Stacking robot system of cold-end glass on floatation glass production line

A robot system and palletizing robot technology, applied in the field of cold end glass palletizing robot system of float glass production line, can solve the problem of lack of equipment, and achieve the effect of improving quality and output, saving land cost and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

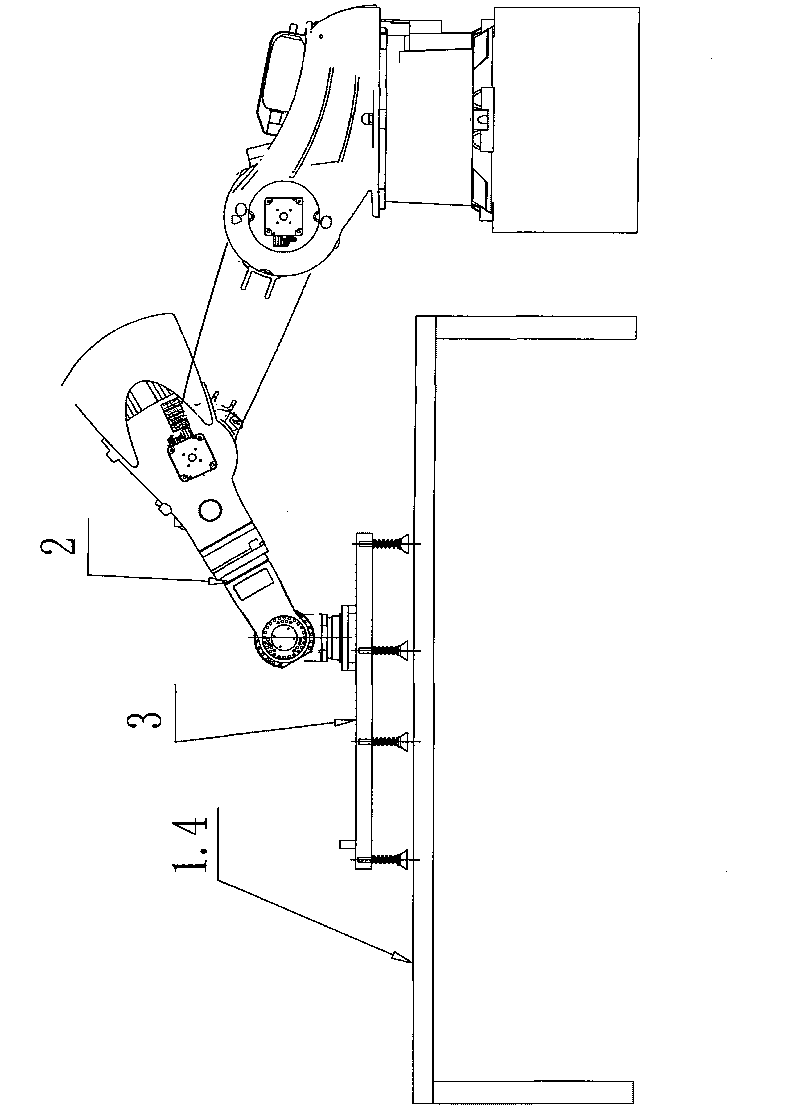

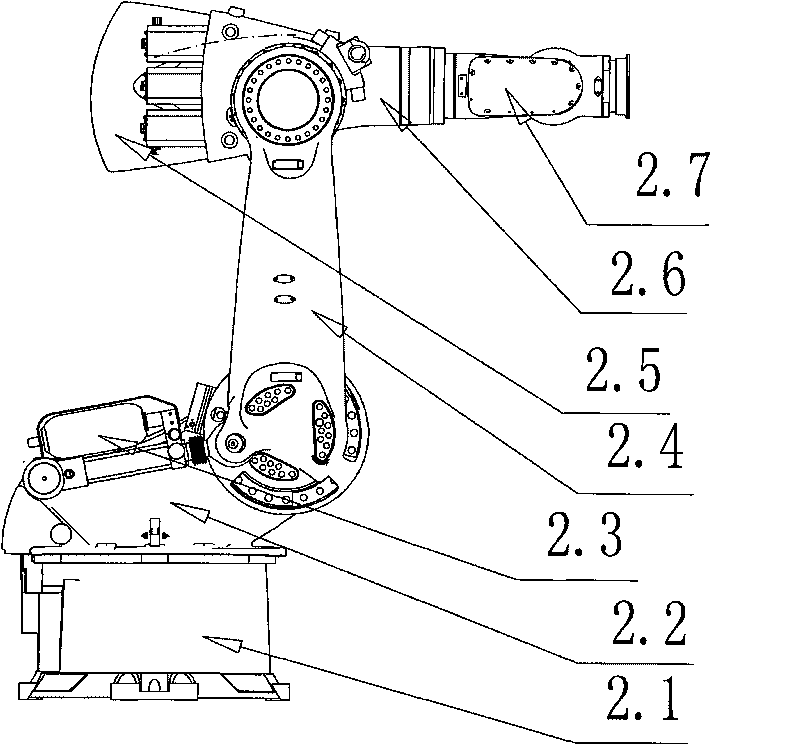

[0039] The glass stacking robot system at the cold end of the float glass production line involved in the present invention includes a vision system, a roller table 1, and a management system 5 ( Figure 16 ) and several groups of stacking manipulators are composed of three parts.

