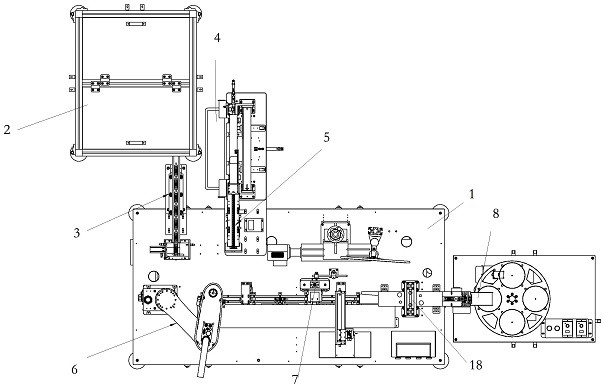

Automatic assembling device for photovoltaic module

A technology for automatic assembly devices and photovoltaic modules, applied in the direction of electrical components, semiconductor devices, conveyor objects, etc., can solve problems such as low efficiency, abnormal equipment, scrapping, etc., to solve production efficiency problems, prevent scrapping and abnormal occurrence of equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, terms used in the specification will be briefly described, and the embodiments will be described in detail. All terms used herein, including descriptive terms or technical terms, should be construed as having the meanings understood by those of ordinary skill in the art. However, these terms may have different meanings according to the intentions of those of ordinary skill in the art, precedents, or the emergence of new technologies.

[0020] Also, some terms may be selected by the applicant, and in this case, the meanings of the selected terms will be described in detail in the detailed description of the embodiments. Therefore, the terms used herein must be defined based on the meanings of the terms together with the descriptions throughout the specification. Furthermore, when a component "comprises" or "comprises" an element, unless there is a specific description to the contrary, the component may also include other elements, but not exclude other elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com