invention, the influence caused by manual operation can be avoided to the maximum extent, the production transformation scheme suitable for user requirements can be quickly, conveniently and efficiently generated for the user to select, the problems of low production efficiency and low quality caused by manual participation in an existing production process can be solved, and meanwhile better use experience can be brought to the user.

Owner:TIANJIN MASITE BODYWORK EQUIP TECH CO LTD

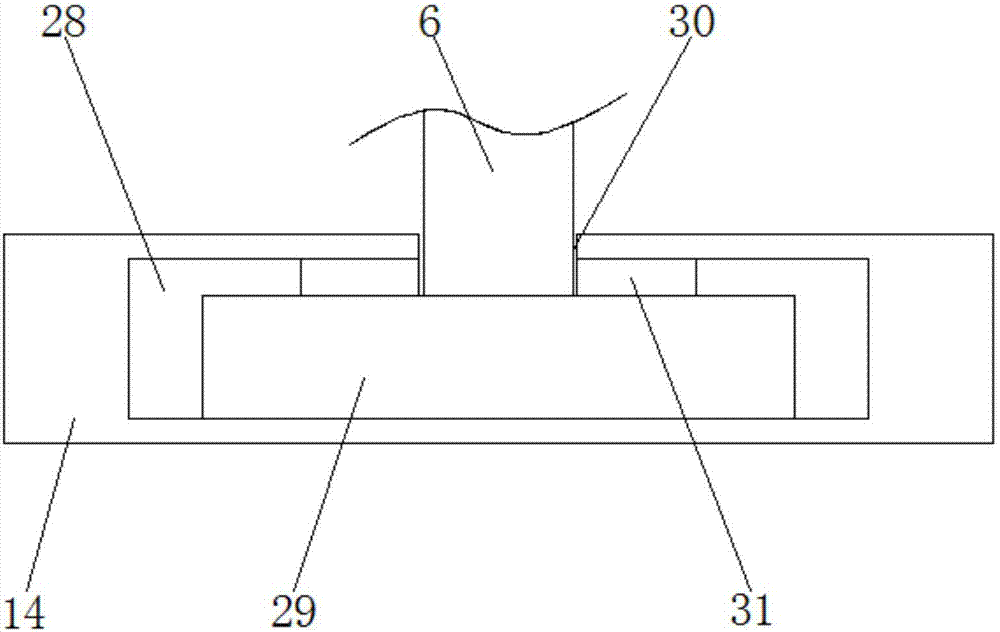

Resin production equipment

PendingCN108514858AReduce in quantitySolve the quality of productionChemical/physical/physico-chemical stationary reactorsLiquid degasification arrangementsArchitectural engineeringVacuum pump

The invention discloses resin production equipment which comprises a body. A vibration motor is fixedly installed at the middle end of the bottom of the body. Supporting legs are fixedly installed atthe periphery of the bottom of the body, a discharging outlet is formed in the bottom of the left side of the body, the outer surface of the body is sleeved with a water tank, a vacuum pump is fixedlyinstalled at the upper end of the left side of the water tank, the vacuum pump is movably connected with the body through a pipeline, a water injection opening is formed in the left end of the top ofthe water tank, a water outlet is formed in the right end of the bottom of the water tank, and an oil and water separator is fixedly installed at the lower end of the right side of the outer surfaceof the water tank. By arranging the vibration motor, the vibration and bubble removing effects are achieved; due to effects of a first stirring blade and a second stirring blade, the layering turbulent flow stirring effect can be achieved, the number of bubbles is further lowered, and the problems that in the existing resin production process, a large number of bubbles are generated, and thereforethe resin production quality is lowered are solved.

Owner:林丽敏

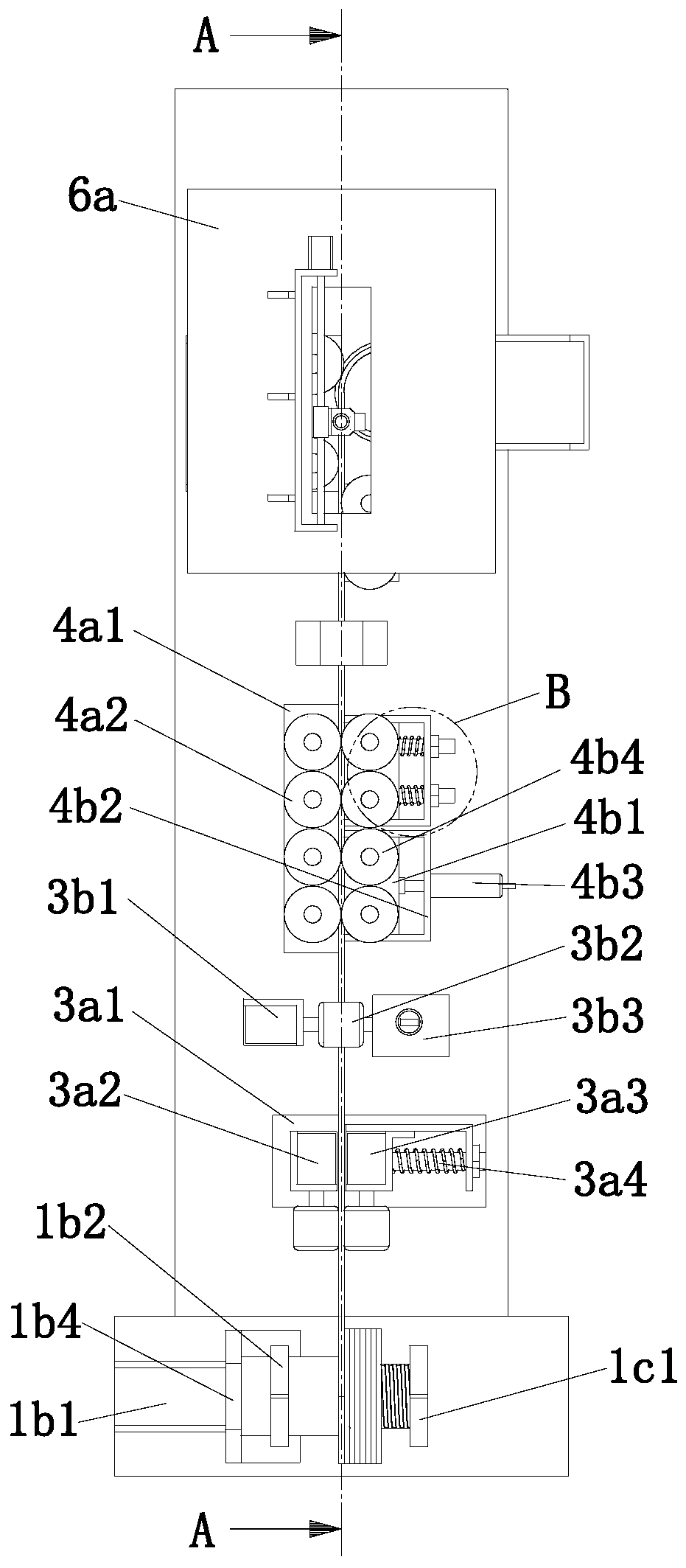

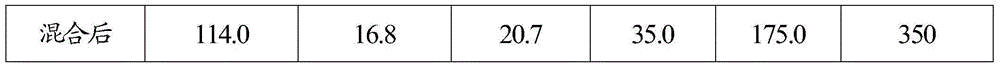

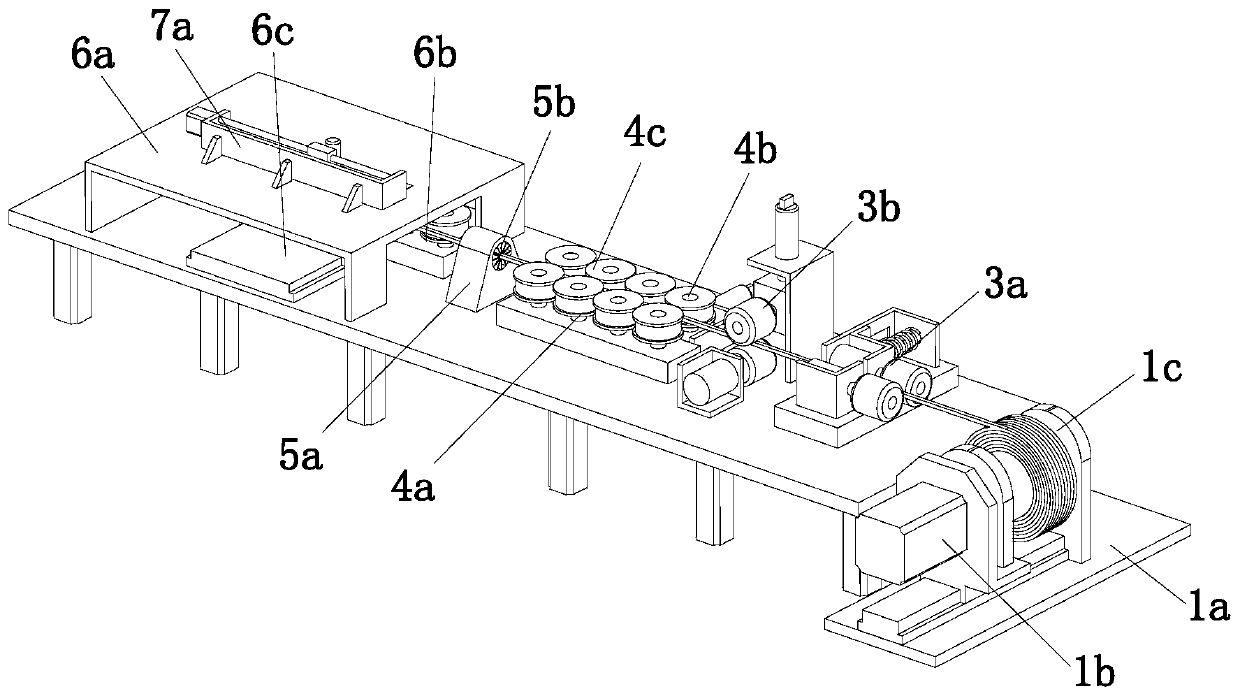

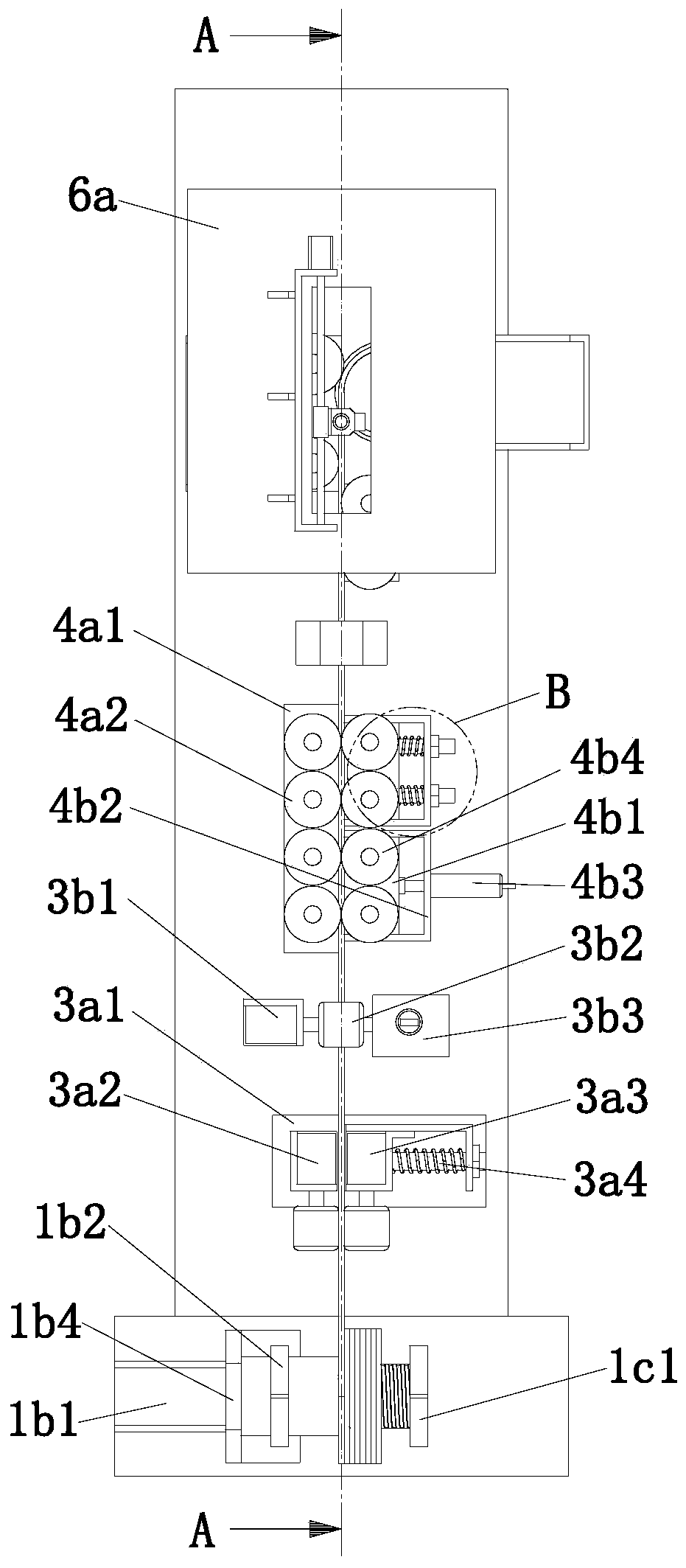

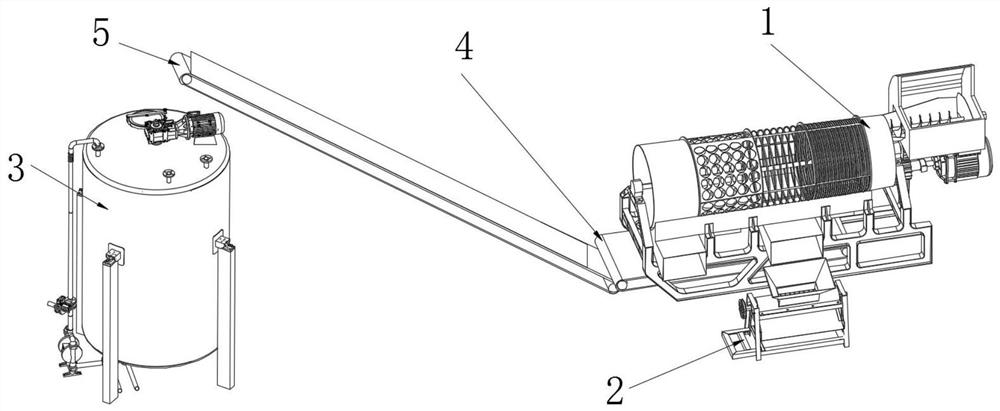

Production process of inner ring of metal wound gasket

InactiveCN111347226AReduce manual laborQuality improvementWashersGrinding machinesManufacturing engineeringMetal

The invention discloses a production process of an inner ring of a metal wound gasket and belongs to the technical field of metal part processing. The production process comprises the following stepsof S1, loading steel strips automatically; S2, adjusting the size of a channel automatically; S3, polishing and derusting the steel strips automatically; S4, cleaning burrs on the surfaces of the steel strips; S5, carrying out bend forming; and S6, cutting and unloading the steel strips automatically. The production process is high in degree of automation, reduces the labor force, can transfer thesteel strips of different sizes and is relatively high in practicality, so that the production quality of the inner ring of the metal wound gasket is improved.

Owner:李林清

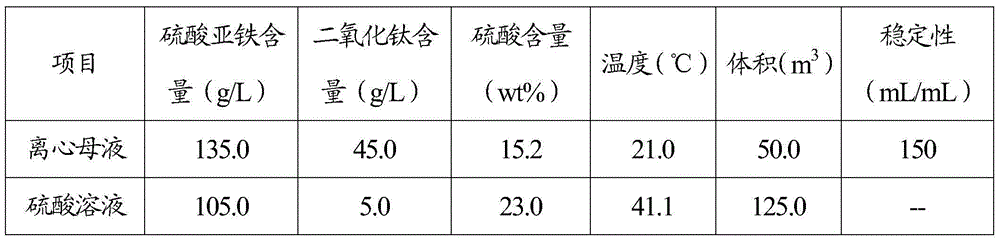

Recycling method of ferrous sulfate heptahydrate centrifugal mother liquid in production of sulfate process titanium dioxide

ActiveCN104477988AHigh yieldHigh acidityTitanium dioxideFerrous sulfate heptahydrateTitanium dioxide

The invention discloses a recycling method of ferrous sulfate heptahydrate centrifugal mother liquid in production of sulfate process titanium dioxide. The method comprises the step of adding 20-25 percent by mass of sulfuric acid solutions into the centrifugal mother liquid to ensure that the centrifugal mother liquid added with the sulfuric acid solutions is used in an acidolysis leaching step. The problems that delivery pipelines are blocked in the use process of the centrifugal mother liquid and the quality of the product is influenced caused by early-stage hydrolysis in a storage and transfer process are solved by adding the sulfuric acid solutions into the centrifugal mother liquid and controlling the concentration and the temperature of the sulfuric acid solutions and the volume ratio of the mother liquid to the sulfuric acid solutions, and the yield and the quality of titanium dioxide in the system are improved.

Owner:PANZHIHUA DONGFANG TITANIUM IND

Preparation process of carbon-free steel packing refractory bricks

The invention discloses a preparation process of carbon-free steel packing refractory bricks, which comprises the following steps: 1) mixing 16-18 parts of 7-10mm white corundum particles, 20-22 parts of 4-7mm white corundum particles and 6-8 parts of 1-4mm white corundum particles in a mixer for 5-8 minutes; 2) mixing 3-5 parts of alpha-Al2O3 of -200 meshes, 6-8 parts of fused aluminum-magnesium spinel powder of -200 meshes, 5-7 parts of magnesium oxide of -200 meshes and 2-4 parts of metal aluminum powder of -200 meshes in a mixer for 10-15 minutes; 3) adding the mixture prepared in the step 1) into the mixer in the step 2), mixing for 10-15 minutes, adding 1.5-2.5 parts of sodium hexametaphosphate, 3-5 parts of 25% magnesium chloride solution and 0.5-1.5 parts of sodium lignin sulfonate, and mixing for 10-15 minutes before discharge; 4) aging for 1-2 hours, performing compression moulding with a press, and drying for 24 hours in a drying kiln at 200 DEG C.

