Turning method for winding heat-proof layer on metal shell cabin section and device thereof

A metal shell and heat-proof layer technology, which is applied in the field of non-metallic material cutting and processing, can solve problems such as slag falling, outer circle deformation, and deblocking, etc., to improve easy layering, reduce clamping deformation, and easy alignment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

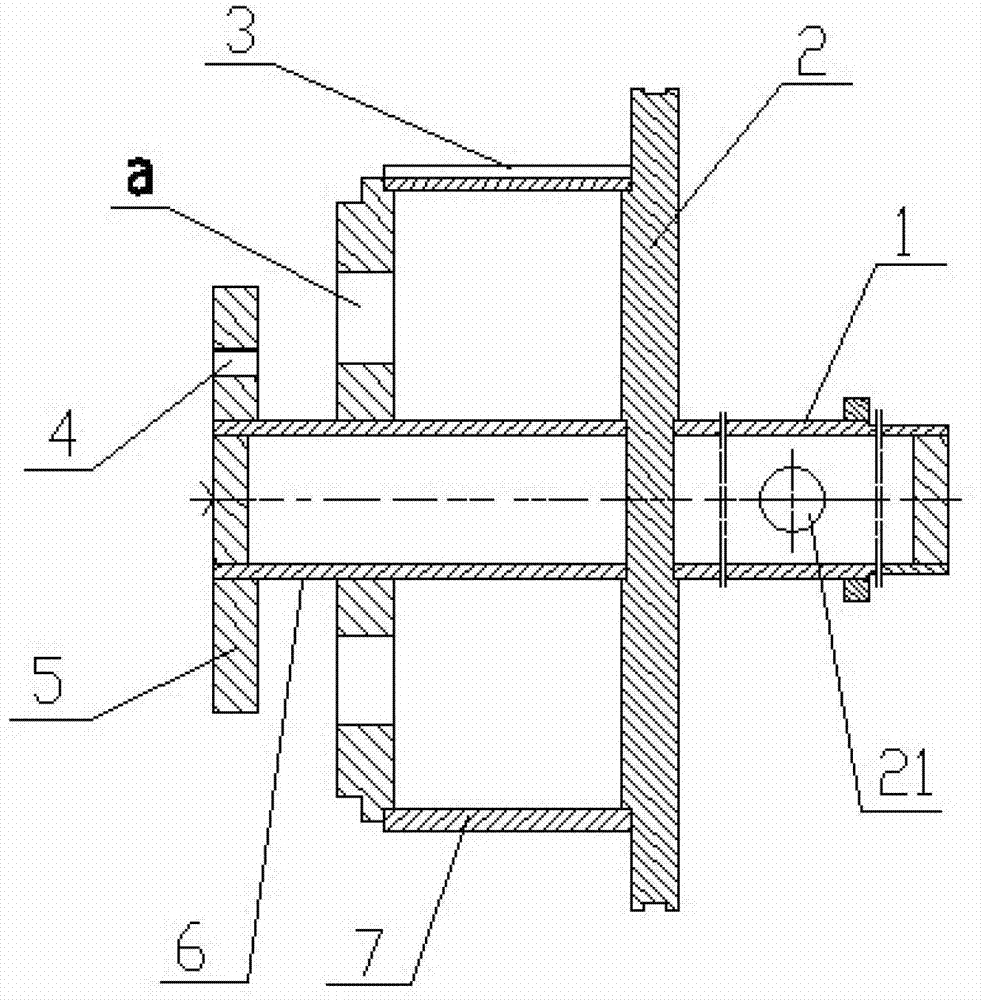

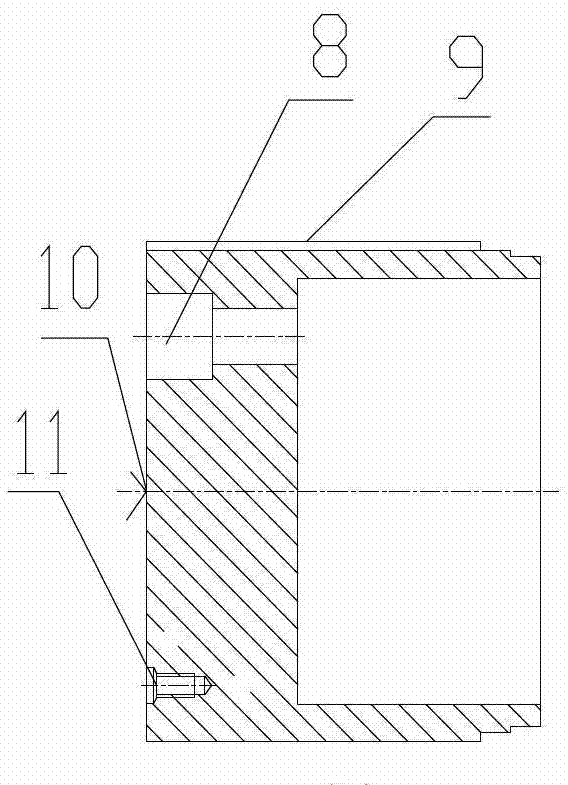

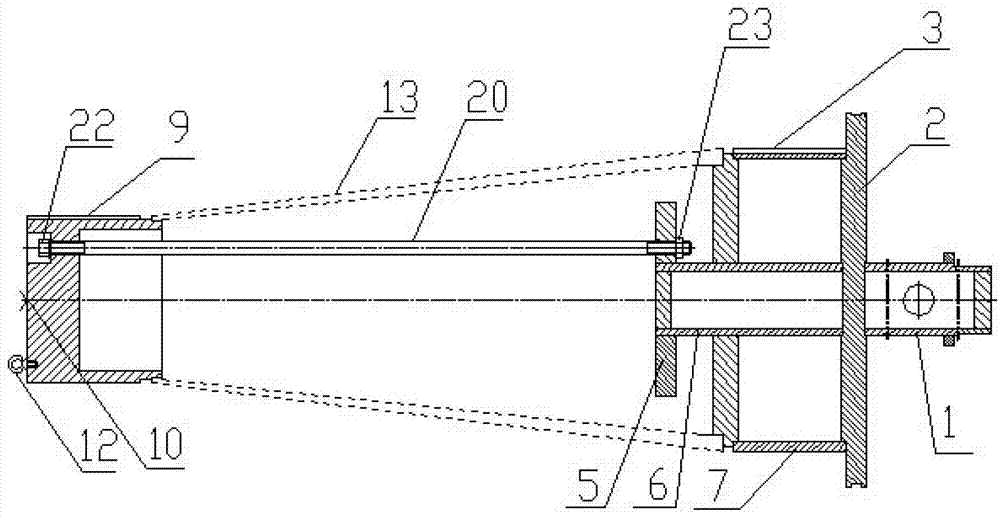

Method used

Image

Examples

specific Embodiment 1

[0066] Specific embodiment 1: the spindle speed n=80r / min, the feed rate f=0.2mm, the cutting depth 0.3mm, the gap between the inner hole of the front end of the metal shell cabin and the winding mandrel is 0.2mm, and the metal shell cabin The butt gap between the inner hole at the rear end of the section and the winding mandrel is 0.15mm, the butt gap between the inner hole at the front end of the metal shell cabin section and the axial positioning clamp is 0.1mm, and the butt gap between the inner hole at the rear end of the metal shell cabin section and the axial positioning clamp 0.1mm. A total of 10 heat-resistant layers were processed, all of which were in good condition, and the qualified rate of finished products was 100%.

specific Embodiment 2

