Diffusion and brightening composite optical film and preparation method thereof

An optical film and composite technology, applied in optics, optical components, instruments, etc., can solve problems such as environmental pollution, production efficiency, product quality, and yield, and PET extrusion film cannot meet the requirements of high-fog and high-transparency optics. Achieve the effect of reducing the cost of use and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0039] Specific embodiments: the present invention will be further described in detail below in conjunction with specific embodiments.

[0040] The following examples will help to further understand the present invention, but do not limit the content of the present invention. In the embodiments, unless otherwise specified, the rest of the unspecified parts refer to the mass or mass ratio, and the film or the diffusion-enhancing composite functional optical film of the present invention have the same meaning.

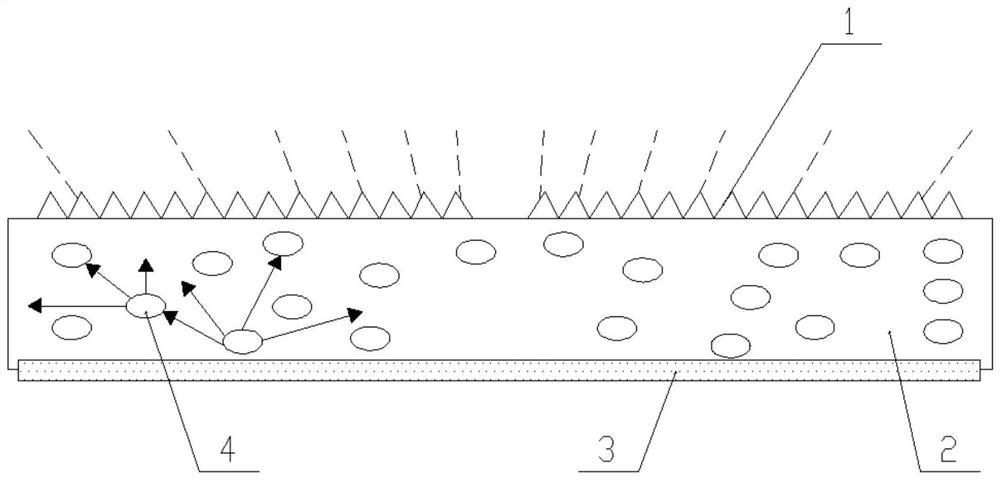

[0041] The invention discloses a diffusion brightening composite optical membrane, which is made by co-extruding a diffusion layer with a diffusion microstructure function and a brightness enhancement layer with a brightness enhancement function structure; the diffusion layer with a diffusion microstructure function It is prepared by mixing optically transparent resin and diffusion particles, including a diffusion layer containing diffusion particles and a surface functi...

Embodiment 1

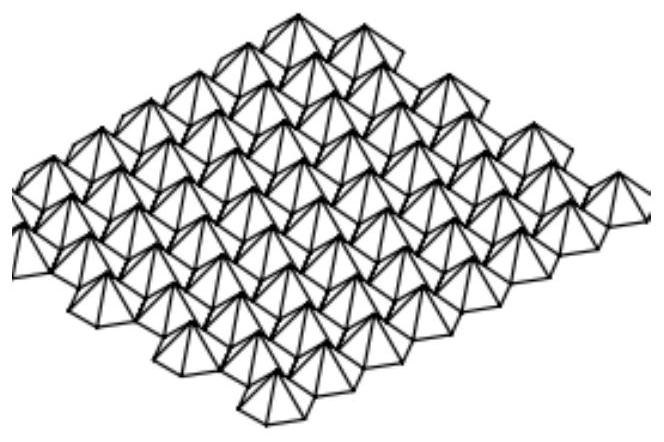

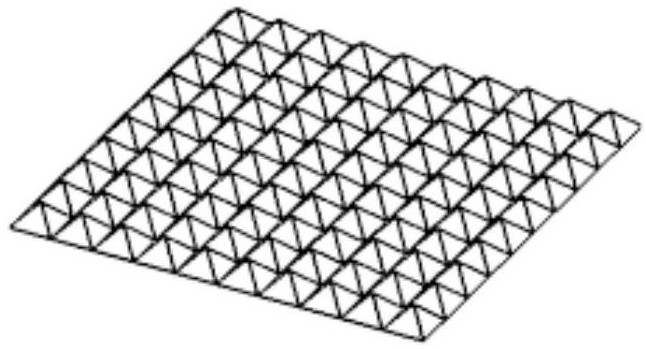

[0057] This embodiment is to produce 0.2mm diffusion brightening composite film, or called diffusion brightening composite optical film, the structure is as follows figure 1 As shown, polymethyl methacrylate is used as the microstructure diffusion layer, no diffusion agent is added, the thickness of the PMMA layer is 0.05-0.06, and a 500-mesh diffusion microstructure is formed; transparent polycarbonate is used as the brightness enhancement layer to form a prismatic enhancement. Bright structure and brightening structure; this product has high fog and high transparency, and is suitable for display modules equipped with light guide plates; the prepared diffusion-enhancing composite optical film or brightness-enhancing diffusion film has performance tests as shown in Table 2.

[0058] Table 2

[0059]

[0060] Explanation: From the test results in Table 2 above, it can be seen that the diffused brightening composite optical film prepared in Example 1, the brightening diffused...

Embodiment 2

[0063] This embodiment is to produce a 1.5mm diffusion brightening composite sheet, using polycarbonate resin as the main material, adding 1.5% organic silicon diffusion agent, with a layer thickness of 0.3-0.5mm, and forming a 100-mesh diffusion microstructure; using transparent polycarbonate Ester is used as the brightening layer, and the quadrangular pyramid brightening layer is formed; this product has high fog and high transparency, good temperature resistance, and is suitable for supporting direct-emitting large-screen displays.

[0064] table 3,

[0065]

[0066]

[0067] Description: Test conditions: the same backlight, the light transmittance haze test instrument is a Japanese company NDH-5000 haze meter, integrating sphere tester; the preparation method of the above-mentioned embodiment is the same as that of the comparative example; the comparative example is shown in Table 1 illustrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com