Owner:WUXI CHENGBO SCI & TECH DEV

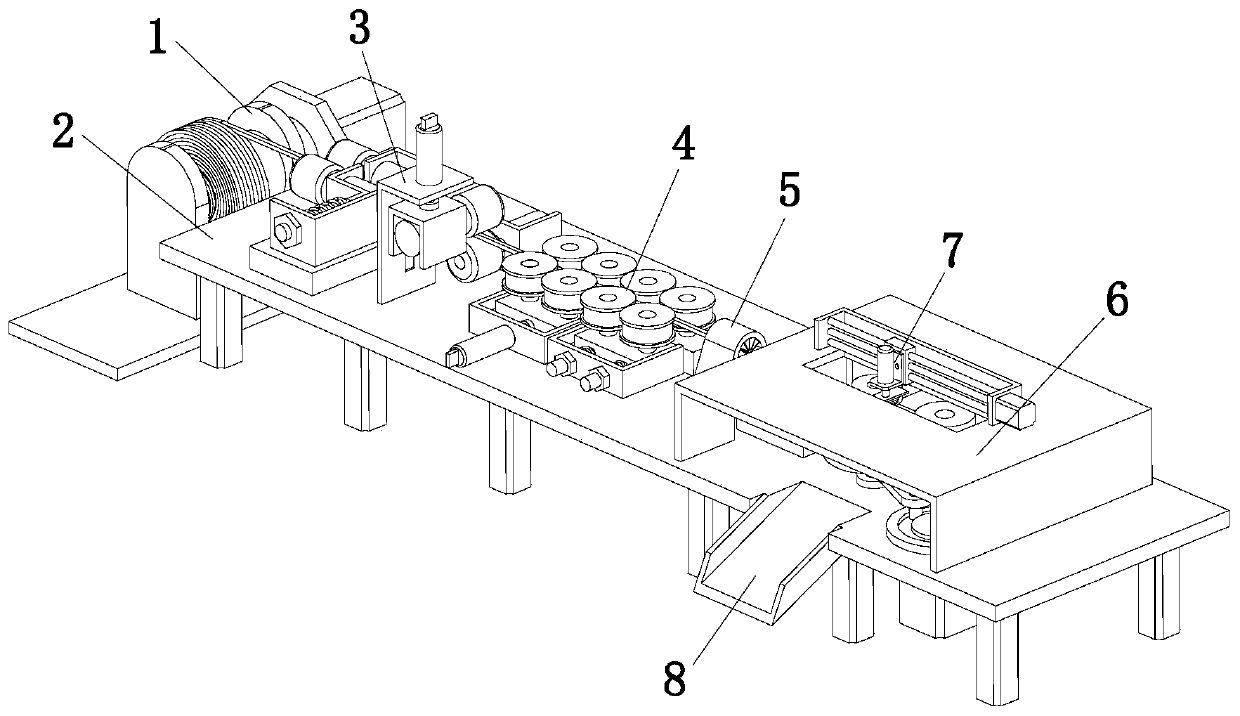

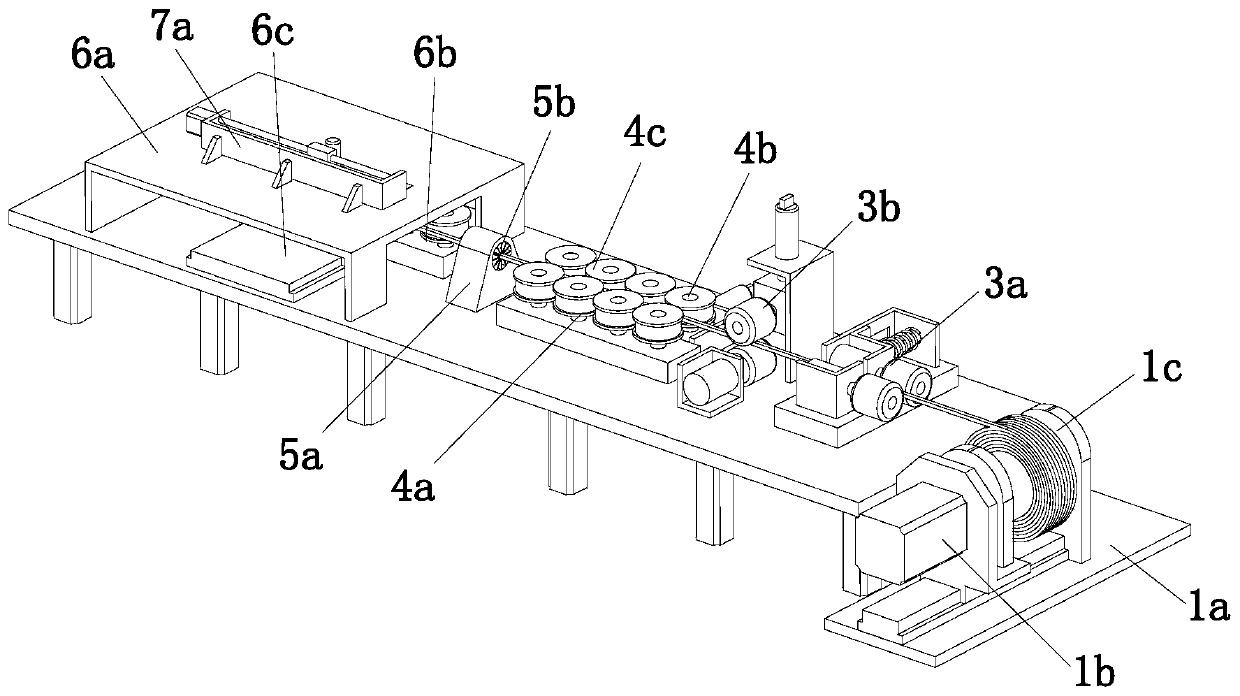

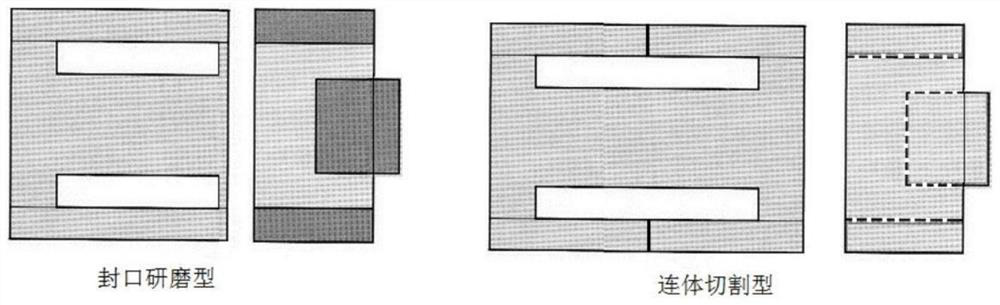

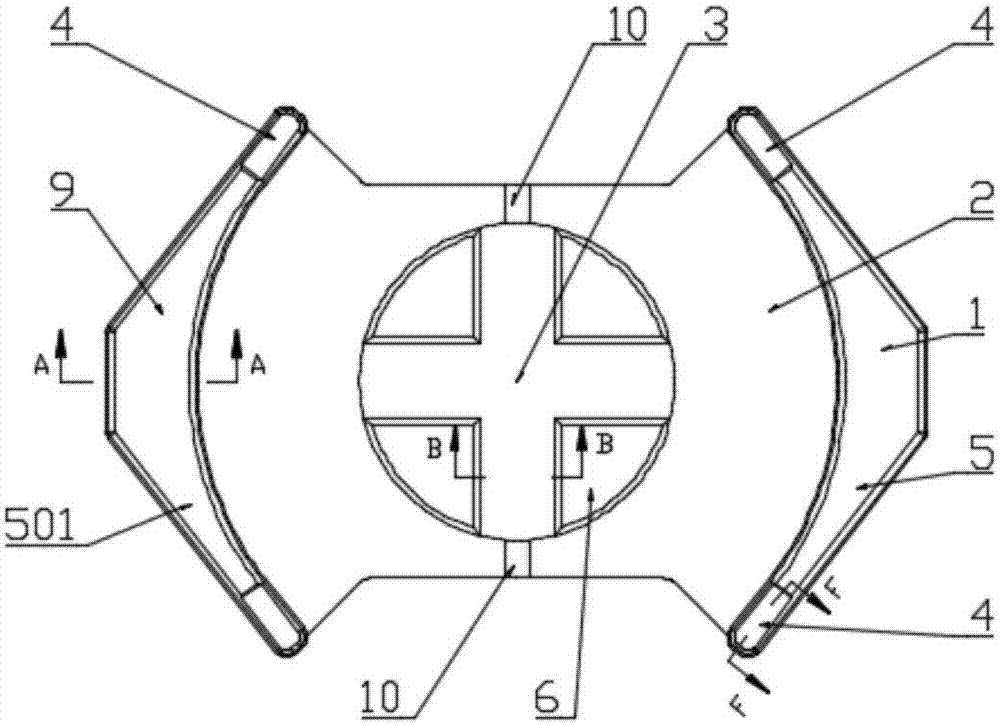

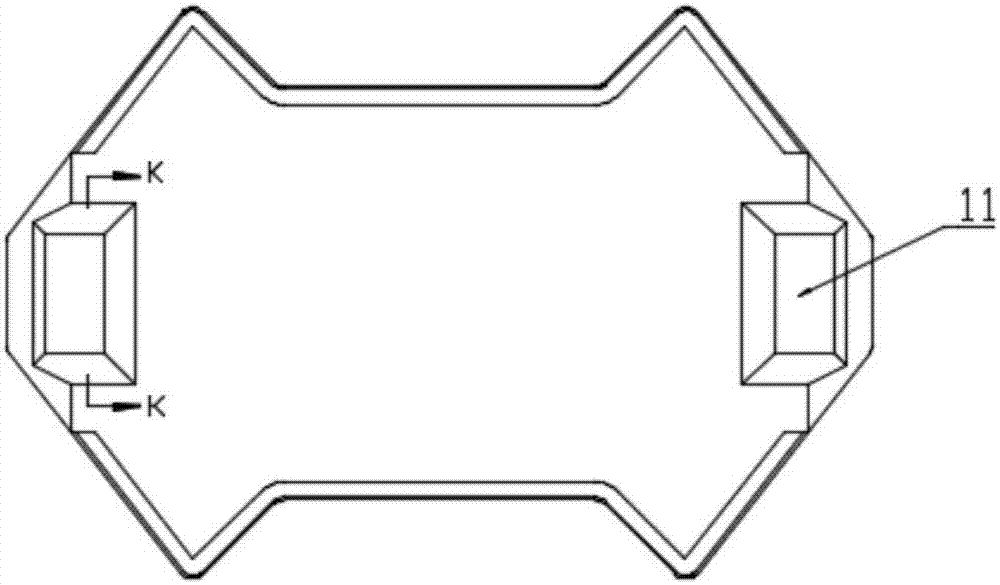

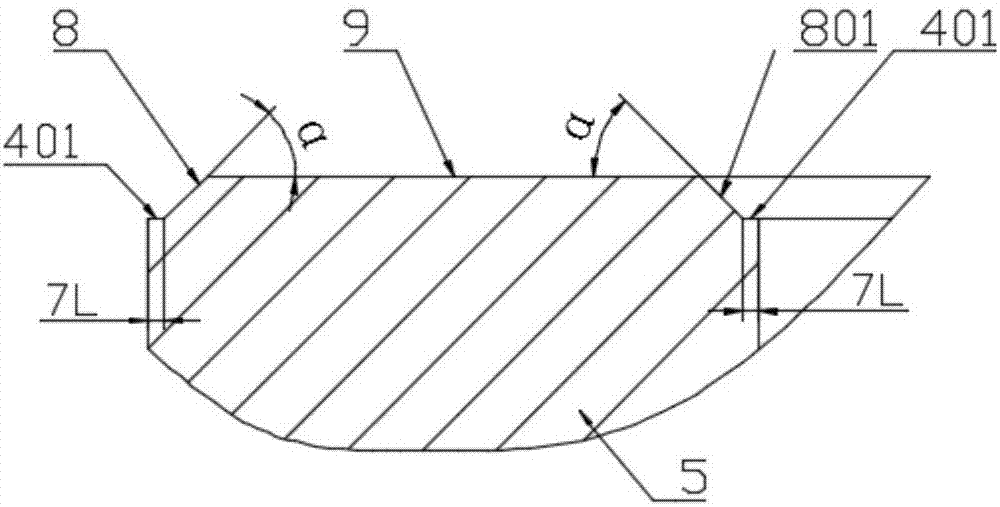

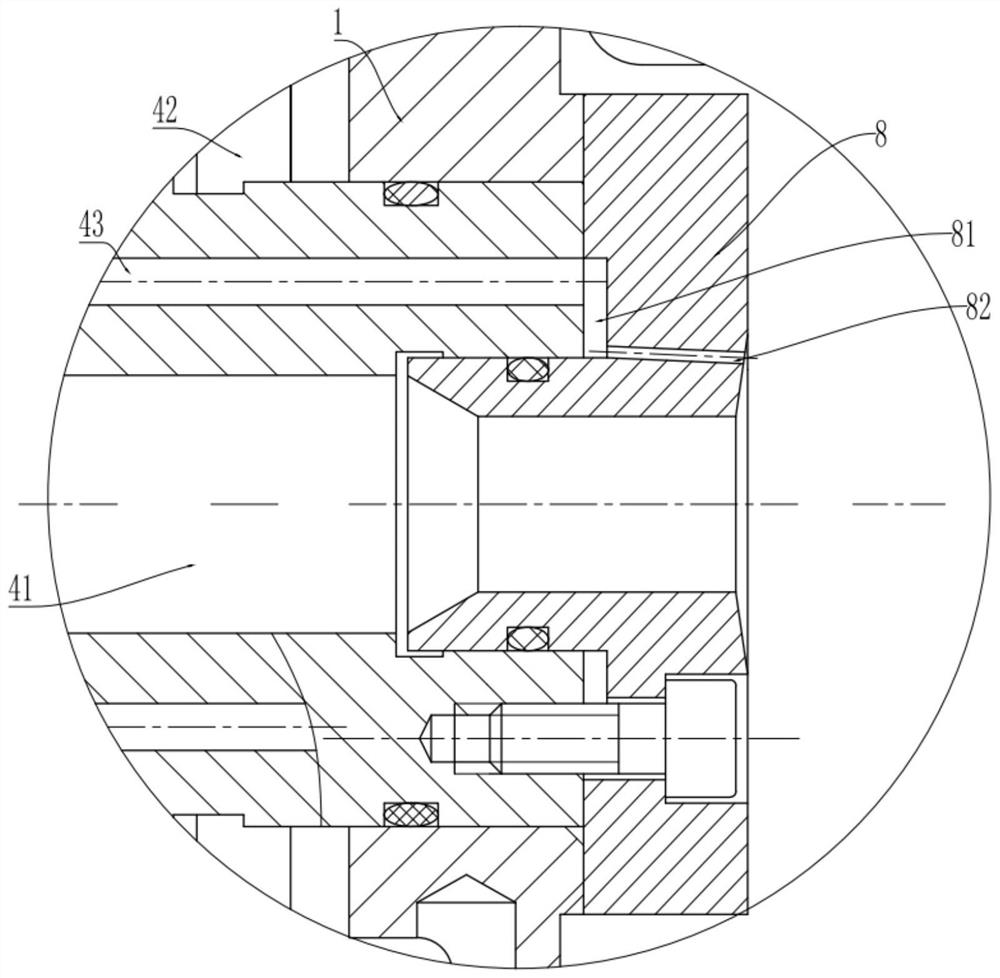

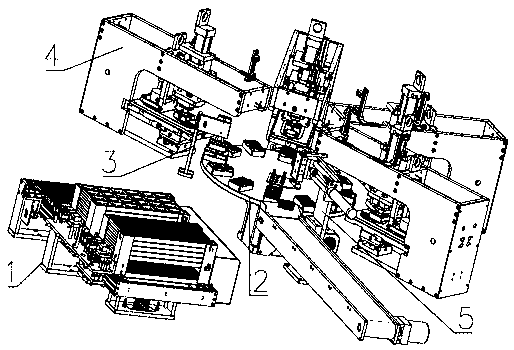

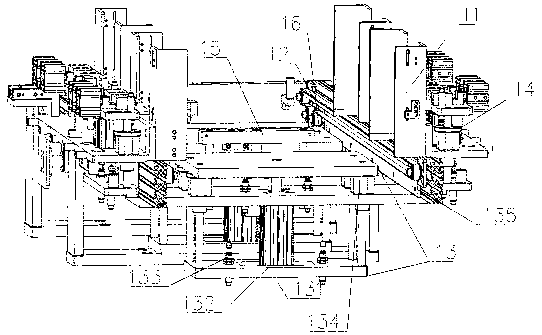

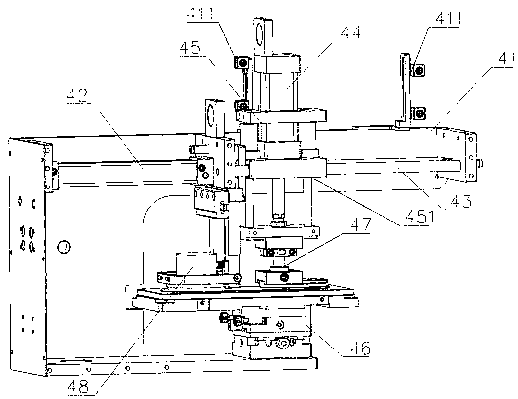

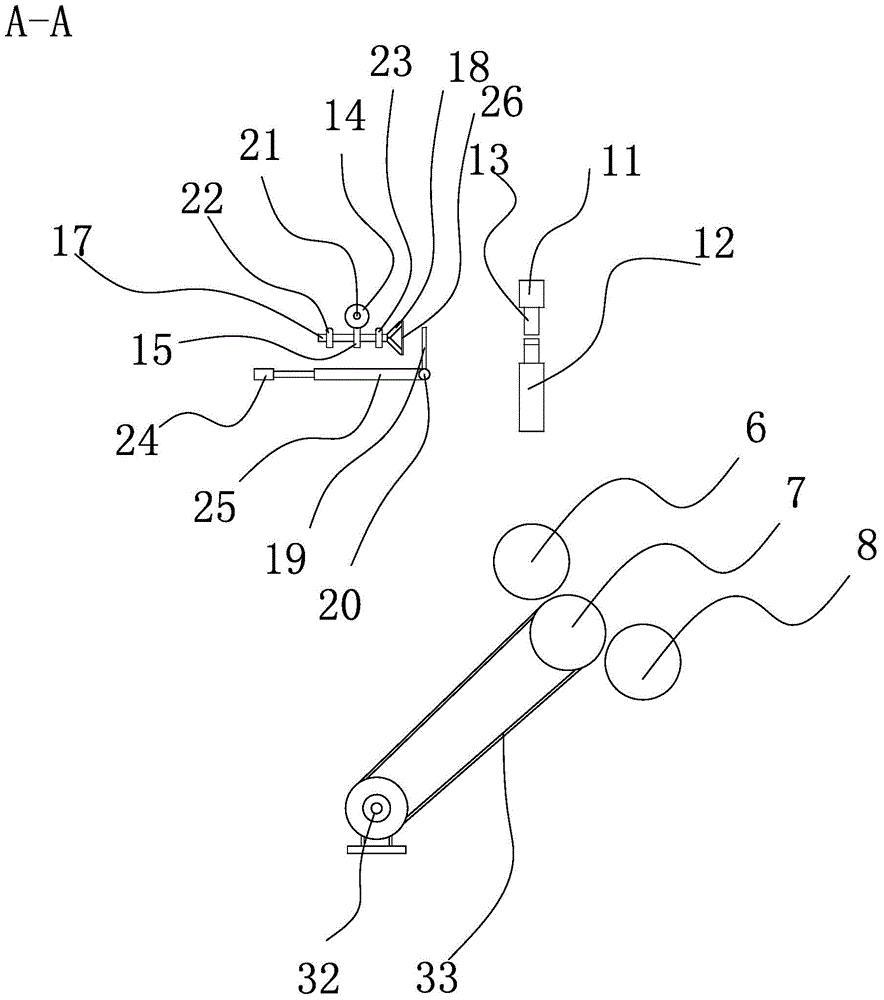

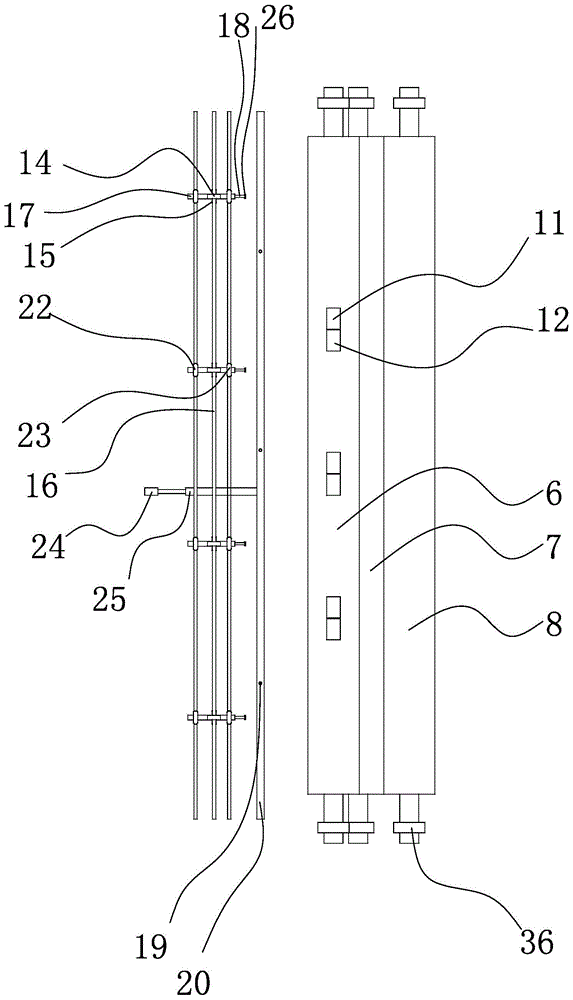

Metal wound gasket inner ring machining equipment

InactiveCN111451782AAuto resizeSolve processing efficiencyOther manufacturing equipments/toolsGrinding machinesMachiningWorkbench

The invention discloses metal wound gasket inner ring machining equipment, and belongs to the technical field of metal part machining. The metal wound gasket inner ring machining equipment comprises afeeding device and a workbench, a grinding and rust removing device, a guide traction device, a cleaning device and a bending forming device are sequentially arranged in the length direction of the workbench, a cutting device is arranged above the bending forming device, the feeding device comprises a bearing base plate, a driving assembly and a fixing assembly, the grinding and rust removing device comprises a first grinding assembly and a second grinding assembly, the guide traction device comprises a positioning guide assembly, a driving guide assembly and an adjusting traction assembly, and the bending forming device comprises a protective cover, a limiting assembly, a forming assembly and a driving adjusting assembly; and the protective cover is arranged on the top of the workbench in a covering mode and can form a containing space, and a guide slide way is arranged on the workbench. The metal wound gasket inner ring machining equipment has the advantages that the automation degree is high, the manual labor force is reduced, in addition, conveying of steel bars with different sizes can be realized, the practicability is higher, and the production quality of metal winding gasket inner rings is improved.

Owner:李林清

Automobile axle material

The invention discloses an automobile axle material. The automobile axle material comprises, by weight, 0.25%-0.35% of C, 0.2%-0.5% of Si, 0.5%-0.8% of Mn, 06%-1.2% of Cr, 0.40%-0.60% of Mo, 015%-0.25% of V, 0.001%-0.030% of S, 0.1%-0.5% of Al, 0.25%-0.55% of Cu, 0.6%-1.2% of Ti, 0.05%-0.2% of Ni and the balance Fe and inevitable impurities. In addition, the weight percentage of P is limited below 0.05%, and the weight percentage of O is limited below 0.06%. An axle steel pipe prepared from the material is high in strength and surface hardness, good in impact toughness, excellent in anti-fatigue performance; and steel has excellent hardenability and good comprehensive mechanical performance, and the surface hardness of a nitride layer of the steel is 1000 HV or over.