[0067] Specific embodiment 2: the speed of the main shaft is n=70r / min, the feed rate is f=0.1mm, the cutting depth is 0.1mm, the gap between the inner hole of the front end of the metal shell cabin and the winding mandrel is 0.25mm, and the metal shell cabin The gap between the inner hole at the rear end of the segment and the winding mandrel is 0.1mm, the gap between the inner hole at the front end of the metal shell cabin and the axial positioning clamp is 0.09mm, the inner hole at the rear end of the metal shell cabin and the axial positioning clamp Butt gap 0.05mm. A total of 10 pieces of heat-resistant layers were processed, of which 1 piece of heat-resistant layer dropped slag, and the qualified rate of finished products was 90%.

specific Embodiment 3

[0068] Specific embodiment 3: the spindle speed is n=60r / min, the feed rate is f=0.1mm, the cutting depth is 0.3mm, the gap between the inner hole of the front end of the metal shell cabin and the winding mandrel is 0.18mm, and the metal shell cabin is The gap between the inner hole at the rear end and the winding mandrel is 0.1mm, the gap between the inner hole at the front end of the metal shell cabin and the axial positioning clamp is 0.15mm, and the inner hole at the rear end of the metal shell cabin is docked with the axial positioning clamp The gap is 0.12mm. A total of 10 heat-resistant layers were processed, all of which were in good condition, and the qualified rate of finished products was 100%.

[0069] Below, 5 groups of cutting parameters of the present invention are not used, and 5 groups of cutting parameters of the present invention are used, each group processes 10 heat-resistant layers, and the comparison list of the processing quality of the heat-resistant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com