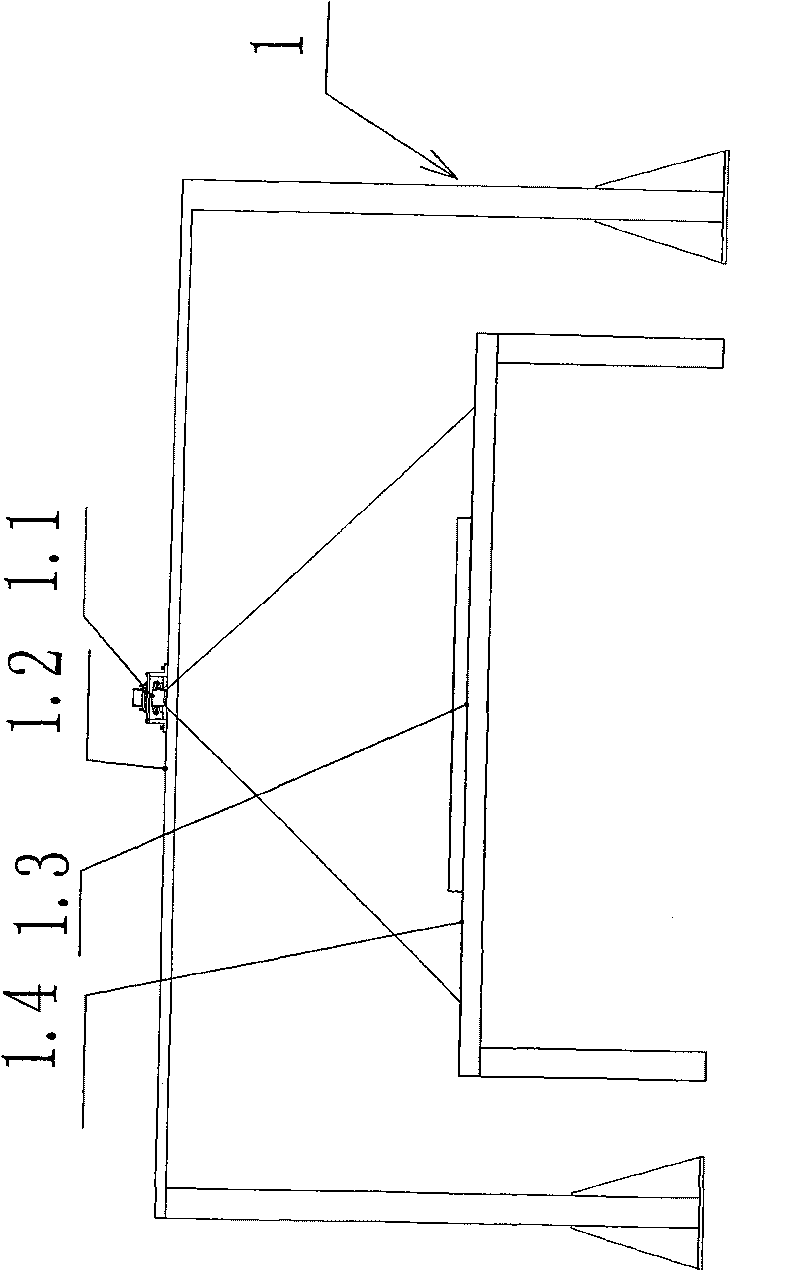

[0040] see figure 1 , figure 1 It is a schematic diagram of the vision system and the roller table involved in the present invention. Depend on figure 1 It can be seen that the vision system and the roller table 1 include a roller table 1.4, a glass 1.3, a mounting frame 1.2 and a camera system 1.1, the glass 1.3 is arranged on the roller table 1.4, the mounting frame 1.2 spans above the roller table 1.4, and the camera system 1.1 is set in the middle of the top of the installation frame 1.2. Uninterrupted scanning of the area below it, when the cut glass is conveyed to the area below the camera system 1.1 through the roller table, the camera system 1.1 can detect the corresponding position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com