Owner:ANQING JIAN AUTO PART FORGING & ROLLING

Cleaning device for wheel hub processing

InactiveCN107470200AEfficient removalEasy to dryDrying gas arrangementsCleaning using toolsEngineeringStain

The invention discloses a cleaning device for wheel hub processing. The cleaning device for wheel hub processing comprises a wheel hub processing cleaning device body which comprises a cleaning box. The top of the cleaning box is fixedly connected to fixed racks, a wheel hub placing chamber is formed between the fixed racks, a drying box is fixedly connected to the tops of the fixed racks, an inner shell is arranged in the cleaning box, and a baffle plate is arranged in the cleaning box. According to the cleaning device for wheel hub processing disclosed by the invention, a wheel hub is rotated, so that a hairbrush can eliminate stains on the surface of the wheel hub thoroughly, and the cleaning effect of the wheel hub is improved; as the hairbrush is in direct contact with the surface of the wheel hub, stains attached to the surface of the wheel hub can be taken away effectively, so that the cleaning effect of the wheel hub is improved; the wheel hub is dried from different angles by means of a drier, so that the drying effect of the wheel hub is improved, and the advantage of cleaning the wheel hub thoroughly is achieved, and therefore, the problem that the production quality of the wheel hub is affected as the cleaning effect of the existing wheel hub is relatively poor is solved effectively.

Owner:孙永丽

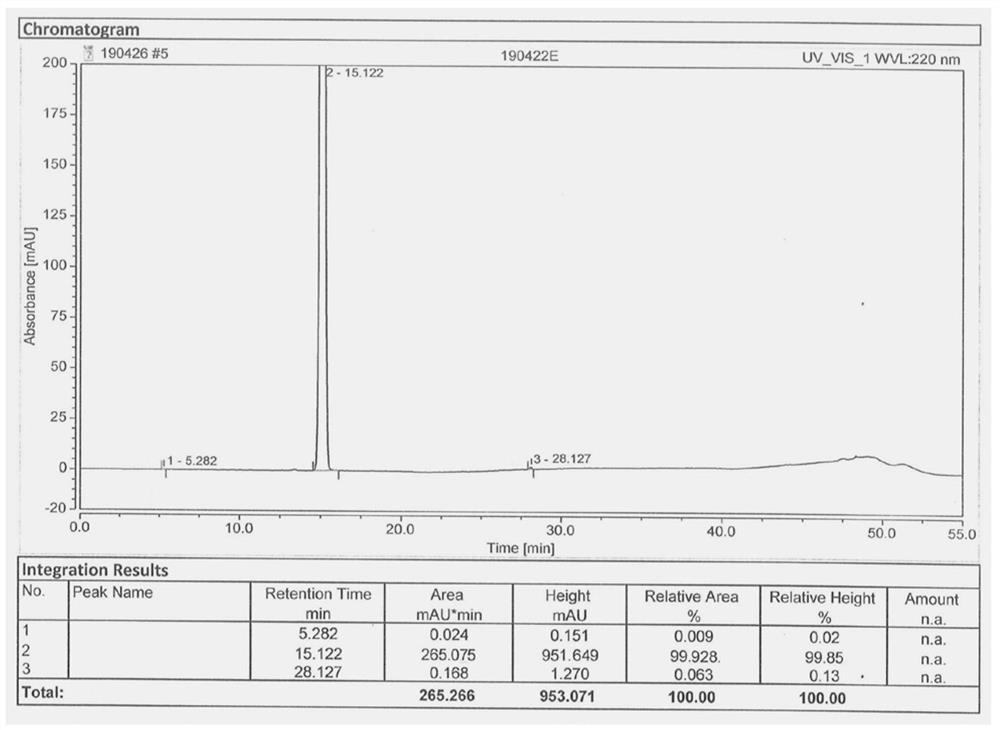

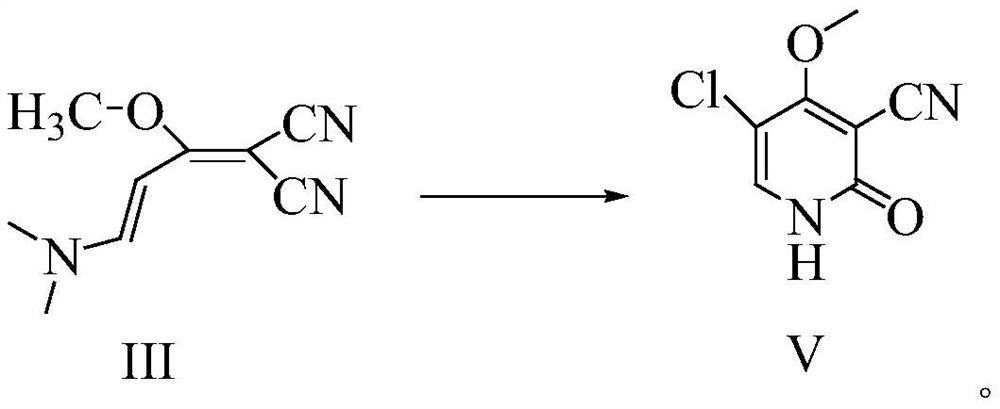

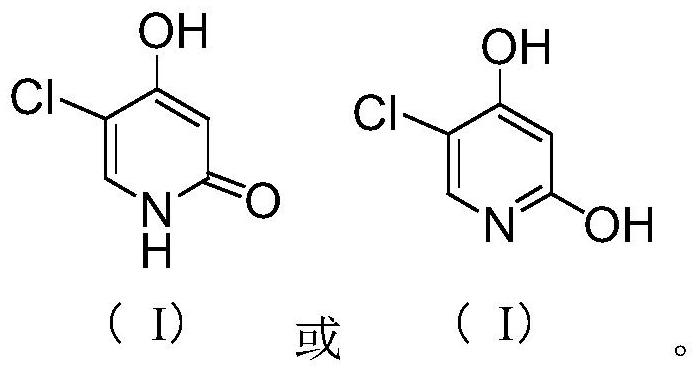

Preparation method of gimeracil intermediate

PendingCN112110854AHigh puritySolve the quality of productionOrganic chemistrySulfonyl chlorideChemical synthesis

The invention belongs to the technical field of chemical synthesis, and provides a method for preparing a gimeracil intermediate 5-chloro-3-cyano-4-methoxy-2(1H)-pyridone, wherein the method comprisesthe steps: by using 1,1-dicyano-2-methoxy-4-(N,N-dimethylamino)-1,3-butadiene as a starting material, carrying out reflux cyclization in an acetic acid aqueous solution with the mass fraction of 80%,cooling the reaction solution, adding acetic anhydride, heating to a required temperature, dropwise adding sulfonyl chloride for chlorination, and treating to obtain a product. The method is good inyield, high in purity, easy to operate, capable of saving production cost and suitable for industrial production.

