Soft magnetic ferrite magnetic core component and formation method thereof

A technology of soft ferrite and magnetic core components, applied in electrical components, magnetic core/yoke, inductor/transformer/magnet manufacturing, etc. Problems such as poor glue removal can improve the grinding efficiency, prevent collision damage, and improve the pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

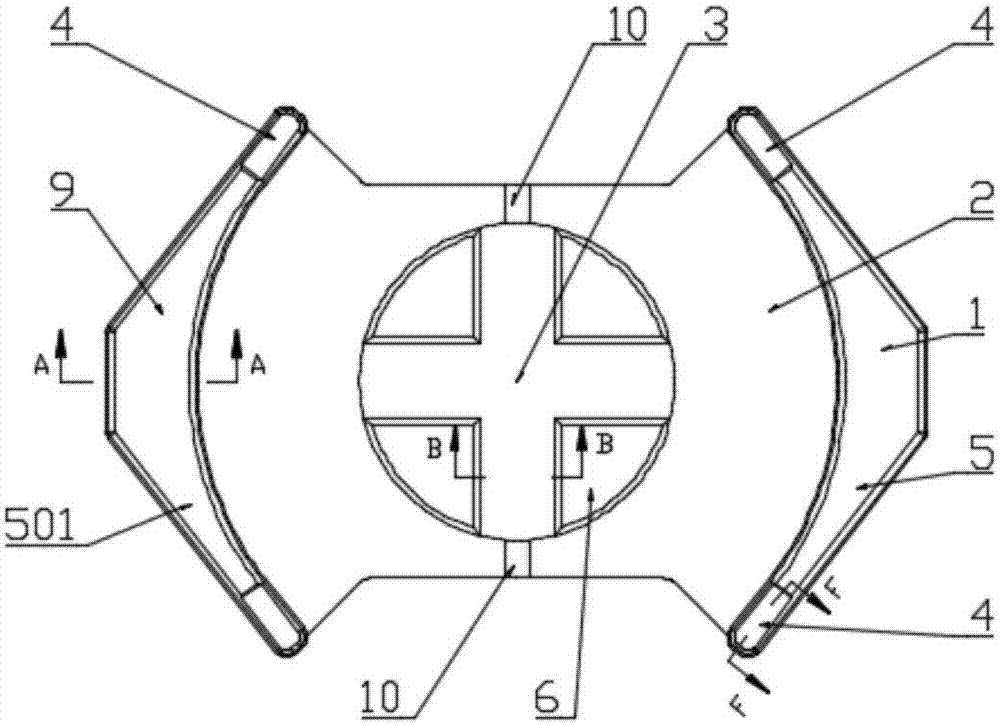

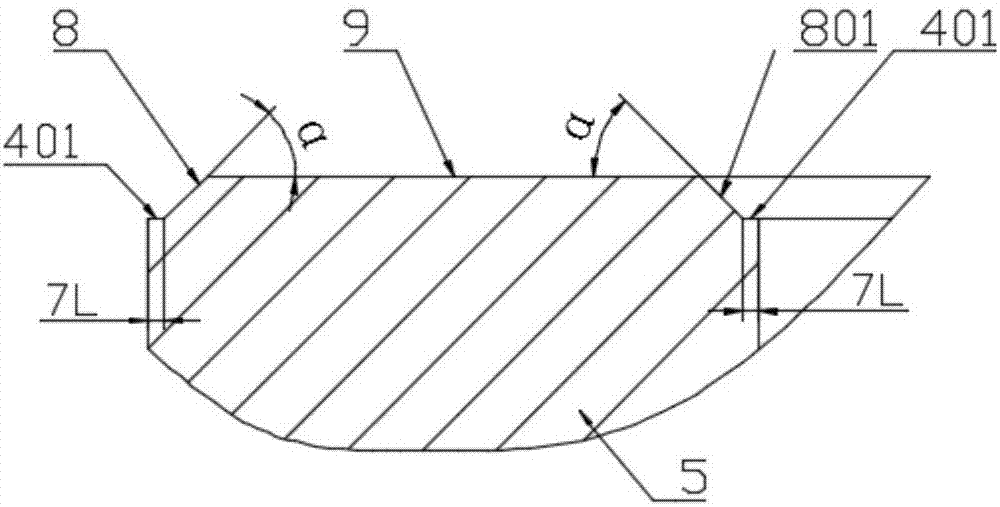

[0038] Such as figure 1 As shown, it is a front view of a soft ferrite magnetic core element blank prepared by the molding method of the present invention. The magnetic core element blank 1 includes a magnetic core bottom plate 2, and two ends of the magnetic core bottom plate 2 are respectively provided with two sides. Leg post 5,501, on the magnetic core bottom plate 2 between both sides leg posts 5,501, be provided with magnetic core middle post 6, described magnetic core middle post 6 is set as garden cylindrical structure, on the magnetic core of garden cylindrical shape The other end of the central column 6 connected to the magnetic core bottom plate 2 is provided with a cross-shaped groove 3 on the top surface of the central column 6 of the magnetic core. An arc-shaped groove 10 is provided on the plane connecting the magnetic core bottom plate 2 and the center column 6 between the two ends of the base plate 2 without side leg columns, and the maximum depth of the arc-s...

