Iron-based amorphous alloy with high soft magnet performance and low cost and manufacturing method thereof

An iron-based amorphous alloy and manufacturing method technology, applied in the direction of magnetic materials, manufacturing tools, magnetic objects, etc., can solve the problems of unfavorable amorphous alloy magnetic properties, uneven heating of iron core, slow heating speed, etc., and achieve effective Conducive to the improvement of magnetic properties, fast heating speed and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The raw materials are industrial pure iron, industrial iron boron, silicon and carbon rods. The raw materials are designed according to the atomic percentage range determined in claim 1 to design the following component alloys: Fe 75 B 10 Si 13 C 2 , Fe 76 B 10.5 Si 11.5 C 2 , Fe 77 B 11 Si 10 C 2 , Fe 78 B 11.7 Si 9.3 C 2 , Fe 79.5 B 15 Si 3.5 C 2 , Fe 79.5 B 13 Si 5.5 C 2 , Fe 80 B 16 Si 2 C 2 , Fe 80 B 16.5 Si 3 C 0.5 , Fe 81 B 16 Si 2.5 C 0.5 , Fe 81 B 14 Si 3 C 2 , Fe 82 B 15 Si 2 C 1 . As shown in Table 1,

[0042] Serial number

distinguish

Fe content (atom%)

B amount (atom%)

Si content (atom%)

C amount (atom%)

1

Comparative example

75

10

13

2

2

Comparative example

76

10.5

11.5

2

3

Invention Examples

77

11

10

2

4

Invention Examples

78

11.7

9.3

2

5

Invention Examples

79.5

13

5.5

2

6

Invention Examples

79.5

15

3.5

2

7

Invention Examples

80

16

2

2

8

Invention Examples

80

16.5

3

0.5

9

Invention Examples

...