Owner:LUNAN PHARMA GROUP CORPORATION

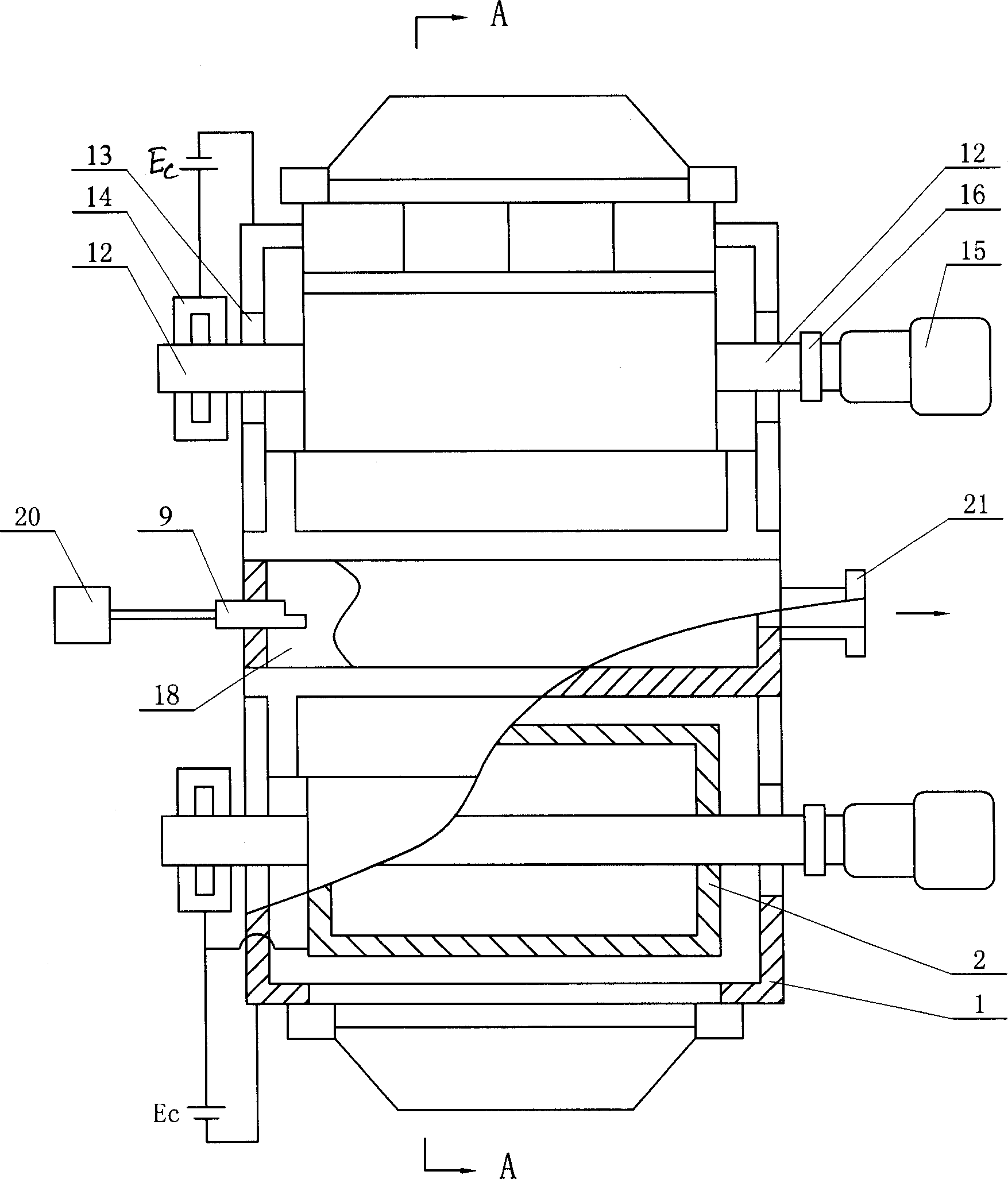

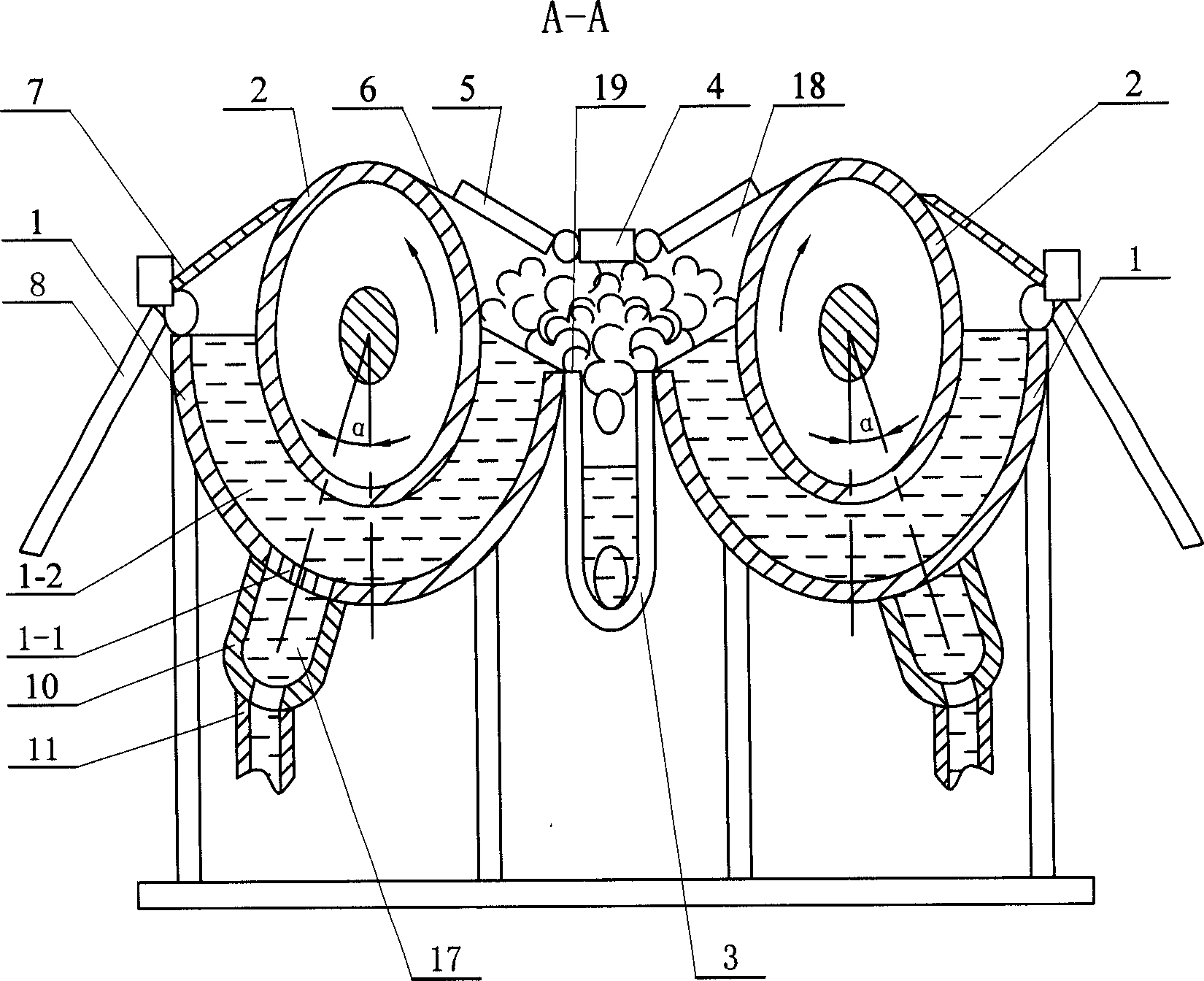

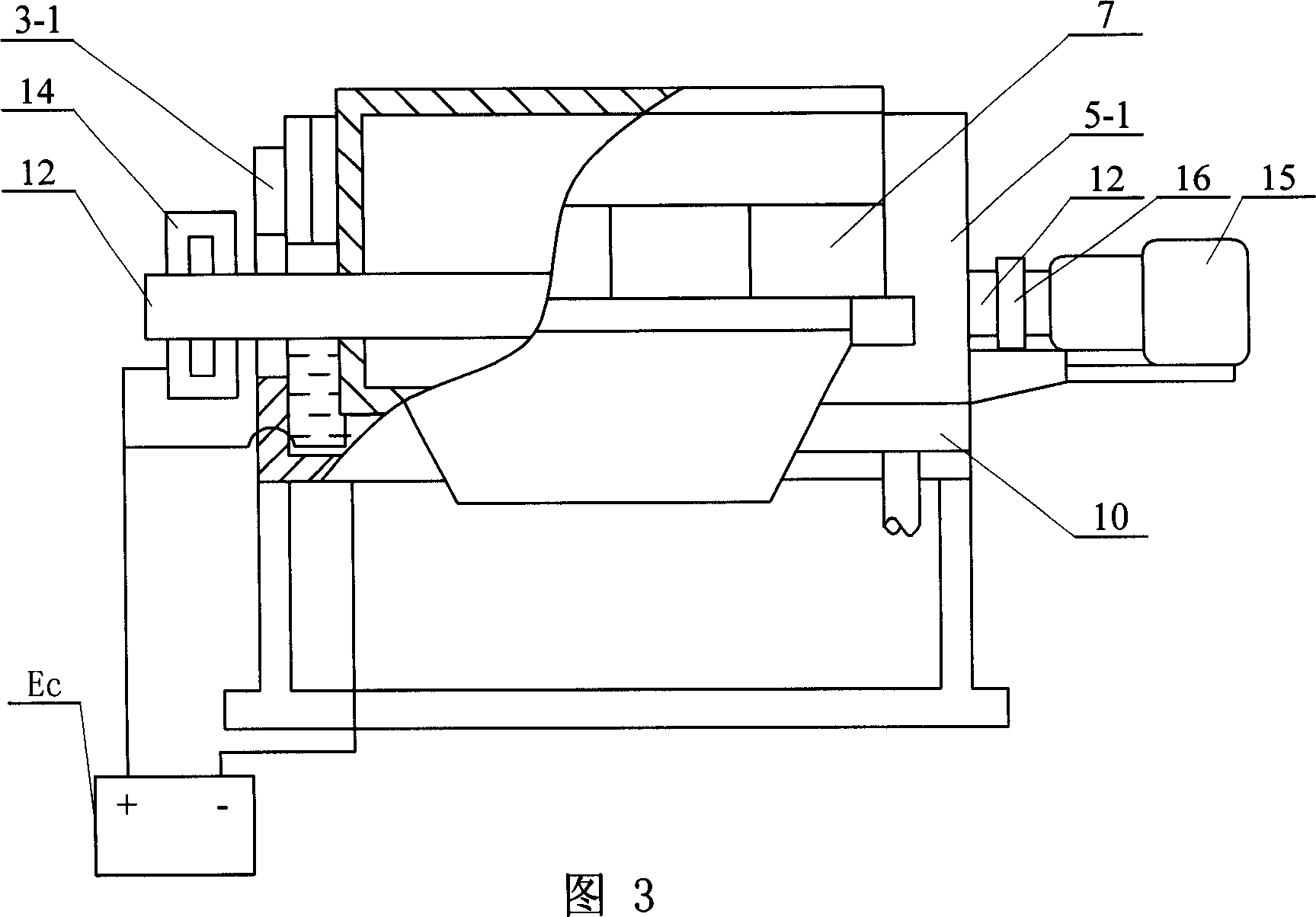

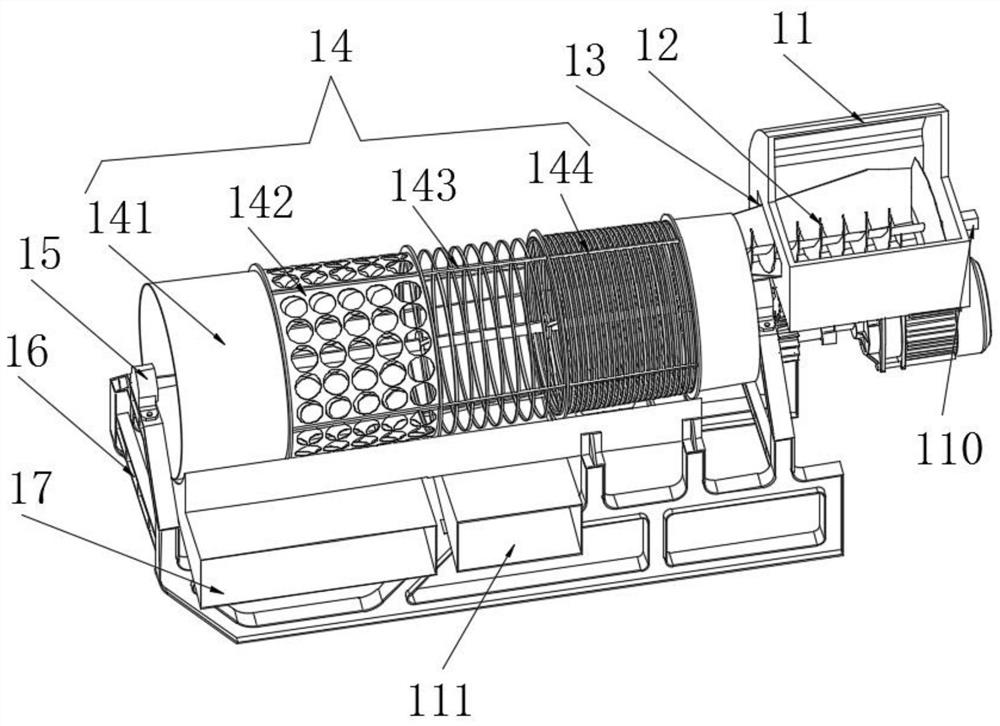

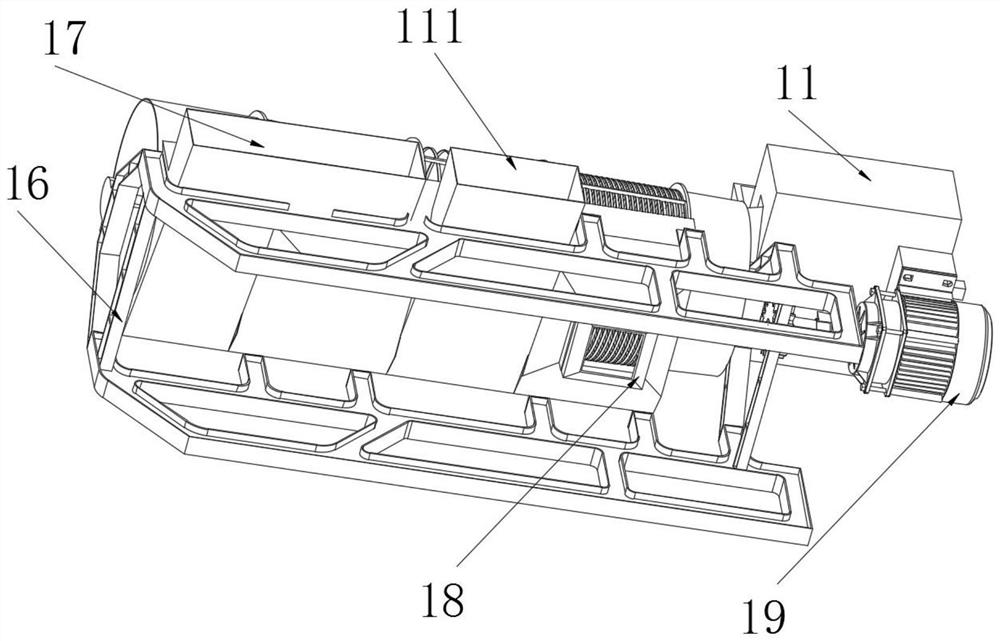

Agricultural organic acid, organic acid preparation method and its preparing apparatus

InactiveCN1769257ASurfactantWith ion exchangeElectrolysis componentsOrganic compound preparationOrganic acidElectricity

The invention relates an organic acid, used for agriculture, and the equipment and method for preparation of it. It is not good for ecological balance if the polluted farmland is not detoxicated and purified on time. The said organic acid is made by extracting humic coal and carbonaceous flammability biogenetic rock by alkali and then electrolyzing, electrophoresing and using electroflotation. The method comprises the following steps: extracting the homogeneous slip grinded by humic coal and carbonaceous flammability biogenetic rock by alkali, then entering it into preparing equipment, electrolyzing, electrophoresing, and using electroflotation, finally educing the end product. In preparing equipment, the electrolyser(1) is connected with the negative pole of electrical source, the revolving drum(2), on the top of which there is a scraping knife, is connected with the positive pole of electrical source. In the invention, the raw material is easy to get, the method is easy to operate, and the simple construction of preparing equipment is favorable for producing organic acid.

Owner:陈静

Processing technology of polypropylene household appliance plastic product

The invention discloses a processing technology of a polypropylene household appliance plastic product, and relates to the technical field of plastic products. A stirring reaction kettle comprises a stirring reaction kettle main body, a plurality of reaction kettle main body supporting columns are fixedly arranged on the surface of the stirring reaction kettle main body, a stirring reaction kettlefeeding port is formed in the upper surface of the stirring reaction kettle main body, a stirring reaction kettle driving motor is fixedly arranged on the upper surface of the stirring reaction kettle main body, a stirring rod main body is arranged at the position, located at the driving end of the stirring reaction kettle driving motor, inside the stirring reaction kettle main body through a coupler, a stirring rod main body connecting block is fixedly arranged on the surface of the stirring rod main body, and a second rotating shaft is arranged on the surface of the stirring rod main body connecting block in a penetrating mode. The problems that a polypropylene material cannot be completely mixed with a corresponding catalyst through a traditional device, so that the quality of subsequent injection molding products is influenced, and adverse effects are brought to the products produced by enterprises are solved.