Embodiment 2

[0045] The specific embodiment of this implementation is another structural magnetic core component product, using another structural embodiment;

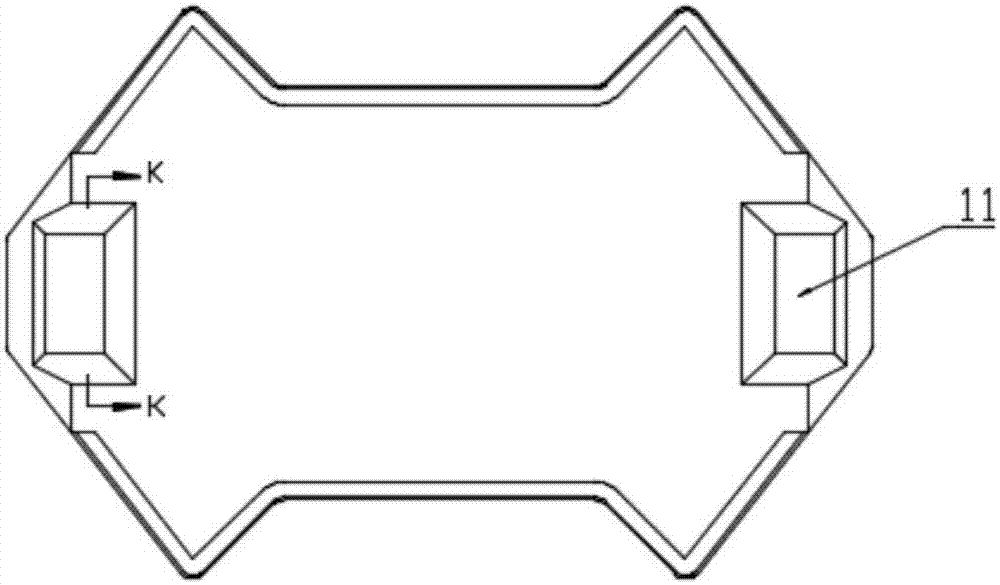

[0046] Such as Figure 8-10 As shown, the two ends of the magnetic core base plate 2 are respectively provided with one leg column 5, 501, and the magnetic core base plate 2 between the leg columns 5, 501 on both sides is provided with a rounded square column magnetic core middle column 601. One end of the column 601 of the square columnar magnetic core is connected to the magnetic core base plate 2, and the longest side of the column 601 of the rounded square columnar magnetic core is smaller than the shortest side of the magnetic core base plate 2, on the magnetic core base plate 2 There are two arc-shaped grooves 1001 at the place where the center column 601 of the rounded square column magnetic core is connected, and a small step 402 is respectively provided at the four corners of the magnetic core bottom plate 2, and the leg c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com