Microprocessor controlled contravariant multifunctional argon arc welding machine

A argon arc welding machine and microprocessor technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of unreasonable cooling air duct design, prone to failure, low load duration rate, etc., and achieve good cost performance. and market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

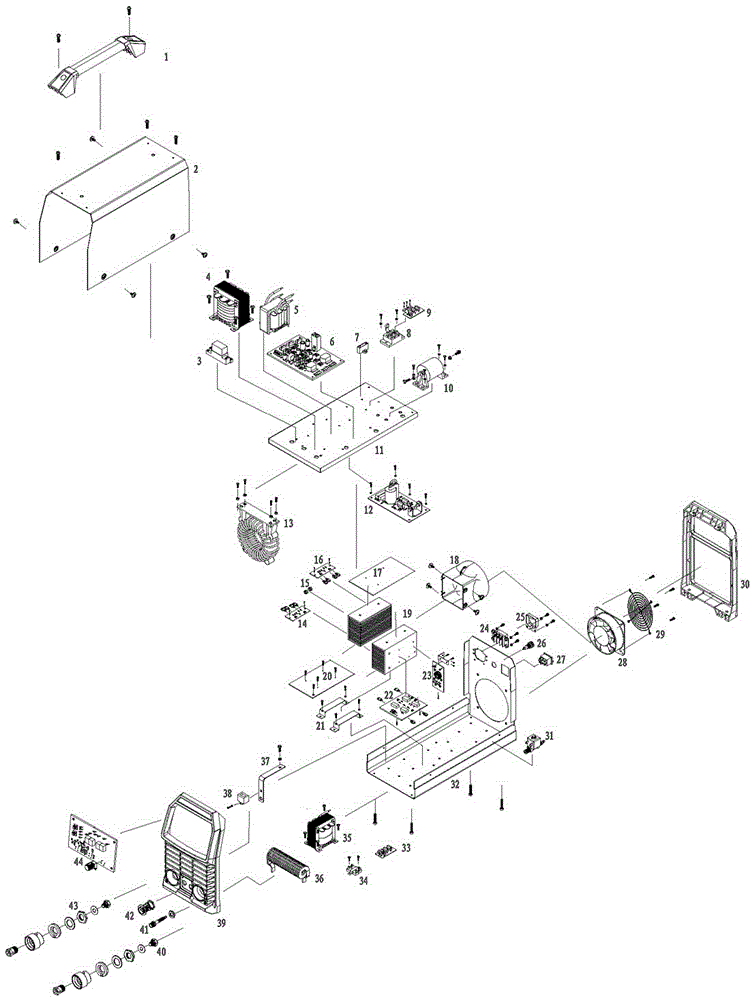

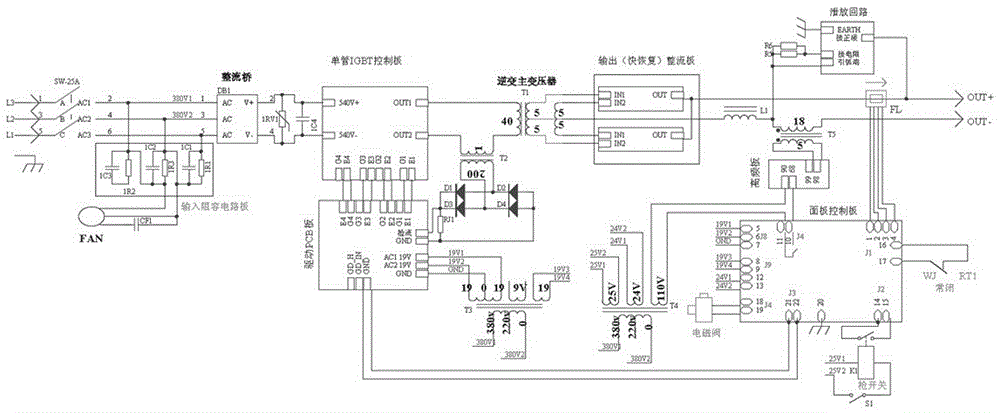

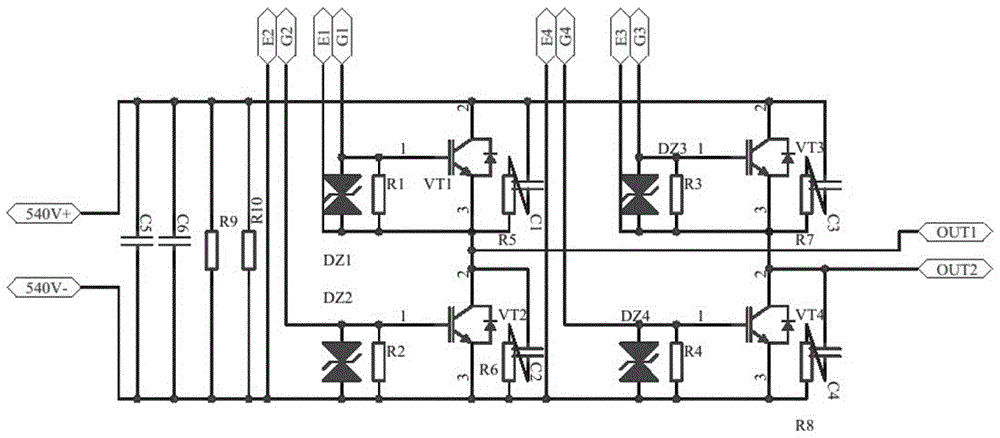

[0020] Such as Figure 1-10 As shown, a microprocessor-controlled inverter multifunctional argon arc welding machine, the main components include:

[0021] 1) The front panel part mainly includes the positive output quick connector and connector seat assembly 43, the negative output quick connector and connector seat assembly 40, the plastic front shell 39, the gas connector 41, and the aviation socket 42 connected to the aviation plug of the argon arc welding torch switch and control panel 44.

[0022] 2) The rear panel mainly includes a three-phase air power switch 27, a power input line junction box 24, a junction box cover 25, a safety tube and its socket 26, a cooling fan 28, a fan cover 29, a plastic rear shell 30 and a current detection plate 23 ; The cold air enters from the air inlet at the rear of the welding machine, which can make some heating devices or parts inside the welding machine have a good cooling effect.

[0023] 3) The shell part includes the outer cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com