Owner:杭州临安百盛生物科技有限公司

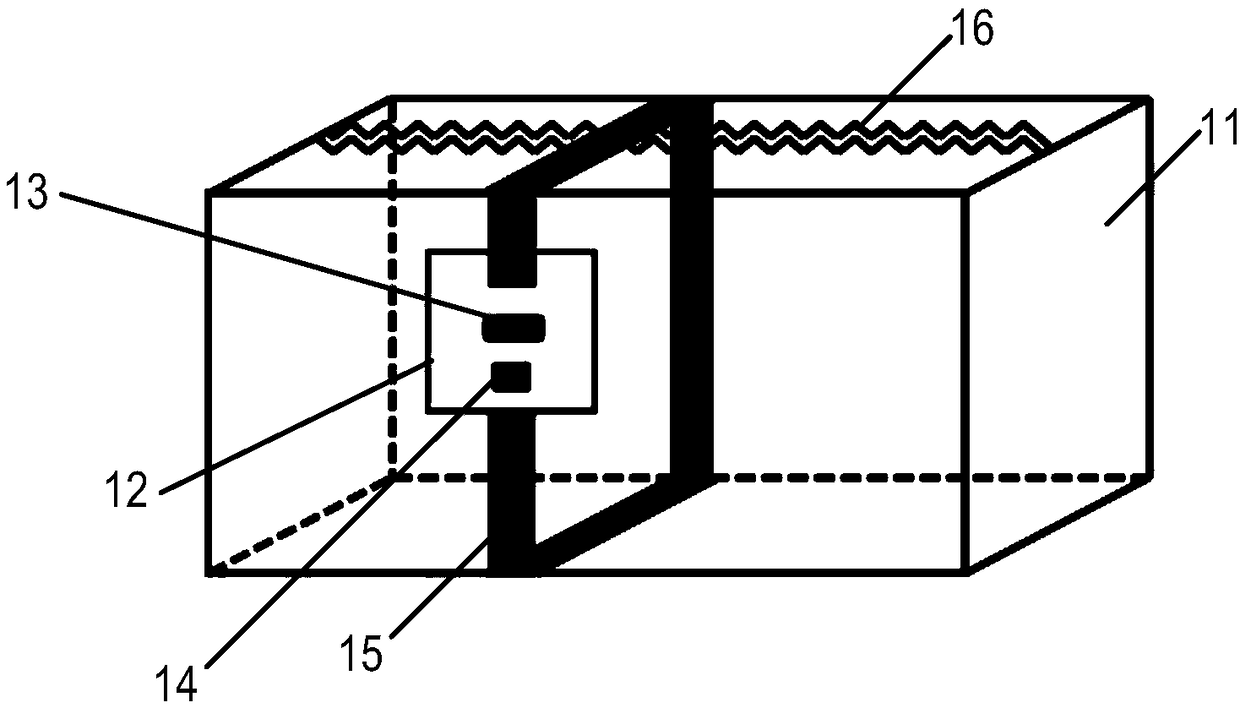

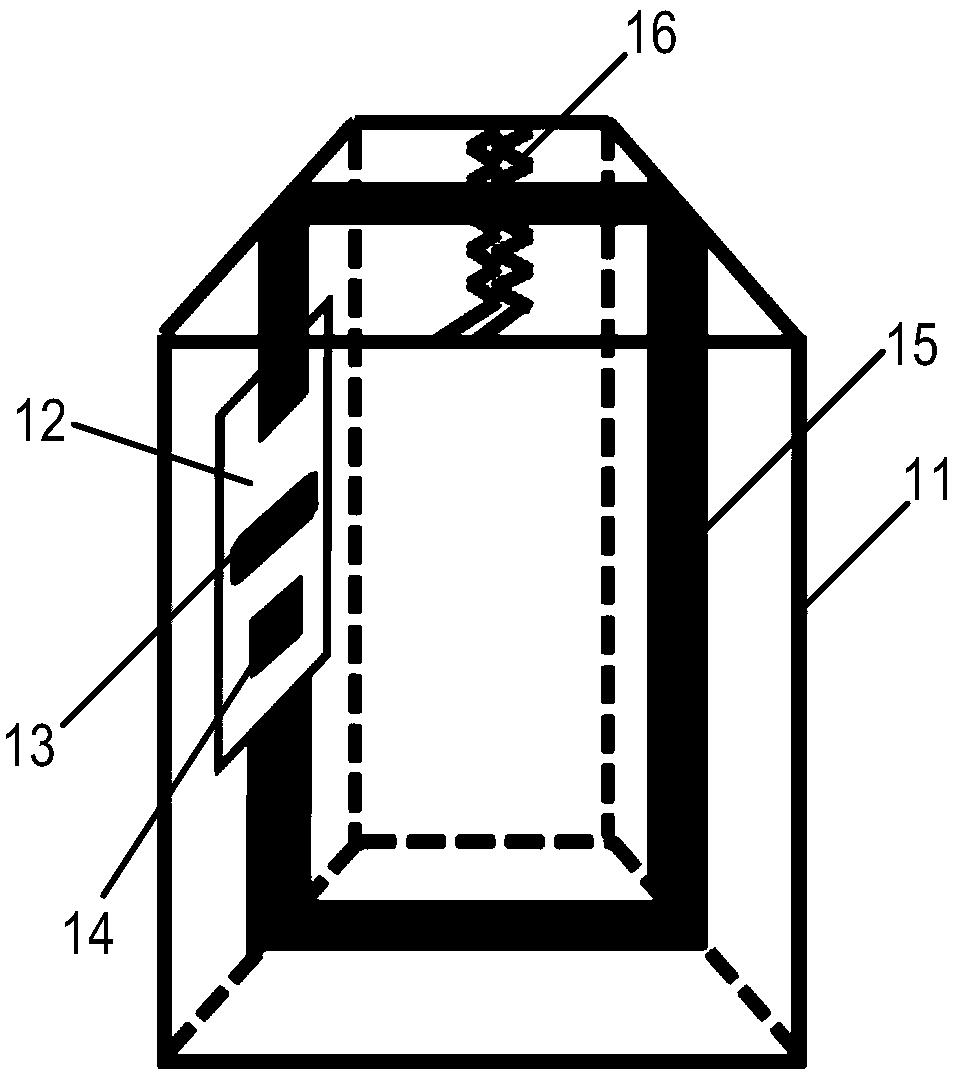

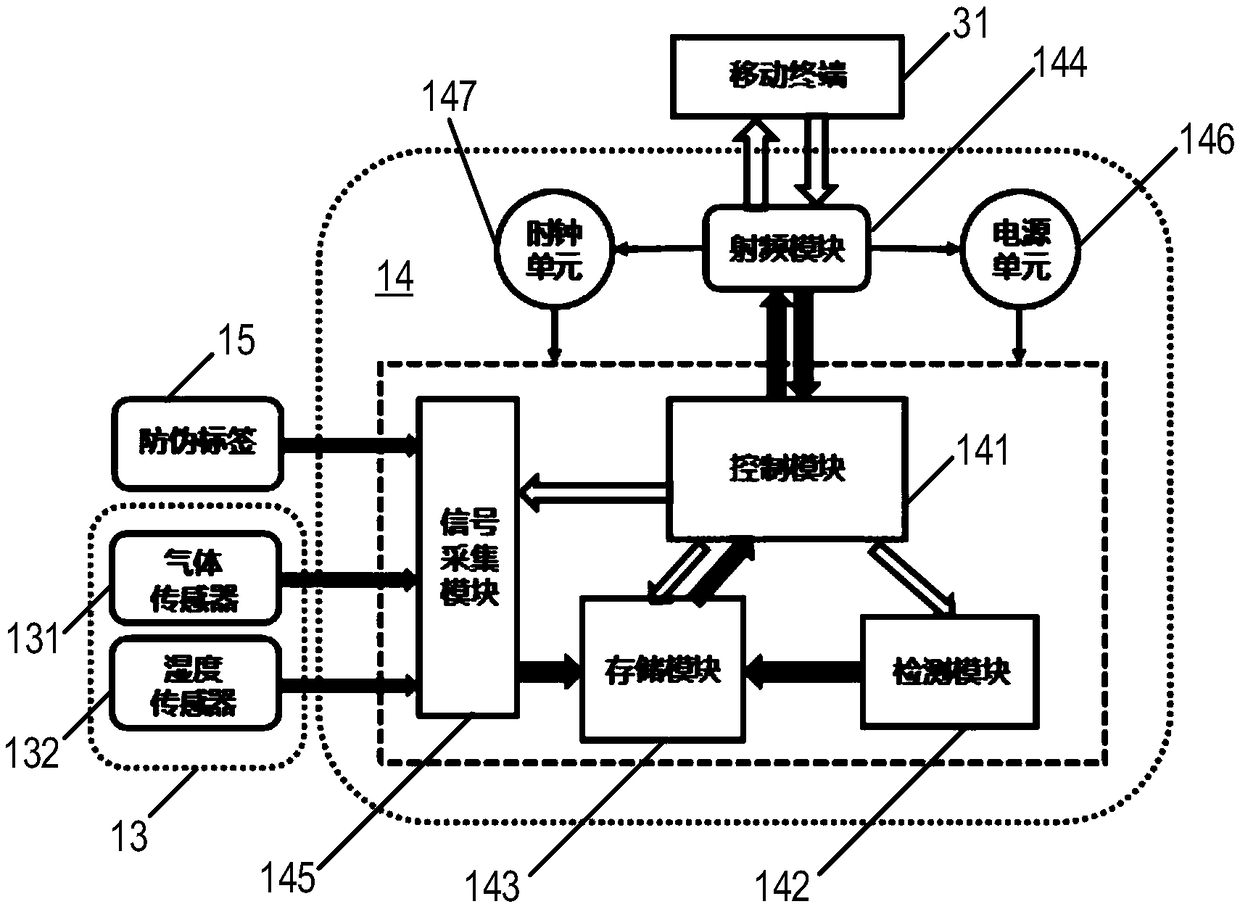

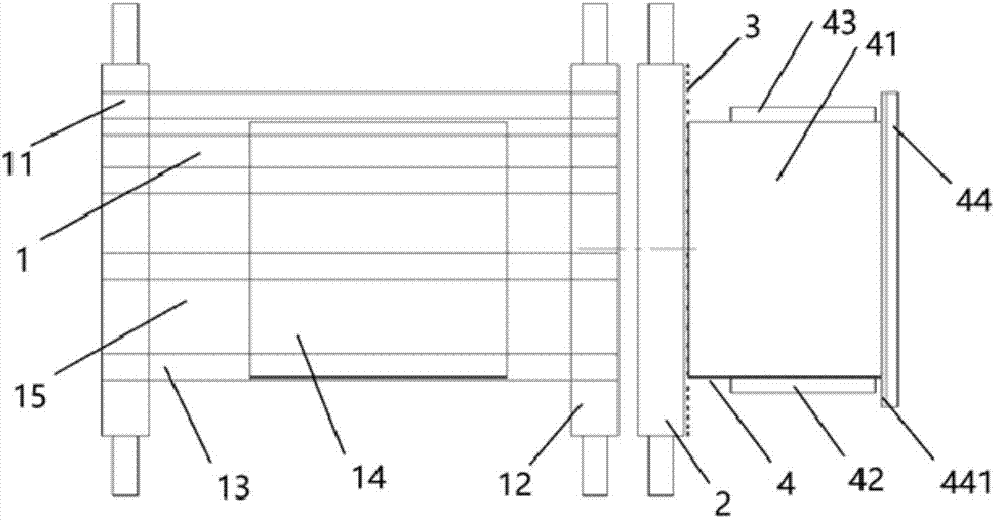

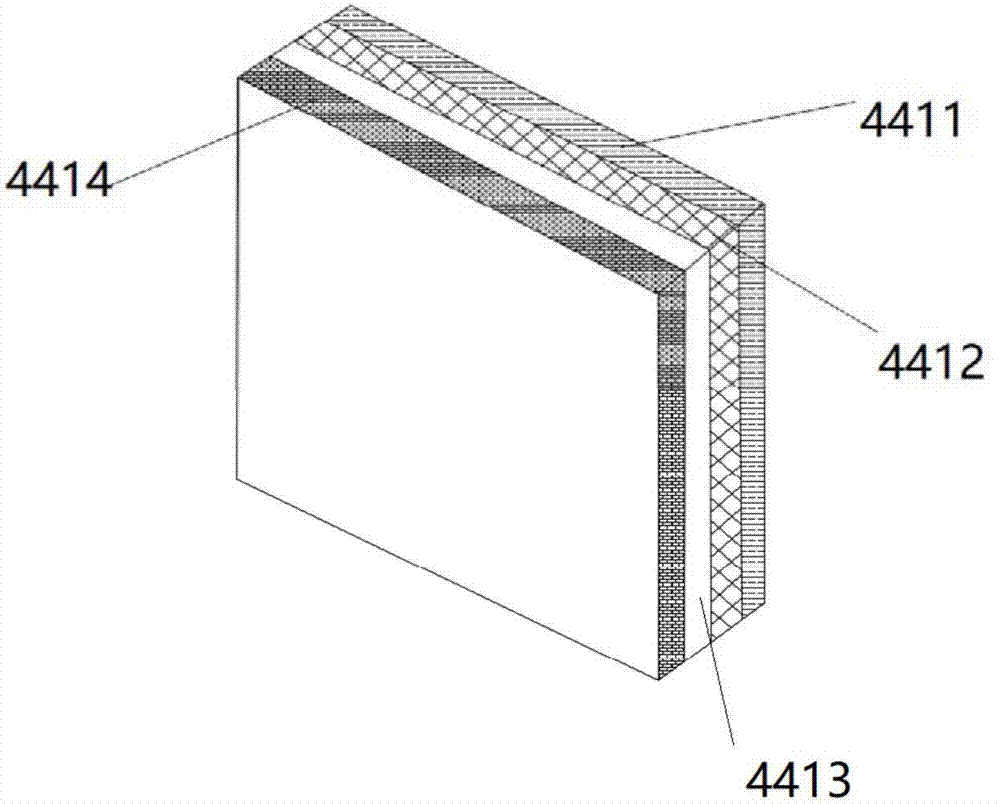

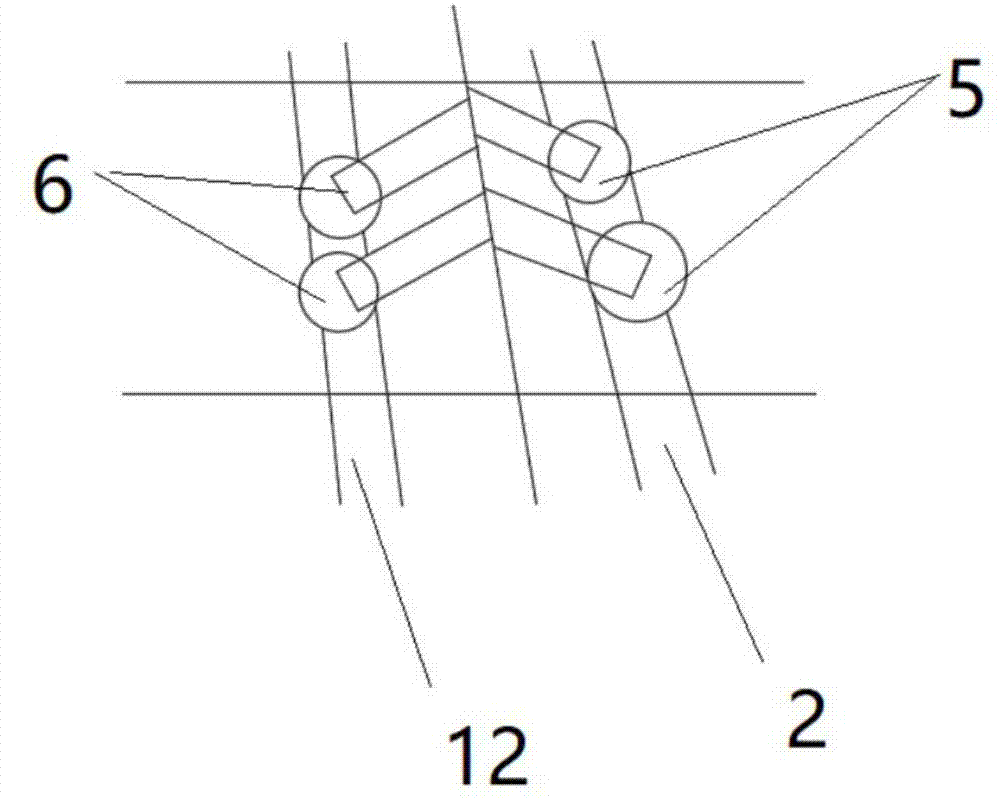

Packaging box with near field communication (NFC) chip, and control method thereof

ActiveCN108382729ARealize real-time detectionAvoid buyingPackagingElectrical resistance and conductanceNegative temperature

The invention relates to the technical field of product packaging, in particular to a packaging box with a near field communication (NFC) chip, and a control method thereof. The packaging box with theNFC chip comprises a sealed box body, a substrate, a sensing module and the NFC chip, wherein the substrate is adhered to the inner surface of the box body; the sensing module is arranged in the substrate and comprises a gas sensor and a humidity sensor; the NFC chip is arranged in the substrate, is connected with the sensing module, and comprises a detection module for detecting the temperatureof the inner part of the box body; and the detection module obtains the temperature of the inner part of the box body through the calculation of a temperature-sensitive resistor with a positive temperature coefficient, a first weight corresponding to the temperature-sensitive resistor with the positive temperature coefficient, a temperature-sensitive resistor with a negative temperature coefficient, a second weight corresponding to the temperature-sensitive resistor with the negative temperature coefficient. According to the packaging box with the NFC chip provided by the invention, the product quality in the packaging box can be accurately known without the need for disassembling the packaging box, and the use experience of a user is improved.

Owner:SHANGHAI JIAO TONG UNIV

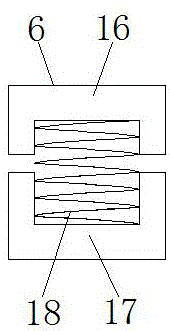

Finished paper winding device

InactiveCN107986077ASolve the quality of productionSolve problems affecting film production qualityPile receiversArticle deliveryPulp and paper industryConductor Coil

