Components and preparing process of VHF plate sensor material

A VHF laminated chip and formula technology, applied in the direction of magnetic materials, inorganic material magnetism, electrical components, etc., can solve the problems of complex powder process, high cost, poor material performance, etc., and achieve simple process and low cost. , The effect of wide firing temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

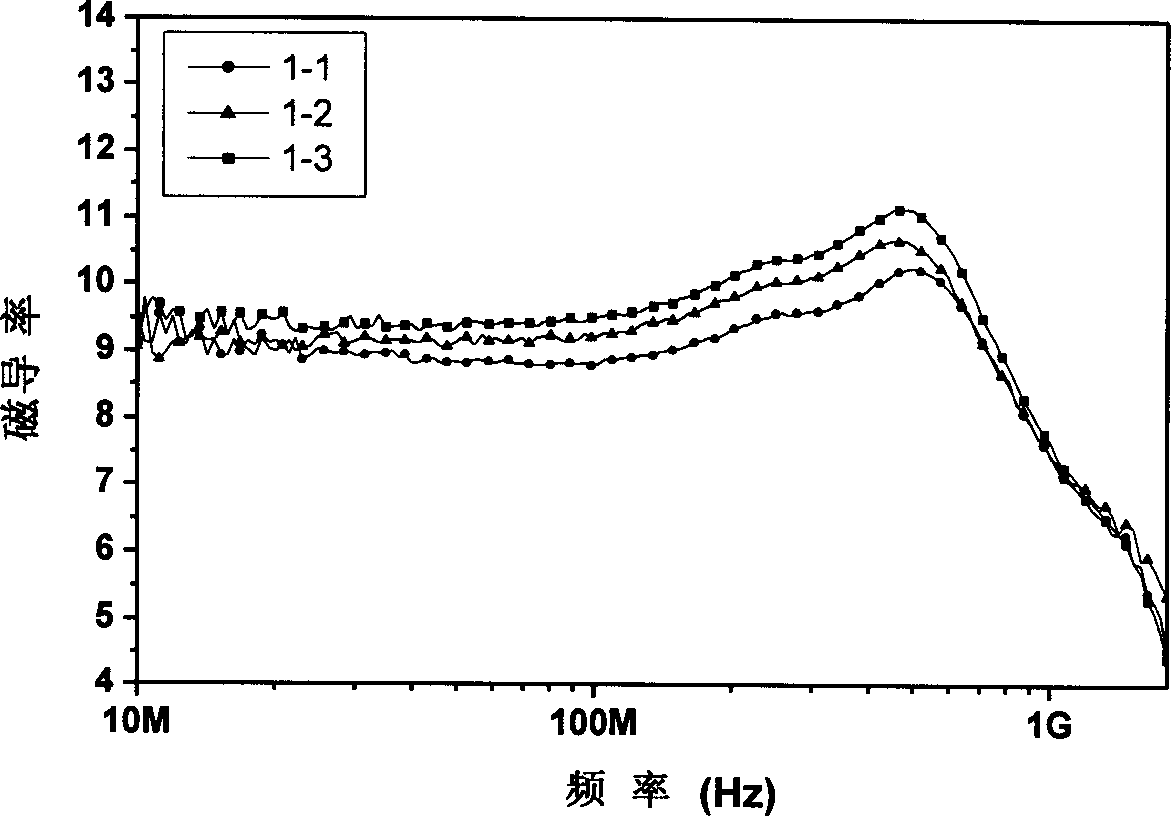

Embodiment 1

[0025] Synthesis of planar hexagonal Z-type soft magnetic ferrite Ba by solid state method 3 co 1.0 Zn 0.8 Cu 0.2 Fe 23 MnO 41 , The sintering aids are bismuth oxide and silicon oxide. Initial raw material BaCO 3 ,Co 3 o 4 , ZnO, CuO, Mn 2 o 3 , Fe 2 o 3 , Weighed 59.20g, 8.03g, 6.511g, 1.591g, 7.89g, 183.6g respectively according to the stoichiometric ratio. Mix ball milling for 24 hours, after drying, pre-sinter at 1000-1300°C to form Z-shaped soft ferrite. Take 20 grams of ferrite powder, add sintering aid, the content is 3% by weight of the total material, mix through ball milling for 24 hours, after drying, pass through 100~200 mesh sieve, shape, at 870°C, 890°C, 920°C ℃ sintering for 6 hours, respectively recorded as samples 1-1, 1-2, 1-3. A ring sample has an outer diameter of 20mm, an inner diameter of 10mm, a thickness of 3mm, and a molding pressure of 7MPa; a disc sample has a diameter of 10mm, a thickness of 1mm, and a molding pressure of 2MPa. The el...

