A method for 3D manufacturing an OGS capacitive touch screen

A technology of capacitive touch screen and touch screen, which is applied in the direction of additive manufacturing, electrical digital data processing, process efficiency improvement, etc. It can solve the problems of poor adhesion of ITO conductive layer, high printing accuracy and alignment accuracy, waste of raw materials, etc., so as to improve product quality. Yield and production efficiency, saving raw materials and manufacturing costs, improving performance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

[0038] The present invention will be further described in detail through specific examples below.

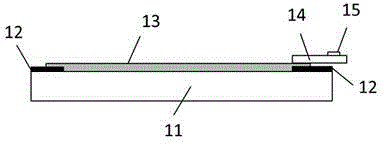

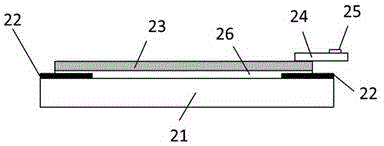

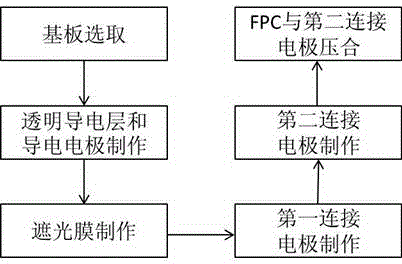

[0039] refer to image 3 and Figure 4 , a method for 3D manufacturing an integrated OGS touch screen, comprising the following steps:

[0040] ( S11 ) Provide a glass substrate 110 . According to the design size, select a suitable glass substrate, place the glass substrate 110 in a cleaning solution with a volume ratio of Win-10: DI water = 3: 97, use an ultrasonic machine with a frequency of 32KHz to clean for 15 minutes, and spray for 2 minutes. , and then placed in a cleaning solution with a volume ratio of Win41: DI water = 5: 95, using an ultrasonic machine with a frequency of 40KHz to clean for 10 minutes, spraying and rinsing with circulating tap wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com