Owner:CHANGDE JINDE NEW MATERIAL TECH CO LTD

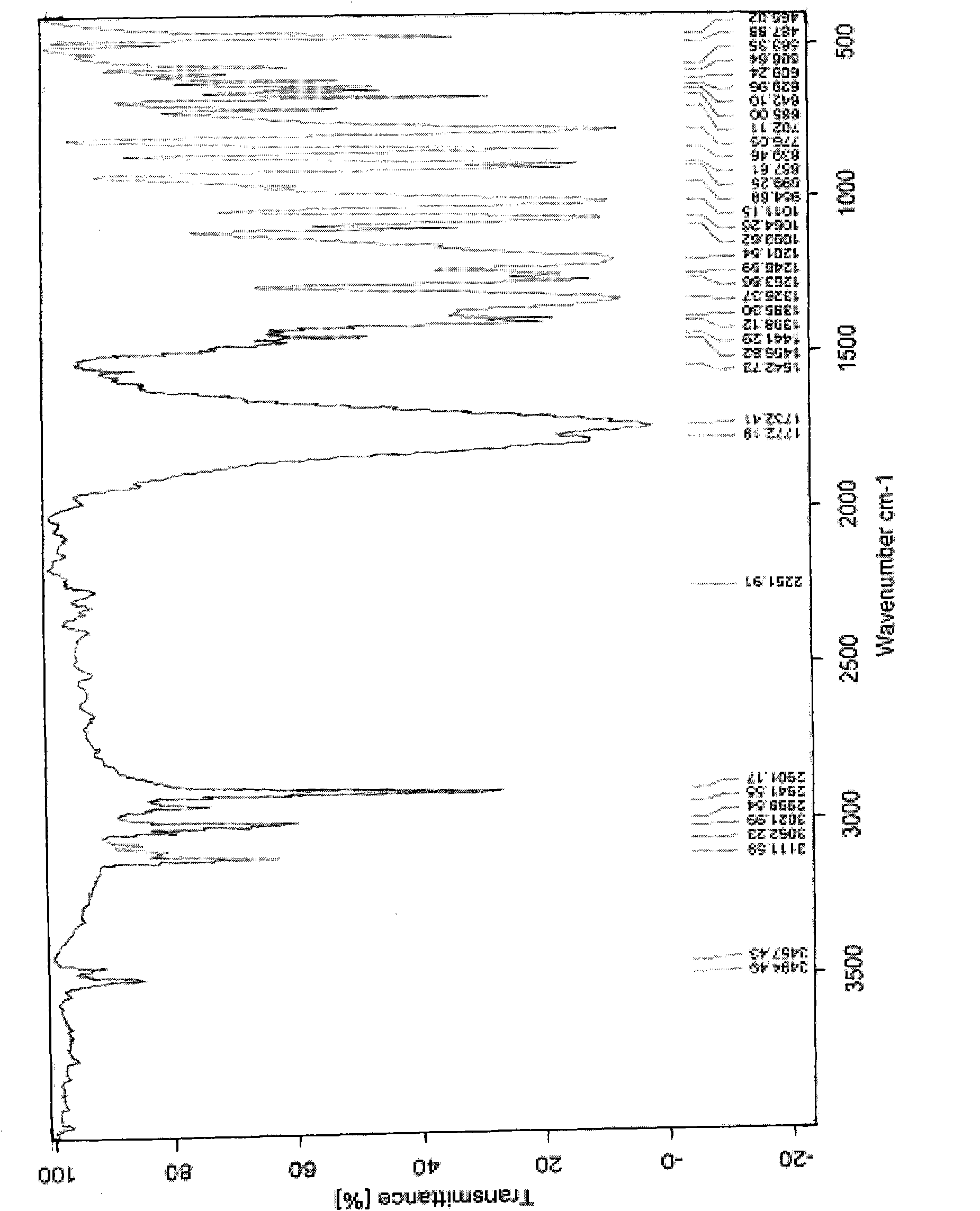

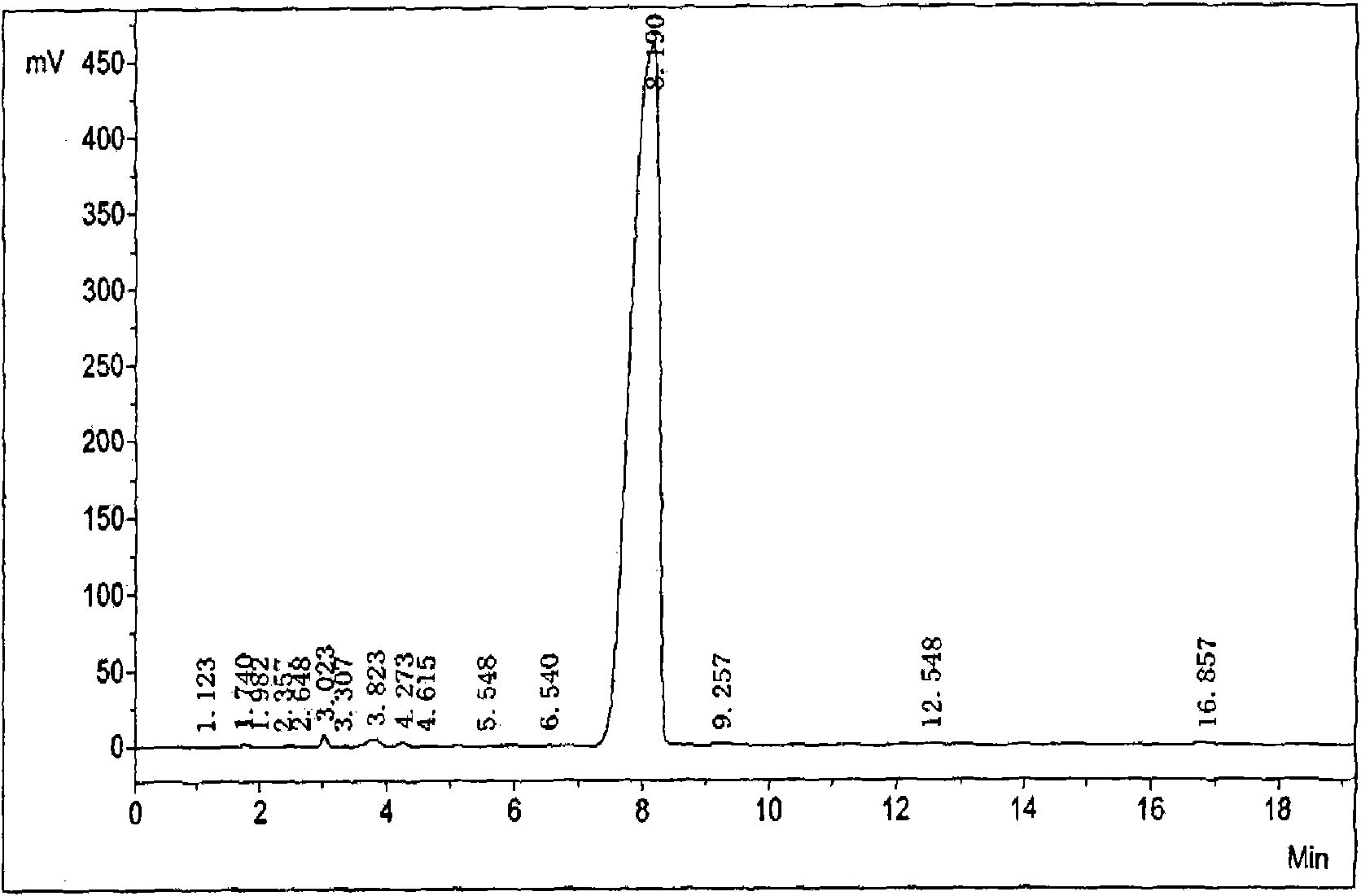

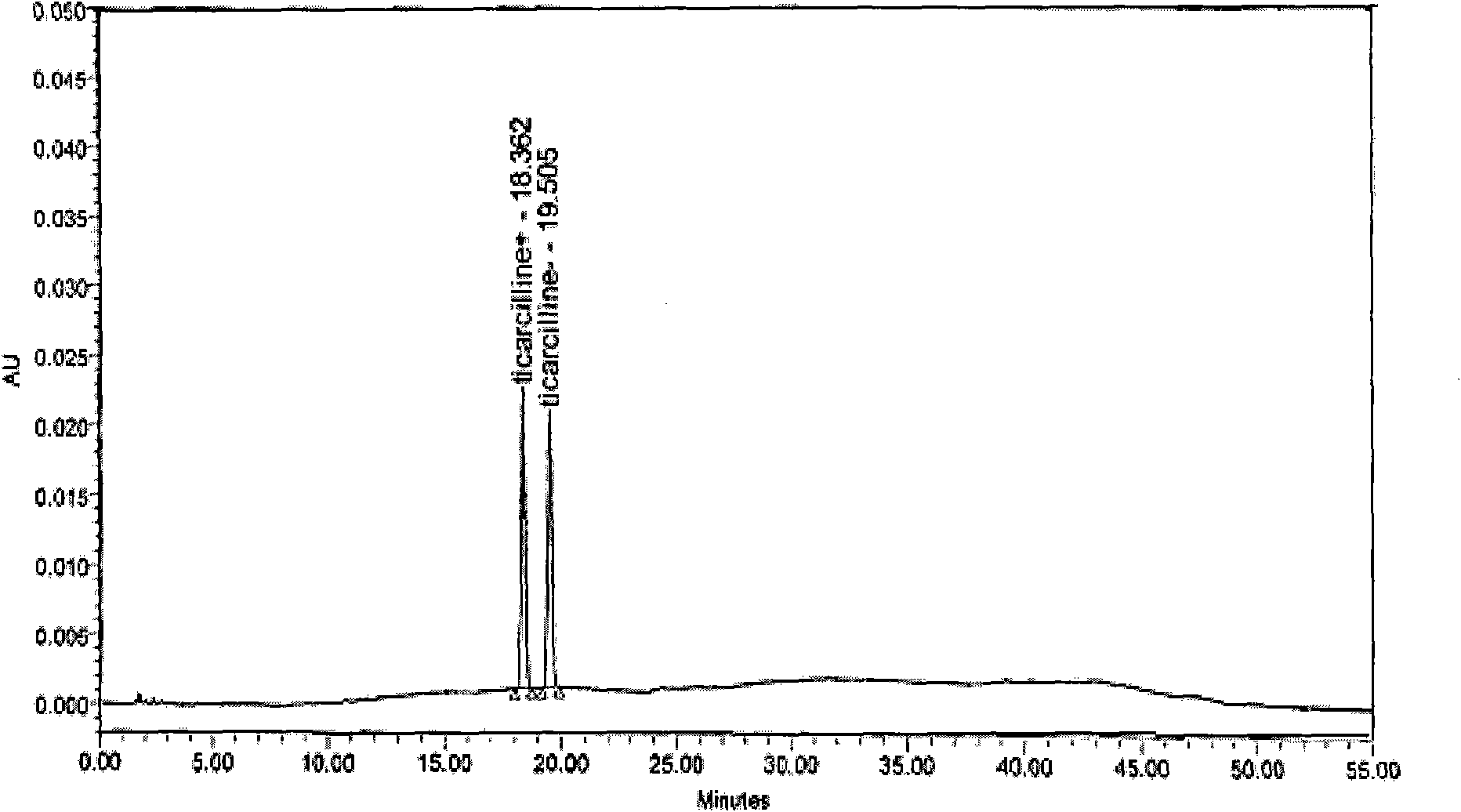

Carboxylic acid penicillin amine salt and application thereof in preparing high-purification sodium oxacillin salt

The invention relates to a carboxylic acid penicillin dibenzyl (substituting benzyl) ethylenediamine salt compound and an application thereof in preparing a high-purification sodium oxacillin salt. The carboxylic acid penicillin dibenzyl (substituting benzyl) ethylenediamine salt compound has a structure as the formula II, and carboxylic acid penicillin comprises ticacillin, carbenicillin and thelike, wherein R is thiofuran-3-group or phenyl; R1, R2 and R3 are respectively independent H, alkyls of C1-C5, halogens and nitryl; and substituent groups of the substituted alkyl are selected from the halogens and alkoxy groups of C1-C5.

Owner:QILU PHARMA HAINAN +1

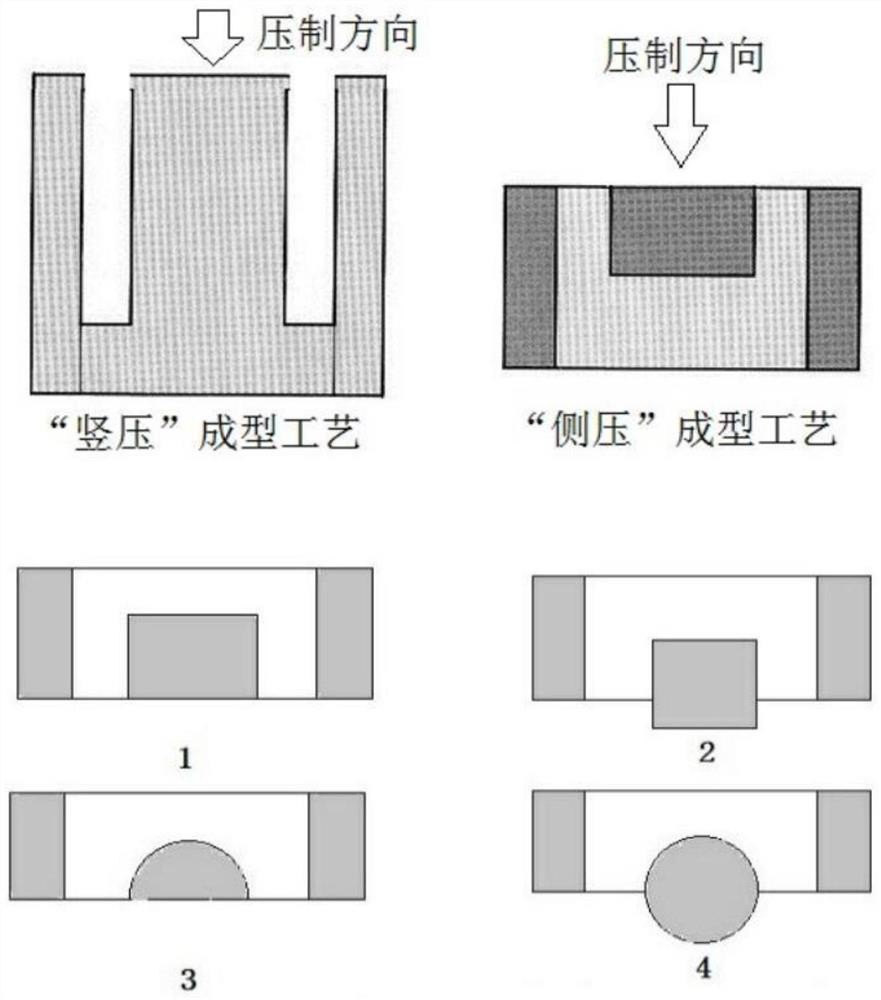

Manufacturing process of special-shaped ferrite magnetic core

PendingCN114005669AHigh dimensional accuracyOvercome the phenomenon that easily leads to product deformationMagnetic core manufactureManufacturing technologyPunching

The invention belongs to the technical field of ferrite, and particularly relates to a manufacturing process of a special-shaped ferrite core. The manufacturing process comprises the steps of (1) conducting punch forming, specifically, selecting soft magnetic ferrite particle powder, and preparing a sealed blank or a connected blank designed by the process on a vertical forming machine or a high-speed rotary forming machine by adopting a mold in a bidirectional punching manner; (2) sintering; (3) cutting and grinding; (4) carrying out ultrasonic cleaning; and (5) inspecting. According to the process, the phenomenon that a conventional preparation method for preparing the special-shaped magnetic core element is prone to causing product deformation can be overcome, the thinking frame that the special-shaped magnetic core element can only be formed in a vertical pressing mode but cannot be formed in a side pressing mode is broken through, and the process is achieved through a density compensation method. The manufacturing process is easy to operate, convenient to process and easy to industrialize, the special-shaped magnetic core element with high dimensional precision can be manufactured, the percent of pass is greatly increased, the cost is saved, and the manufacturing process has high industrial utilization value and is worthy of popularization and application.

Owner:江西尚朋电子科技有限公司

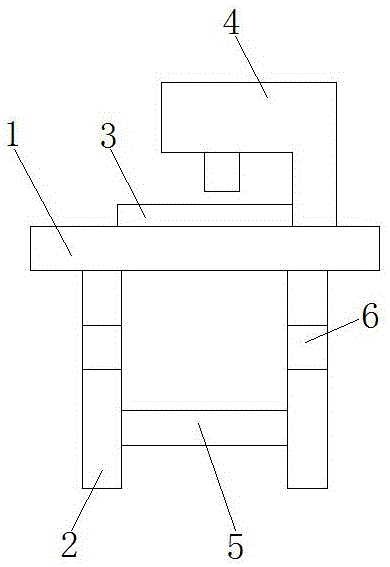

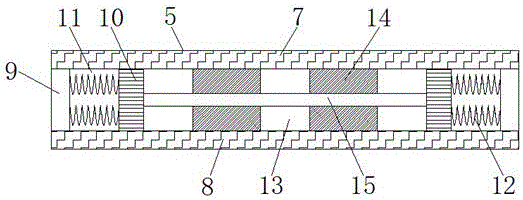

Sander with damping function

ActiveCN106695545AReduce vibrationSolve the quality of productionGrinding carriagesNon-rotating vibration suppressionDamping functionEngineering

The invention discloses a sander with a damping function. The sander comprises a connecting base, wherein two supporting legs are fixedly connected to the bottom of the connecting base; and a damping and stabilizing rod is fixedly connected between the two supporting legs and comprises a first connecting plate and a second connecting plate between which a supporting plate is fixedly connected. The sander can be damped to enable the supporting legs to keep stable, so that the vibration amplitude of the sander is reduced, and a damping role is played accordingly; and vibration energy generated in the sanding process of the sander is absorbed by buffering springs and damping springs, and energy generated in the vibrating process can be effectively absorbed by rubber layers, so that the vibration amplitude of the sander is reduced, the advantage of damping is achieved, and accordingly, the problem that the production quality of mechanical parts is reduced because the sanding effect on the mechanical parts is influenced by large vibration amplitude of a conventional sander is effectively solved.

Owner:中山市魅旗雕塑有限公司

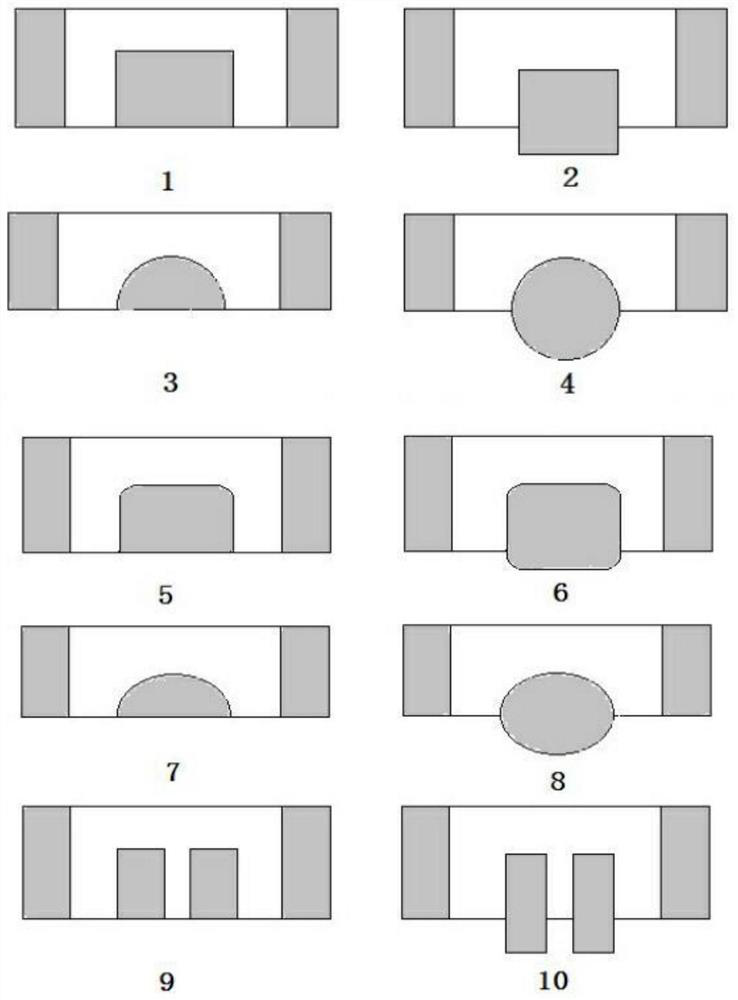

Soft magnetic ferrite magnetic core component and formation method thereof

InactiveCN106971839ABreak the traditional craft design ideasReduce the grinding surfaceTransformers/inductances detailsInductances/transformers/magnets manufactureSoft magnetGrinding wheel

The invention provides a formation method of a soft magnetic ferrite magnetic core component. A magnetic core component blank is fabricated by taking soft magnetic ferrite magnetic core powder as a raw material and by employing a die pressing formation process, the magnetic core component blank is sintered to form a soft magnetic ferrite magnetic core component product, the soft magnetic ferrite magnetic core component blank comprises a magnetic core bottom plate, an edge leg post is arranged at each of two end parts of a magnetic core bottom plate, an intermediate post is arranged between the two edge leg posts on the magnetic core bottom plate, the magnetic core component blank is placed in a sintering device for sintering in a mode that the magnetic core component blank is laminated and tightly stacked, and grooves and / or steps or miniature step structures in different shapes are arranged in an intermediate post end surface, the edge leg posts, edge leg post corners and / or a bottom plate end surface of the magnetic core component blank. By arranging miniature steps on the edge leg corners of the magnetic core component, the leg corners can be prevented from being collided and damaged during transportation, and the qualified rate is improved; by arranging the miniature steps on the edge leg posts of the magnetic core component, mutual adhesion and deformation during sintering can be effectively improved; the intermediate post density of the magnetic core component can be improved, and the problem of small size of the intermediate post after sintering is effectively solved; and the grinding surface of the magnetic core component is reduced, the grinding efficiency can be improved, the loss of a grinding wheel is reduced, and the cost is reduced.

