Mechanical expanding machine for large-diameter ring piece

A large-diameter, diameter-expanding machine technology, applied in the field of diameter-expanding machines, can solve the problems of overall size and volume, material waste, energy loss and energy waste, and achieve the effects of convenient use, material saving and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

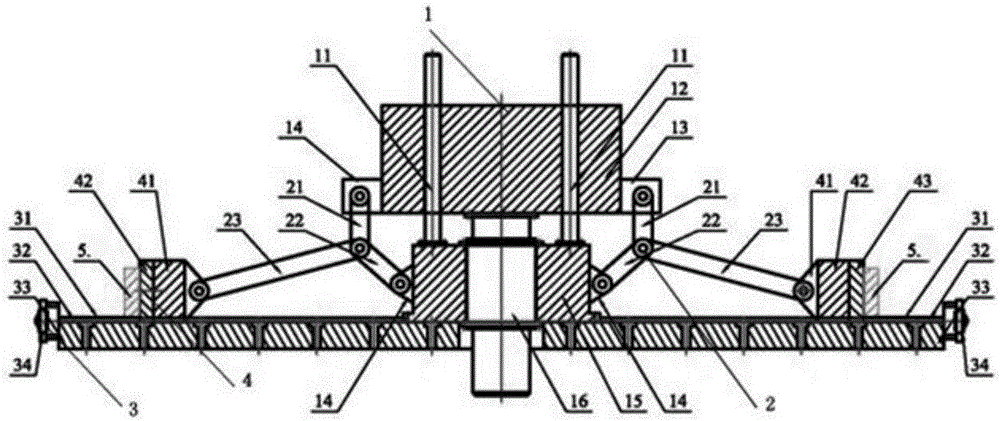

[0028] Such as figure 1 As shown, the large-diameter ring mechanical expansion machine provided by the present invention includes a hydraulic drive device 1, a hinge rod booster device 2, a support disc structure 3 and a split punch 4, and the support disc 33 is fixed on the ground On the upper surface, a fixed worktable 15 is arranged at the center of the upper surface. The piston cylinder 16 is installed in the center hole of the fixed worktable 15 and connected with the lower end surface of the slider 12 through the piston rod. The lower ends of four guide columns 11 evenly distributed along the circumference are fixed. On the fixed worktable, the cylinder part fits with the four guide sleeves inside the slider 12, and the upper and lower chambers of the piston cylinder 16 are connected with hydraulic oil circuits (not shown in the figure). Under the action of not ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com