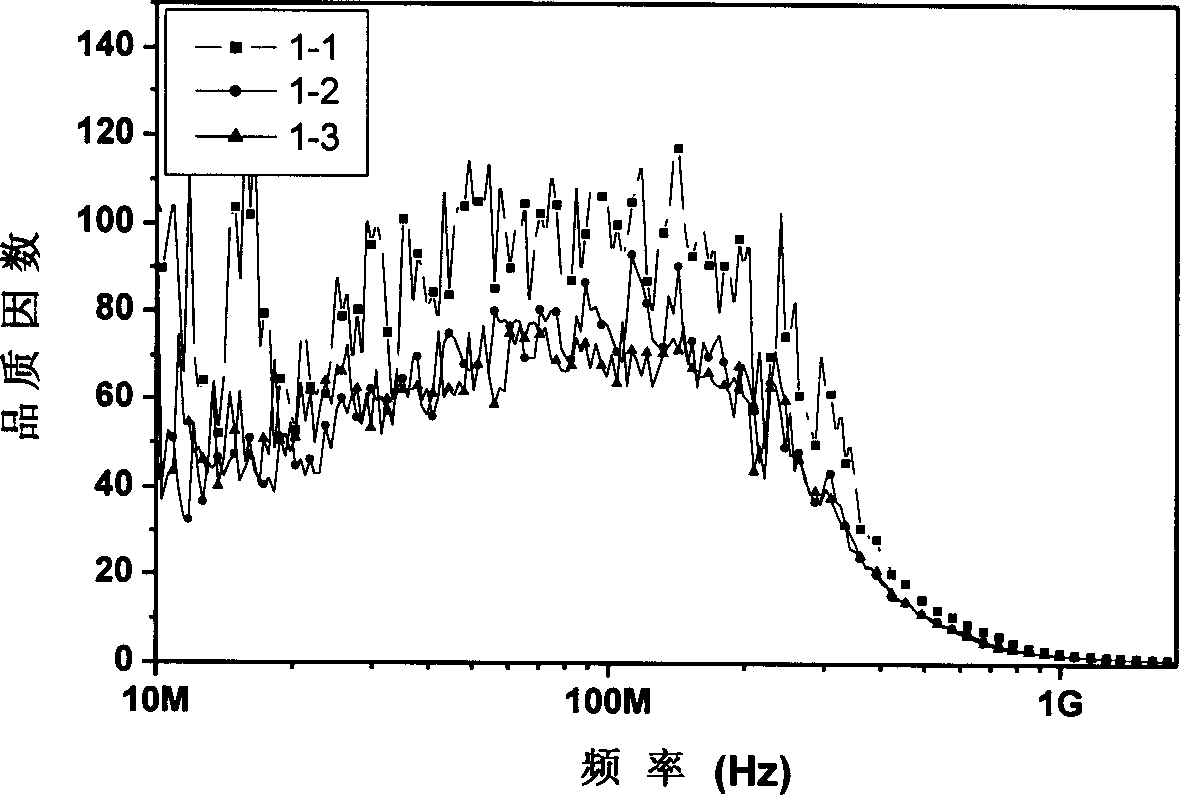

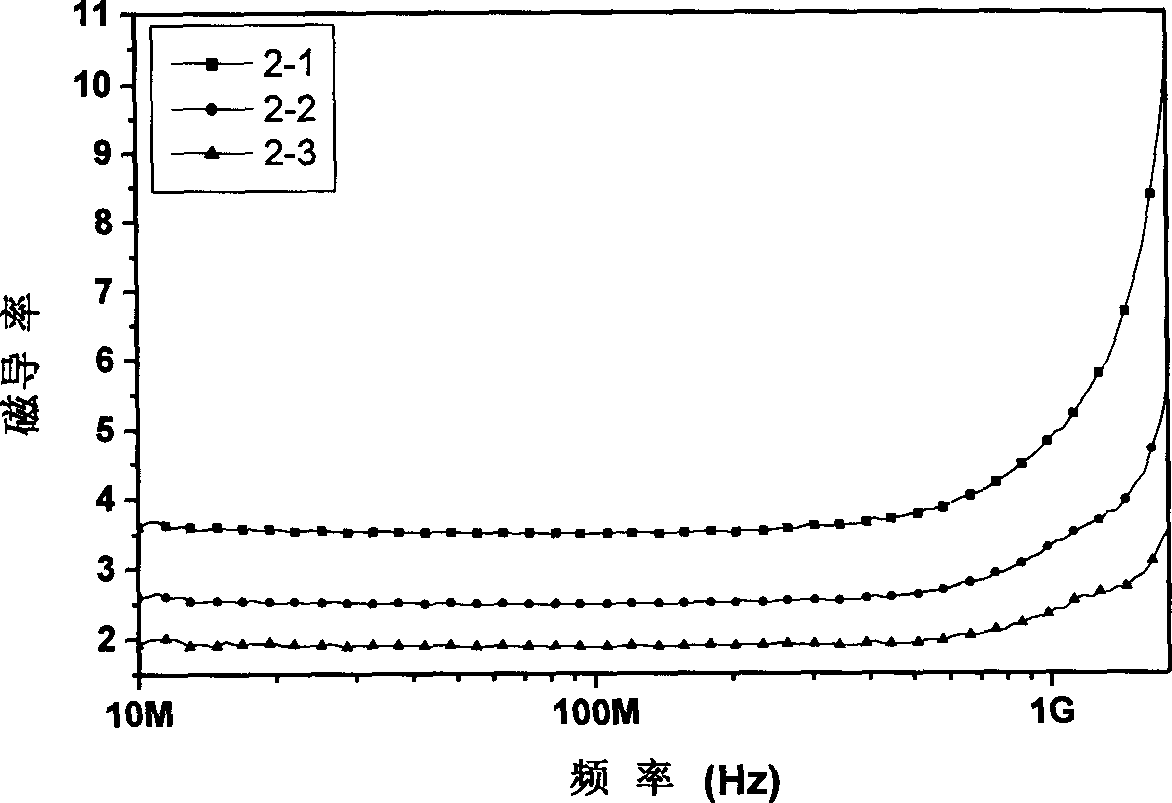

Embodiment 2

[0030] Synthesis of planar hexagonal Z-type soft magnetic ferrite Ba by solid state method 1.5 Sr 1.5 co 2 Fe 23 MnO 41 , The sintering aids are boron oxide and lead oxide. Initial raw material BaCO 3 , SrCO 3 ,Co 3 o 4 , Mn 2 o 3 , Fe 2 o 3 , Weighed 29.60g, 22.14g, 16.05g, 7.89g, 183.6g respectively according to the stoichiometric ratio. Mix ball milling for 24 hours, after drying, pre-sinter at 1000-1300°C to form Z-shaped soft ferrite. Take 20 grams of ferrite powder, add sintering aid, the content is 3, 6, 9% by weight of the total material, mix by ball milling for 12 hours, after drying, pass through a 100-200 mesh sieve, shape, at 890 ℃ sintering for 6 hours, respectively recorded as samples 2-1, 2-2, 2-3. A ring sample has an outer diameter of 20mm, an inner diameter of 10mm, a thickness of 3mm, and a molding pressure of 7MPa; a disc sample has a diameter of 10mm, a thickness of 1mm, and a molding pressure of 2MPa. The electrical resistivity of the fired...

Embodiment 3

[0035] Synthesis of planar hexagonal Z-type soft magnetic ferrite Ba by solid state method 3 co 2 Fe 24 o 41 , The burning aid is lead fluoride. Initial raw material BaO, Co 3 o 4 , Fe 2 o 3 , Weighed 45.96g, 16.05g, and 191.6g respectively according to the stoichiometric ratio. Mix ball milling for 24 hours, after drying, pre-sinter at 1000-1300°C to form Z-shaped soft ferrite. Take 20 grams of ferrite powder, add sintering aid, the content is 6% by weight of the total material, mix by ball milling for 24 hours, after drying, pass through a 100-200 mesh sieve, shape, and sinter at 890 ° C for 4 , 8 hours, respectively recorded as samples 3-1, 3-2. A ring sample has an outer diameter of 20mm, an inner diameter of 10mm, a thickness of 3mm, and a molding pressure of 7MPa; a disc sample has a diameter of 10mm, a thickness of 1mm, and a molding pressure of 2MPa. The electrical resistivity of the fired tiles was measured after being covered with silver from top to bottom....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com