Owner:江西尚朋电子科技有限公司

Nitriding steel for shaft type materials and preparing method of nitriding steel

InactiveCN105908077AImprove hardenabilityExcellent machinabilitySolid state diffusion coatingMetal rolling arrangementsMetallurgyImpurity

The invention discloses nitriding steel for shaft type materials and a preparing method of the nitriding steel. The nitriding steel comprises, by weight percent, 0.2%-0.3% of C, 0.1%-1% of Si, 0.5%-1% of Mn, 1%-1.2% of Cr, 0.001%-0.030% of S, 0.1%-0.5% of Al, 0.6%-1.2% of Ti, 0.05%-0.2% of Ni and the balance Fe and inevitable impurities. The content of the element P is limited to be lower than 0.02%, and the content of the element O is limited to be lower than 0.06%. According to the nitriding steel for the shaft type materials and the preparing method of the nitriding steel, the technical problems in the aspects of a traditional nitriding steel production technology, quality and using can be effectively solved.

Owner:ANQING JIAN AUTO PART FORGING & ROLLING

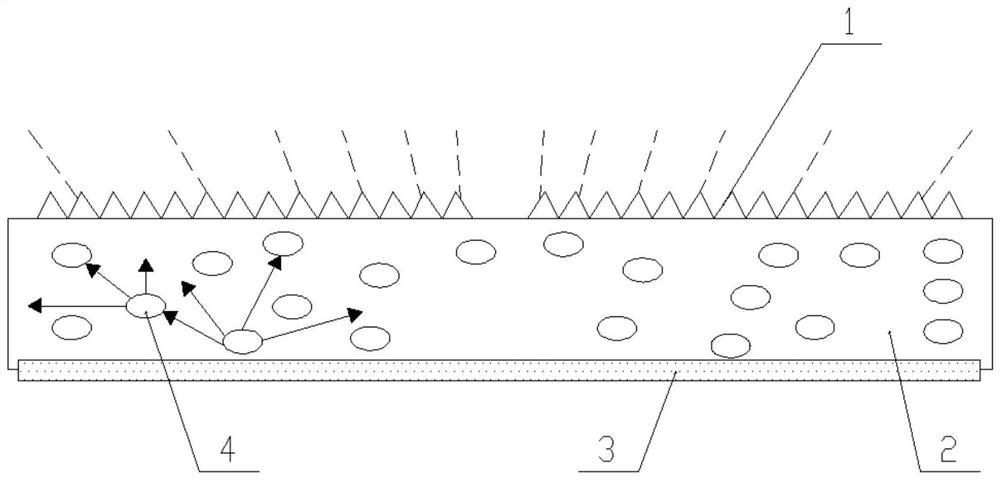

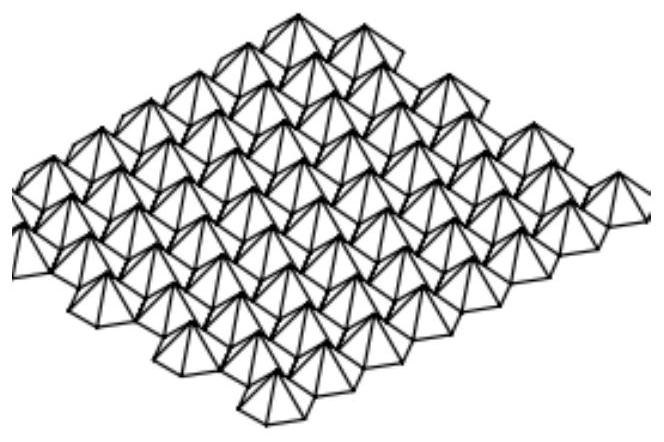

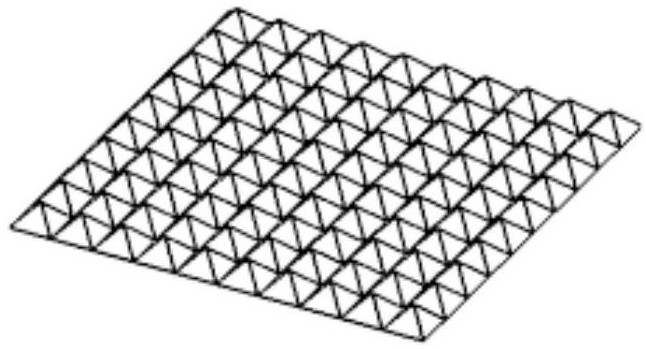

Diffusion and brightening composite optical film and preparation method thereof

ActiveCN113504591AReduce use costIncrease productivityPrismsDiffusing elementsThin membraneChemistry

The invention provides a diffusion and brightening composite optical film and a preparation method thereof, the diffusion and brightening composite optical film is prepared by co-extruding and compounding a diffusion layer with a diffusion microstructure function and a brightening layer with a brightening functional structure, and the problems that in the coating process of an existing optical diffusion film product, the production efficiency and the quality yield of the prepared product are reduced, The result shows that the PET extrusion film cannot meet the optical requirements of high fog and high transmittance; meanwhile, a coating process is adopted, so that pollution to the environment is caused, and in the subsequent processing process, the defect that the product quality is affected by dust generated by coating falling does not occur. The use convenience and the thin film use turning-out are improved, the use cost is reduced, and the production efficiency is improved.

Owner:JIANGXI SHENGHUI OPTICAL TECH

Water absorbing and toughening material for plastic moulding

The invention discloses a water absorbing and toughening material for plastic moulding. Raw materials comprise 10-20 weight parts of flexibilizer, 50-60 weight parts of inorganic silicate material, 0.5-1.5 weight parts of coupling agent and 20-30 weight parts of resin. The flexibilizer is a butadiene-styrene, styrene-butadiene or acrylonitrile-styrene copolymer; the strengthening agent is powdered steatile or montmorillonite; the inorganic silicate is one or more selected from magnesium silicate, calcium silicate, sodium silicate and barium silicate; and the coupling agent is a silane coupling agent. The invention provides a water absorbing and toughening material for plastic moulding processing, which can absorb water, enhance toughness and increase product quality, and solves a problem that product quality is influenced by fragile and damped raw materials in a prior plastic moulding processing. Besides, the material can be used in a plurality of plastic moulding processes, such as plastic tubing, injection moulding and hollow blow molding moulding, to realize functions of toughening and bubble elimination.