Embodiment 2

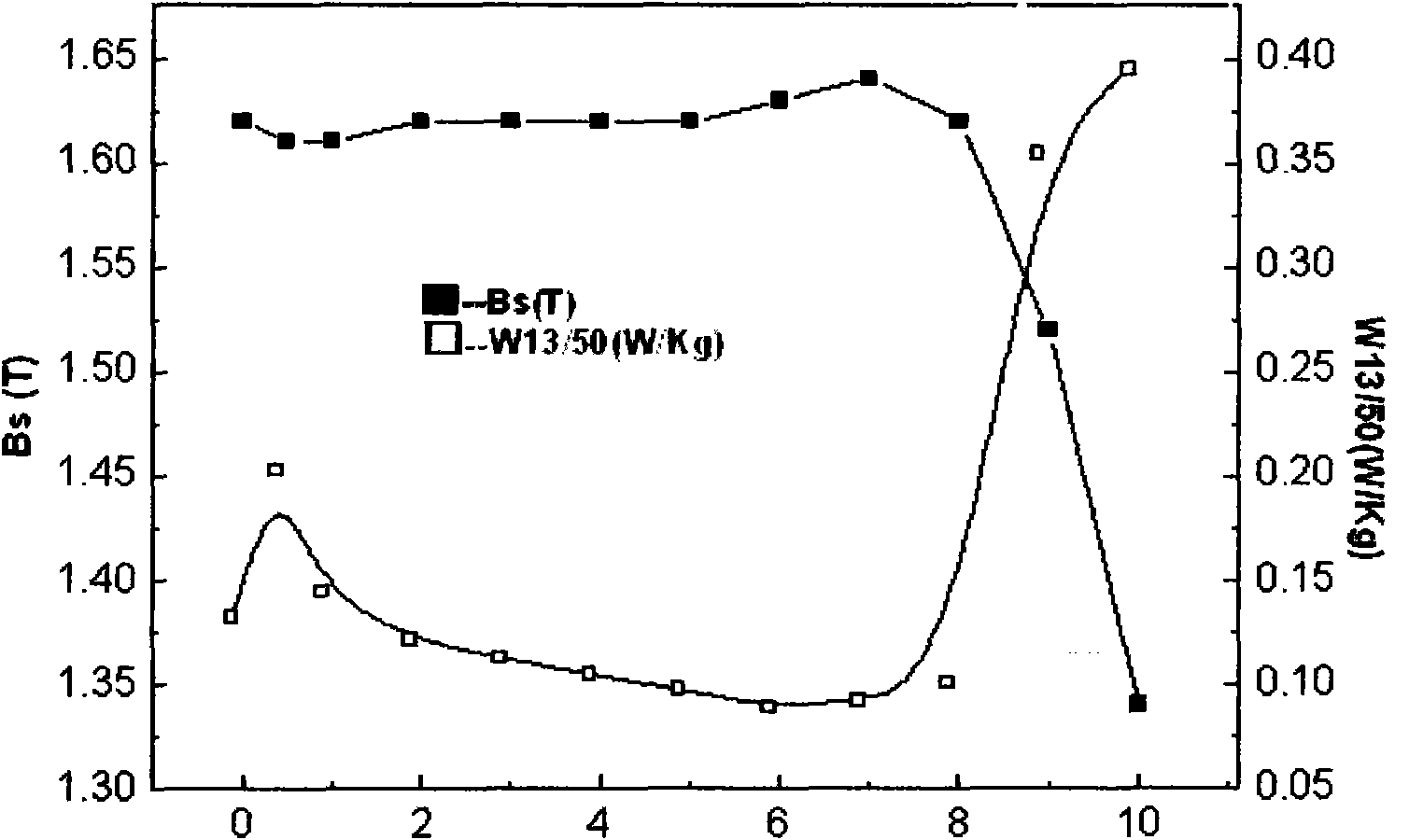

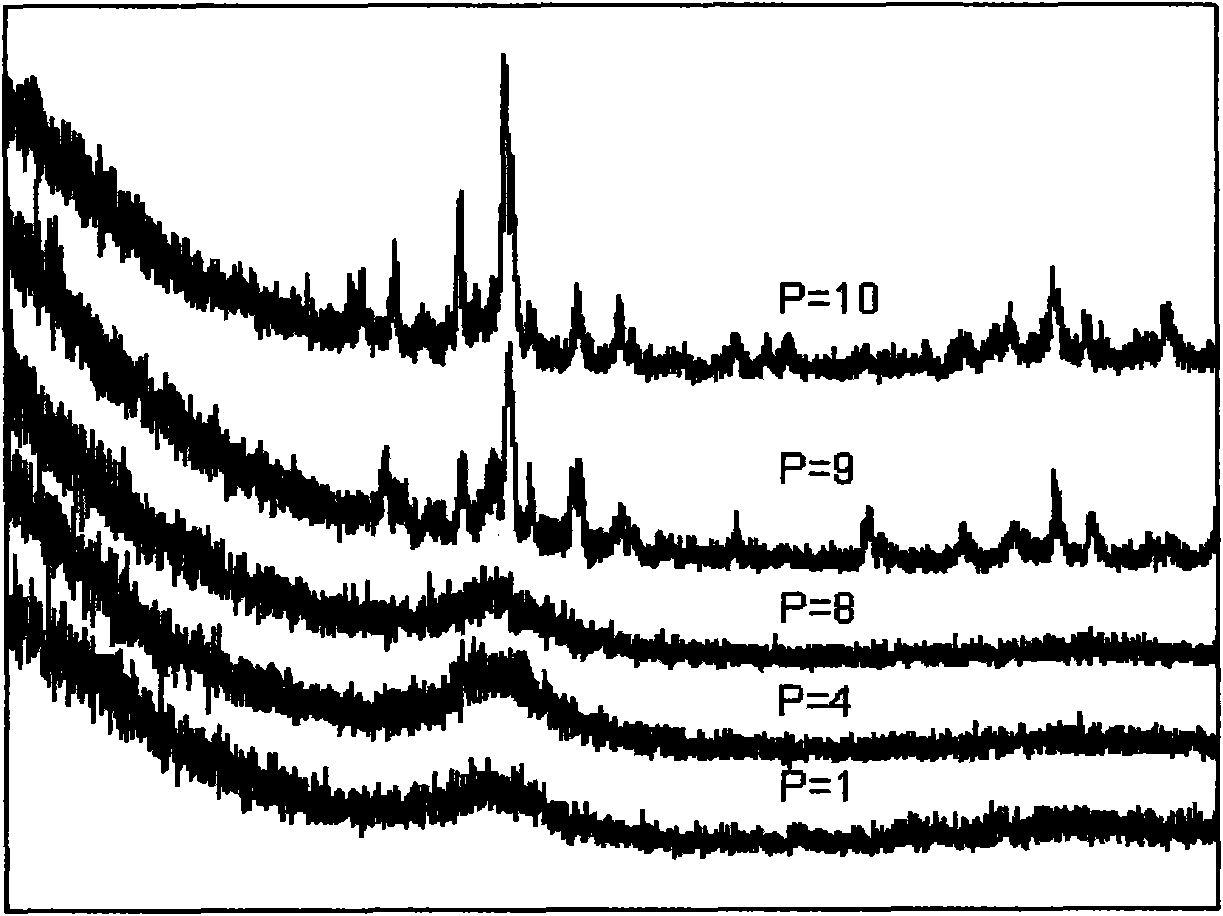

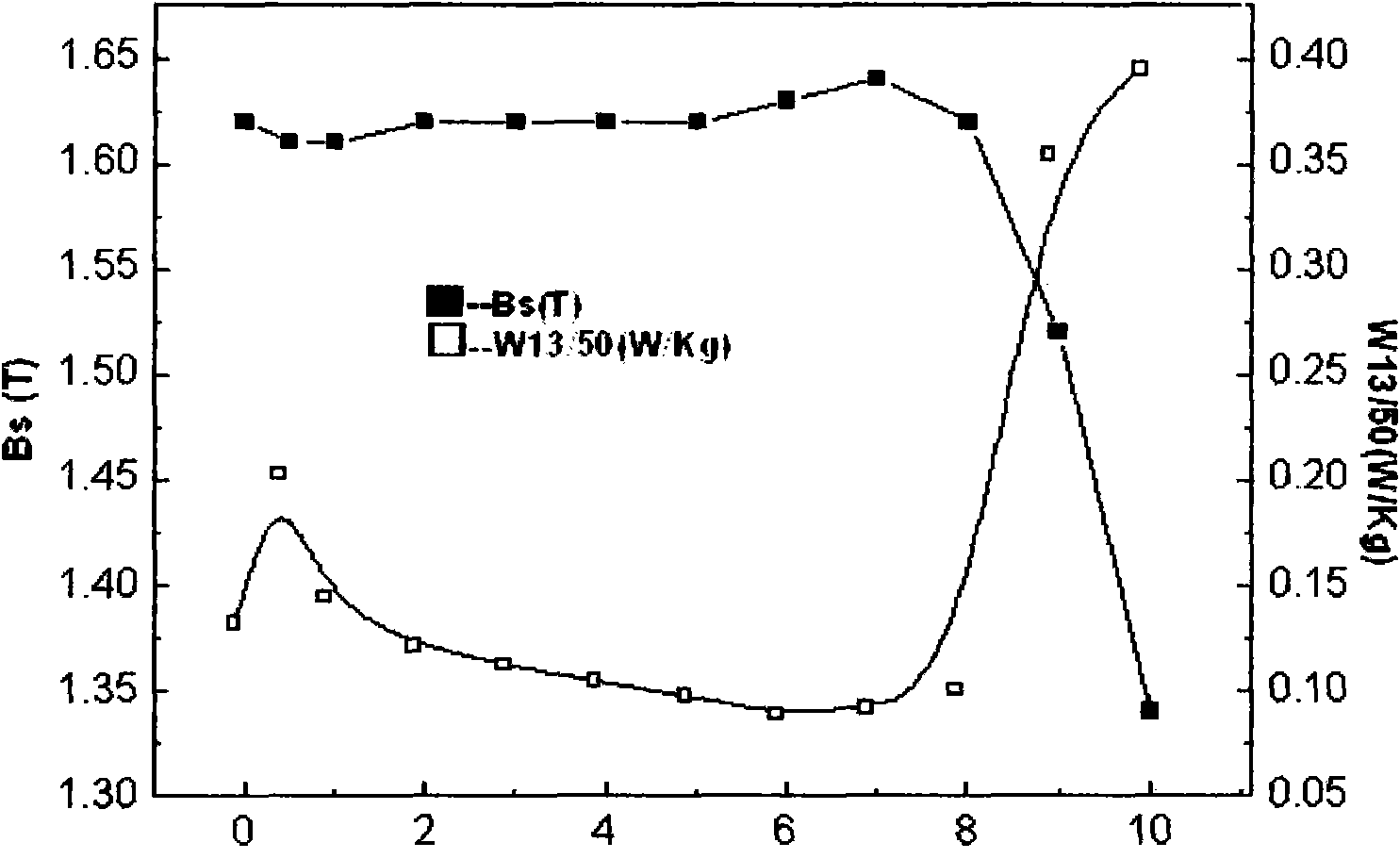

[0051] Reference Fe (100-x-y-z-w) B x Si y C z P w Chemical formula; where x is 4-20, y is 3.5-5, z is 1.8-2.3, w is 0-10, and the balance is Fe. x+y+z+w is 19 to 23, preferably 19 to 20.5 or 20.5 to 23, more preferably 20 to 20.5. The element P is used to replace the part B, w is preferably 1-7, and x+w is preferably 11-20. The composition of the iron-based amorphous alloy expressed in atomic ratio is preferably: Fe 79.5 B 12 Si 3.5 C 2 P 3 Or Fe 79.5 B 13 Si 3.5 C 2 P 2 Or Fe 79.5 B 11 Si 3.5 C 2 P 4 Or Fe 79.5 B 15-w Si 3.5 C 2 P w . The high saturation magnetic induction intensity Bs of the iron-based amorphous alloy of the present invention is 1.3-1.64T, and the iron loss is P13 / 50<0.3W / kg. The Curie temperature changes from 381 to 418°C.

[0052] The Fe with the best comprehensive performance is selected from Example 1. 79.5 B 15 Si 3.5 C 2 As a basis, part of B is replaced with cheap P to reduce the cost of alloy components. The general formula for amorphous alloy des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com