Substrate packaging structure

A technology for packaging structures and substrates, which is applied in the directions of transportation and packaging, packaging of vulnerable items, types of packaging items, etc., can solve the problems of increasing the cost of mold opening of the substrate packaging structure 100 and the burden of inventory management, and saves mold production. Costs and inventory management costs, the effect of a good pack load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

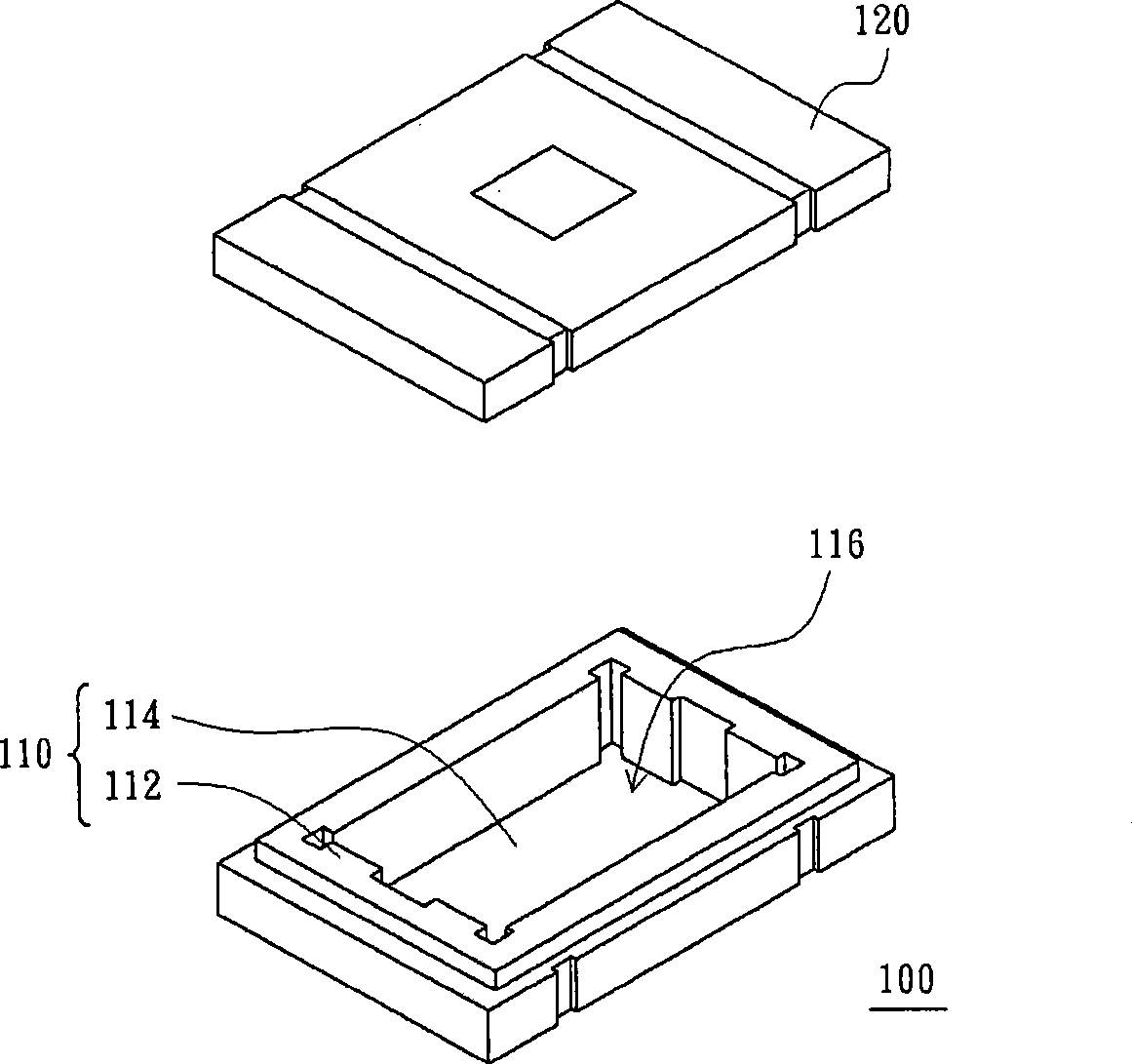

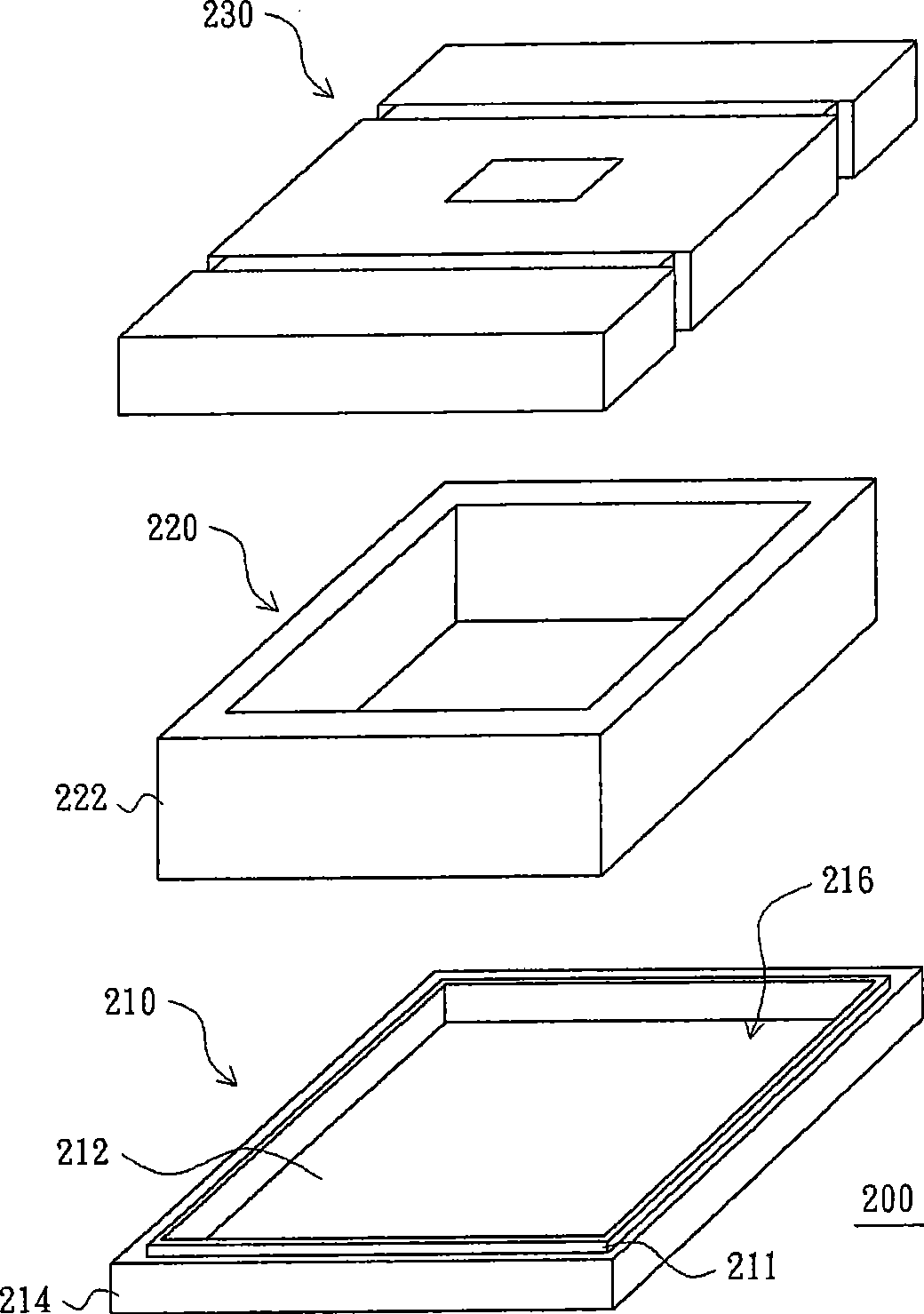

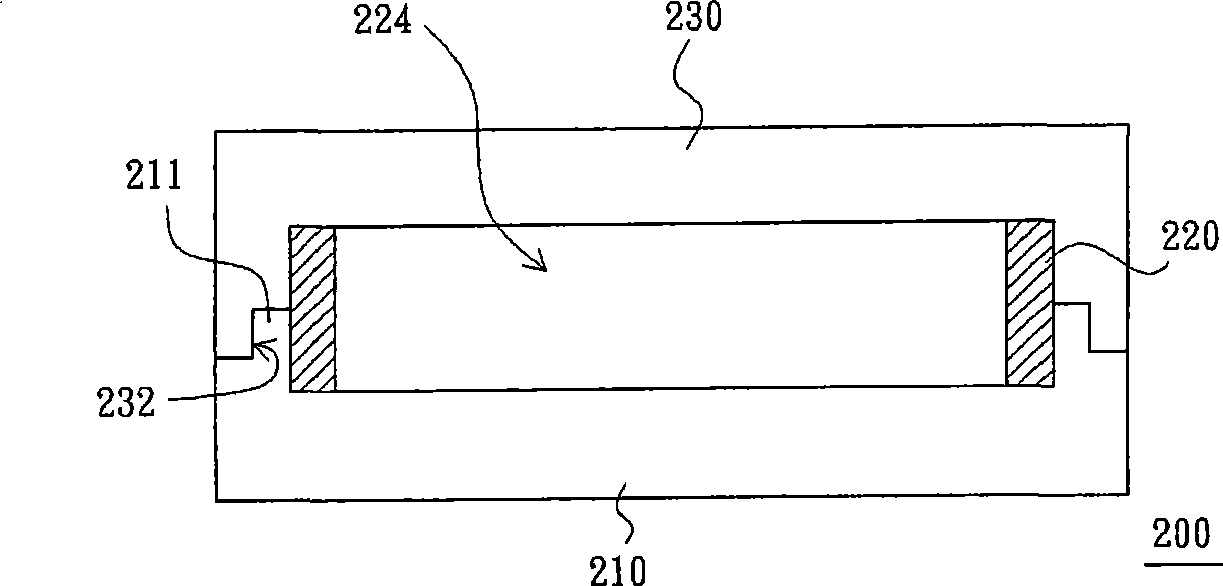

[0037] Figure 2A It is a three-dimensional exploded schematic view of the substrate packaging structure in an embodiment of the present invention, Figure 2B It is a schematic cross-sectional view of the substrate packaging structure in an embodiment of the present invention. Please refer to Figure 2A and Figure 2B , the substrate packaging structure 200 includes a box body 210 , a lining body 220 and a cover body 230 . Wherein, the material of the box body 210, the lining body 220 and the cover body 230 is, for example, expanded polypropylene (Expanded Polypropylene Foam, EPP) or expanded polystyrene (Expanded Polystyrene Foam, EPS), but the present invention is not limited thereto .

[0038] Based on the above, the box body 210 is composed of a bottom plate 212 and a plurality of side plates 214 , and the side plates 214 are connected to the bottom plate 212 to enclose a first accommodating space 216 . The liner 220 is detachably disposed in the first accommodation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com