A method and device for producing high-power tube chip welding

A chip welding, high-power technology, applied in auxiliary devices, welding equipment, electrical components, etc., can solve the problems of low production efficiency, high operating costs, unstable product quality, etc., to reduce operating costs, solve production efficiency problems, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

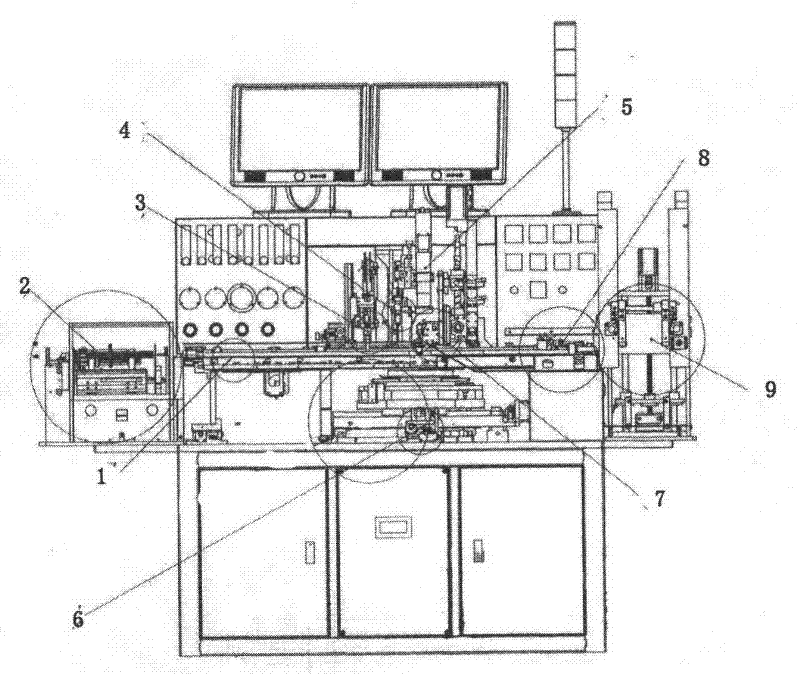

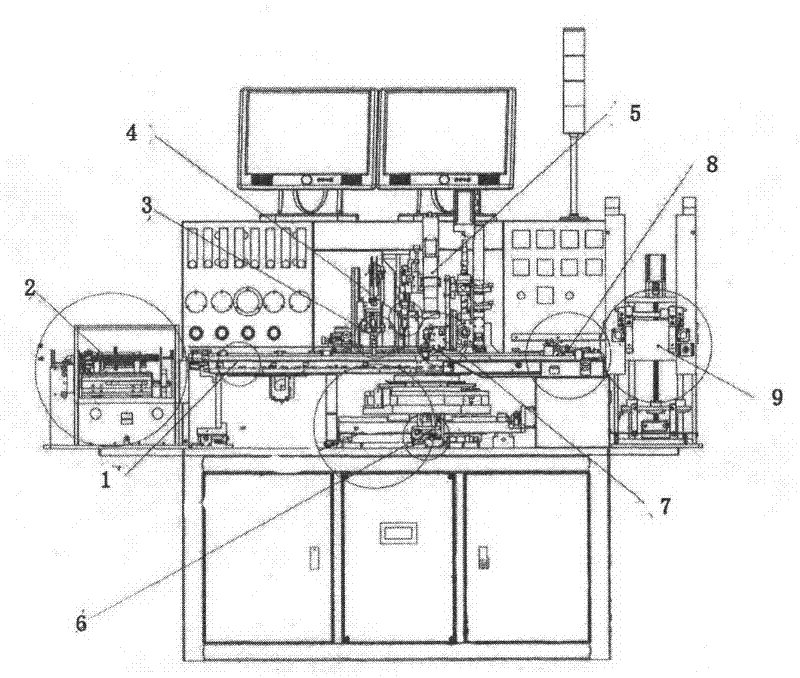

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention are described in further detail below

[0022] The method of the present invention is:

[0023] (1) Put the chip on the workbench, the machine will automatically support the film, make a template for the chip, and save the template to the device file;

[0024] (2) Put the lead frame on the loading table, the machine automatically sucks the material to the worktable through the suction cup, and transports it to the track protected by hydrogen and nitrogen through the transport hook;

[0025] (3) When the lead frame is transported to the fifth temperature zone, the wire feeding mechanism supplies tin wire to the frame;

[0026] (4) When the frame is transported to the sixth temperature zone, use a cemented carbide die head to press the solder point on the frame into a square shape;

[0027] (5) When the frame reaches the seventh temperature zone, the suction head sucks the chip from the blue film and welds it to the frame. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com