Special metal pole plate rolling machine

A metal pole plate and special-purpose machine technology, which is applied to metal rolling stands, metal rolling mill stands, driving devices for metal rolling mills, etc., can solve the problems of reducing production efficiency, increasing production costs, and incapable of continuous production, etc. Achieve the effect of low equipment cost, convenient roll installation and roll change, solving production cost and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

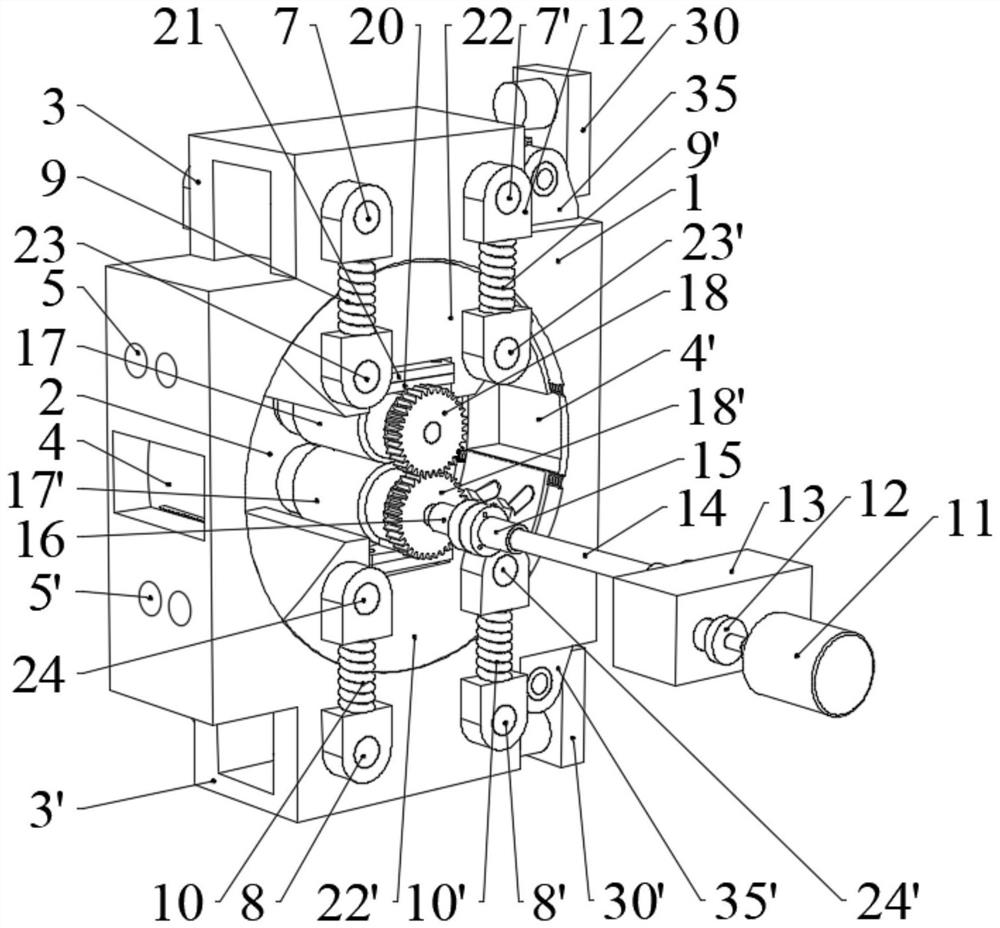

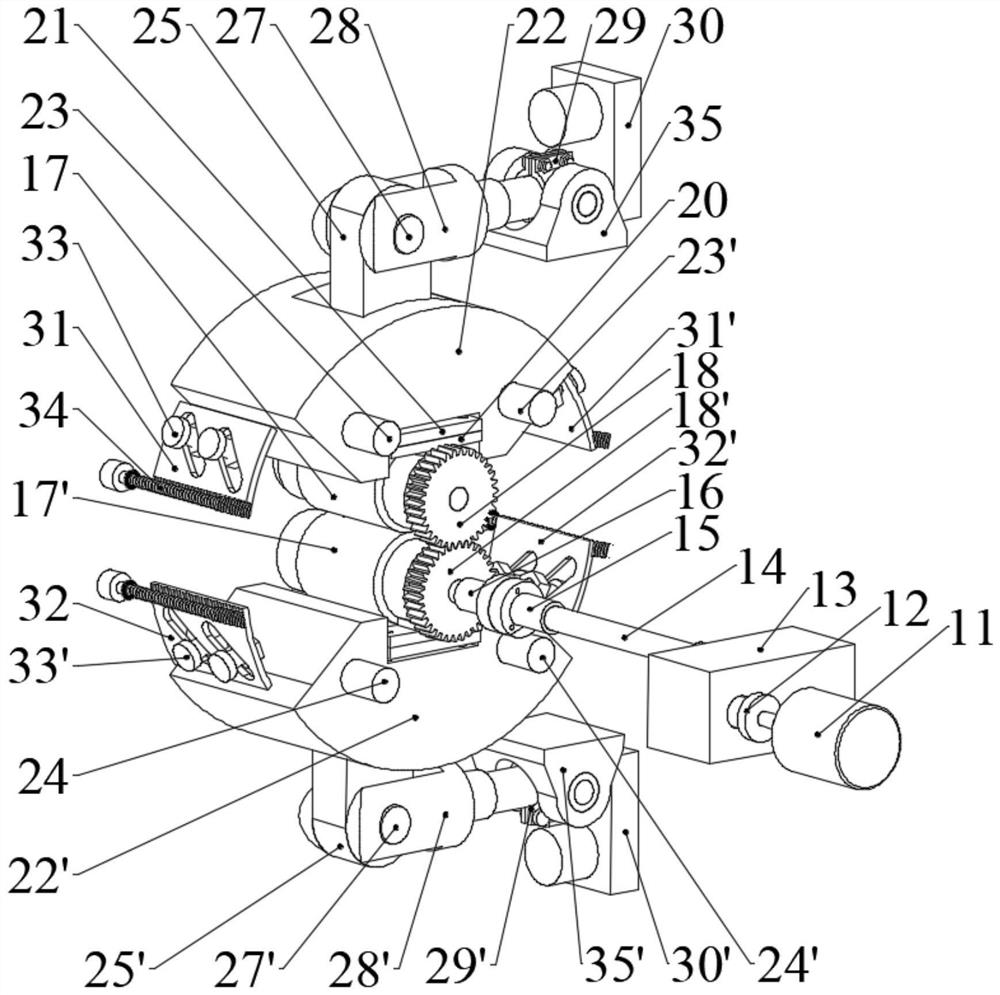

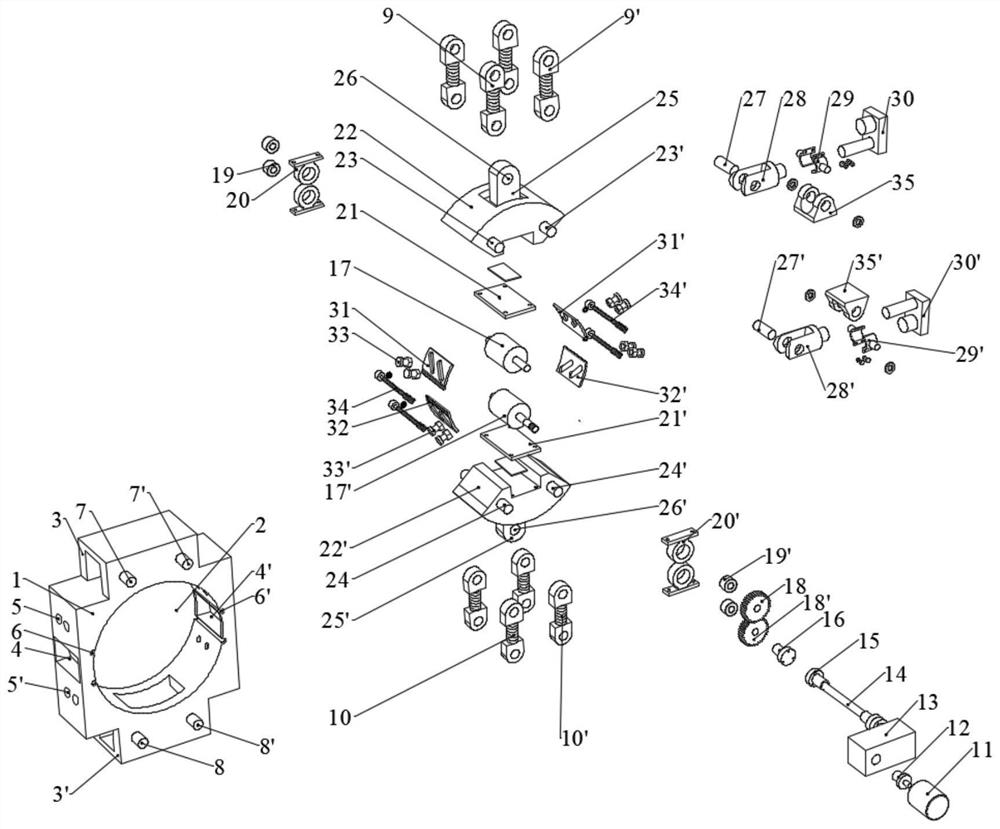

[0017] The present invention is realized like this, as figure 1 , 2 As shown, the main transmission of the present invention is driven by the servo motor 11 through the safety coupling 12, the reduction box 13, the transmission shaft 14, the spline sleeve 15, the lower and upper synchronous gears 18, 18' and the upper and lower pressure rollers 17, 17 'Rotate, and then implement the rolling processing and production of the metal pole plate; the radial fine-tuning of the upper and lower pressure rollers is performed by the upper and lower servo electric cylinders 30, 30' through the upper and lower connecting rods 28, 28' and their relative The hinged upper and lower rotating blocks 22, 22' drive the upper and lower pressure rollers 17, 17' to rotate slightly to realize the radial fine adjustment of the upper and lower pressure rollers; The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com