Agricultural organic acid, organic acid preparation method and its preparing apparatus

An organic acid and equipment technology, applied in the field of equipment for preparing the organic acid, can solve the problems of easy hydrogen escape, poor defoaming effect, and difficulty in recycling waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Embodiment 1: The agricultural organic acid of this embodiment is a product obtained by extracting humic coal and carbon-containing combustible bio-rock with alkali to obtain the alkaline slurry of organic acid salt, and then undergoing electrolysis, electrophoresis, and electroflotation. The aforementioned carbon-containing combustible biological rocks include combustible shale, coal, peat, etc., and humic coal includes sediments at the bottom of rivers, lakes, oceans, etc., and organic matter processing products such as compost.

[0006] The preparation method of the agricultural organic acid in this embodiment, its preparation steps are as follows: first, extract the homogeneous slurry that humus coal and carbon-containing combustible biological rock are ground into with lye, the consumption of alkali accounts for the proportion of humus coal and carbon-containing combustible bio-rock. 2-20% of the total weight of bio-rock, let the slurry stand for 60 minutes, then ad...

specific Embodiment approach 2

[0012] Specific implementation mode two: the raw materials selected in this implementation mode are oxidized lignite (Krasnoyarsk Border Region) and lignite (May Kubinski), and the sample is ground into 3mm particles, which are vigorously stirred at 90-95°C , extracted with lye to form a homogeneous slurry, the amount of lye is 2-20% of coal (dry material to dry material), and the ratio of solid phase to liquid phase varies from 1:2 to 1:6. The slurry was left to stand for 60 minutes, and the flow part was separated from the sediment. The flow part of the slurry contained sodium organic acid, strongly hydrated finely dispersed and moderately dispersed humic matter-mineral particles and complexes, and the precipitate was a non-coal Active ingredient, dry matter > 12%, the mobile part becomes viscous and eventually gelatinous. Below 12%, good fluidity, at which point hydrated finely and moderately dispersed humic-mineral particles and complexes account for 30-35% of the above 12...