Owner:DALIAN RUIXIANDA PLASTIC CO LTD

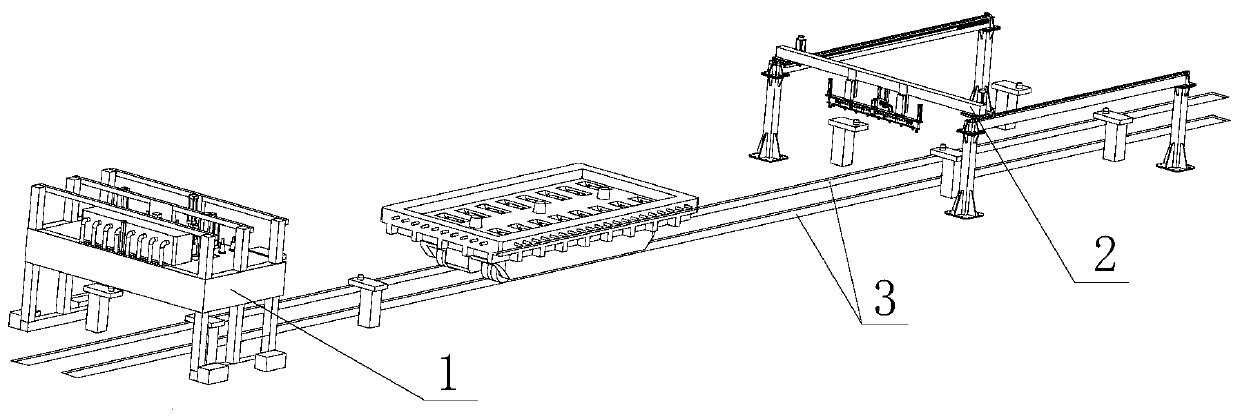

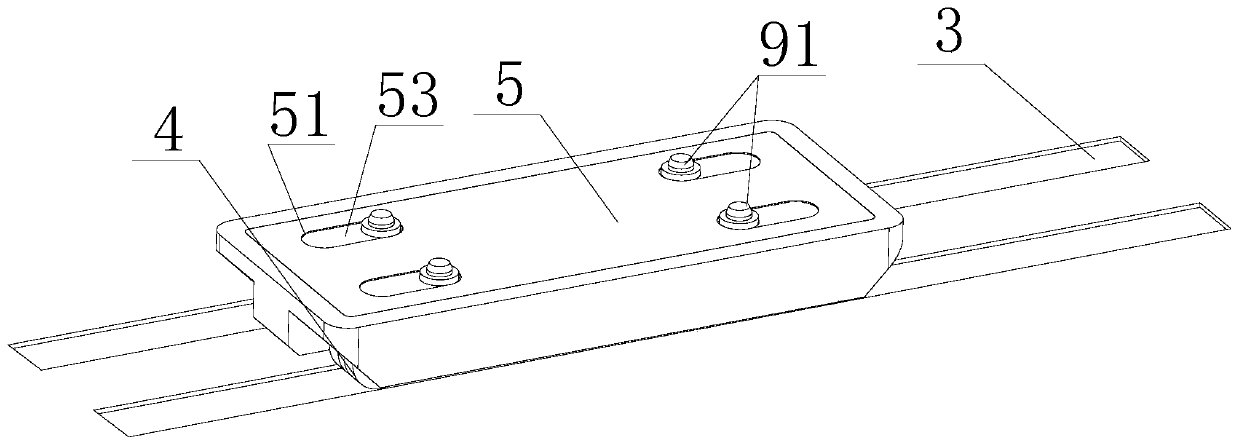

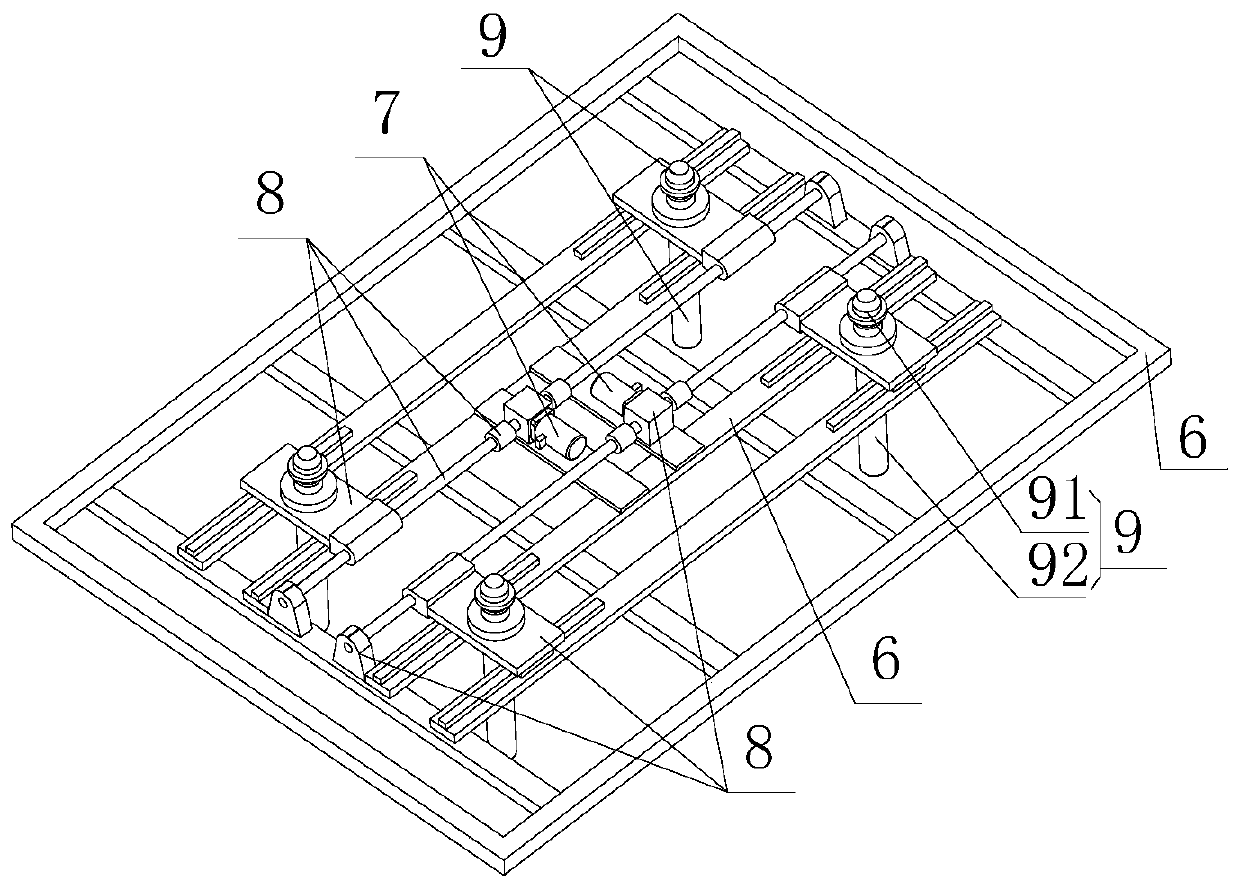

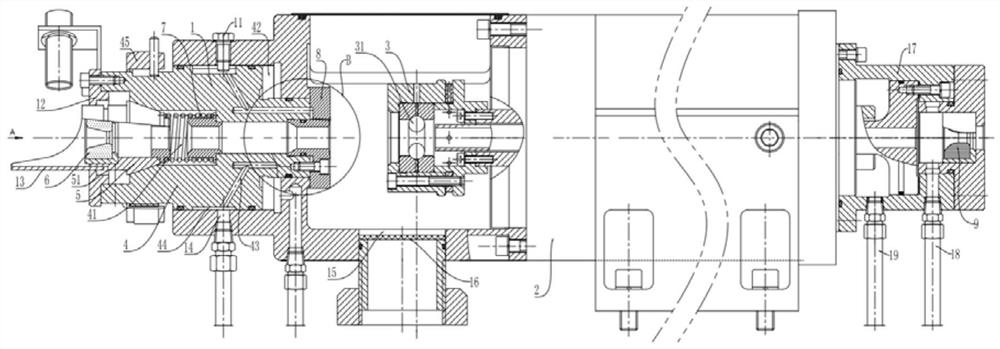

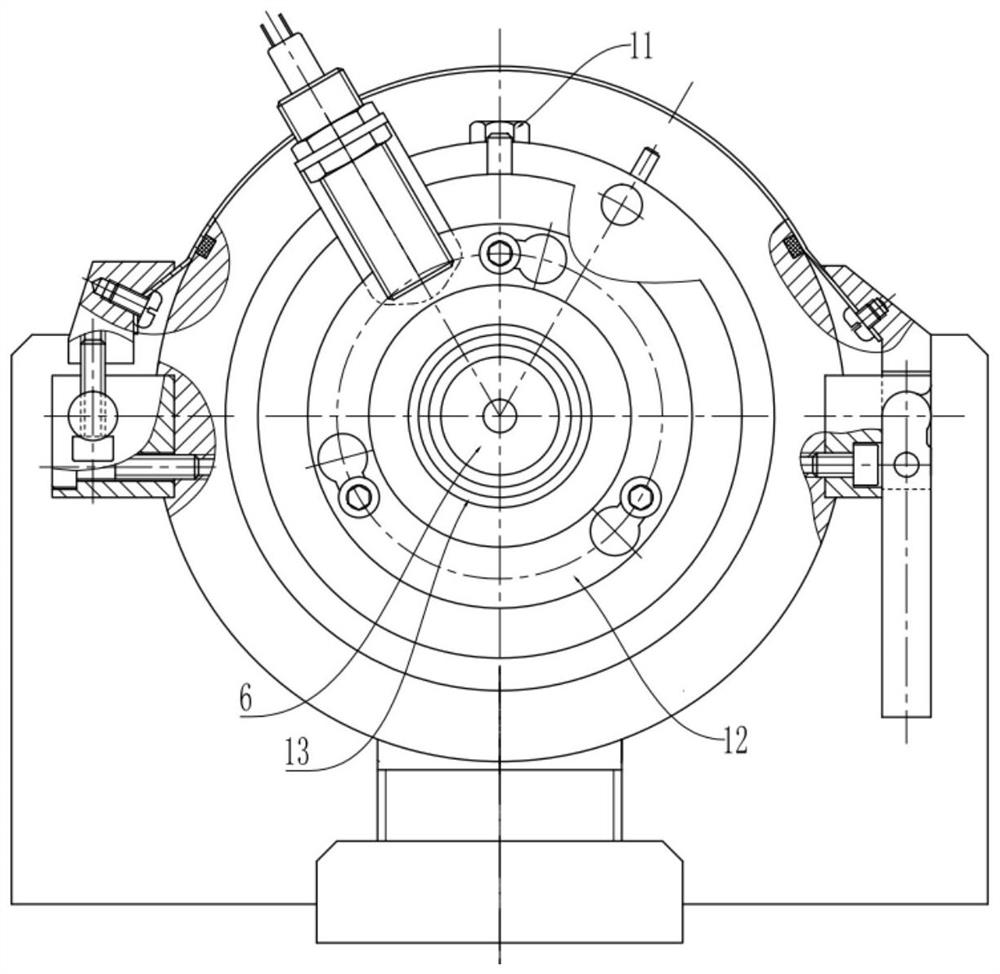

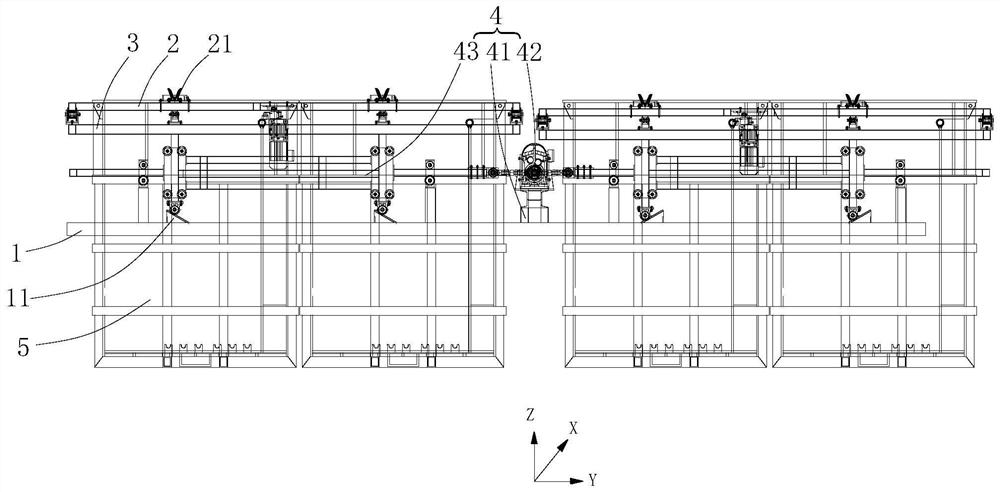

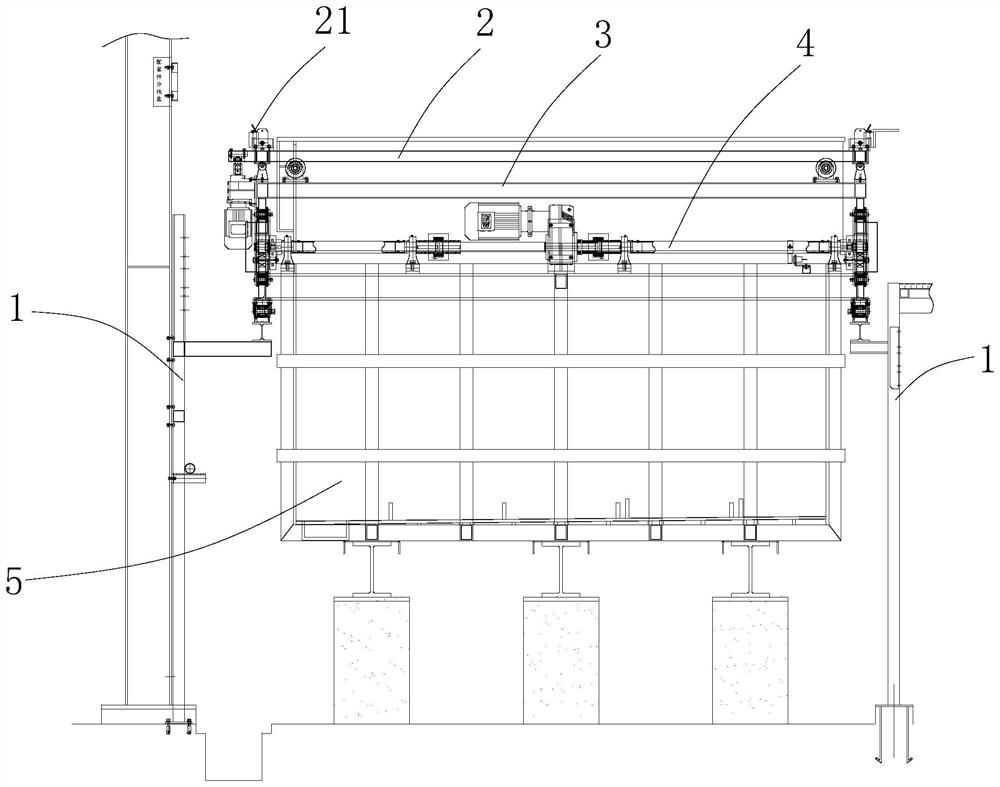

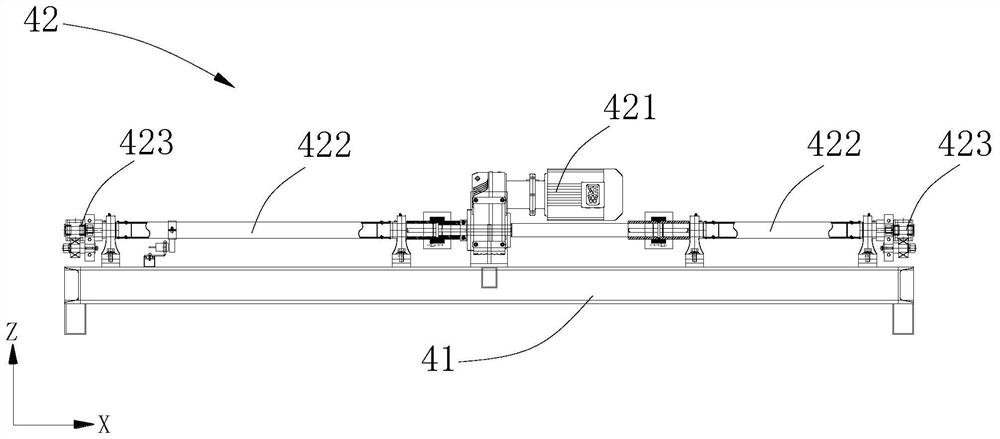

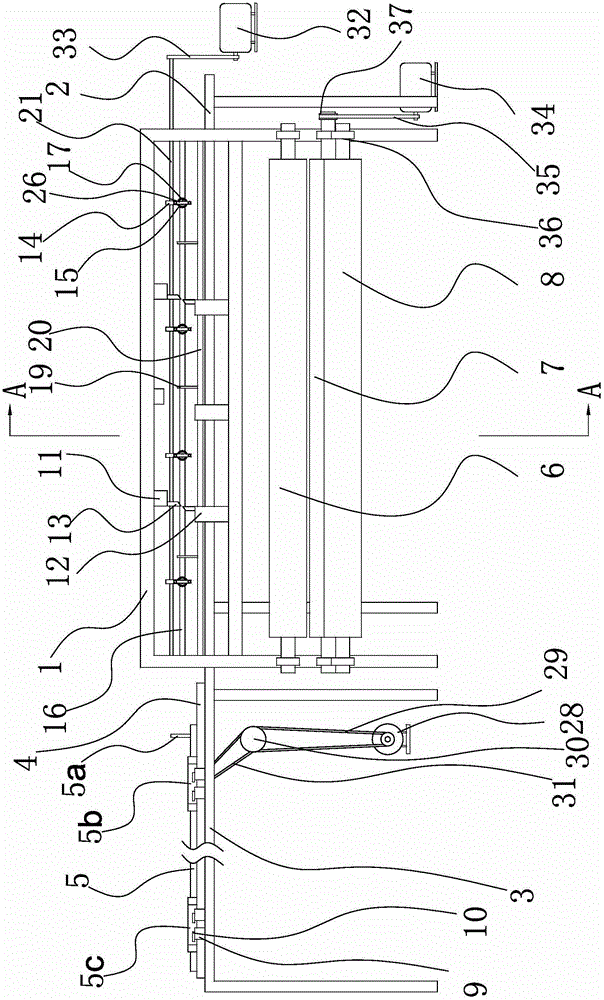

Movable type rail plate machining table

PendingCN110587802ASolve problems that affect the quality of track slab productionSolve the quality of productionDischarging arrangementCeramic shaping plantsMovable typeMachining

The invention provides a movable type rail plate machining table. The table comprises a first station, a second station and a conveying rail connected with the first station and the second station andfurther comprises wheels, a shell and a truss arranged in the shell. The wheels are arranged on the bottom of the shell, the truss is provided with a driving mechanism, a transmission mechanism and multiple positioning mechanisms, the driving mechanism is connected with the transmission mechanism, the transmission mechanism is connected with the positioning mechanisms, multiple strip grooves areformed in the upper plane of the shell, positioning columns of the positioning mechanisms are located in the strip grooves, the movable type rail plate machining table transports a rail plate mold onthe conveying rail, the driving mechanism, the transmission mechanism and the positioning mechanisms are arranged on the truss of the shell, positioning columns on the positioning mechanisms are inserted in positioning holes in the rail plate mold, position restraint of the rail plate mold can be achieved, the driving mechanism synchronously drives the positioning mechanisms to transversely move through the transmission mechanism, and rail plate molds of multiple types can be positioned.

Owner:北京好运达智创科技有限公司

Threaded pipe production process

ActiveCN113385550AReduce forming difficultyReduce life expectancyShaping toolsDrawing diesSpinningThreaded pipe

The invention relates to the technical field of metal pipe machining, in particular to a threaded pipe production process which needs to use threaded pipe production equipment, an inner core and traction equipment for traction of a pipe. During production, the threaded pipe production process comprises the following steps of 1, reducing the diameter of the pipe, wherein the pipe is continuously subjected to traction by the traction equipment to move forwards, when the pipe moves forwards to the position between a moving drawing die and a moving core head, the moving core head rotates continuously, and the diameter of the pipe is reduced under the rotation of the moving core head and the traction of the traction equipment; 2, forming threads, wherein the pipe moves forwards to the position between a spinning ring and a threaded core head of the inner core, internal threads are formed on the inner wall of the pipe, cooling of the pipe, the spinning ring and the inner core is achieved in the pipe thread forming process, and meanwhile, lubricating of the spinning ring is achieved; and 3, sizing a threaded pipe, wherein the pipe is sized through a sizing die. The scheme is used for solving the problems that in the prior art, a large amount of heat generated in spinning forming affects the spinning forming quality, and the service life of the spinning ring and the inner core is shortened.

Owner:CHONGQING LONGYU PRECISION COPPER TUBE CO LTD

Fully automatic spraying machine with variable color registration

ActiveCN108466482BIncrease productivitySolve production efficiencyPrintingConveyor partsClip deviceEngineering

The invention discloses an automatic spraying machine with a variable color register. The top of a box bracket is divided into a loading area and a printing area; an automatic tray feeding and changing mechanism and a feeding mechanism are placed in the loading area, and a product printing mechanism and a product discharging mechanism are placed in the printing area; the automatic tray feeding andchanging mechanism is provided with a full tray clip device, an empty tray clip device, a tray conveying mechanism, a full tray pushing mechanism, an empty tray pushing mechanism, a full tray removalmechanism, and an empty tray removal mechanism; the full tray clip device and the empty tray clip device are mounted on the top of the tray conveying mechanism; the bottom of the tray conveying mechanism is fixedly connected to the top of the box bracket; the full tray pushing mechanism and the empty tray pushing mechanism are arranged at the bottom of the tray conveying mechanism and are symmetric to the full tray clip device and the empty tray clip device in order; and the full tray removal mechanism and the empty tray removal mechanism are arranged at the side of the tray conveying mechanism.

Owner:羊宋英

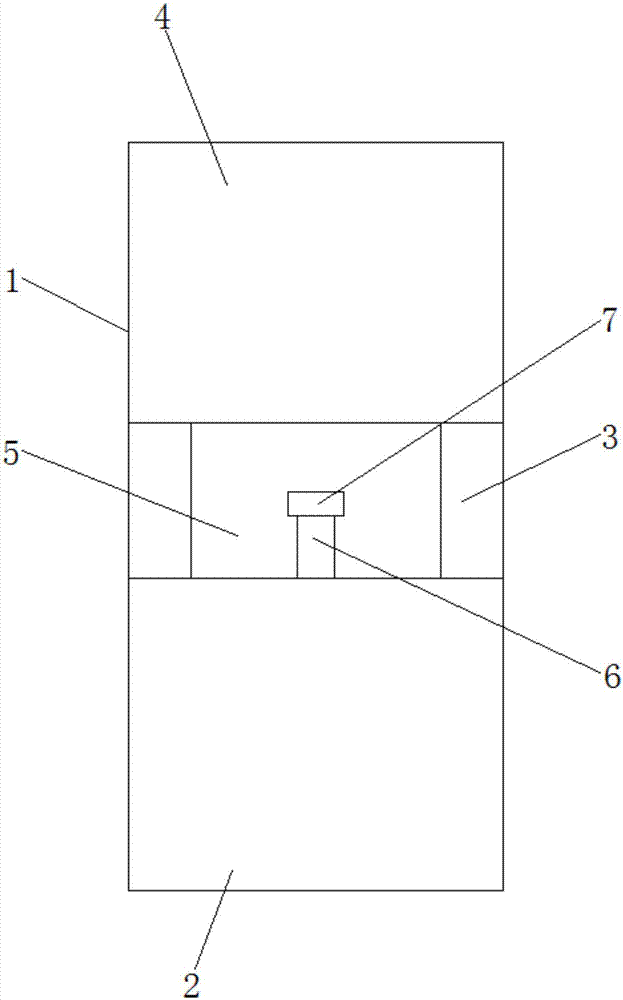

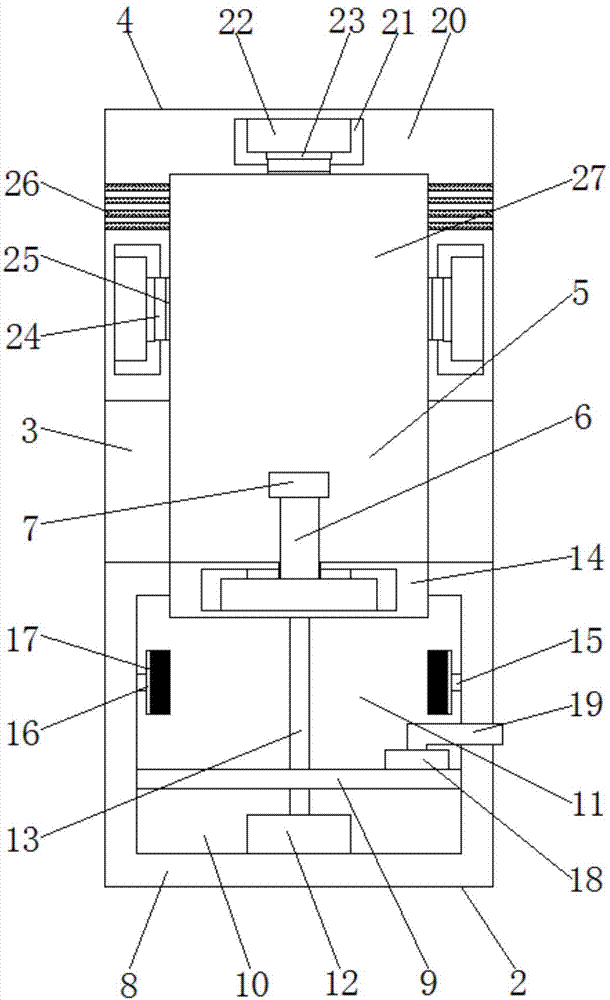

Moving device and electroplating bath

ActiveCN114364828ASolve production efficiencySolve the quality of productionCellsTanksMobile deviceElectrical and Electronics engineering

The invention relates to the technical field of mobile equipment, and discloses a mobile device and an electroplating bath. The moving device comprises a supporting frame, a top seat, a base and a linkage module, a pole seat is arranged on the top seat, and the pole seat is used for placing a part to be moved; a top seat is arranged on the bases, and the number of the bases is at least two; wherein the linkage module comprises a linkage support, a first driving mechanism and a transmission mechanism, the linkage support is arranged on the supporting frame, the first driving mechanism is arranged on the linkage support, the transmission mechanism is connected to the driving end of the first driving mechanism, and the base is arranged at the driving end of the transmission mechanism.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

Structurally-improved fence weaving machine

ActiveCN103406957BIncrease productivityInhibit sheddingCane mechanical workingEngineeringElectric control

Owner:ZHEJIANG MINZO NEW MATERIALS CO., LTD

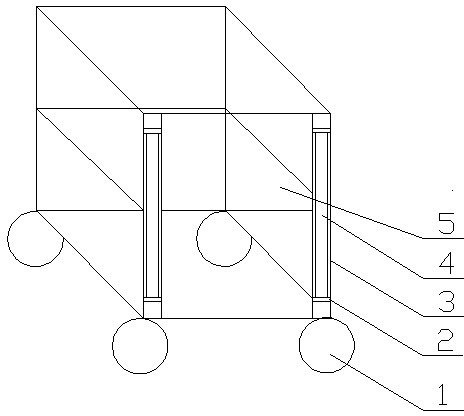

Movable illumination device

InactiveCN104197208ASolve agingSolve quality problemsLighting support devicesPortable electric lightingEconomic benefitsPulp and paper industry

The invention discloses a movable illumination device and belongs to the technical field of lithium battery machining. The movable illumination device comprises lamp tubes and a lamp holder. The lamp holder comprises a support and pulleys, the support is a cuboid stand column structure formed by welding angle steel, four pulleys with brakes are arranged under four corners of the bottom face of the support respectively, and the lamp tubes are fixed on the two front side edges of support through lamp tube fixing pieces respectively; rectangular separation plates matched with the support are arranged on the bottom face and the middle portion of the support. The movable illumination device is simple in structure and convenient to use, the adverse effect of illumination on lithium battery capacity grading when capacity grading is carried out in a workshop is effectively solved, product quality is guaranteed, and economic benefits are improved.

Owner:洛阳特斯拉能源科技有限公司

Carbon-free ladle brick and preparation method thereof

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com