specific Embodiment approach 3

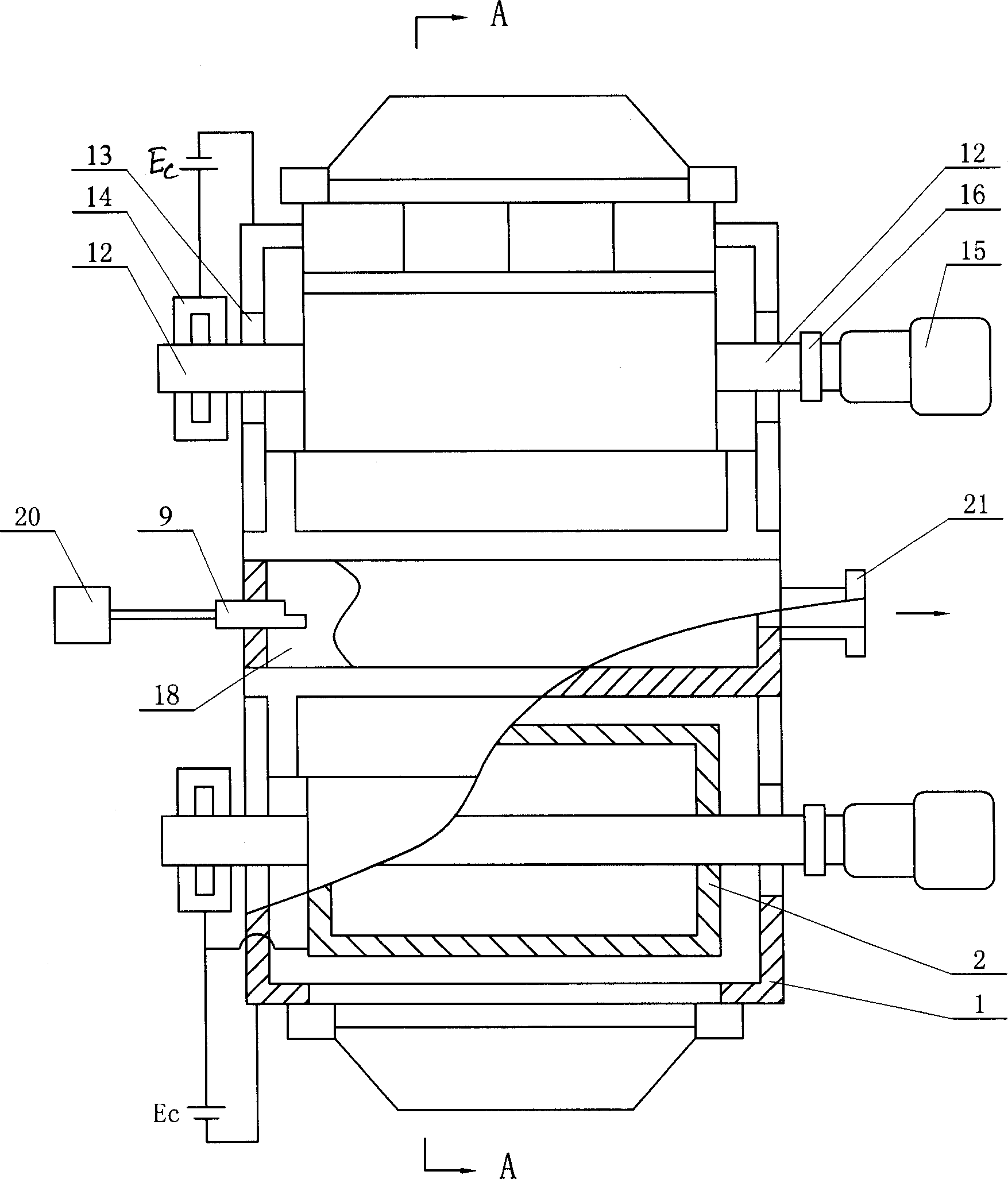

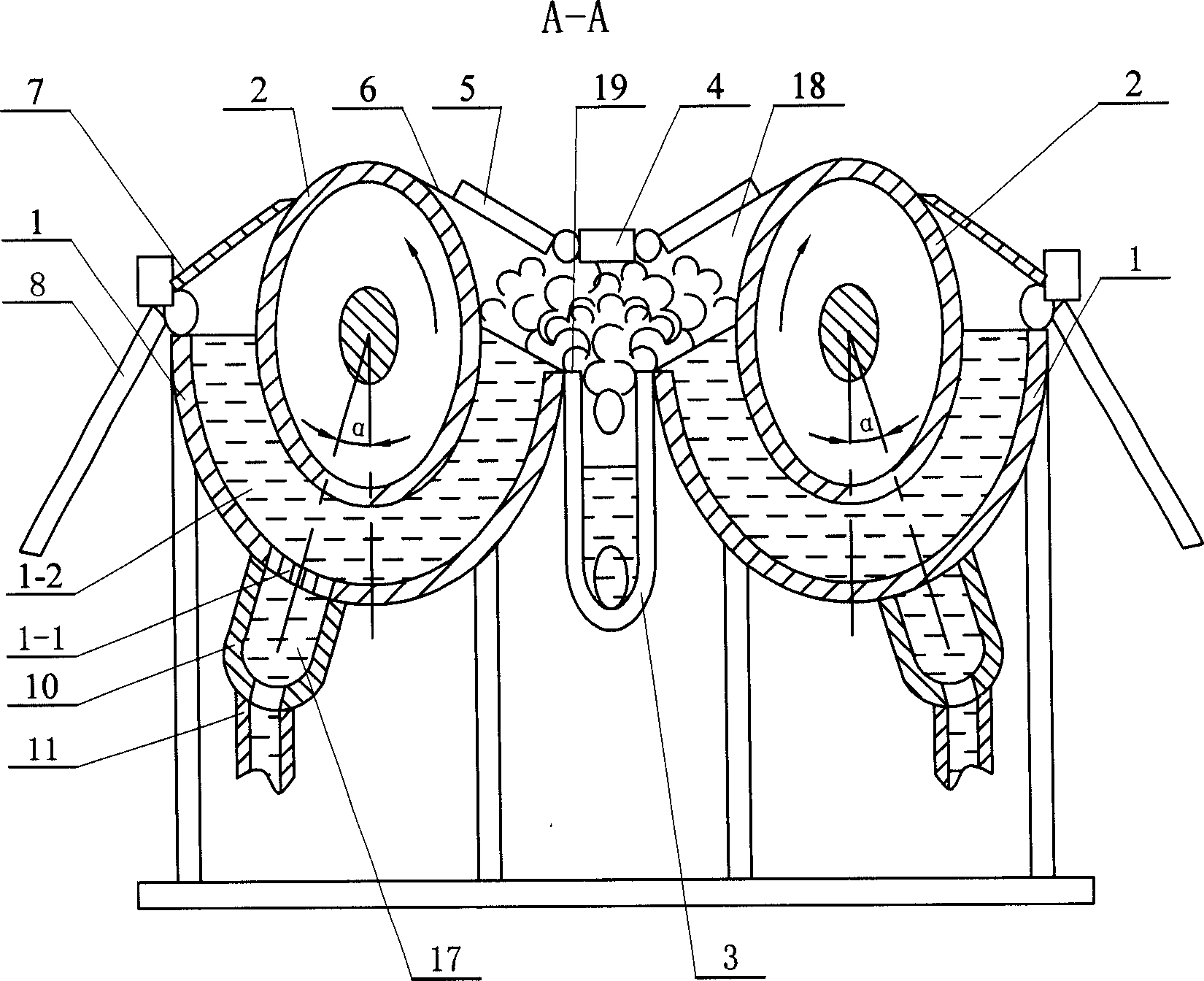

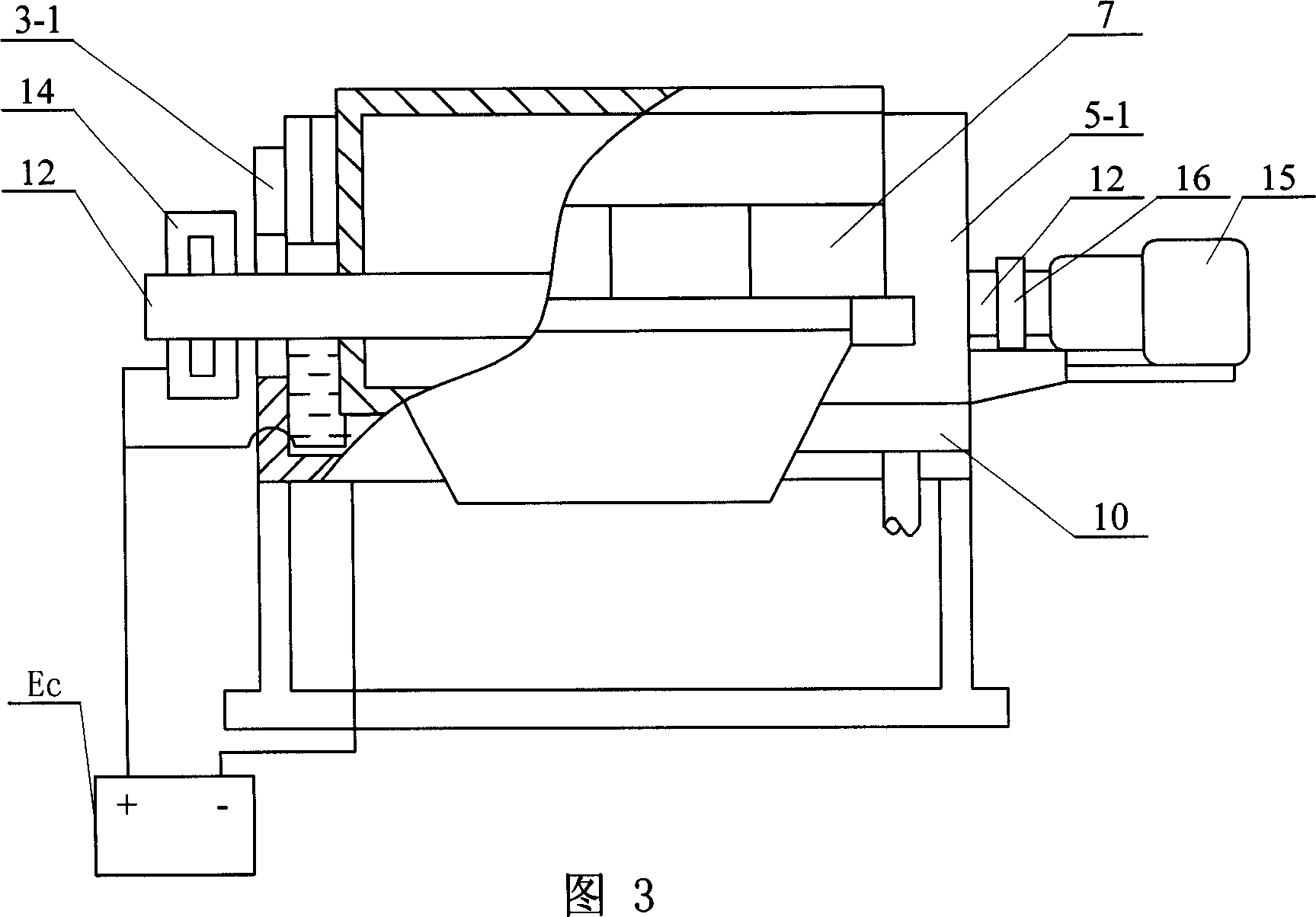

[0016] Specific embodiment three: this embodiment is the equipment for producing agricultural organic acid, refer to figure 1 , figure 2 And Fig. 3, it comprises electrolyzer 1, drum 2, is provided with the chute 3 that is all communicated with two electrolyzers 1 between adjacent two electrolyzers 1, electrolyzer 1 is connected with the negative pole of power supply Ec, and drum 2 It is connected to the positive pole of the power supply Ec, and a top cover 4 is provided above the chute 3 and between two adjacent drums 2. The top cover 4 is connected with the frame 5, and the other end of the frame 5 is connected with a cloth plate 6, and the cloth The plate 6 is overlapped on the upper surface of the drum 2; the other end of the upper surface of the drum 2 corresponding to the cloth plate 6 is overlapped with a scraper 7, and a discharge chute 8 is connected below the scraper 7; between the chute 3 and the The space enclosed by the top cover 4, the frame 5, the cloth plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com